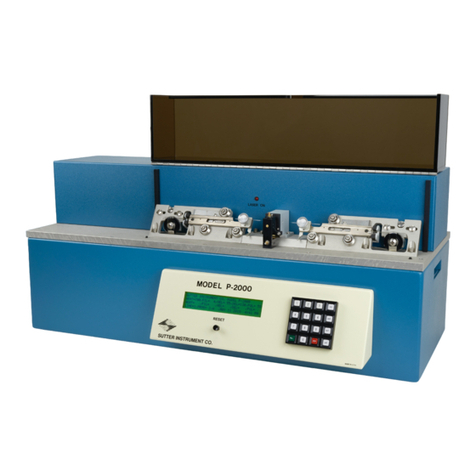

P-2000 MICROPIPETTE PULLER OPERATION MANUAL -– REV. 2.4C (20160412)

viii

3.5.1 RAMP TEST <1> ...................................................................................................................25

3.5.2 WRITE-PROTECT THIS PROG[RAM] <2>......................................................................26

3.5.3 RESET TIME AND DATE <3>............................................................................................27

3.5.4 MEMORY TEST <4>.............................................................................................................27

3.5.5 COPY A PROGRAM <5> ......................................................................................................28

3.6 Pulling Pipettes...............................................................................................................................29

3.6.1 Procedures ................................................................................................................................29

3.6.1.1 Looping ...............................................................................................................................29

3.6.1.2 Pull Results ........................................................................................................................30

3.6.2 Notes on Program Operation..................................................................................................31

3.6.2.1 HEAT ON...........................................................................................................................31

3.6.2.2 Program Memory ..............................................................................................................32

3.7 Parameter Adjustment...................................................................................................................32

3.7.1 General Information ................................................................................................................32

3.7.2 Micropipette/Microinjection Needle Fabrication..................................................................32

3.7.2.1 Programs ............................................................................................................................32

3.7.2.2 Selecting Program Parameters........................................................................................32

3.7.2.3 Glass Selection ...................................................................................................................34

3.7.2.4 Glass-specific Parameter Adjustment .............................................................................34

3.7.2.5 Sample Programs (for Quartz glass) ...............................................................................35

3.7.3 Patch Pipette Fabrication .......................................................................................................36

3.7.3.1 Programs ............................................................................................................................36

3.7.3.2 Selecting Program Values ................................................................................................36

3.7.3.3 Glass Selection ...................................................................................................................37

3.7.3.4 Glass-Specific Parameter Adjustment ............................................................................38

3.7.3.5 Optical System Adjustments ............................................................................................38

3.7.3.6 Suggested Practices...........................................................................................................39

3.7.4 Optic Fiber Fabrication ...........................................................................................................39

3.7.4.1 Fiber Preparation ..............................................................................................................39

3.7.4.2 Programs ............................................................................................................................39

3.7.4.3 Selecting Program Parameters........................................................................................39

3.7.5 Electrospray/Nanospray Tip Fabrication ..............................................................................40

3.7.5.1 Glass Preparation..............................................................................................................40

3.7.5.2 Programs ............................................................................................................................40

3.7.5.3 Selecting Program Parameters........................................................................................41

3.7.6 Technical Tips ..........................................................................................................................41

3.7.6.1 Maintaining Pipette Wall Thickness of Quartz Glass...................................................41

4. APPLICATIONS AND TECHNIQUES ..........................................................................................43

4.1 Pulling Very Short Micropipettes .................................................................................................43

4.2 Pulling Large-Diameter Glass.......................................................................................................44

4.2.1 Background...............................................................................................................................44

4.2.2 Principles and Strategies.........................................................................................................44

4.2.3 Suggested Practices..................................................................................................................45

4.3 Determining Tip Concentricity .....................................................................................................45

5. MAINTENANCE...............................................................................................................................49

5.1 Cleaning ...........................................................................................................................................49

5.1.1 Exterior .....................................................................................................................................49