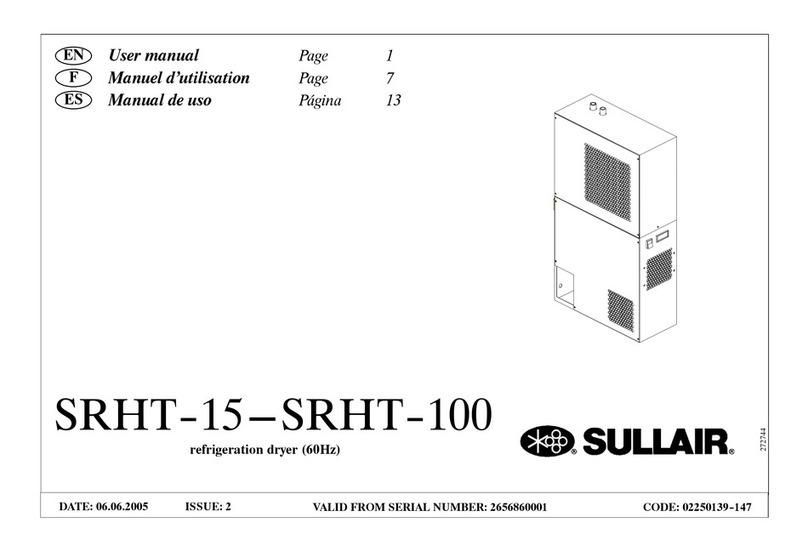

Sullair SMC-3 User manual

User Guide

Manuel opératoire Manual de instrucciones Manual de Instruções

SMC-3 to SMC-20

COMPRESSED AIR DRYERS

SÉCHEURS D’AIR COMPRIMÉ

SECADORES DE AIRE COMPRIMIDO

SECADORES DE AR COMPRIMIDO

GB F ES PO

®

®

English 1

Français 15

Español 29

Português 43

1

WARNING!

Do not operate the dryer until the instructions in this manual have been read and understood by

all personnel concerned.

When handling, installing or operating, personnel must employ safe engineering practices and observe all

related regulations, health and safety procedures, and legal requirements for safety.

Most accidents that occur during the operation and maintenance of machinery are the result of failure to

observe basic safety rules and procedures. Accidents can be avoided by recognising that any machinery

is potentially hazardous.

Sullair can not anticipate every possible circumstance which may represent a potential hazard.

The WARNINGS in this manual cover the most known potential hazards, but by definition cannot be all

inclusive. If the dryer user employs an operating procedure, item of equipment or a method of working

which is not specifically recommended by Sullair the user must ensure that the dryer will not be damaged

or made a potential hazard to persons or property.

IMPORTANT

Caution: Power

Risk of Electric Shock

Attention

PLEASE NOTE THAT YOUR WARRANTY MAY BE INVALIDATED IF THE EQUIPMENT HAS NOT

BEEN INSTALLED, COMMISSIONED AND MAINTAINED BY Sullair OR A Sullair APPROVED

AGENT.

2

INDEX

1.0 Introduction 3

2.0 Installation 4

3.0 Start-up and Operation 10

4.0 Maintenance 12

5.0 Spare Parts 13

6.0 Troubleshooting 14

3

INTRODUCTION

The SMC range of compressed air dryers are designed to remove moisture from

compressed air by utilising state of the art technology to obtain dewpoints of -40°F

PDP and by appropriate de-rating -100°F PDP.

SMC dryers have been designed to require minimal maintenance and can be installed

virtually anywhere.

The SMC dryer consists of upper and lower head assemblies joined together with an

aluminium extrusion containing twin internal chambers. The upper head assembly

contains inlet and outlet manifolds, pre-filter and autodrain. The lower head assembly

contains two exhaust valves and a passive shuttle ball valve. Contained in each

internal chamber is a combination desiccant / after-filter cartridge. During operation

one chamber is on-line (drying) while the other is regenerating, using the Pressure

Swing Adsorption (PSA) process.

Pressure Swing Adsorption (PSA)

A small percentage of dried air is taken from the dryer outlet flow and is used to

regenerate the saturated chamber by expanding the dried air from line pressure to

atmospheric pressure. During this process, the moisture is physically removed from

the regenerating chamber and vented to atmosphere through the exhaust.

4

2.0 INSTALLATION (refer to figure 1)

2.1 ESSENTIAL INFORMATION

Care must be taken to ensure that the dryer is not subject to flows (even peaks) in

excess of the dryers rated capacity, e.g. dryers downstream of an air receiver have

increased potential to be overflowed.

The dryer can be installed free standing, secured to the floor via the fastening points

provided in the base or secured to a wall using optional brackets.

The control enclosure (A) must be at the bottom and the dryer must be installed

vertical and level.

Two inlet and two outlet connections are available at the top of the dryer to enable

connection from either left or right. Unused connections (B) and (C) must be sealed

with the threaded plugs provided. Suitable rated pipe and connections must be used

for the installation. All pipework must be secure and safely positioned.

The purge flow is factory set for 87 psi g minimum operating pressure. Should the

minimum pressure requirement be different, the purge flow must be reset by a Sullair

engineer or a Sullair approved agent.

Ensure the dryer is electrically connected to a supply suitable for the unit. See wiring

diagram printed in 2.3 Electrical Details.

1. Filtration

A 0.01 micron pre-filter is contained within the upper head assembly. 1 micron after-

filters are integral within desiccant cartridges screwed into inserts in the upper head

assembly. Filters must be maintained by Sullair or a Sullair approved agent.

2. By-pass Line (D)

A by-pass line, 3/8" NPT (D) ensures complete safety during maintenance and

enables a continuous supply of compressed air to be maintained if required. It should

be remembered that air bypassing the dryer is dirty untreated air.

3. Valves (E, F, G)

Isolation valves, 3/8" NPT are recommended on the inlet (E), outlet (F) and bypass (G)

lines at the positions indicated in Figure 1.

5

2.2 TECHNICAL SPECIFICATION

Operating Specification

Parameter Minimum Maximum Nominal

Inlet Pressure 58 psi g (4.0 bar g) 175 psi g (12.0 bar g) 102 psi g (7.0 bar g)

Parameter Minimum Maximum Nom inal

Inlet Temperature 35˚F (1.5˚C) 122˚F (50˚C) 95˚F (35˚C)

Electrical Specification

Dryer Model Voltage Supply Supply Need Electrical Approval

60 Hz 24V / 115 / 230 V 1 phase CE

50 Hz 24V / 115 / 230 V 1 phase CSA/UL

General Specification

Inlet Flowrate

SMC-3 3 cfm 5.1 m3/hr

SMC-5 5 cfm 8.5 m3/hr

SMC-8 8 cfm 13.6 m3/hr

SMC-10 10 cfm 17.0 m3/hr

SMC-13 13 cfm 22.1 m3/hr

SMC-15 15 cfm 25.5 m3/hr

SMC-20 20 cfm 34.0 m3/hr

Outlet Dewpoint -40 ˚F (-40˚C) Optional – -100˚F (70˚C)

Environmental Protection IP65 (NEMA4)

Noise Level <70 dB(A)

Dryer Weights

SMC-3 24.3 lbs 11 Kgs

SMC-5 28.7 lbs 13 Kgs

SMC-8 35.3 lbs 16 Kgs

SMC-10 39.7 lbs 18 Kgs

SMC-13 44.1 lbs 20 Kgs

SMC-15 50.7 lbs 23 Kgs

SMC-20 61.7 lbs 28 Kgs

Note: All flow rates referenced at 68˚F (20˚C) , 102 psi g (7 bar g)

6

2.3 ELECTRICAL DETAILS

Only competent qualified electricians must work on dryer circuitry.

Check the rating plate for power supply requirements.

Correct isolator switches must be provided at a safe and accessible point near to the

dryer.

The dryer must be provided with a live, neutral and earth.

Connect power to the dryer (via the conduit entry aperature *) at the fused terminal

block mounted on the small base plate located under the enclosure. Four screws

retain the base plate.

*For CE/BSP dryers, the conduit entry aperature is replaced by a mains cable gland

Brown

Blue

Live

Earth

Neutral

T500mA / T1A / T2A

230V, 50Hz - T500mA

115V, 60Hz - T1A

24V, 50 / 60Hz - T2A

ground

7

KEY

(A) Control Box (E) Inlet Valve

(B) Optional Inlet (F) Outlet Valve

(C) Optional Outlet (G) By-pass Valve

(D) By-pass Line (H) Display Unit

2.4 INSTALLATION PROPOSAL

Figure 1

3/8”NPT

!

✓

H

Orange Red

Orange

Green

8

Position 1

Dryers running below

102 psig (7 Bar g)

Position 2

Dryers running above

102 psig (7 Bar g)

2.5 RUNNING THE DRYER WITH A MINIMUM PRESSURE BELOW 102 PSIG

If the dryer is to be run with a minimum pressure of 102psig (7 Bar g) an alteration to

the timer board is required.

To carry out the alteration,ensure the electrical supply is isolated, lie the dryer on its

back, to gain access to the control base. Remove the large plate to gain access to the

timer board. Move electric jumper from Position 1 to Position 2, as shown.

9

3.0 START-UP AND OPERATION

3.1 INTIAL STARTUP

Ensure a suitable supply of compressed air between 58 psi g and 175 psi g pressure

is available and check that the dryer cannot be overflowed. Inlet temperature must be

between 34°F to 122°F at all times.

IMPORTANT NOTE

Ensure all valves are opened and closed gradually.

Proceed as follows: (Refer to figure 1)

3.2 WITHOUT THE BY-PASS LINE (D)

Close inlet (E) and outlet (F) valves.

Introduce air to the dryer by gradually turning the inlet valve (E) until fully open.

Allow dryer to fully pressurise, then gradually open the outlet valve (F).

Switch on the electrical isolator, the yellow ‘power on’ LED and the green ‘correct

operation’ LED will illuminate and the dryer will commence cycling. The dryer is now

on stream.

3.3 USING THE BY-PASS LINE (D)

With the inlet (E) and outlet (F) valves closed and the by-pass (G) valve open,

introduce air to the dryer by gradually turning inlet valve (E) until fully open.

Allow the dryer to fully pressurise, then open the outlet valve (F) while simultaneously

closing the by-pass valve (G).

Switch on the electrical isolator, the yellow ‘power on’ LED and the green ‘correct

operation’ LED will illuminate and the dryer will commence cycling. The dryer is now

on stream.

3.4 NORMAL OPERATION

Following the start-up procedure the operation of the dryer is fully automatic and

requires no further attention until shut down.

The yellow ‘power on’ LED and the green ‘correct operation’ LED should be illuminated

continuously.

!

✓

*

Power On

Correct Operation

*

10

The dryer contains two desiccant chambers, while one chamber is drying the

compressed air (adsorption), the other chamber is simultaneously undergoing

regeneration (desorption). At a predetermined time both exhaust valves close and

repressurisation begins. Every three minutes the chambers are reversed in function,

this is the changeover point. Changeover is characterised by an immediate venting of

compressed air from the chamber entering regeneration.

The dryer can be shut down at any point in its cycle and when restarted will enter an

automatic repressurisation stage. After repressurisation the cycle will commence at

the point at which it stopped.

NB

If power is switched on, the dryer will enter an automatic repressurisation stage at the

point at which it stopped.

3.5 SHUT-DOWN PROCEDURE

To Depressurize the Dryer

Prior to isolating the electrical supply close the outlet valve (F) while simultaneously

opening the by-pass valve (G) if fitted. Close the inlet valve (E). The dryer will now be

isolated from mains pressure. Cycle the dryer for a minimum of 3 minutes to ensure

the dryer vents and is completely depressurized. When the dryer is completely

depressurized, isolate the electrical supply.

NB

The by-pass valve (G) should only be opened if the dryer is undergoing maintenance.

11

4.0 MAINTENANCE

Daily

• Ensure the yellow ‘power on’ LED and the green ‘correct operation’ LED are

illuminated.

Weekly

• Check dryer seals, fittings and pipe work for air leaks.

• Ensure correct operation of inlet filtration condensate drainage.

The Combination desiccant / after-filter cartridges have a finite life dependent upon

operating conditions.

Cartridge status is indicated

Cartridges require changing and audible alarm will sound every 6 seconds.

NOTE: Temporary resetting of the alarm to prevent nuisance noise is possible after

alarm has sounded for the first time. This is done by depressing once the reset button

located inside the control enclosure, accessed by removing the black insert on the

side. The alarm will be muted for a 24 hour interval until the dryer has been serviced

and the reset sequence completed.

Servicing of the dryer must only be carried out by Sullair personnel or trained Sullair

service agents.

!

✓

!

✓

*

*

Power On

Power On

Cartridge Wear

Service Required

*

*

12

5.0 SPARE PARTS LIST

Genuine Sullair Service kits must only be used when servicing the dryer.

Dryer Model Spares Kit Part Numbers

SMC-3 02250155-152

SMC-5 02250155-153

SMC-8 02250155-154

SMC-10 02250155-155

SMC-13 02250155-156

SMC-15 02250155-157

SMC-20 02250155-158

X 2

13

6.0 TROUBLESHOOTING

Reference to Known Misuse

Filters

• Opening inlet valve too quickly, causing initial high differential pressure across

filter element.

Inlet / outlet head

• Pipe diameter too small

• Pipework unsupported

• Inlet pipework taken from low point of manifold range allowing bulk water

intrusion into the dryer.

Electric control box

• Incorrect wiring configuration by user or incorrect supply voltage.

• No fuse fitted or fuse blown.

Additional items

• Use of non-recommended components.

• Untrained, unauthorised maintenance / installation personnel used.

• Subsequent increase in air consumption without relation to dryer flow capacity.

• Purging of pneumatic system and dryer with cleaning agents that have the

potential to damage desiccant material.

• Covers removed or loose during operation.

• Cartridges and filter / autodrain not changed when red LED is illuminated.

• LED failure.

Problem Indication Probable Cause Remedy

Poor Dewpoint N/A Entrained Water Check pre-filtration and pre-filtration drains

Excessive air flow demand Check actual flow against rated flow of dryer

Check for recent additions to air system

Inlet pressure too low Check against technical specification

Excessive inlet air Check against technical specification

temperature

Insufficient purge air flow Factory set for 87 psi g system pressure

Exhaust silencers blocked Change by Sullair trained personnel

Contaminated desiccant Eliminate source of contamination. Desiccant

change by Sullair trained personnel

Cartridges not fitted Check and fit cartridges

Electrical Fault Power LED ‘OFF’ Hardware fault Contact Sullair customer service

Failure to purge No depressurisation Purge valve blocked or shut domnick hunter trained personnel to adjust

and poor dewpoint Exhaust silencer blocked Change by Sullair trained personnel

Outlet air flow Downstream No air supply to the Check compressor air supply to dryer

stops pressure drops dryer Check all pipework and fittings for leaks

Constant Erratic air flow from Damaged valve Change by Sullair trained personnel

depressurisation exhaust

14

ATTENTION !

Ne pas faire fonctionner le sécheur avant que les instructions de ce manuel aient été lues et

comprises par tous les personnels concernés.

Lors de la manipulation, de l’installation ou de l’exploitation, le personnel doit utiliser des pratiques

d’ingénierie sécurisées et observer l’ensemble des règlements liés, procédures d’hygiène et sécurité et

exigences juridiques de sécurité.

La plupart des accidents qui surviennent lors de l’exploitation et de l’entretien des machines résultent de

manquements aux procédures et règles de base de la sécurité. Les accidents peuvent être évités en

reconnaissant que n’importe quelle machine est potentiellement dangereuse.

Sullair ne peut prévoir toutes les circonstances possibles qui peuvent représenter un risque potentiel.

Les AVERTISSEMENTS de ce manuel couvrent la plupart des risques potentiels connus mais, par

définition, ne peuvent être exhaustifs. Si l’utilisateur du sécheur emploie un mode opératoire, un

équipement ou une méthode de travail qui n’est pas spécifiquement recommandée par Sullair,

l’utilisateur doit s’assurer que le sécheur ne sera pas endommagé ou ne constituera pas un risque

potentiel pour les personnes ou les biens.

IMPORTANT

Prudence : Équipement sous tension

Risque de choc électrique

Attention

VEUILLEZ NOTER QUE VOTRE GARANTIE PEUT ÊTRE INVALIDÉE SI L’ÉQUIPEMENT N’A PAS

ÉTÉ INSTALLÉ, MIS EN SERVICE ET ENTRETENU PAR Sullair OU UN AGENT AGRÉÉ PAR Sullair.

15

TABLE DES MATIÈRES

1.0 Introduction 17

2.0 Installation 18

3.0 Démarrage et exploitation 24

4.0 Entretien 26

5.0 Pièces détachées 27

6.0 Dépannage 28

16

INTRODUCTION

La gamme SMC de sécheurs d’air comprimé est conçue pour éliminer l'humidité de

l'air comprimé en utilisant une technologie de pointe pour obtenir des points de rosée

sous pression de -40 °F et, par un déclassement approprié, de -100 °F.

Ces sécheurs SMC ont été conçus pour demander un entretien minimal et peuvent

être installés virtuellement n’importe où.

Le sécheur SMC se compose d’ensembles de têtes haut et bas assemblés par un

profilé extrudé d’aluminium contenant des chambres internes jumelles. L’ensemble de

têtes haut contient des collecteurs d’entrée et de sortie, un pré-filtre et une purge

automatique. L’ensemble de têtes bas contient deux soupapes d’échappement et un

sélecteur de circuit passif à tournant sphérique. Chaque chambre interne contient une

cartouche combinée déshydratant / post-filtre. En exploitation, une chambre est en

ligne (en séchage) tandis que l'autre est en régénération, par le processus

d'adsorption modulée en pression (AMP).

Adsorption modulée en pression (AMP)

Un faible pourcentage d’air séché est extrait du courant de sortie du sécheur et sert à

régénérer la chambre saturée en détendant l’air séché de la pression de canalisation

à la pression atmosphérique. Lors de ce processus, l’humidité est éliminée

physiquement de la chambre en régénération et évacuée dans l’atmosphère via

l’échappement.

17

2.0 INSTALLATION (se reporter à la figure 1)

2.1 Informations essentielles

Il faut faire attention de s’assurer que le sécheur n’est pas soumis à des débits (même

en crête) dépassant sa capacité nominale, par exemple que les sécheurs en aval d’un

collecteur d’air comprimé présentent un risque accru d’être débordés.

Le sécheur peut être posé au sol, fixé au sol via les points de fixation de sa base ou

fixé au mur par des équerres en option.

Le boîtier de commande (A) doit se trouver au fond et le sécheur doit être installé

vertical et plan.

Deux raccords d’entrée et deux raccords de sortie sont disponibles en haut du

sécheur pour permettre le raccord à gauche ou à droite. Les raccords non utilisés (B)

et (C) doivent être scellés par les bouchons filetés fournis. Des tuyaux et raccords

convenablement évalués doivent être utilisés pour l’installation. Toute la tuyauterie

doit être sûre et positionnée de façon sécurisée.

Le débit de purge est réglé en usine à 7 psi eff de pression de service minimale. Si la

pression minimale requise s’avérait différente, le débit de purge doit être réinitialisé

par un ingénieur de Sullair ou un agent agrée par Sullair.

S’assurer que le sécheur est raccordé électriquement à une alimentation qui convient

pour l’unité. Voir le schéma de câblage imprimé en 2.3 Détails électriques

1. Filtration

Un pré-filtre de 0,01 micron est contenu dans l’ensemble de têtes haut. Des post-

filtres de 1 micron sont intégrés dans les cartouches déshydratantes vissées dans les

pièces rapportées de l’ensemble de têtes haut. Les filtres doivent être entretenus par

Sullair ou un agent agréé par Sullair.

2. Conduite de dérivation (D)

Une conduite de dérivation, 3/8" NPT (D) garantit une complète sécurité lors de

l’entretien et permet de maintenir une fourniture continue d’air comprimé si

nécessaire. Il faut se souvenir que l’air qui contourne le sécheur est un air sale et non

traité.

3. Vannes (E, F, G)

Des vannes d’isolement, 3/8" NPT sont recommandées sur les conduites d’admission

(E), de refoulement (F) et de dérivation (G) aux positions indiquées à la figure 1.

18

2.2 CARACTÉRISTIQUES TECHNIQUES

Caractéristiques de fonctionnement

Paramètre Minimum Maximum Nominal

Pression d’entrée 4,0 bar eff (58 psi eff) 12,0 bar eff (175 psi eff) 7,0 bar eff (102 psi eff)

Paramètre Minimum Maximum Nominal

Température d’entrée 1,5 °C (35 °F) 50 °C (122 °F) 35 °C (95 °F)

Spécifications électriques

Modèle Alimentation Alimentation Homologation

de sécheur en tension nécessaire électrique

50 Hz 24V / 115 / 230 V Monophasé CE

60 Hz 24V / 115 / 230 V Monophasé CSA/UL

Spécifications générales

Débit d’entrée

SMC-3 3 cfm 5.1 m3/hr

SMC-5 5 cfm 8.5 m3/hr

SMC-8 8 cfm 13.6 m3/hr

SMC-10 10 cfm 17.0 m3/hr

SMC-13 13cfm 22.1 m3/hr

SMC-15 15 cfm 25.5 m3/hr

SMC-20 20 cfm 34.0 m3/hr

Point de rosée en sortie -40 °C (-40 °F), en option -70 °C (-100 °F)

Protection de l’environnement IP65 (NEMA4)

Niveau de bruit <70 dB(A)

Poids des sécheurs

SMC-3 11 Kgs 24.3 lbs

SMC-5 13 Kgs 28.7 lbs

SMC-8 16 Kgs 35.3 lbs

SMC-10 18 Kgs 39.7 lbs

SMC-13 20 Kgs 44.1 lbs

SMC-15 23 Kgs 50.7 lbs

SMC-20 28 Kgs 61.7 lbs

Remarque : Tous les débits sont référencés pour 20 °C (68 °F), 7 bar eff (102 psi eff)

This manual suits for next models

6

Table of contents

Languages:

Other Sullair Dehumidifier manuals

Sullair

Sullair SRHT-15 User manual

Sullair

Sullair SM1100 Installation and operating instructions

Sullair

Sullair SR 10 AC User manual

Sullair

Sullair SAR024 User manual

Sullair

Sullair SRL Series User manual

Sullair

Sullair DHL-80 Troubleshooting guide

Sullair

Sullair RC Series Troubleshooting guide

Sullair

Sullair SRC User manual

Sullair

Sullair SD Series User manual

Sullair

Sullair SD Series User manual