Disclaimer of Liability

These assembly and installation instructions have been provided by Sunstream Corporation at

the request of the potential installer and/or assembler. If you are not an authorized Sunstream

Dealer and are not a reasonably skilled mechanic, please contact Sunstream so that we can

refer you to a local dealer who can skillfully and safely perform the assembly and installat

i

on

of your Sunstream boatlift.

It is the potential installer's and/or assembler’s responsibility to determine whether he or she has

the necessary skills, knowledge, and tools to properly and safely assemble and/or install the

Sunstream Lift described herein. Improper assembly and/or installation may cause the lift to

function improperly or not to function. Improper assembly and/or installation may additionally

cause a risk to personal safety or property. If the assembler and/or installer is confused or has

questions or concerns about a particular assembly or installation, he or she should contact

Sunstream by telephone at (888)-786-5438 before proceeding further. The information

contained in these instructions does not constitute a warranty or guarantee of any kind.

An assembler’s and/or installer’s failure to correctly follow these assembly and installation

instructions constitutes a waiver of the assembler and/or installer’s rights against Sunstream

regarding any subsequent damages to property or personal injury caused by the assembler’s

and/or installer’s improper assembly and/or installation

.

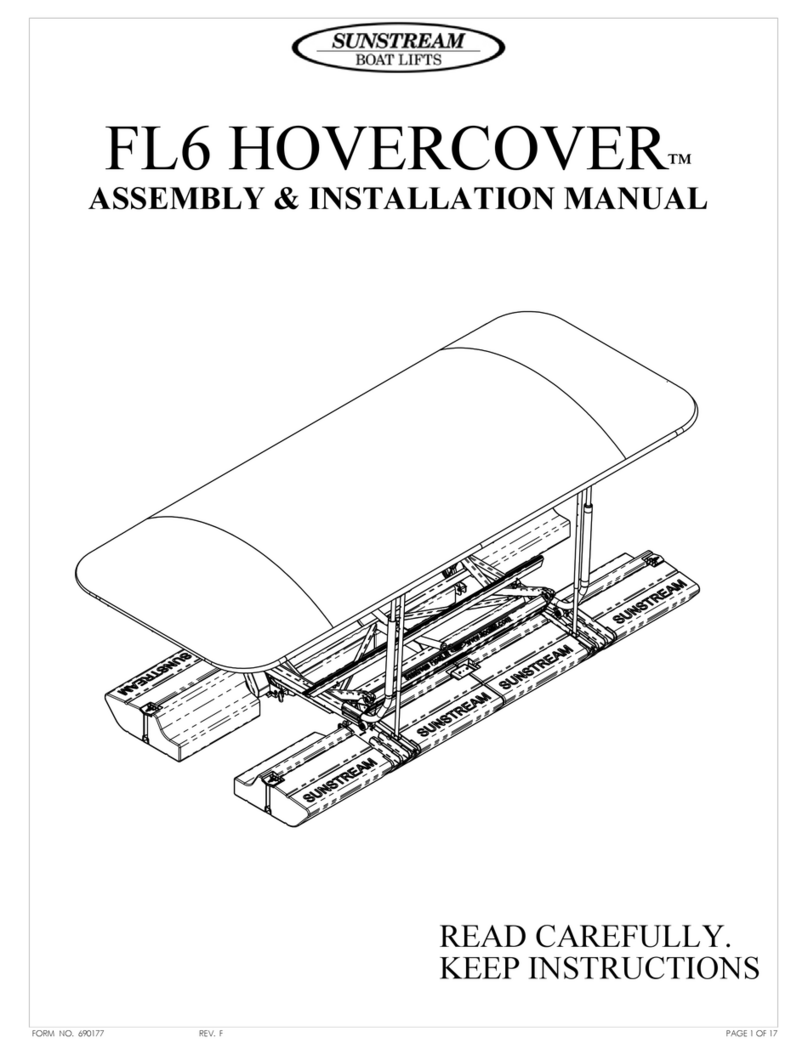

Table of Contents

Disclaimer of Liability……………………………………………..………..………………..

Tools Needed/recommended…………………………………………...…………….....

Assembly Instructions for FL6012A-D/FL6012S-D………………………...………….

Zinc Information & Installation…………………………………………………..............

Prior to Launch............................................................................................................

Installation Instructions/Mooring the FloatLift…………………….………………..

Operating Instructions………………………………………………………………...

Important Safety Instructions…………………………………………………....…...

Use and Maintenance Tips (programming remote control)……...………...….....

Battery Tips..................................................................................................................

Troubleshooting Tips...................................................................................................

Warranty…………………………………………………………………………….……….

3

4

4-14

15

16

17-20

21-22

23-24

25

26

27

28

FORM NO.

PAGE 2 OF 28

REV.

690187

G-01