TABLE OF CONTENTS

SECTION 1- SAFETY

SAFETY- ALERT SYMBOL & GENERAL SAFETY PRACTICES ........................................................................................ [1-1]

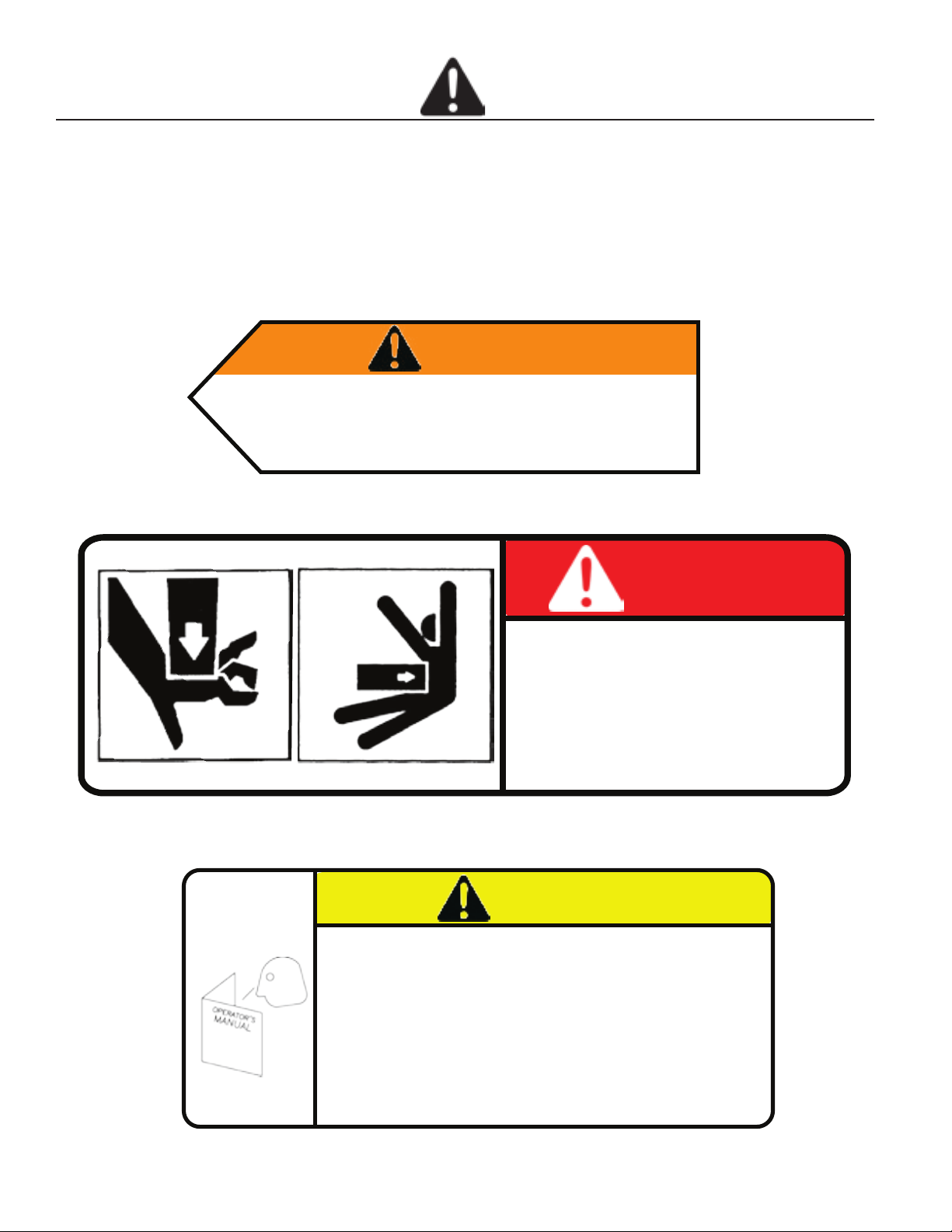

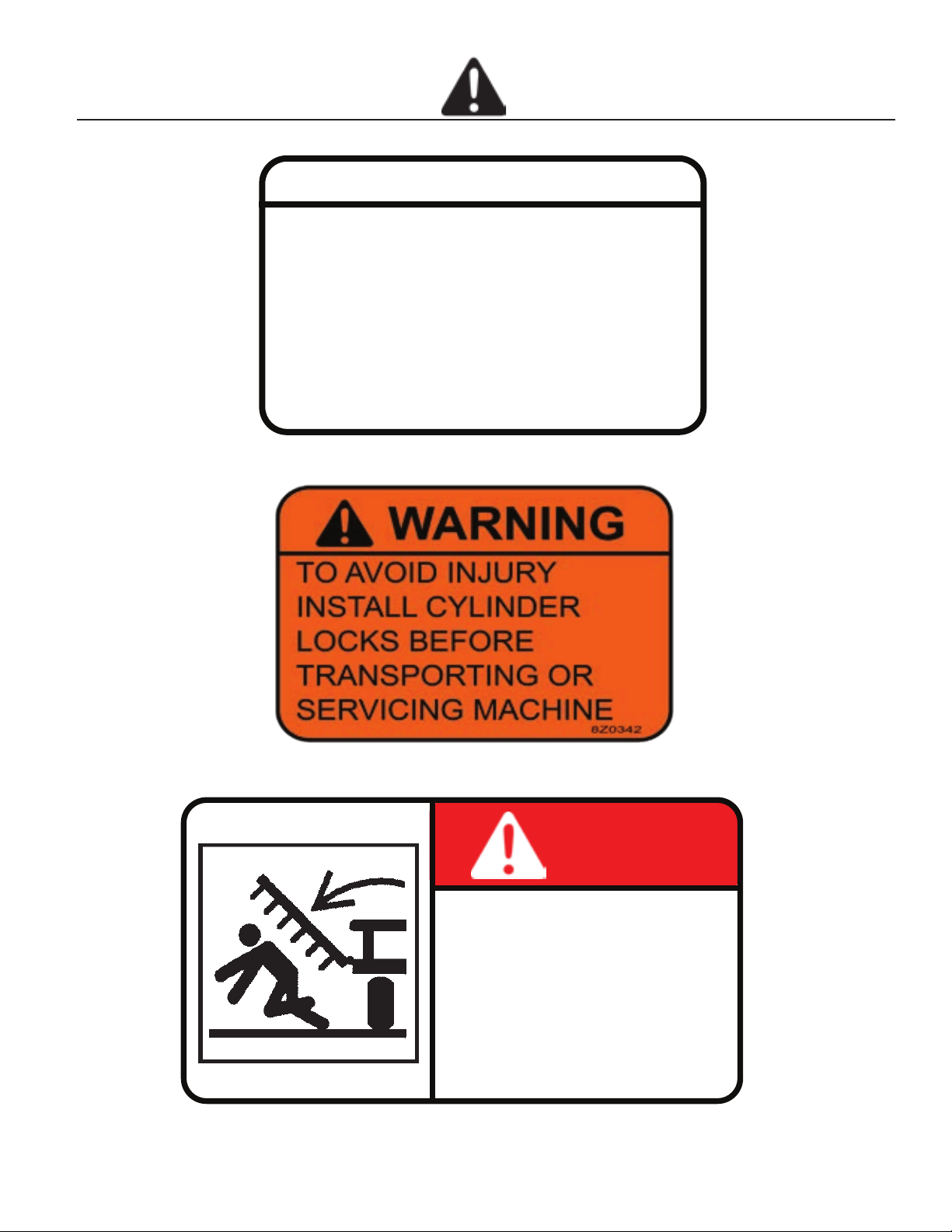

SAFETY DECALS .............................................................................................................................................. [1-2]-[1-6]

SECTION 2 – OPERATION & MAINTENANCE

START-UP ........................................................................................................................................................ [2-1]-[2-2]

I-PAD SETUP ................................................................................................................................................... [2-3]-[2-4]

ICONTROL APP BUTTON MAP ................................................................................................................................... [2-5]

USING THE ICONTROL APP ............................................................................................................................. [2-6]-[2-10]

TRANSPORTING ...................................................................................................................................................... [2-11]

UNHOOKING VRT RENEGADE ................................................................................................................................ [2-11]

STORAGE ................................................................................................................................................................ [2-11]

MAINTENANCE ....................................................................................................................................................... [2-12]

BOLT TORQUE SPECIFICATION ................................................................................................................................ [2-12]

TROUBLESHOOTING ..................................................................................................................................... [2-13]-[2-15]

DIMENSIONS ........................................................................................................................................................... [2-15]

SENSOR REPLACEMENT .......................................................................................................................................... [2-16]

SECTION 3 - PARTS

25’ - 30’ CENTER TRANSPORT ...................................................................................................... [3-1]-[3-2]

25’ - 30’ CENTER .......................................................................................................................... [3-3]-[3-4]

25’ - 30’ WINGS ............................................................................................................................ [3-5]-[3-6]

25’ – 30’ HITCH ............................................................................................................................ [3-7]-[3-8]

25’ – 30’ SENSORS ...................................................................................................................... [3-9]-[3-10]

25’ – 30’ LIGHTING ................................................................................................................... [3-11]-[3-12]

35’ - 40’ CENTER TRANSPORT .................................................................................................. [3-13]-[3-14]

35’ - 40’ CENTER ..................................................................................................................... [3-15]-[3-16]

35’ - 40’ HITCH ......................................................................................................................... [3-17]-[3-18]

35’ – 40’ WINGS ....................................................................................................................... [3-19]-[3-20]

35’ – 40’ SENSORS ................................................................................................................... [3-21]-[3-22]

35’ – 40’ LIGHTING ................................................................................................................... [3-23]-[3-24]

25’ – 40’ DECALS ..................................................................................................................... [3-25]-[3-26]

GANG/TRIP/HUB ASSEMBLIES .................................................................................................. [3-27]-[3-28]

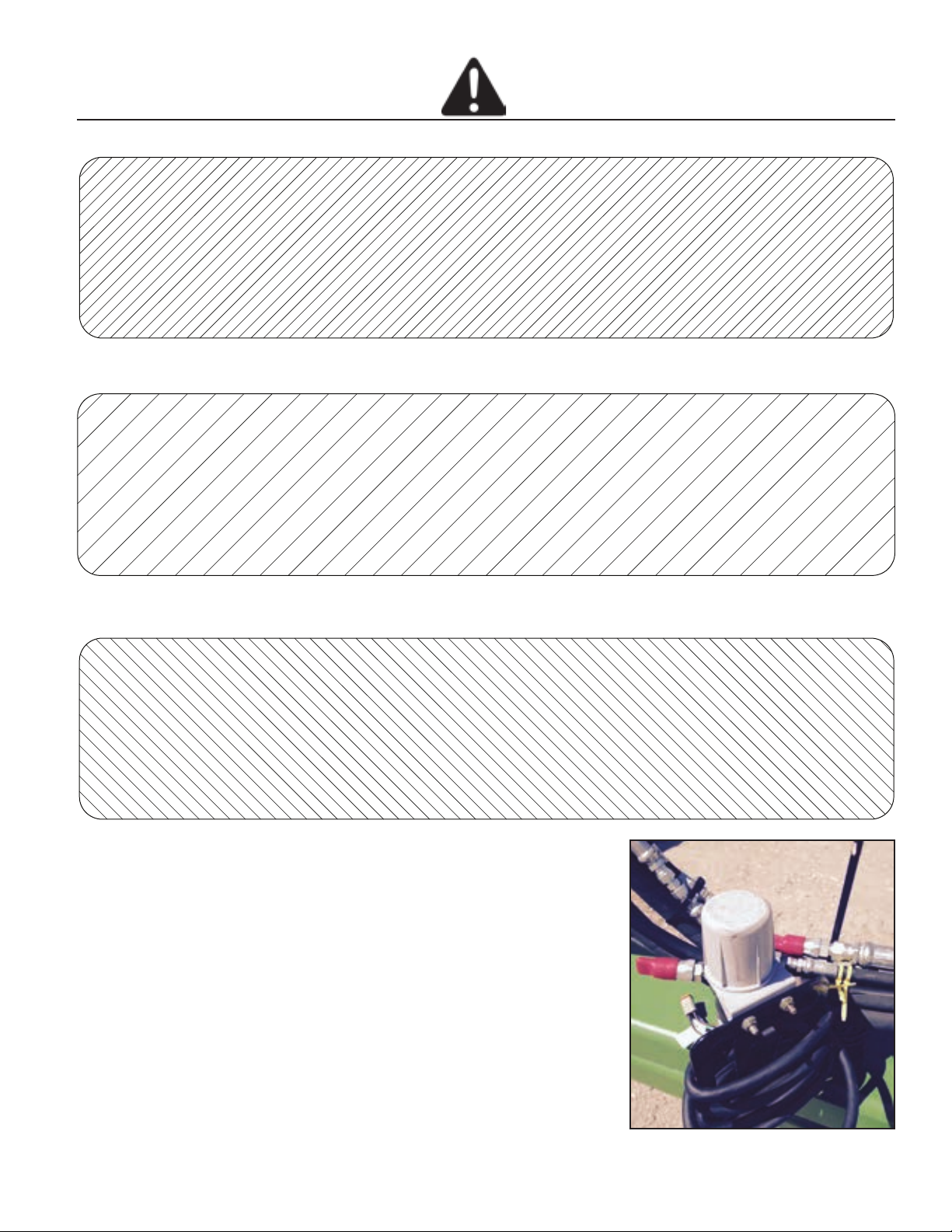

HYDRAULIC BLOCK ASSEMBLY ................................................................................................ [3-29]-[3-30]

25’ – 30’ MAIN LIFT HYDRAULIC CIRCUIT .......................................................................................... [3-31]

25’ – 30’ BLADE ANGLE HYDRAULIC CIRCUIT .................................................................................... [3-32]

25’ – 30’ BASKET DOWNPRESSURE HYDRAULIC CIRCUIT ................................................................... [3-33]

25’ – 30’ WING FOLD/DOWNPRESSURE HYDRAULIC CIRCUIT ............................................................. [3-34]

25’ – 30’ GAUGE WHEEL HYDRAULIC CIRCUIT ................................................................................... [3-35]

25’ – 30’ HITCH HYDRAULIC CIRCUIT ................................................................................................. [3-36]

25’ – 30’ AUXILIARY BLOCK HYDRAULIC CIRCUIT ............................................................................. [3-37]

35’ – 40’ MAIN LIFT HYDRAULIC CIRCUIT .......................................................................................... [3-38]

35’ – 40’ BLADE ANGLE HYDRAULIC CIRCUIT .................................................................................... [3-39]

35’ BASKET DOWNPRESSURE HYDRAULIC CIRCUIT ............................................................................ [3-40]

40’ BASKET DOWNPRESSURE HYDRAULIC CIRCUIT ............................................................................ [3-41]

35’ – 40’ WING FOLD/DOWNPRESSURE HYDRAULIC CIRCUIT ............................................................. [3-42]

35’ – 40’ GAUGE WHEEL HYDRAULIC CIRCUIT ................................................................................... [3-43]

35’ – 40’ HITCH HYDRAULIC CIRCUIT ................................................................................................. [3-44]

35’ – 40’ AUXILIARY BLOCK HYDRAULIC CIRCUIT ............................................................................. [3-45]

MOUNTED HARROW ASSEMBLY ............................................................................................... [3-47]-[3-48]

ROLLING BASKET ASSEMBLY ................................................................................................... [3-49]-[3-50]

HARROW/BASKET ARM ASSEMBLY .......................................................................................... [3-51]-[3-52]

HUBS/AXLES ............................................................................................................................ [3-53]-[3-54]

ACRE METER ....................................................................................................................................... [3-55]

SECTION 4 – PART NUMBER AND DESCRIPTION

PARTS NUMBER AND DESCRIPTIONS ................................................................................................................ [4-1]-[4-3]

ii