10. Installation and Commissioning

10.1 Package Contents

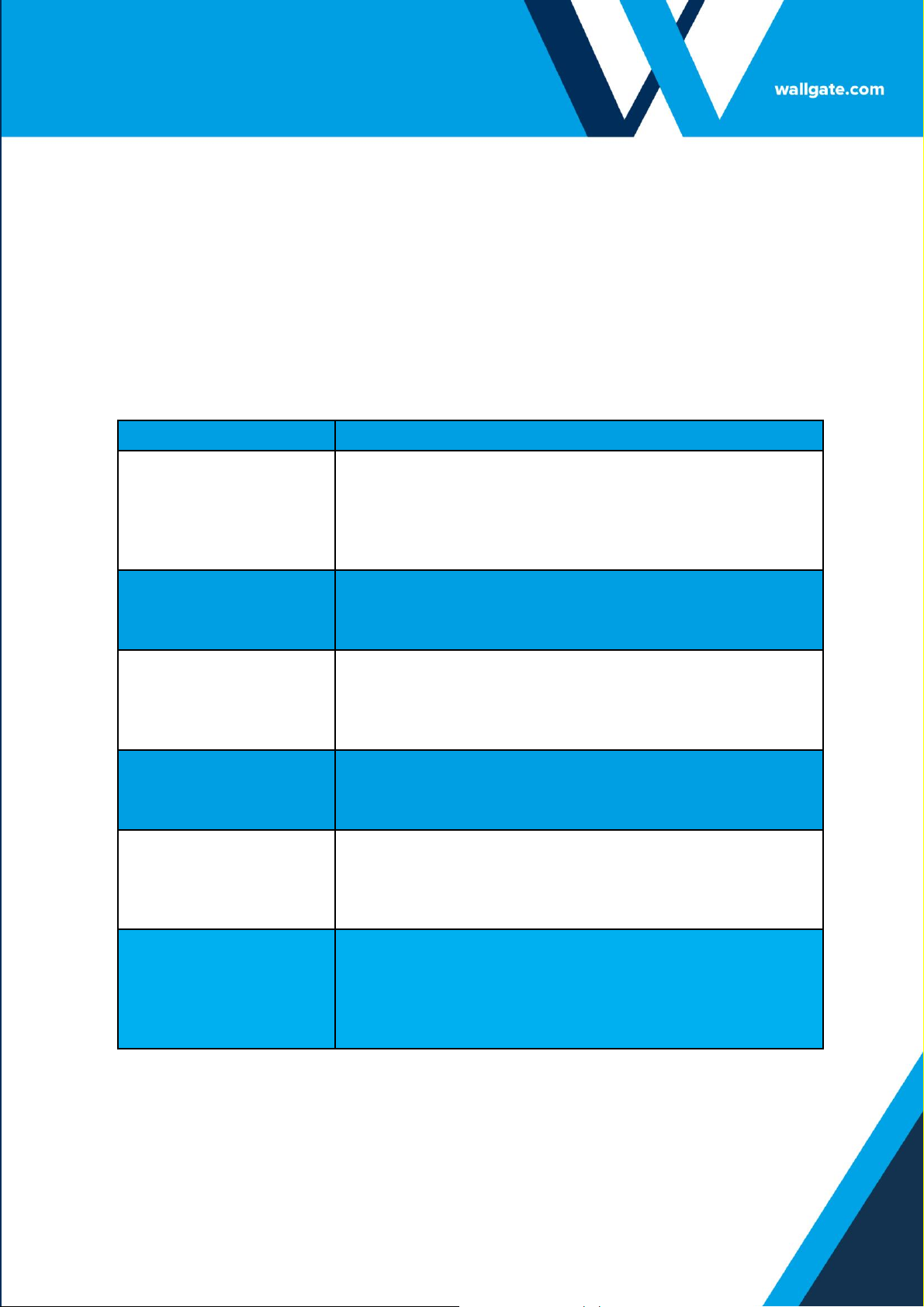

Before you begin the installation, make sure that you have the following items:

✓PSH-20: 1 x PSH basin fascia with mounting brackets, M10 studs & fixings, 1 x PSH

control cabinet, 1 x metal air duct, 1 x flexible water hose, 2 x button blanks with fixing

tube & nut, 1 x bottle of soap.

✓PSH-20R: 1 x PSH basin fascia with mounting brackets, M10 studs & fixings, 1 x

PSH control cabinet, 1 x flexible air duct, 2 x hose clips,1 x flexible water hose, 2 x

button blanks with fixing tube, 1 x bottle of soap.

✓PSHD20: 1 x PSH basin fascia with mounting brackets M10 studs & fixings,1 x PSH

control cabinet, 1 x metal air duct, 2 x flexible water hoses, 1 x bottle of soap.

✓PSHD20R: 1 x PSH basin fascia with mounting brackets M10 studs & fixings, 1 x

PSH control cabinet, 1 x flexible air duct, 2 x hose clips, 2 x flexible water hoses, 1 x

bottle of soap.

✓PSH-25-PNEU: 1 x PSH basin fascia with mounting brackets M10 studs & fixings, 1 x

PSH control cabinet, 1 x flexible water hose, 1 x Stainless steel push button with air

pump, air hose and pneumatic water valve.

NOTE: The PSH-23 model series that use a WDC electronic control unit sold

separately as an option are detailed in the PSH-23 product manual.

10.2 Site Preparation

•Prepare an opening in the wall surface, accurate to the dimensions shown on

the installation drawing provided with the product. It is important that the

aperture is square and within tolerance to the stated dimensions.

•An electrical supply (230v 50Hz) should be provided with a switched fused

spur-13Amp, double pole connection point that is local (within 0.7 metre) of

the Control cabinet (the contact separation of the fused switch spur should be

at least 3mm). The PSH unit comes with a 1 metre mains cable flex attached.

•A mains cold water supply with a static pressure of 2-3bar should be provided

to the rear of the wall below the cabinet mounting position and terminated with

a suitable isolating tap for final connection to the unit inlet connections. If the

unit is to be connected to a gravity (tank) fed supply, further advice should be

requested from Wallgate as the minimum required water pressure as stated

above is important to the performance of the unit water dispensing system.

•The basin includes a waste outlet pipe tail 1 ½” (40mm) connection. It should