7 | P a g e

1.2 General Safety

It is the responsibility of the owner/user to ensure a safe working environment, not only

for themselves, but those around them. The following instructions are advised to help

ensure this is made possible.

Due to the nature of Sumo machines, the entire machine and surrounding area is

classified as a Danger Zone, and the following instructions must be followed:

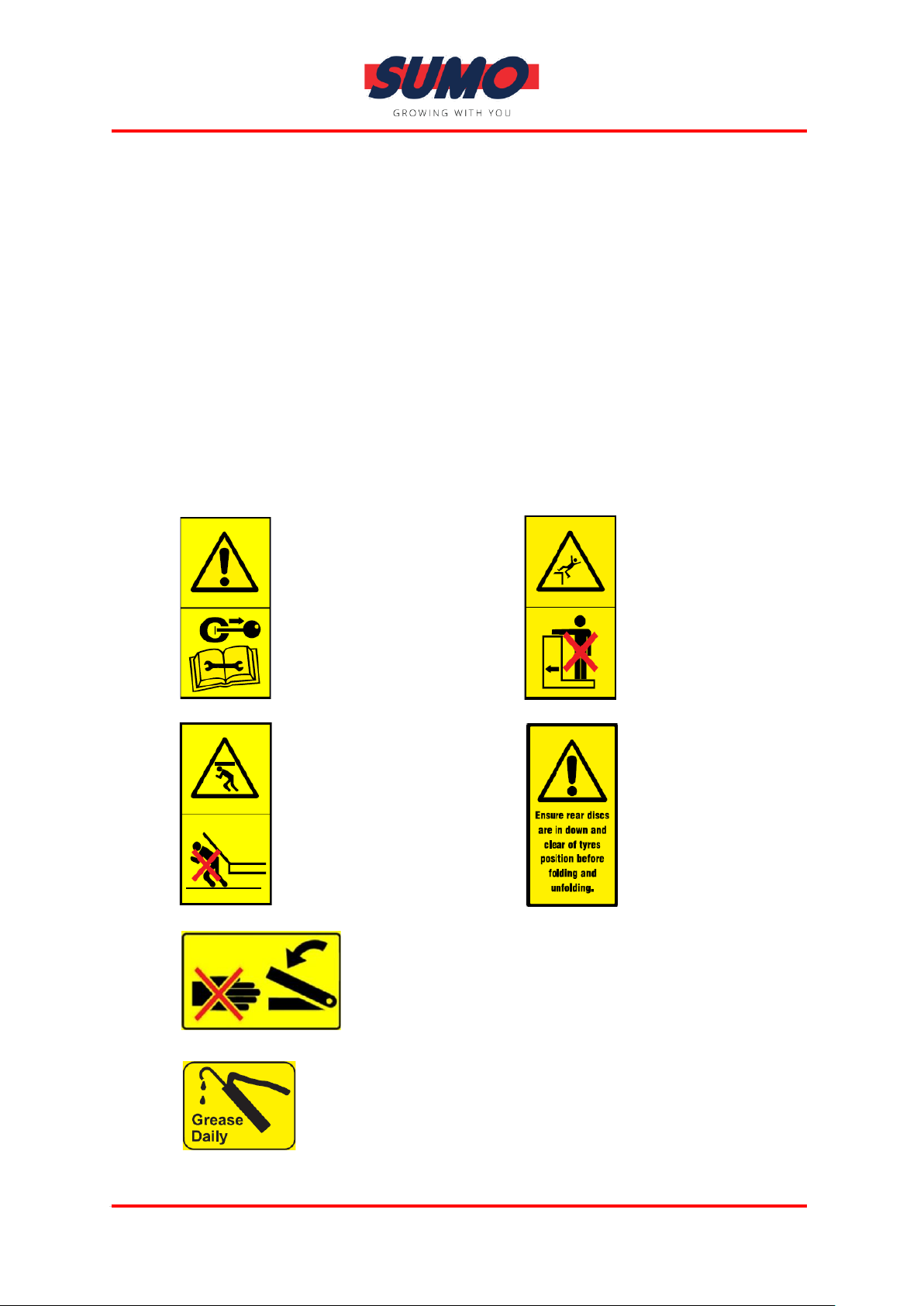

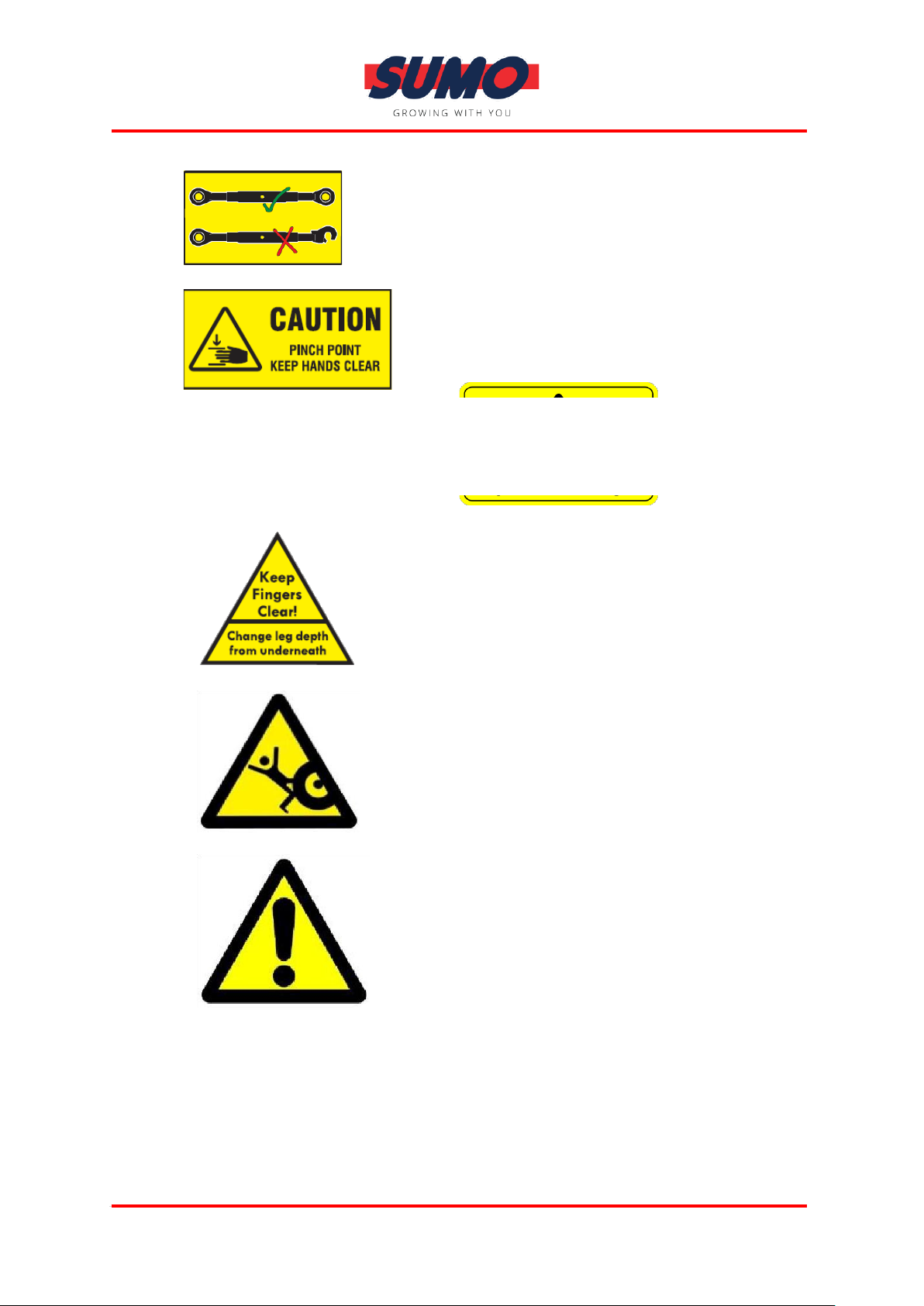

-Warning signs and other notices on the machine provide important information

for safe operation. Observing and following them will serve your safety. Ensure

they are clean, undamaged and clearly visible at all times.

-To avoid serious injury, ensure tractor keys are removed before making any

adjustments or maintenance.

-With the drive still running/turned off, machine parts may fall, rotate or swing

out. Ensure to stay clear of any risk area.

-Never allow anyone to stand, beside or behind the stationary machine, or whilst

attached to a tractor, unless it is fully secured against rolling away by means of

parking brake and/or wheel chocks. Even then all safety precautions herein must

be followed.

-Before starting work, make yourself familiar with all the equipment and controls

as well as their functions.

-The user should wear all necessary PPE as described in the PPE section of this

manual.

-Adhere to all maintenance instructions given within this manual.

-Avoid any finger traps.

-Keep the machine and the bearings clean to avoid risk of fire.

-Maintain the upkeep of any electronics. Defective, incorrectly fastened electric

lines, exposed wires can cause electric shocks.

-Always remain vigilant around the machine as hydraulically raised machine parts

can lower slowly and unnoticed.

-It is expressly Forbidden for anyone to ride on our machines at any time.

-Never stand under the machine or lifted loads. Lower to the ground first.

-Machines should never be parked, folded or unfolded, or accessed in the

presence of overhead power lines or pylons to ensure no flashover is possible.

Special care should also be taken when manoeuvring nearby, folding or

unfolding to ensure no contact is made.

-Instruct persons to leave the danger zone around the machine and tractor.

-Before working in the danger zone of the machine or between machine and

tractor: Shut down the tractor! This also applies for short-term inspection work.

Many accidents happen because of carelessness and running machines!

-Accidental operation of the hydraulic system can trigger dangerous movements

of the machine.