Swagelok AHSU Installation manual

www.swagelok.com

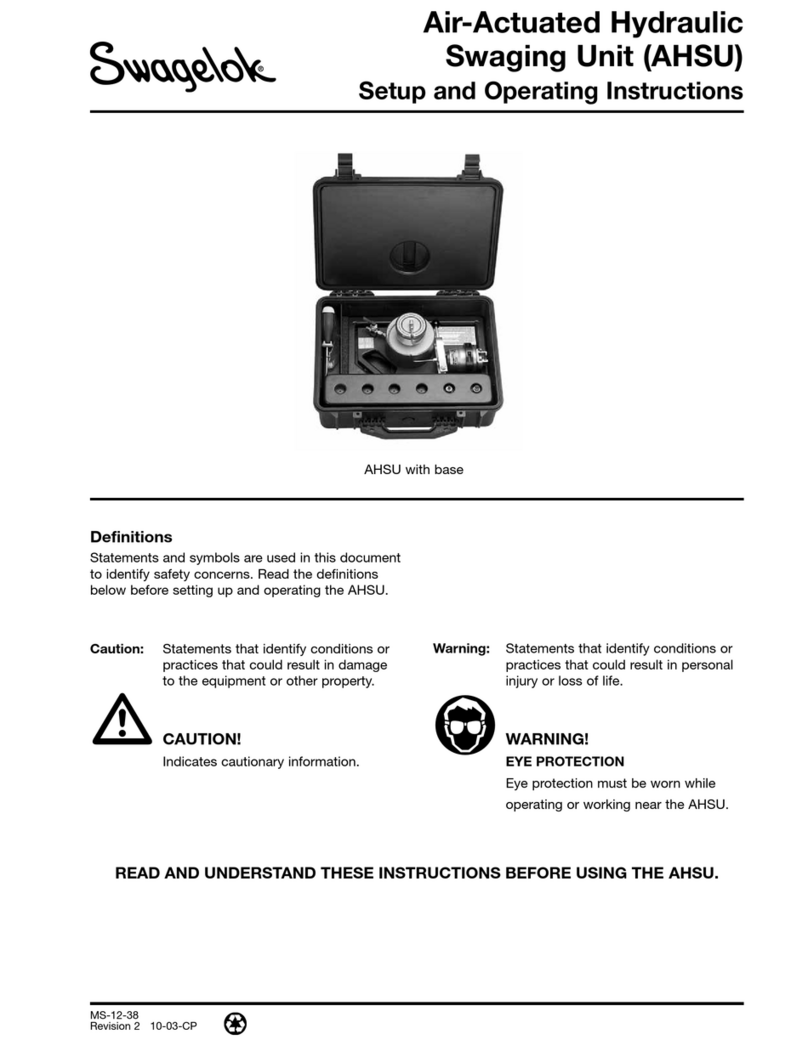

AHSU with base

Air-Actuated Hydraulic Swaging

Unit (AHSU)

Setup and Operating Instructions

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE USING THE AHSU.

Definitions

Statements and symbols are used in this document to identify safety concerns. Read the definitions below

before setting up and operating the AHSU.

CAUTION!

Statements that identify conditions or

practices that could result in damage to the

equipment or other property.

WARNING!

Statements that identify conditions or

practices that could result in personal injury

or loss of life.

WARNING!

EYE PROTECTION

Safety glasses must be worn when setting

up and operating the AHSU.

CAUTION!

Do not tamper with or alter any

components of the AHSU.

CAUTION!

Limit air inlet pressure to less than 90 psig

(6.2 bar). If the inlet pressure exceeds 90

psig, a pressure relief valve in the unit will

activate

Safety Precautions

CAUTION!

Do not operate AHSU unless all tooling is

installed and the tubing, nut and ferrules

are properly positioned within tooling.

CAUTION!

Return the AHSU to your independent

Swagelok sales and service representative

if any signs of hydraulic fluid leakage or

malfunction occur.

2Air-Actuated Hydraulic Swaging Unit (AHSU) Setup and Operating Instructions

Components (Unit with Die Heads and Base)

Safety glasses

Gap

inspection

gauge

Hex key

Nut retainer

Base Air input

decal

Air inlet

valve

Air pump

Indicator knob

set lever

Operating

instructions

Indicator knob

Die heads

Air input

Hydraulic housing

Adapter plates

Air-Actuated Hydraulic Swaging Unit (AHSU) Setup and Operating Instructions 3

5. For 1/4 and 3/8 in. and 6, 8, and 10 mm sizes,

insert the appropriate adapter plate into the nut

retainer. Refer to the mark on the plate for size

information.

6. Connect the appropriate air source to the AHSU

air inlet valve.

7. Adjust the source pressure to the value shown

in the table or on the air input decal for the

tubing material and size.

CAUTION!

Air inlet pressure should be limited

to 90 psig (6.2 bar) or less. If the inlet

pressure exceeds 90 psig, there is a

pressure relief valve in the unit that will

activate.

Setup

1. Select the proper size die head (reference the

size marking on each die head).

2. Remove the screw located in the bore of the

die head previously installed in the hydraulic

housing by turning counterclockwise with the

hex key.

Required Air Inlet Working Pressure, psig (bar)

Fitting/Tooling

Size

Stainless Steel or

Steel Tubing

Soft Copper

Tubing

Fractional Series

400 40 (2.8) 35 (2.4)

600 60 (4.2) 35 (2.4)

810 70 (4.9) 45 (3.1)

Metric Series

6M0 40 (2.8) 35 (2.4)

8M0 50 (3.5) 35 (2.4)

10M0 60 (4.2) 40 (2.8)

12M0 70 (4.9) 45 (3.1)

3. Depress the nut retainer to remove the die head.

4. Depress the nut retainer and install the selected

die head. Tighten the shaft screw sufficiently to

keep the die tight, being careful not to break the

screw by over-tightening it.

Die head

Size marking

Screw

Nut retainer

Adapter plate

4Air-Actuated Hydraulic Swaging Unit (AHSU) Setup and Operating Instructions

3.Insert tubing into the Swagelok end fitting to be

pre-swaged. Disassemble the nut from the end

connection, leaving the nut and ferrules on the

tubing. The orientation of the nut, rear ferrule,

and front ferrule should be as shown.

4. Insert the tubing into the die head. Make sure

that the tubing rests firmly on the shoulder of the

die head.

5. Depress the nut retainer and slide the nut over

the die head.

6. The front edge of the nut should line up with the

groove on the outside of the die head.

7. Allow the nut retainer to return to its starting

position.

8. Hold the tubing firmly in the die head and

depress the air inlet valve handle for three

seconds after the indicator knob is released.

The ferrules have now been preswaged onto the

tubing.

Hacksaw burrs

OD and ID

Tube cutter

burrs ID only

Tube

0.06 in.

(1.5 mm)

10º

Operation

1. Set the indicator knob by pivoting the indicator

knob set lever until the knob snaps into position

and is flush with the hydraulic housing.

2. Prepare tube ends as follows.

A. Cut tubing squarely. Use of a Swagelok

tube saw guide is recommended.

B. Remove any burrs. Use of Swagelok

deburring tools is recommended.

Tubing

Saw guide

WARNING!

Failure to deburr the OD of the tube

could prevent the tube from properly

resting against the piston shoulder. ID

burrs could break off and cause damage

in other components of the system.

C. If a file is used on the OD, make a 10° x

0.06 in. (1.5 mm) chamfer.

Indicator knob set lever

Tubing

Die head

Tubing

Die head Indicator knob set lever

Air-Actuated Hydraulic Swaging Unit (AHSU) Setup and Operating Instructions 5

9. Release the air inlet valve handle.

Note: Releasing the air inlet valve handle too

soon may result in an insufficiently preswaged

assembly.

10. Depress the nut retainer to remove the

preswaged assembly.

11. Install the preswaged assembly into the fitting

body. Turn the nut onto the fitting body until it is

finger-tight.

12. Mark the nut at the 6 o’clock position.

13. While holding the fitting body steady, tighten

the nut one-half turn until the mark reaches the

12 o’clock position.

Nut retainer

Gauging Instructions

Position the Swagelok AHSU gap inspection gauge

adjacent to the gap between the nut and body hex.

■

If the gauge will not enter the gap, the fitting is

sufficiently tightened.

■If the gauge will enter the gap, additional tightening

is required.

Note: 3-sided AHSU gap gauge is for fractional

fittings.4-sided AHSU gap gauge is for metric

fittings.

Inspect the fitting with a gap inspection gauge

Tightening is requiredSufficiently tightened

AHSU gap

inspection gauge

6Air-Actuated Hydraulic Swaging Unit (AHSU) Setup and Operating Instructions

Swagelok—TM Swagelok Company

© 2002 - 2021 Swagelok Company

Printed in U.S.A

MS-12-38 RevD, October 2021

Troubleshooting

Symptom Causes Remedy

Tubing is difficult to remove from

the AHSU after preswaging.

Tubing wall may be below

recommended minimum wall

thickness.

Gently rock the tubing back and forth to remove it.

Use tubing that is thicker than the minimum

recommended wall thickness.

CAUTION!

Do not rotate the tubing.

The indicator knob does not

release.

Improper inlet pressure being used for

tubing material and size.

Adjust inlet pressure to the correct value for the tubing

size and material.

Oil is leaking from unit. Return the unit to your independent Swagelok sales

and service representative.

The front edge of the Swagelok

nut does not line up with the

groove on the outside of die

head.

Improper die head being used.

The ferrules are not oriented properly.

Use the proper die head.

Place the ferrules in proper orientation.

The unit fails to swage

sufficiently as indicated by the

gap inspection gauge after

assembly.

The working pressure is too low.

Verify the working air pressure is set to the appropriate

pressure recommended on the air input decal.

CAUTION!

Do not swage a tube more than once.

Warranty Information

Swagelok products are backed by The Swagelok Limited

Lifetime Warranty. For a copy, visit swagelok.com or contact

your authorized Swagelok representative.

The AHSU cannot be used for alloy 2507 tubing or for medium-pressure tubing.

Refer to Swagelok Gaugeable Tube Fittings and Adapter

Fitting catalog, MS-01-140, for additional information.

Refer to Swagelok Tube Fitters manual, MS-13-03, for

additional information.

Refer to Swagelok Tubing Data catalog, MS-01-107, for

additional information.

Table of contents

Other Swagelok Industrial Equipment manuals