Sutter Instrument MT-75 Series User manual

Other Sutter Instrument Laboratory Equipment manuals

Sutter Instrument

Sutter Instrument P-97 Installation manual

Sutter Instrument

Sutter Instrument TRIO MP-235 User manual

Sutter Instrument

Sutter Instrument LB10-3 User manual

Sutter Instrument

Sutter Instrument MP-225A User manual

Sutter Instrument

Sutter Instrument P2000/G User manual

Sutter Instrument

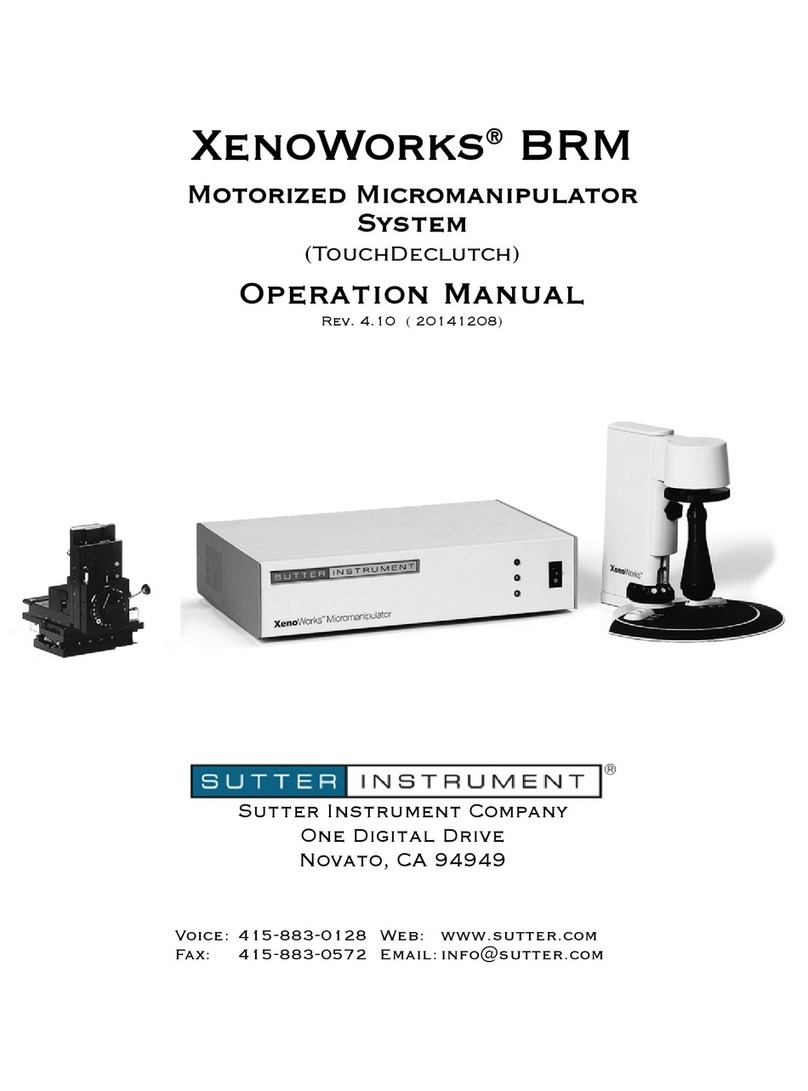

Sutter Instrument XenoWorks BRM User manual

Sutter Instrument

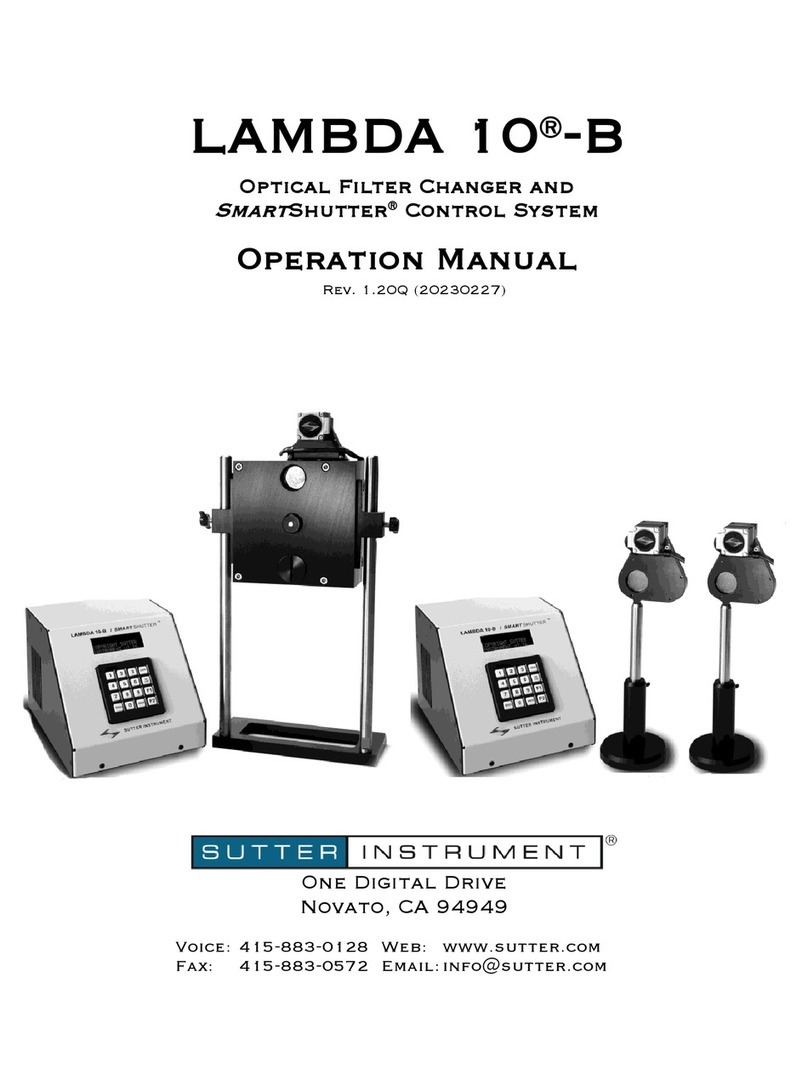

Sutter Instrument LAMBDA 10-B User manual

Sutter Instrument

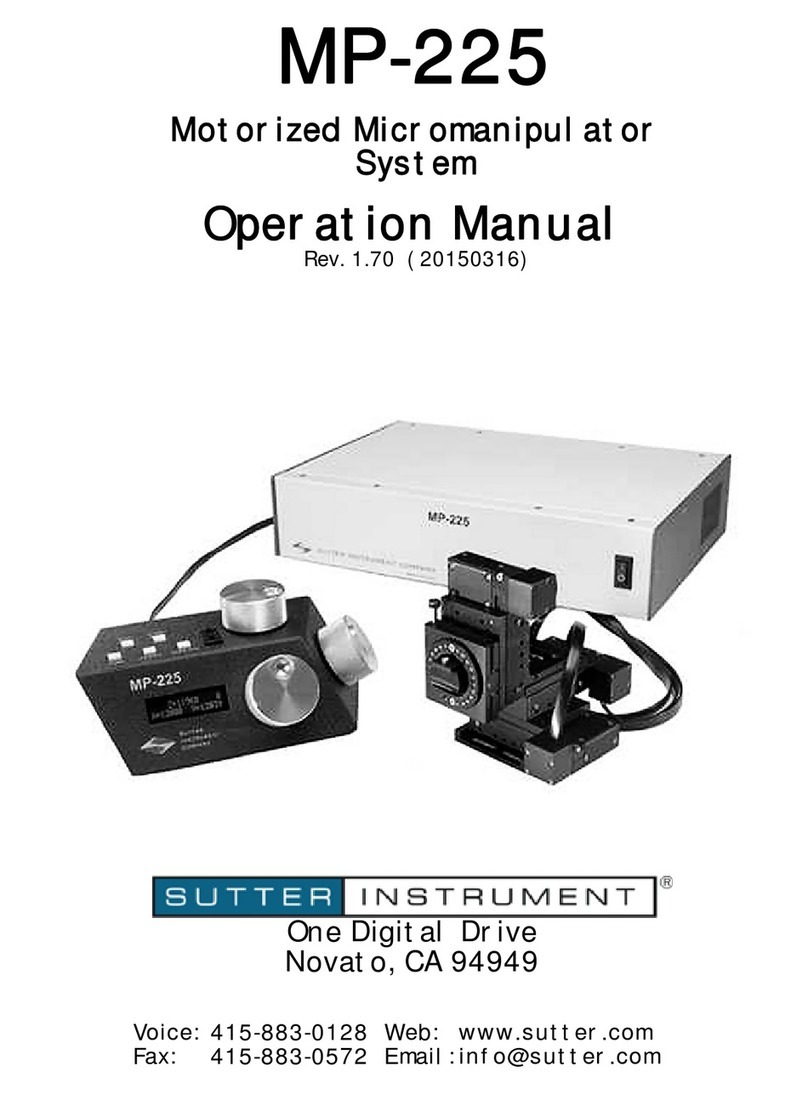

Sutter Instrument MP-225 User manual

Sutter Instrument

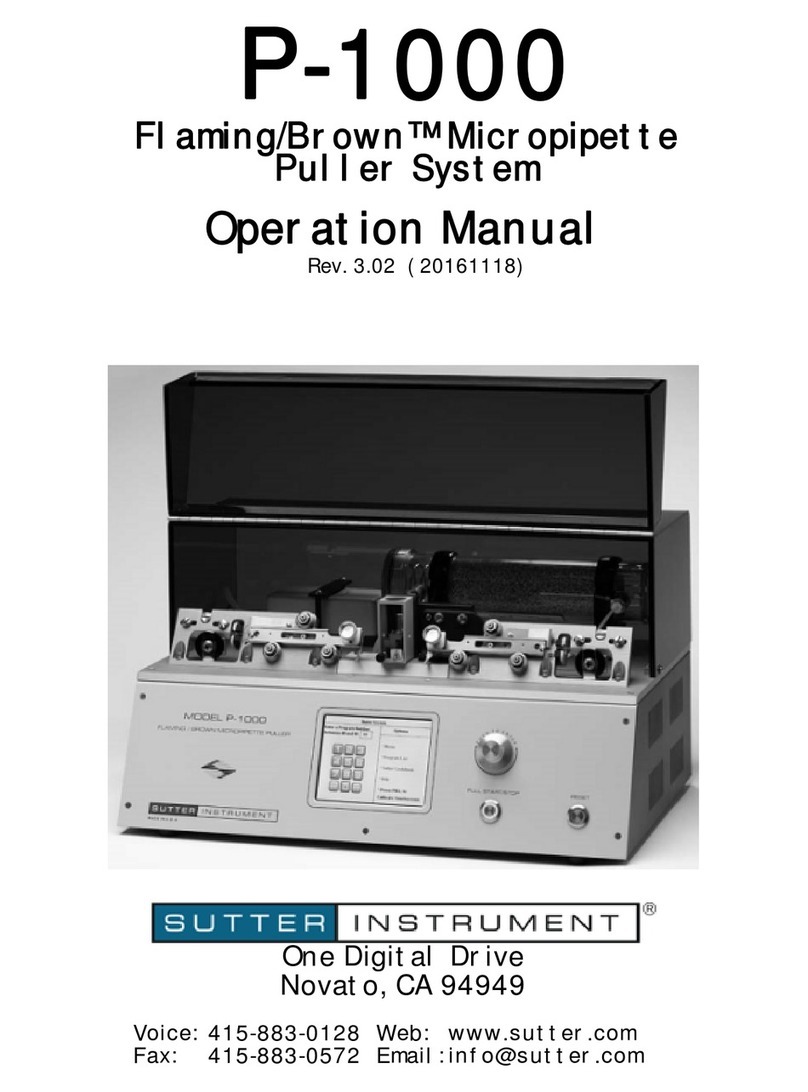

Sutter Instrument P-1000 User manual

Sutter Instrument

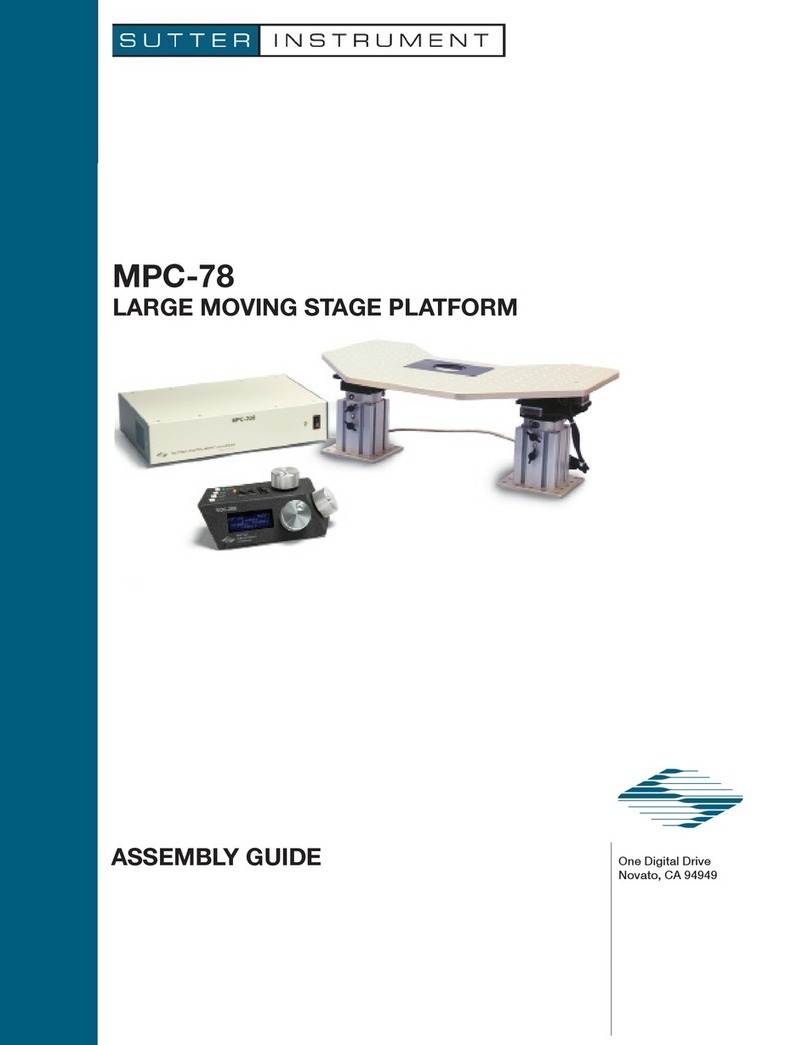

Sutter Instrument MPC-78 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual