Safety instructions

There is a risk to life if these safety instructions are not

observed.

• If even the slightest of faults is detected during the

inspection, the personal protective equipment may

not be used.

• Damaged, fall-stressed, dubious personal protective

equipment or safety devices must be immediately

withdrawn and not used. The equipment may only be

inspected by an expert or a workshop authorised in

writing by BORNACK. This must be documented in the

test card.

• No independent changes or repairs may be carried out.

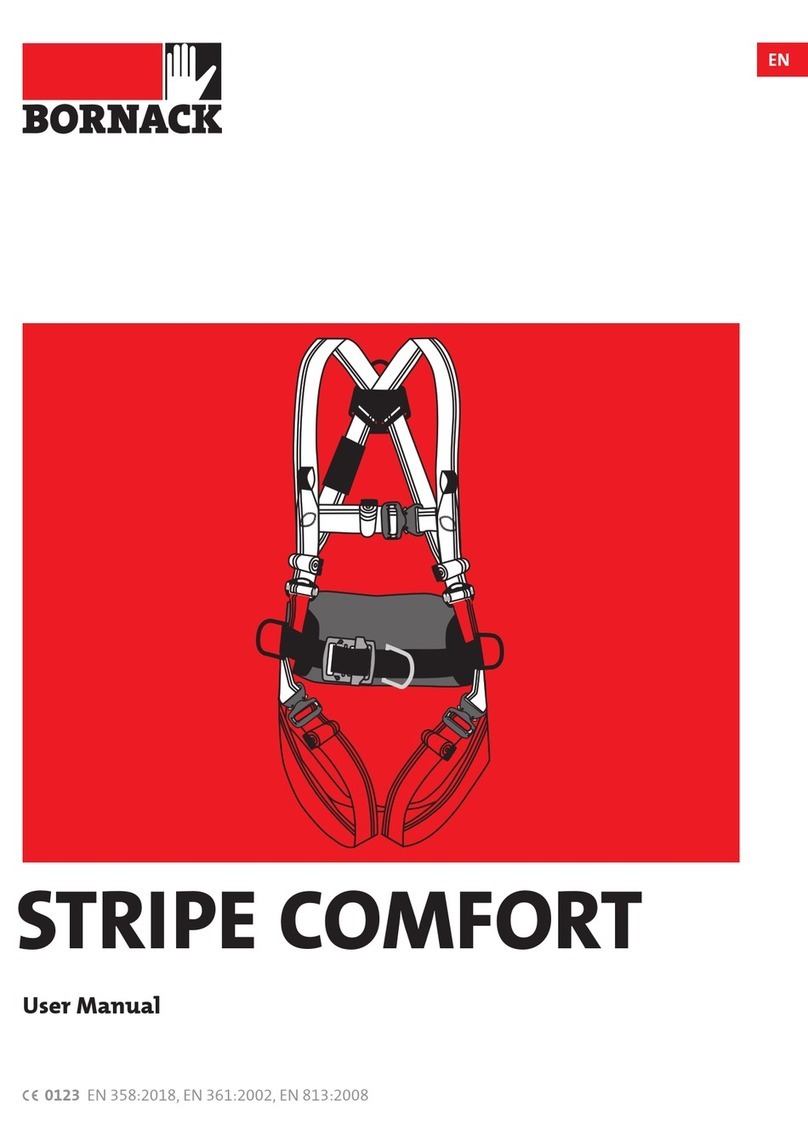

• This fall protection equipment is part of the personal

protective equipment and should be assigned to a specific

person.

• The personal protective equipment may only be used by

qualified staff that are familiar with the material. They

must be proficient in handling the personal protective

equipment and must have been briefed about the

possible risks associated with its use.

• In accordance with the accident prevention guidelines

(UVV) the users of fall protective equipment (Category III)

must attend a theoretical training course and a practical

training course. Make use of the training competence of

the BORNACK training centres: – BORNACK-hotline.

• Accessories from other manufacturers may only be used if

approved by BORNACK and may not impair the function

and safety of the protective equipment.

Clothing and shoes must be suitable for the task at hand

and the weather conditions.

• Only use the equipment if you are fully fit.

• The user should be healthy enough to ensure that safety

is not jeopardised under normal conditions or in

emergency situations.

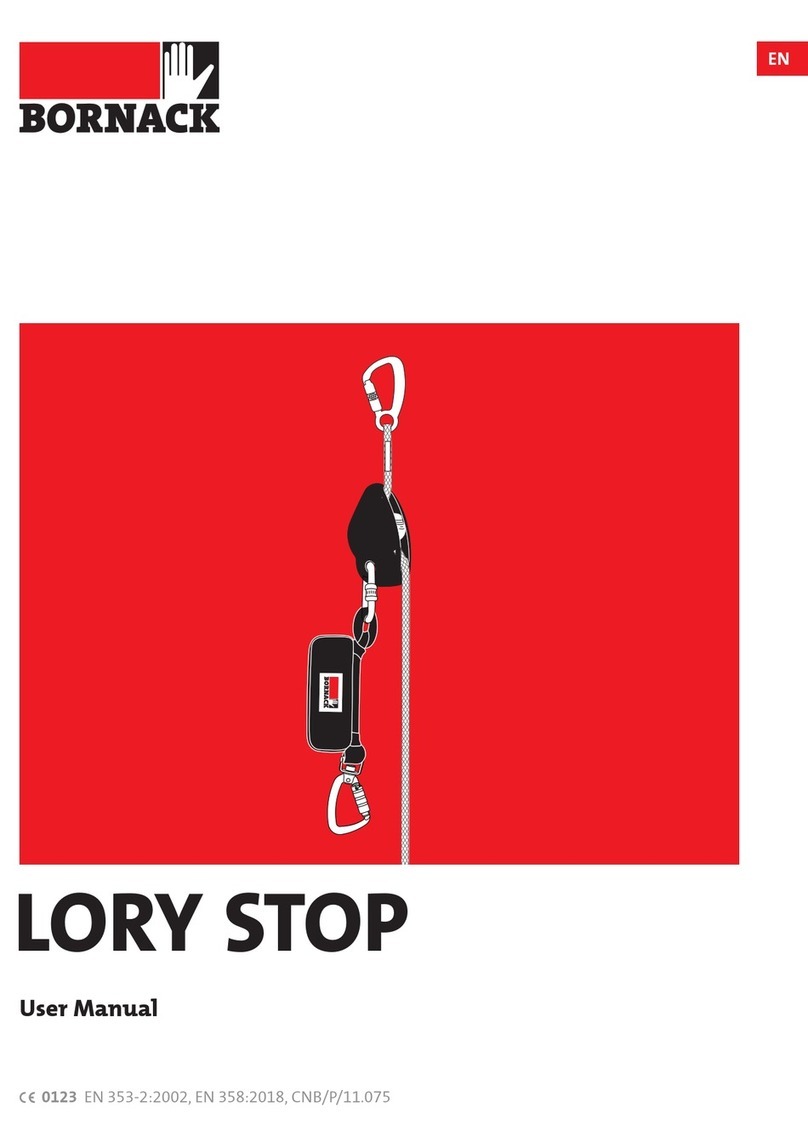

• The anchor point for den rope protection must be

adequately strong (EN 795), min. 10.0 kN (for one person)

in the rope pull direction.

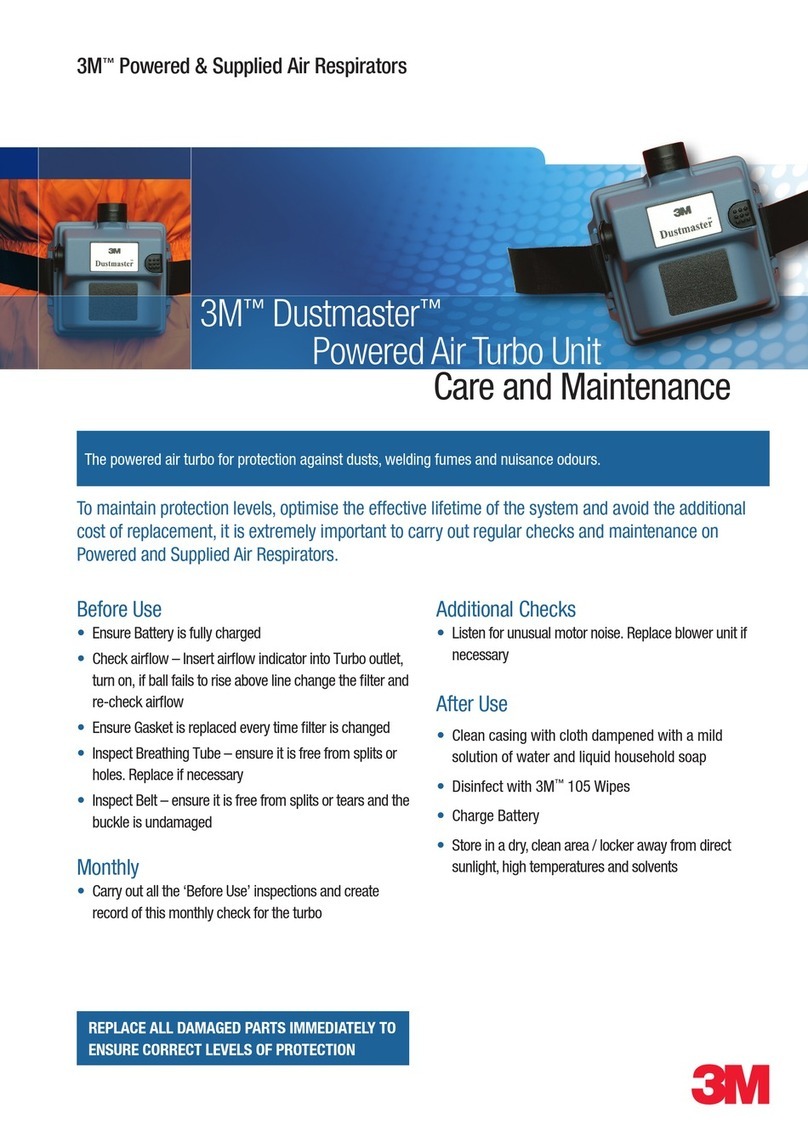

• Dry damp personal protective equipment before storing.

• Store away from light in a dry place.

• Do not store personal protective equipment close to

radiators.

Permanent temperatures of over +50 °C have a negative

impact on the strength of the textile material and will

reduce the life span.

• Do not allow personal protective equipment to come into

contact with aggressive substances (e.g. oils, grease, acids,

chemicals).

• Store the personal protective equipment in the

device case or device bag.

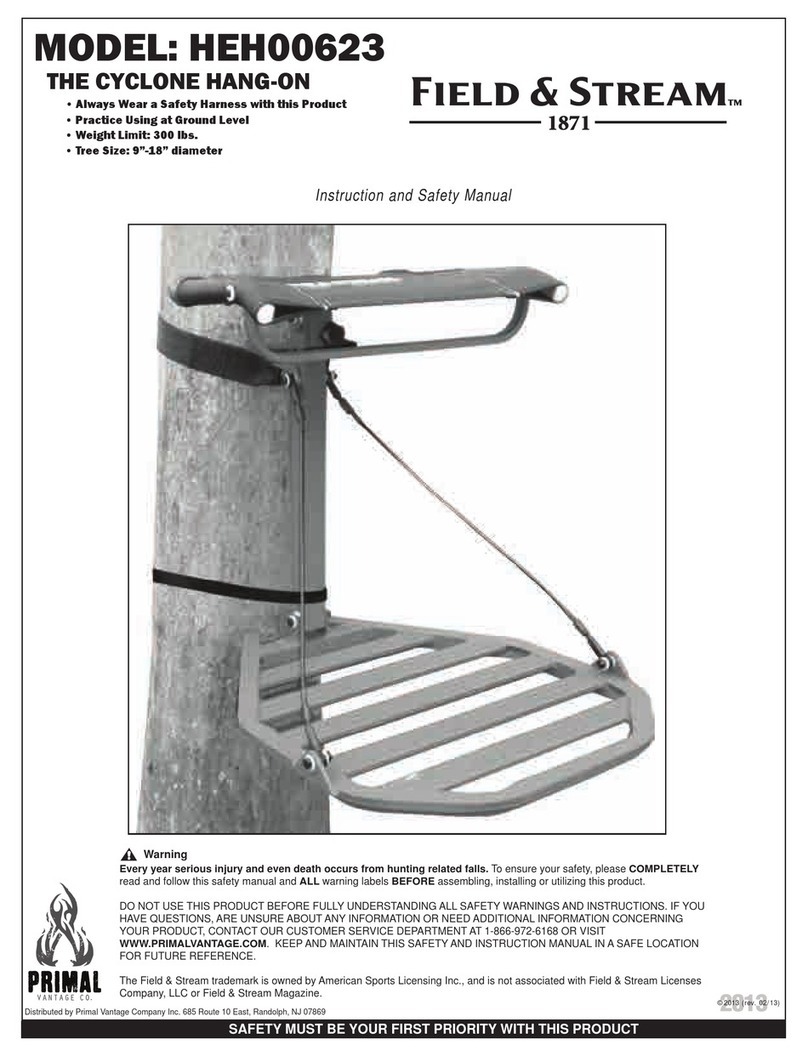

• If possible, select an anchor point overhead.

• The possible free fall height should be kept as short

as possible. The overall possible fall height should

be noted.

There is a risk of falling onto protruding parts of

structures or even onto the ground. Risk of injury

during swinging after a fall.

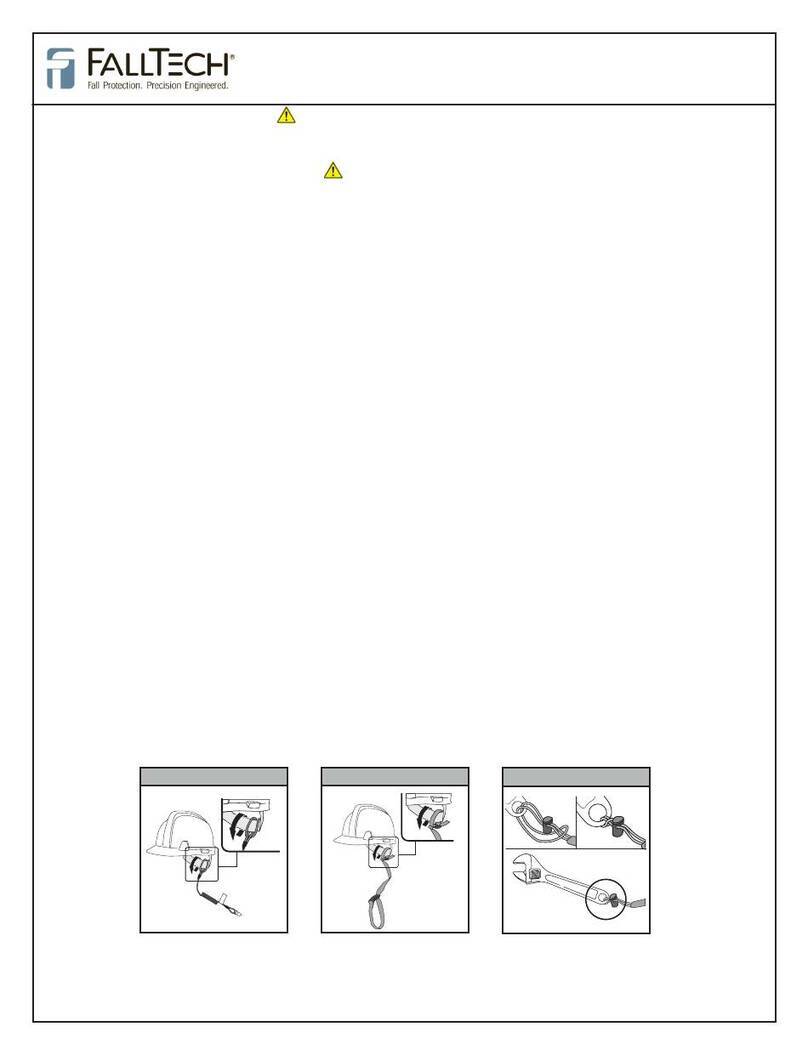

• This PPE has been tested for edge loads; however,

this external load always represents a higher risk.

This situation should be avoided by means of

preventive work or the equipment should be

protected from sharp edges (edge protection

collars).

• If this PPE is used as an arrester system (free fall is

possible), a full body harness in compliance with

EN 361 must always be used.

• Possible fall path if all required PPE components are

used correctly: brake path fall arrester (max. 175 cm)

+ (if necessary reaction time HSG) + physical height

(clear height of the PPE) + safety reserve 1 m.

• Choose the highest possible anchor point.

• Protect the personal protective equipment during

storage, use or transport from the effects of heat

(e.g. welding flame or sparks, hot cigarette ash) and

chemicals (acids, lyes, oils, etc.) and mechanical

effects (sharp edges etc.).

• Before starting work, the responsible person must

draw up a plan of rescue measures that defines how

to rescue casualties quickly and safely and ensures

first aid measures. Casualties must be rescued

within 10 to 30 minutes. BORNACK can help you

draw up tailor-made rescue plans in specific

training courses – BORNACK-hotmail.

• The local safety guidelines (e.g. in Germany, the

guidelines issued by the professional associations

BGR 198 and BGR 199) and the accident prevention

guidelines for the specific industry (UVV) must be

observed