Sullair SD Series User manual

SD-820 / SD-1710

DDS OPTION

3V OPTION

LDP OPTION

SD Heatless Desiccant

Compressed Air Dryer

REF 02250130-737

SERIES SD

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 2

TABLE OF CONTENTS

FOREWORD................................................................................................................................. 4

SECTION 1 INTRODUCTION.................................................................................................... 5

1.1 GENERAL INFORMATION.............................................................................................. 5

1.2 SAFETY INSTRUCTIONS................................................................................................. 5

1.2.1 Identification of signs and symbols in this technical manual.............................................. 6

1.2.2 Safety tips for maintenance, inspection and assembly work............................................. 6

1.3 PERSONNEL QUALIFICATION ...................................................................................... 7

1.4 PRODUCT INFORMATION.............................................................................................. 8

1.4.1 Pressure vessel regulations............................................................................................. 8

1.4.2 Airtightness test............................................................................................................. 8

1.4.3 Overloading.................................................................................................................. 8

1.4.4 Technical data sheet...................................................................................................... 9

1.4.5 Transport.................................................................................................................... 10

1.4.6 Storage....................................................................................................................... 10

1.4.7 Use of a pre and after filter.......................................................................................... 10

SECTION 2 INSTALLATION................................................................................................... 11

2.1 SET-UP AND INSTALLATION....................................................................................... 11

SECTION 3 START UP AND OPERATION.......................................................................... 12

3.1 START UP/ SHUT DOWN ............................................................................................... 12

3.2 DESCRIPTION OF THE OPERATION ........................................................................... 12

3.2.1 Description of the operation......................................................................................... 13

3.2.2 Dryer operating sequence (No control or alarm option)................................................ 14

3.2.3 Operating sequence (DDS Option).............................................................................. 15

3.2.4 Alarms........................................................................................................................ 18

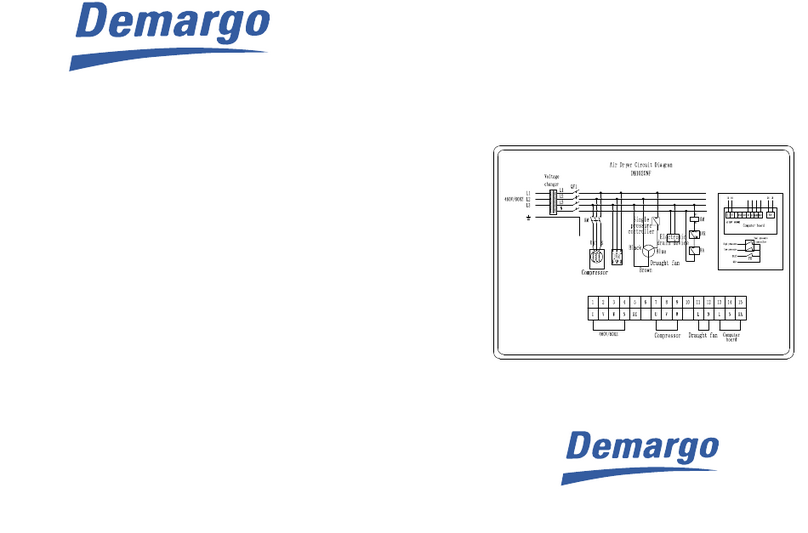

3.2.5 Electrical control......................................................................................................... 19

3.3 SPECIAL EQUIPMENT................................................................................................... 19

3.3.1 DDS Controls............................................................................................................. 19

3.3.2 DDS Controls – Start up and operation....................................................................... 20

SECTION 4 MAINTENANCE.................................................................................................. 22

4.1 REPLACEMENT OF THE DESICCANT......................................................................... 23

4.2 DISPOSAL OF THE DESICCANT.................................................................................. 23

4.3 CHANGING OF THE REGENERATION ORIFICE........................................................ 23

4.4 FILTERS............................................................................................................................ 24

4.4.1 General comments and use.......................................................................................... 24

4.4.2 Function...................................................................................................................... 24

4.4.3 Assembly and installation............................................................................................. 24

4.4.4 Maintenance ............................................................................................................... 24

4.4.5 Changing of filter elements........................................................................................... 25

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 3

4.4.6 Accessories ................................................................................................................ 25

SECTION 5 DRYER FLOW CAPACITY AND PURGE ADJUSTMENT............................ 26

5.1 DRYER FLOW CAPACITY............................................................................................. 26

5.2 CORRECTION FACTOR FOR INLET TEMPERATURE................................................ 26

5.3 PURGE ADJUSTMENT.................................................................................................... 27

SECTION 6 SPARE PARTS LIST.......................................................................................... 28

6.1 SPARE PARTS LIST FOR SD820 – SD1710................................................................... 28

6.2 SERVICE BULLETIN ....................................................................................................... 33

SECTION 7 TROUBLE SHOOTING & FAULTS................................................................... 47

7.1 THE DEW POINT IS TOO HIGH..................................................................................... 47

7.2 THE ADSORPTION DRYER DOES NOT SWITCH OVER............................................ 48

7.3 BACK PRESSURE IS TOO HIGH DURING REGENERATION PHASE....................... 49

7.4 SHORT-TERM SHUT-DOWN......................................................................................... 49

7.5 SHUT-DOWN IN CASE OF A FAULT OR FOR MAINTENANCE.............................. 50

7.6 RE-STARTING................................................................................................................. 50

SECTION 8 ANNEX................................................................................................................... 1

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 4

FOREWORD

This technical manual of S

Su

ul

ll

la

ai

ir

r®®is an aid in getting to know the adsorption dryer better

and in utilising its possibilities for application in accordance with its intended use.

Furthermore, this manual contains important information for safe, proper and economic

operation.

All instructions must be followed as written in order to avoid danger and damages

which could cause downtime and premature wear and tear on the adsorption dryer.

In addition to the technical manual and the accident prevention regulations which are

valid and compulsory in the country and in the particular workplace where the

adsorption dryer is being used, the recognized special rules for safe and proper

working procedures are also to be heeded. The technical manual must always be within

reach wherever the adsorption dryer is being used.

Each person involved with the set-up, start-up, operation, maintenance and repair of

the adsorption dryer in the User Company must have first read and understood the

technical manual and especially the safety tips.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 5

SECTION 1 INTRODUCTION

1.1 GENERAL INFORMATION

The adsorption dryer of the SD-820 – SD-1710 series is built according to the latest

technological developments and recognized safety rules. Its use however can endanger

life and limb of the user or of third parties, and can lead to considerable damage to the

adsorption dryer and other material assets if:

•it is operated by personnel not trained or instructed in its use,

•it is improperly used,

•it is improperly maintained or serviced.

This can result in the loss of all damage claims.

This adsorption dryer is designed for neutral media free of aggressive water, oil and

solid elements. S

Su

ul

ll

la

ai

ir

r®®accepts no liability for corrosion damage and malfunctions

caused by aggressive media.

Applications other than those mentioned in this manual must be agreed to by S

Su

ul

ll

la

ai

ir

r®®

and confirmed in writing.

In the interest of further development,

S

Su

ul

ll

la

ai

ir

r®®reserves the right to make changes at any

time, which, in keeping with the essential characteristics of the adsorption dryer

described here, may be necessary for increasing efficiency or for reasons relating to

safety or to normal business practice.

1.2 SAFETY INSTRUCTIONS

This technical manual contains basic tips, which must be followed during set-up,

operation and servicing. It is thus of utmost importance that it be read by the assembly

technician before installation and start-up as well as by the specialist / operator in

charge, and it must always be within reach at the place where the adsorption dryer is

being used.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 6

SECTION 1

1.2.1 Identification of signs and symbols in this technical manual

The safety tips contained in this technical manual, whose disregard could endanger

people and machines, are indicated by a general danger sign and the additional

markings Danger!or Attention!

Danger! / Attention!

Safety sign in accordance with DIN 4844 - W9

Warning against electrical voltage!

Safety sign in accordance with DIN 4844 - W8

Safety tips printed directly on the adsorption dryer must be heeded at all times and

must be kept completely legible.

*Advices

This sign refers to a procedure or sequence of particular interest or

importance. All tips must be followed to ensure proper use of this adsorption

dryer.

•This dot refers to working or operational steps. The steps are to be carried out in

the order of their appearance from top to bottom.

•The sign of a hyphen marks enumerations.

1.2.2 Safety tips for maintenance, inspection and assembly work

The operator is to make sure that all maintenance, inspection and assembly work is

carried out by special personnel who are authorized and qualified, and who are

adequately informed through careful study of the technical manual. For this reason,

special attention should be paid to the following attention and danger sign:

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 7

SECTION 1

Attention!

−Never make structural changes to the adsorption

dryer!

−Only use original spare and accessory parts!

−Never weld on a pressure vessel or change it in any

way!

Carry out maintenance work only when the adsorption

dryer is switched off, is depressurized and

disconnected from the electric power supply.

*Advices

Refer to the desiccant material safety data sheet (MSDS) when installing or

disposing of desiccant.

Danger!

Wear protective goggles when working with the

desiccant!

*Advices for protection

−If desiccant comes into contact with the eyes, rinse eyes immediately with a lot of

clear water.

−If the desiccant is spilled, clean up without causing swirls of dust.

−In case of fire, there is no restriction on the use of fire extinguishing material; the

reaction with water and foam is defined as strong.

−A mask must be worn.

1.3 PERSONNEL QUALIFICATION

The personnel involved in operation, maintenance, inspection and assembly must have

the corresponding qualifications to do this work. Areas of responsibility and supervision

of the personnel must be precisely established by the operator. Should the personnel

not possess the necessary knowledge, then they must be trained and instructed. If need

be, this training may be carried out by the manufacturer / supplier at the request of the

operator of the adsorption dryer. Further, the operator is to make sure that the

personnel completely understand the contents of the technical manual.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 8

SECTION 1

1.4 PRODUCT INFORMATION

The adsorption dryer is used for the purpose of drying compressed air and other gases

according to its respective design. As a "standard model" the adsorption dryer is

equipped with two desiccant vessels and a pre- and after-filter, and depending on

certain conditions at the outlet, provides pure, dry and oil-free compressed air or

gases.

1.4.1 Pressure vessel regulations

The pressure vessels are designed according to the standard technical requirements.

They fulfill the test of the certifying procedure and carry the“U”, “UM” ASME Symbol.

Range of application

Type SD-820 – SD-1710

Operating overpressure Max. 150 PSIG

Temperature Max.

Min.

500 °F

-20 °F

1.4.2 Airtightness test

All adsorption dryers are subjected to an airtightness test prior to shipment using

compressed air.

1.4.3 Overloading

Attention!

Protect the adsorption dryer from overloads!

The adsorption dryer can become overloaded, if:

−The flow capacity of the medium to be dried

increases,

−The temperature of the air at entry, and

correspondingly its humidity increases,

−The min. operating pressure is under cut,

−The pre-filtration and separation of impurities are not

sufficient.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 9

SECTION 1

1.4.4 Technical data sheet

Type SD-820 SD-1050 SD-1200 SD-1450 SD-1710

Medium Air, free of aggressive elements

Connection FLG – 150# 3” 3” 3” 3” 4”

Flow capacity (1) (STD)

SCFM 820 1050 1200 1450 1710

Flow capacity (1) (LDP)

SCFM 574 735 840 1015 1197

Desiccant

Standard Input temp.: from 100°F and dew point (2) –40°C (-40°F)

Filled with: activated alumina

LDP Dryers Input temp.: from 100°F and dew point (2) –73°C (-100°F)

Filled with: activated alumina

Quantity of desiccant

Per vessel [Lbs.] 460 600 700 800 952

Filter size (MPH,MPR) 910 1315 1315 2120 2120

Control PLC Controller

Operating voltage

Standard 120 V / 60 Hz (AC)

Special voltage Consult factory

Drying time

Standard 5 min

LDP Dryers 2 min

(1) Flow capacity in SCFM at 100 PSIG according to DIN ISO 7183

(2) Pressure dew point

NOTE: Settings for DDS:

Standard dryers DDS Control (-41°C) High humidity (-36°C)

LDP Dryers DDS Control (-74°C) High humidity (-69°C)

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 10

SECTION 1

1.4.5 Transport

After the adsorption dryer has been delivered, it must be checked for damage that may

have occurred during transport. If necessary, the Transport company must be informed

to register the damage.

*Advices

For transport within the company, only the skid of the adsorption dryers

SD-820 – SD-1710 may be used.

1.4.6 Storage

If the adsorption dryer is to be stored for a longer period of time, its place of storage

must be dry and free of dust. There has to be a min. ambient temp. of +1°C (33°F).

1.4.7 Use of a pre and after filter

In order to prevent droplets of condensate, oil and dirt from getting into the desiccant,

a pre-filter is installed in front of the adsorption dryer, since an oil film on the desiccant

reduces the drying capacity and the dewpoint. In order to prevent breakdowns in

downstream consumers caused by material that has been abraded from the desiccant

bed, an after-filter is mounted behind the adsorption dryer. Since no condensate

accumulates in the after-filter, this filter is always equipped with a manual valve.

Both filters are equipped with a differential pressure gauge (standard) as this ensures

an indirect display of the degree of contamination of the filter elements.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 11

SECTION 2 INSTALLATION

2.1 SET-UP AND INSTALLATION

Once at the installation location, the adsorption dryers of the series SD-820 – SD-

1710, which are supplied with a base frame, must be positioned so that the side from

which it is to be operated is easily accessible. The piping is to be connected to the

adsorption dryer at a light slope. A shut-off valve is to be installed on the inlet and outlet

sides of the adsorption dryer. Also, a by-pass pipe with an additional shut-off valve

should be mounted onto the adsorption dryer, in order to be able to guarantee an

uninterrupted supply of compressed air in case the adsorption dryer breaks down.

Should vibrations occur on the installation location, the adsorption dryer is to be placed

onto vibration dampers.

Since the adsorption dryer has already been completely wired at our factory, the

customer only has to connect the power supply cable to the terminal strip according to

the supplied wiring diagrams.

*Advice

Should you still have questions regarding installation, you can request

installation blueprints separately from S

Su

ul

ll

la

ai

ir

r®®MichiganCity,Indiana

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 12

SECTION 3 START UP AND OPERATION

3.1 START UP/ SHUT DOWN

Attention!

All pipes and wire connections are to be tightened!

Furthermore, before start-up:

−The pipes must be checked for the presence of scale,

abraded material from the threading, or other similar

impurities.

−All shut off valves on the pre-filter, adsorption dryer, after-

filter and on the bypass line should be closed.

−The ambient temperature must not be less than 33°F.

Breakdowns resulting from faulty installation do not fall under the S

Su

ul

ll

la

ai

ir

r®®warranty

obligation.

*Advices

The following sequence is to be heeded for the initial start-up:

•Slowly open the inlet valve and observe the pressure build-up on the

chamber pressure gauges of the adsorption dryer. A too abrupt pressure

build-up is to be avoided

•Turn the switch to the "POWER ON" position..

•The adsorption dryer must be powered approx. 3-4 h with the shut off valve

behind the after-filter closed; this regenerates the desiccant.

•After the regeneration phase, open the shut off valve behind the after-filter

slowly while observing the chamber pressure gauge; if the shut off valve is

opened too abruptly, it could put a stress on the system.

•The adsorption dryer is now ready for operation and functions continuously

and fully automatically.

3.2 DESCRIPTION OF THE OPERATION

The S

Su

ul

ll

la

ai

ir

r®®adsorption dryer of the series SD-820 – SD-1710 functions according to

the pressure change principle, using dry air regeneration. Two adsorption vessels filled

with desiccant are installed parallel to each other for this purpose. While the medium

is being dried in one vessel, regeneration takes place in the other vessel. The

changeover from one vessel to the other is performed in a fixed rhythm by means of a

time-dependent control system. The adsorption dryer operates continuously and fully

automatically.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 13

SECTION 3

3.2.1 Description of the operation

SD HEATLESS TYPE DRYER (SD-820 – SD-1710)

•The S

Su

ul

ll

la

ai

ir

r®®SD dryer has a NEMA cycle time of 10 minutes (STD) or 4 minutes

(LDP) depending upon the air quality desired. In a 10 minute cycle, 5 minutes is

dedicated to drying for each chamber (5 minutes half cycle). In a 4 minutes cycle,

the half cycle is then 2 minutes.

•Through the inlet switching valve wet air enters either desiccant chamber at the inlet

(bottom) and is dried as it flows upward through the desiccant bed. Dry air exits

the dryer through the outlet check valve.

•At the outlet of each chamber, a portion of the dry air (purge air) is diverted to the

regenerating chamber. The dry air, at near atmospheric pressure, will remove

previously adsorbed moisture as it flows downward through the desiccant bed

exiting through the purge exhaust muffler.

•The purge air is controlled by a purge adjusting valve and purge orifices located

in the purge line. Purge pressure can be monitored on the purge pressure gauge.

Refer to section on purge adjustment for instructions on setting the purge rate.

•Near the end of each half cycle, the chamber being regenerated will be re-

pressurized. For this to occur, the exhaust valve of the chamber being regenerated

closes while purge air continues to flow. Re-pressurizing the regenerated chamber

to operating pressure before placing it into service minimizes fluidization of the

desiccant and helps prevent desiccant abrasion which causes desiccant dust to

prematurely block pilot and after-filter elements.

•Dryers operating at pressures greater than 120-125 PSIG or in an accelerated

NEMA cycle could be fitted with a re-pressurizing valve. This valve assists the

regenerated chamber to reach dryer operating pressure before chamber

switchover.

•Chamber switchover takes place when both towers are fully pressurized to

minimize desiccant movement.

When switchover is complete, the regenerated tower will be placed into service and the

exhausted tower will begin a depressurization/regeneration cycle.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 14

SECTION 3

3.2.2 Dryer operating sequence (No control or alarm option)

The S

Su

ul

ll

la

ai

ir

r®®SD-820 –SD-1710 heatless air dryers use a PLC as its standard controller.

In the event of a power failure, the exhaust valves will close and the dryer will pressurize

both chambers. Since this control panel uses retentive programming the dryer will return

to the same step in the cycle the dryer was in before power was lost.

Energizing control panel : Power is turned ON – electrical circuit energized.

STEP 1 SELECT LEFT CHAMBER DRYING.

- De-energize solenoid EV-1R.

- Energize solenoid EV-1L.

- Inlet valve positioned for left chamber drying.

- When 3 seconds have passed, go to STEP 2

STEP 2 RIGHT CHAMBER DE-PRESSURIZATION.

- Keep energized EV-1L

- Energize EV-2R opening right chamber dump/exhaust valve.

- When regeneration time has passed, go to STEP 3

STEP 3 RIGHT CHAMBER REPRESSURIZATION.

- Keep energized EV-1L.

- De–energize EV-2R closing right chamber dump/exhaust valve.

- The repressurization timer begins a countdown of 45 seconds.

- Inlet valve remains in current position.

- When repressurization time has passed, go to STEP 4

STEP 4 RIGHT CHAMBER DRYING.

- De-energize solenoid EV-1L

- Energize solenoid EV-1R.

- Inlet valve positioned for right chamber drying.

- When 3 seconds have passed, go to STEP 5

STEP 5 LEFT CHAMBER DEPRESSURIZATION.

- Keep energized EV-1R

- Energize EV-2L, opening right chamber dump/exhaust valve.

- When regeneration time has passed, go to STEP 5

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 15

SECTION 3

3.2.2 Dryer operating sequence (No control or alarm option) – (Continued)

STEP 6 RIGHT CHAMBER REPRESSURIZATION.

- Keep energized EV-1R.

- De–energize EV-2L closing right chamber dump/exhaust valve.

- The repressurization timer begins a countdown of 45 seconds.

- Inlet valve remains in current position.

The dryer has completed 1 full cycle and will repeat steps 1 through 6 until power is

removed from the control panel.

3.2.3 Operating sequence (DDS Option)

The S

Su

ul

ll

la

ai

ir

r®®SD-820-DDS – SD-1710-DDS and all “LDP” heatless air dryers use a PLC

as its standard controller. In the event of a power failure, the exhaust valves will close

and dryer will pressurize both chambers. Since this control panel uses retentive

programming, the dryer will return to the same step in the cycle dryer was in before

power was lost. (See NOTE 2)

Energizing control panel: Power is turned ON – electrical circuit energized.

STEP 1 SELECT LEFT CHAMBER DRYING.

- De-energize solenoid EV-1R.

- Energize solenoid EV-1L.

- Inlet valve positioned for left chamber drying.

- When 3 seconds have passed, go to STEP 2

STEP 2 RIGHT CHAMBER DE-PRESSURIZATION.

- Keep energized EV-1L

If not in DDS mode:

- Energize EV-2R opening right chamber dump/exhaust valve.

If in DDS mode and dewpoint is better than hygrometer setpoint:

-EV-2R does not energize.

When regeneration time has passed, go to STEP 3

STEP 3 RIGHT CHAMBER REPRESSURIZATION.

- Keep energized EV-1L.

- De–energize EV-2R closing right chamber dump/exhaust valve.

- The repress timer begins a countdown of 45 seconds (See Note 1)

- Inlet valve remains in current position.

- When repressurization time has passed, go to STEP 4

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 16

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 17

SECTION 3

3.2.3 Operating sequence (DDS option) – (Continued)

STEP 4 RIGHT CHAMBER DRYING.

- De-energize solenoid EV-1L

- Energize solenoid EV-1R.

- Inlet valve positioned for right chamber drying.

- When 3 seconds have passed, go to STEP 5

STEP 5 LEFT CHAMBER DEPRESSURIZATION.

- Keep energized EV-1R

If not in DDS mode:

- Energize EV-2L opening right chamber dump/exhaust valve.

If in DDS mode and dewpoint is better than hygrometer setpoint:

- EV-2R does not energize.

When regeneration time has passed, go to STEP 6

STEP 6 LEFT CHAMBER REPRESSURIZATION.

- Keep energized EV-1R.

- De–energize EV-2L closing left chamber dump/exhaust valve.

- The repress timer begins a countdown of 45 seconds (See note 1)

- Inlet valve remains in current position.

NOTE 1:EV-3 and repress valves could be used if dryer operating at pressure

above 125 PSI (G) and / or dryer operating on a timing cycle other than

10 minute cycle. Refer to the specification sheet in this manual or to the

flow schematic supplied with the dryer.

NOTE 2:Ifpowerfailureoccurstothedryerorunitisturnedoff,bothexhaustvalves

will close. The inlet valve will remain in its position.

NOTE 3: The actual timer setting may differ from the previously noted sequence.

Example: A dryer requiring 30 seconds to re-pressurize the

regenerating chamber will have a regeneration time of 4 minutes and 30

seconds. The half cycle time will remain at 5 minutes and full cycle at 10

minutes.

NOTE 4: The regeneration and re-pressurization times should be adjusted by

S

Su

ul

ll

la

ai

ir

r®®trained personnel only. Changing the factory settings will result in

loss of dew point and/or failure to re-pressurize before changeover.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 18

SECTION 3

3.2.4 Alarms

** If any alarms options are supplied with dryer then a PLC will control the timing of the

dryer.

COMMON ALARM RELAY

Common alarm relay comes with any optional alarm. If any one of the alarms are

activated, the common alarm relay will also be activated.

SWITCHING FAILURE ALARM (OPTIONAL, INCLUDED WITHDDS OPTION)

Two pressure switches, sensing desiccant chamber pressure, are provided. An alarm

will be activated if both chambers remain at full pressure when regeneration is

required. Furthermore, if pressure in both chambers remain below set pressure, after

depressurization an alarm will be activated.

NOTE:Dryers equipped with DDS and operating in the DDS mode do not

depressurize during the purge cycle (and do not purge) when an

acceptable dew point is maintained. During this condition the switching

failure alarm is cancelled.

The alarm has a 1-minute delay.

HIGH HUMIDITY ALARM (OPTIONAL, INCLUDED WITHDDS OPTION)

The hygrometer provided has been programmed to initiate an alarm if the dryer outlet

dew point falls below the setting. An alarm light is provided.

NOTE:The alarm has a 20-minute delay when the dryer is first powered up, then

the alarm is instant if the condition exists.

IF THE HYGROMETER BOARD TO PROBE CONNECTION FAILS,

then a fault will observed by the hygrometer. The high humidity alarm light will flash on

and off. The dryer will go into a fixed cycle mode. The digital display will indicate “OPN”.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 19

SECTION 3

3.2.5 Electrical control

Danger!

Work on electrical installations may only be done by a

specialist or by other persons instructed in this type of

work as long as they are under the instruction and

supervision of a specialist; the general rules for working

with electricity must be followed!

You find the corresponding operating and control voltage on the data sheet.

The S

Su

ul

ll

la

ai

ir

r®®adsorption dryer of the SD series is normally operated with a PLC

controller. The set times are adjusted at the factoryduring the test run.

Do not change these adjustments!

3.3 SPECIAL EQUIPMENT

3.3.1 DDS Controls

The DDS control option is a Dewpoint Dependant Switching system that monitors the

dryer dewpoint performance and manages the requirement for regeneration of the

dryer. The DDS controls major components are a digital dewpoint display hygrometer

and a humidity sensor.

The S

Su

ul

ll

la

ai

ir

r®®type SD Air dryer is designed to provide a specific pressure dewpoint

performance (generally –40 F (-40 C)) at the most severe operating conditions

specified. (Maximum flow at lowest pressure and highest inlet temperature). The

regeneration purge flow rate required for the dryer is calculated and adjusted to achieve

this dewpoint and is based on these conditions.

For example, for dryers operating at 100 PSIG (690 kPa) and 100 F (38 C) the purge

flow rate is approximately 15% of the specified maximum inlet flow. Dryers operating

under less severe inlet conditions will introduce a reduced humidity load. The DDS

controls have been factory programmed to monitor the dryer outlet dewpoint

performance and prevent initiation of a regeneration cycle under these conditions.

The DDS controls system has the following standard features, refer to the enclosed

technical bulletin for a complete overview of the digital hygrometer display.

Digital display can be toggled to degrees F, C, and PPM.

Detection for cable fault between hygrometer and moisture probe.

Stainless steel humidity probe sampling cell with service valves.

INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 20

SECTION 3

3.3.2 DDS Controls – Start up and operation

The DDS controls system when supplied should be disabled for the initial 8 hours of

dryer operation. A dryer fitted with the DDS control will have a 3-position selector switch

on the electrical control panel. The 3 positions of this switch will perform the following

actions:

Position 1: POWER OFF

Position 2: POWER ON

Position 3: DDS ON

The POWER ON position will allow the hygrometer to be energized yet force the dryer

to operate on a FIXED CYCLE mode. The dryerSHOULD BE OPERATED IN THIS

POSITION AT TIME OF INITIAL STARTUP AND AT ALL TIMES WHEN THE

HYGROMETER OR HUMIDITY PROBE ARE REMOVED FOR SERVICE OR

CALIBRATION.

The DDS ON position will control the dryer regeneration steps when the dewpoint of the

dryer is better than the factory adjusted setpoint programmed into the digital

hygrometer.

The startup procedure for the DDS system will be as follows. Refer to the assembly

drawing in the following section.

1. Verify that the sample line (1/8 Teflon tube) is connected from the dryer outlet (see

flow schematic enclosed) to the inlet valve on the humidity probe sample cell.

2. Verify that the humidity probe is installed into the sample cell

3. Connect the coaxial cable to the humidity probe

4. Fully open the inlet valve to the sample cell

5. Partially open the discharge valve of the sample cell to bleed off a small amount of

sample air. Do not fully open discharge valve

6. Perform a soap test to verify for leaks on all parts of the sample line connections and

the humidity sample cell.

7. The digital display will now read the dewpoint of the dryer system. It will take a short

period of time for a humidity probe to be purged of humidity.

Other manuals for SD Series

3

This manual suits for next models

5

Table of contents

Other Sullair Dehumidifier manuals

Sullair

Sullair SM1100 Installation and operating instructions

Sullair

Sullair SD Series User manual

Sullair

Sullair RC Series Troubleshooting guide

Sullair

Sullair DBP Series Troubleshooting guide

Sullair

Sullair SRL Series User manual

Sullair

Sullair SD Series User manual

Sullair

Sullair SRC User manual

Sullair

Sullair SD-820 Series User manual

Sullair

Sullair SRHT-15 User manual

Sullair

Sullair DHL-80 Troubleshooting guide