TROUBLESHOOTING

9

Display blank

*CheckOn/Offswitchisilluminated.

*Checkexternal250mAfusehasnotfused.

*Checkelectricsupply:210-230V50Hz

*IfproblempersistscontactTECHNICALSERVICE.

Hydrolysis does not reach maximum intensity

*Checksodiumbromideorcommonsaltconcentrationinwater.

*Checkcellstatus(maybeincrustedorcalcified).

*Cleanelectrodefollowinginstructionsinsection6.

*Cleanflowdetectorsituatedinthecellcasing.

*Check titanium cell is not worn (remember that the cell is guaranteed for 5000-6000

hours(approx.2-3yearsofSummerusage)-seetroubleshootingformoreinformation).

Polarity 1 reaches max. intensity but polarity 2 (Auto clean) does not

*IFSALTLEVELISCORRECT(1kg./m3) cellisreachingendoflife.Asofthismomentcheckintensityevery15-30days

*Whenpolarity2doesnotreach50%werecommendsubstitutingcellforanew oneifduring thesummerormaximumusageperiod.Ifthisshouldhappeninwinterchangebefore

thenextseason(summer).

Free chlorine levels don't reach 0,2ppm. First thing in the morning

*INCREASEFILTRATIONtime.

*INCREASEhydrolysislevel.

*Checklevelsofsodiumbromideorcommonsaltinthepool(1gr.NaCl/L).

*Checklevelofisocyanuricacidinpool(30-50ppm.)ONLYifusingCOMMONSALT.

*CheckreactiveagentsintestkitarenotTOOOLD.

*Hasthetemperatureoramountofusersrisen(see3.1/3.2seechapter“Watermaintenance”).

*pHisabove7,8andmustbeadjusted.

Hydrolysis display shows LO

*Waterlacksconductivity(seesection3“waterpreparation”).

*Checkforincrustationsoncell.

*Seetroubleshooting“Hydrolysisdoesnotreachmaximumintensity”.

White flakes in pool

*Thishappensinexcessivelyhardunbalancedwaters.

*Balancethewaterandcheckthecell. cleanitifnecessary.

Hydrolysis display shows FL

*Checkflowdetectorcable.

*Cleanincrustationsofflowdetectorattopofcellcasing.

*Checksystemisfreeofair(Probemustbealwayssubmerged).

RUST on metallic components in pool

*Metallic elements lack standardized earth connection. Contact an electrician to

solve.

*Rustedcomponentsarenotstainlesssteel:

minimum304-recommended316.

EARTHING

All metallic components in the pool, such as lamps, ladders, heat exchangers, drains or similar elements within 3.00m. from pool (10feet) must be connected to an earth below

37Ohms.

WERECOMMENDHEATEXCHANGERSBEMADEOFTITANIUM.

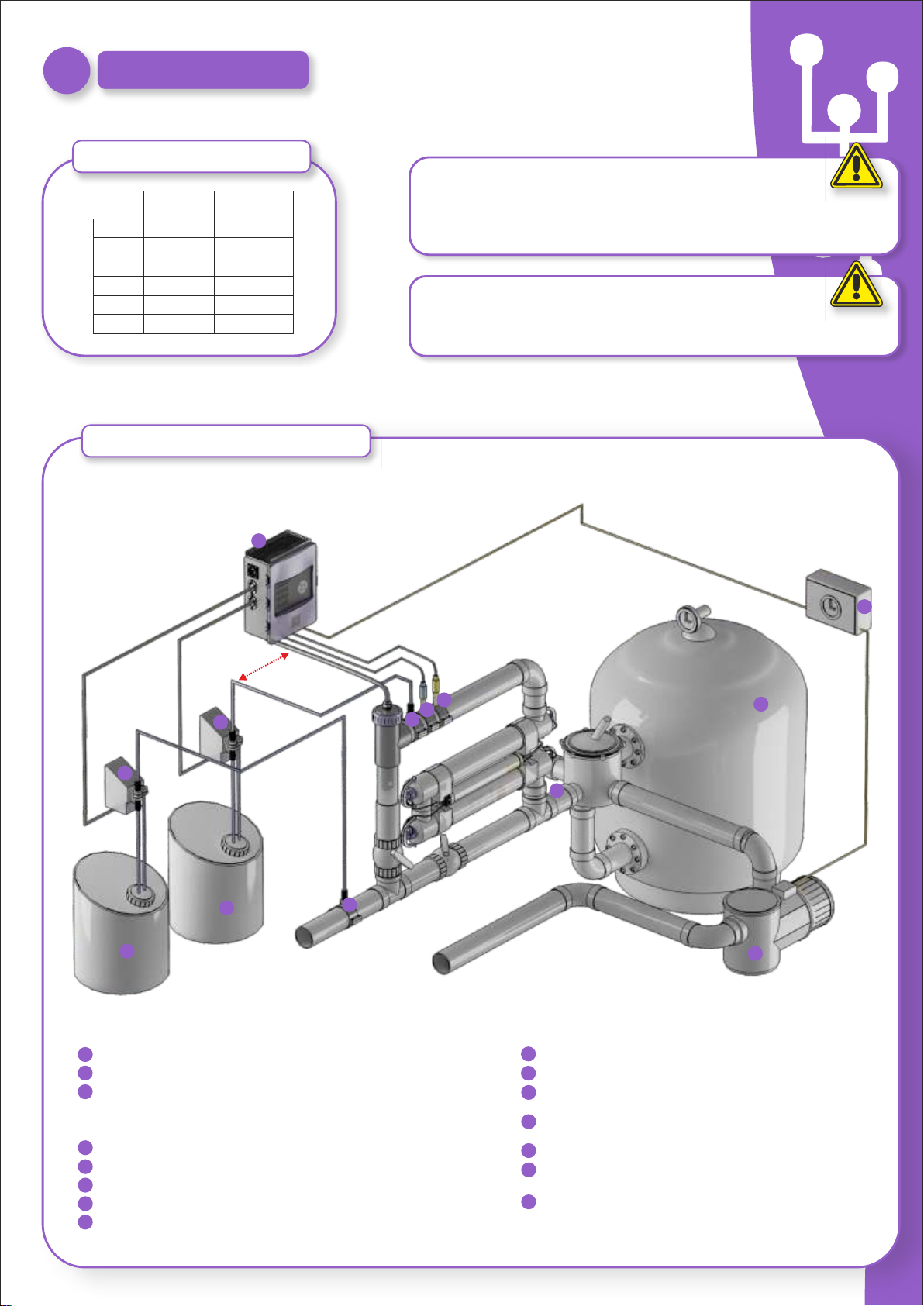

CLEANINGFILTER

Ensure isNOTRUNNINGduringbackwash.UVSCENIC

VERYIMPORTANT

REMEMBERthatthesystemneedssometimetoadapttoyourpoolandyouwillhavetoincreasechemicallevelsforthefirst5days.

WARNING

Keepchemicallevelsinpoolasinstructedinthismanual

SECURITY

Toavoidaccidentsthisproductshouldnotbehandledbychildrenunlesssupervisedbyanadult.

Childrenshouldbesupervisedatalltimeswheninornearaspa,poolorJacuzzi.

HANDLINGANDDOSINGDANGEROUSCHEMICALS

Chemicalsshould behandledwithextremeprecaution.WhenpreparingACID,ALWAYSADDTHEACIDTOWATER,neveraddwaterto acid!!!VERYdangerousgassesmaybe

produced.

EXCESS OXIDATION in water

*LowerHydrolysislevel.

*If your system includesAUTOMATIC REDOX CONTROL check REDOX

SETPOINT.

*CheckREDOXprobeandcalibrateifnecessary.

Titanium cell incrusted in less than 1 month

*Veryhard waterswithahighpHandtotalalkalinity(Balance wateradjusting

pHandtotalalkalinity).

*Checktoensurethesystemautomaticallychangespolarity(LED'salternate

every300min.approx.).

*CONSULT with our technical service to consider ACCELERATING THE

polaritychange(Auto-cleaning)WARNING:acceleratingthepolaritychange

decreasesthecelllifeproportionally.

Undernormalconditions,theUVlampsplacedinsidetheUVwilllast1yearor8,000hours.TheupperrightUVscenicdisplay(display1)indicatesthetotalhoursofoperationofthe

UVunit.

If you change de lamps, use new O-rings. When reassembling the unit, make sure the female threads of the compression fittings and male threads of the main structure are

clean.Thenreplaceand firmlyhandtighten the compressionfittings.Replace thelampor fit anew one. Relocatethelampholders and bluelampholder shrouds ensuringthatyou

matchthecorrectnumberedlampholders.

NOTE: Pinch the blue coating of lamp holder, when reassembling the unit, to release trapped air. If not released any trapped air may provoce disconnection of lamp holder.

Reconnectandturnthewatersupplyon,toensuretherearenoleaksbeforeyoureconnectthepowersupply.

Routine Maintenance