TABLE OF CONTENTS

FORWARD....................................................................................................................................... 5

Preface.......................................................................................................................................... 5

Disclaimer..................................................................................................................................... 5

Contact Information....................................................................................................................... 5

Owner Registration Information.................................................................................................... 5

WARRANTY..................................................................................................................................... 6

SECTION 1 SAFETY....................................................................................................................... 7

Safety Information......................................................................................................................... 7

General Safety Practices.............................................................................................................. 7

Safety During Transport................................................................................................................ 7

Safety Decals................................................................................................................................ 8

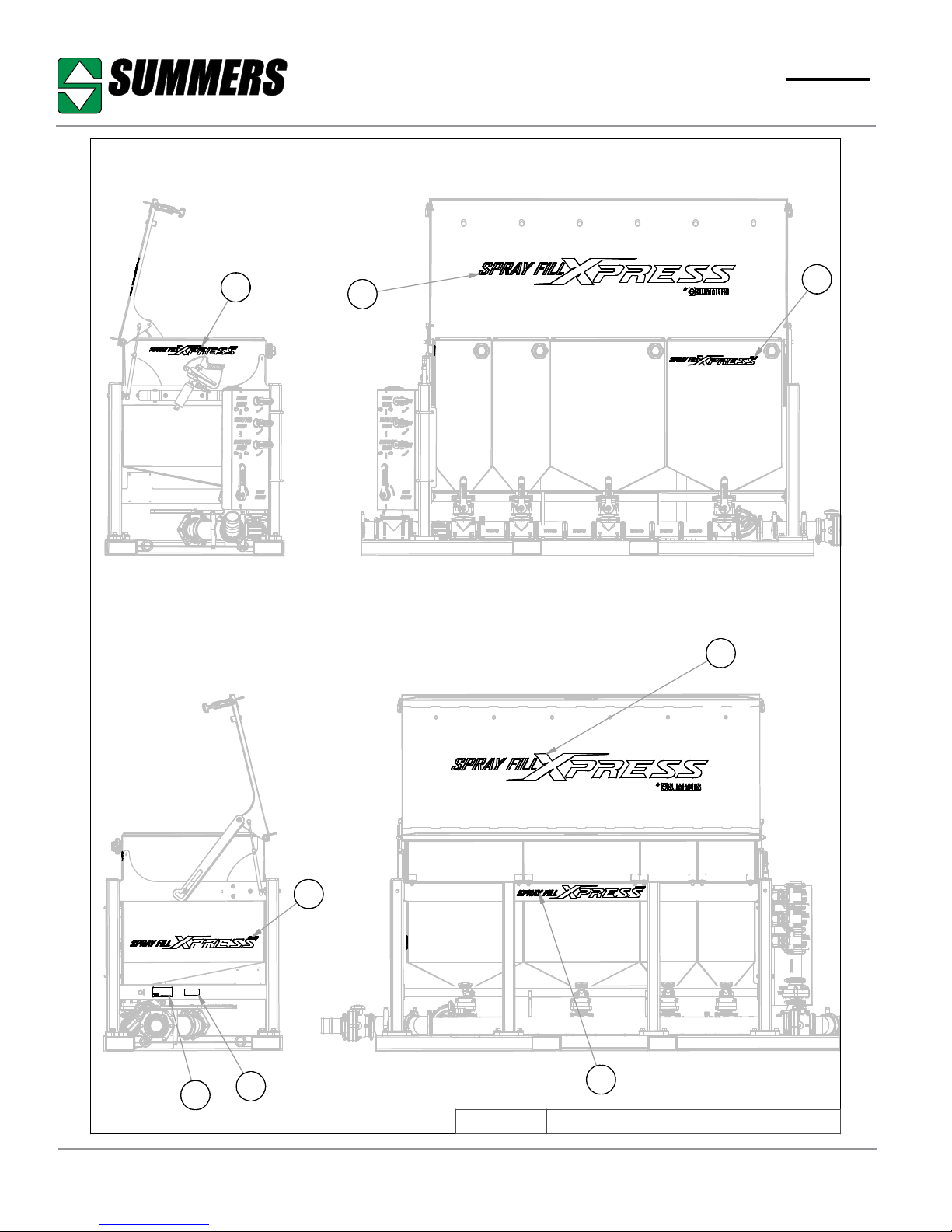

Spray Fill Xpress Safety Decal Locations................................................................................... 10

General Maintenance Safety Practices....................................................................................... 12

SECTION 2 - OPERATION SAFETY ............................................................................................. 13

SECTION 3 - OPERATION ............................................................................................................ 15

Readying for Use........................................................................................................................ 15

Getting Ready for Transfer..........................................................................................................16

SECTION 4 - Maintenance & Specications .................................................................................. 17

Maintenance Safety.................................................................................................................... 17

Daily & Periodic Maintenance..................................................................................................... 17

Storage ....................................................................................................................................... 17

Specications.............................................................................................................................. 18

SECTION 5 - PARTS LIST............................................................................................................. 19

SFX1630 Base Frame ................................................................................................................ 20

SFX1630 Plumbing..................................................................................................................... 22

SFX1630 Tanks.......................................................................................................................... 24

SFX2430 Base Frame................................................................................................................ 26

SFX2430 3 Tank Components.................................................................................................... 28

SFX2430 4 Tank Components.................................................................................................... 30

SFX2430 5 Tank Components.................................................................................................... 32

SFX2430 6 Tank Components.................................................................................................... 34

SFX2430 Side Plumbing............................................................................................................. 36

8Z1105 © Summers Mfg. Co., Inc. 2018 Page 3