Power Swager

5

Section I

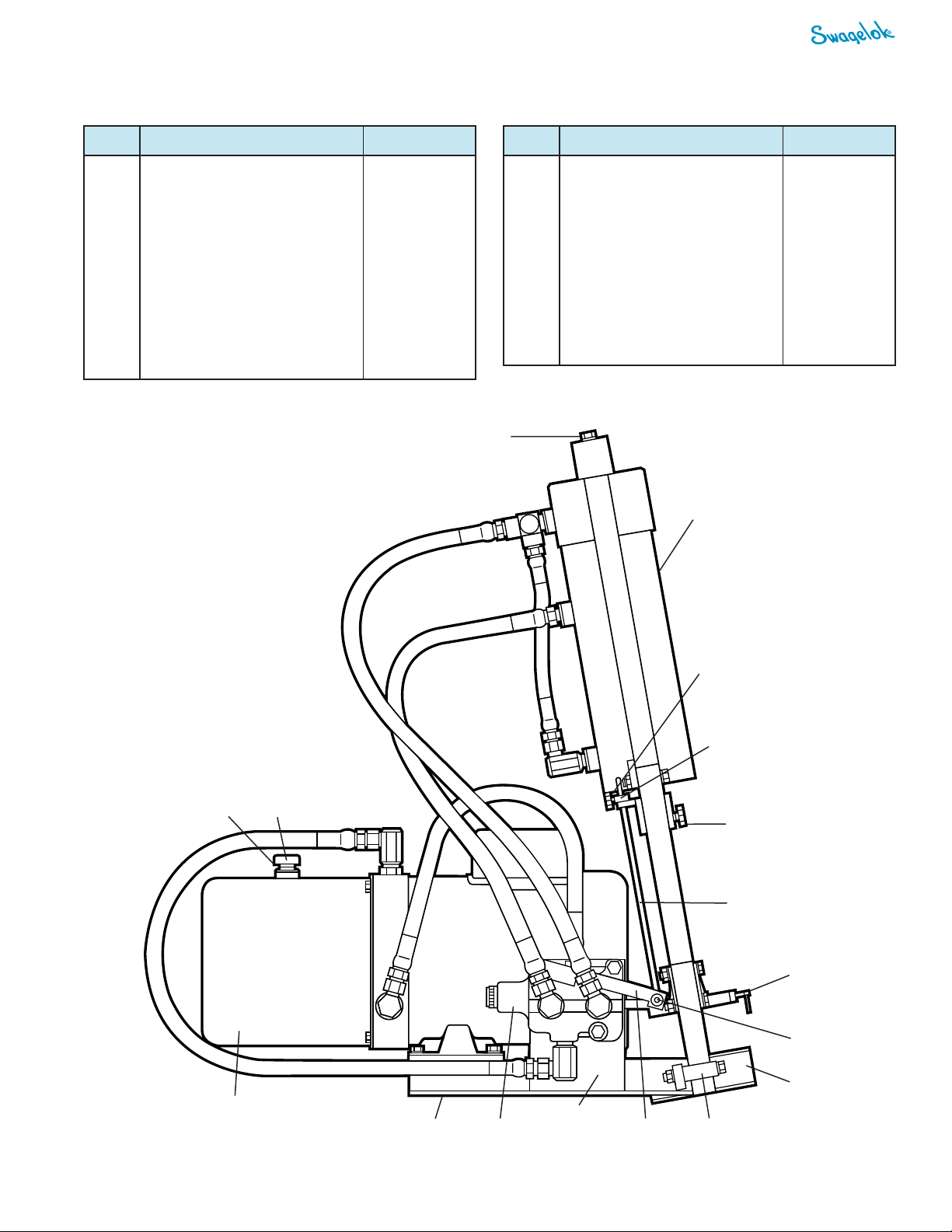

Swagelok Power Swager

Operating Instructions

Note: The swager may be lifted by rigging a suitable fabric

sling around the guide bars and hydraulic cylinder below the

top bar.

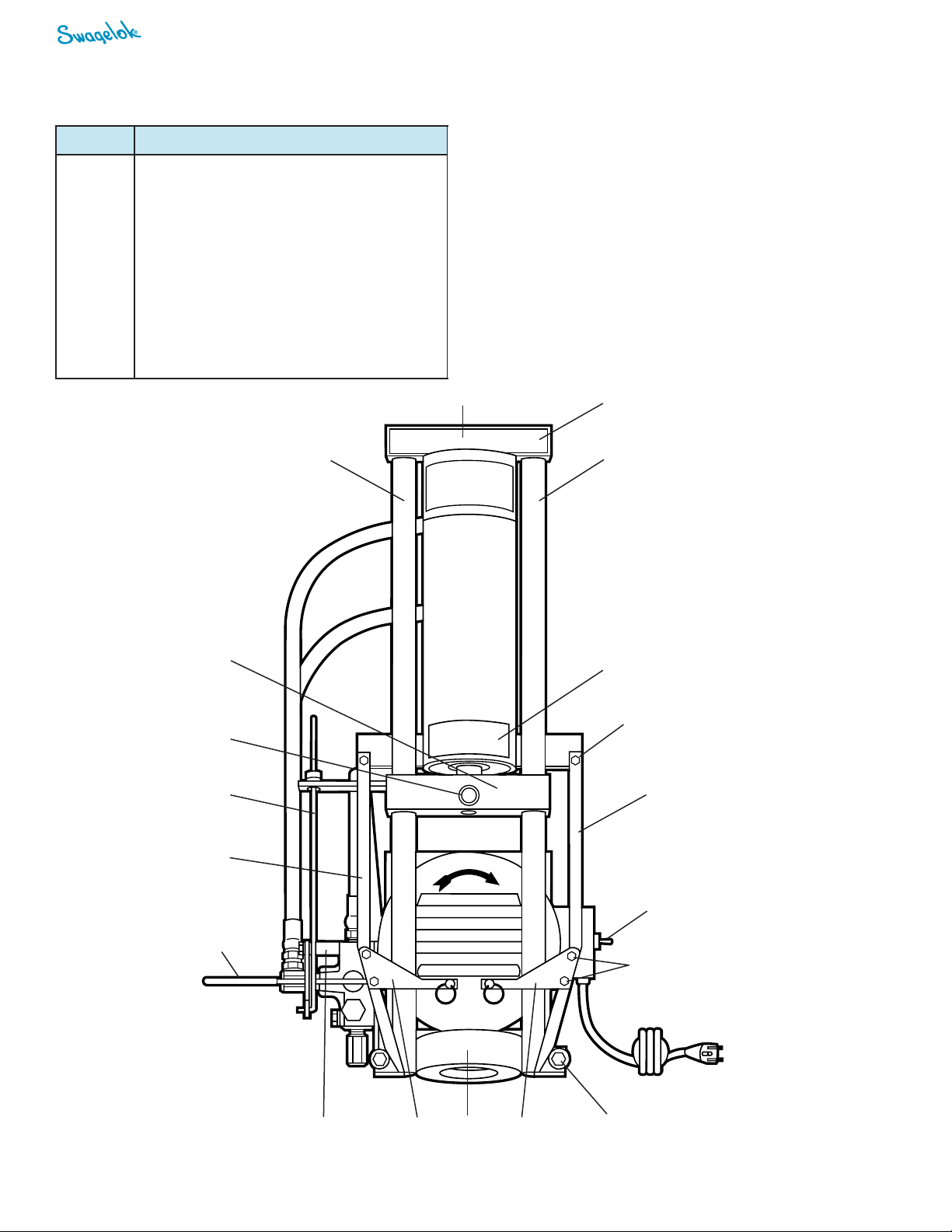

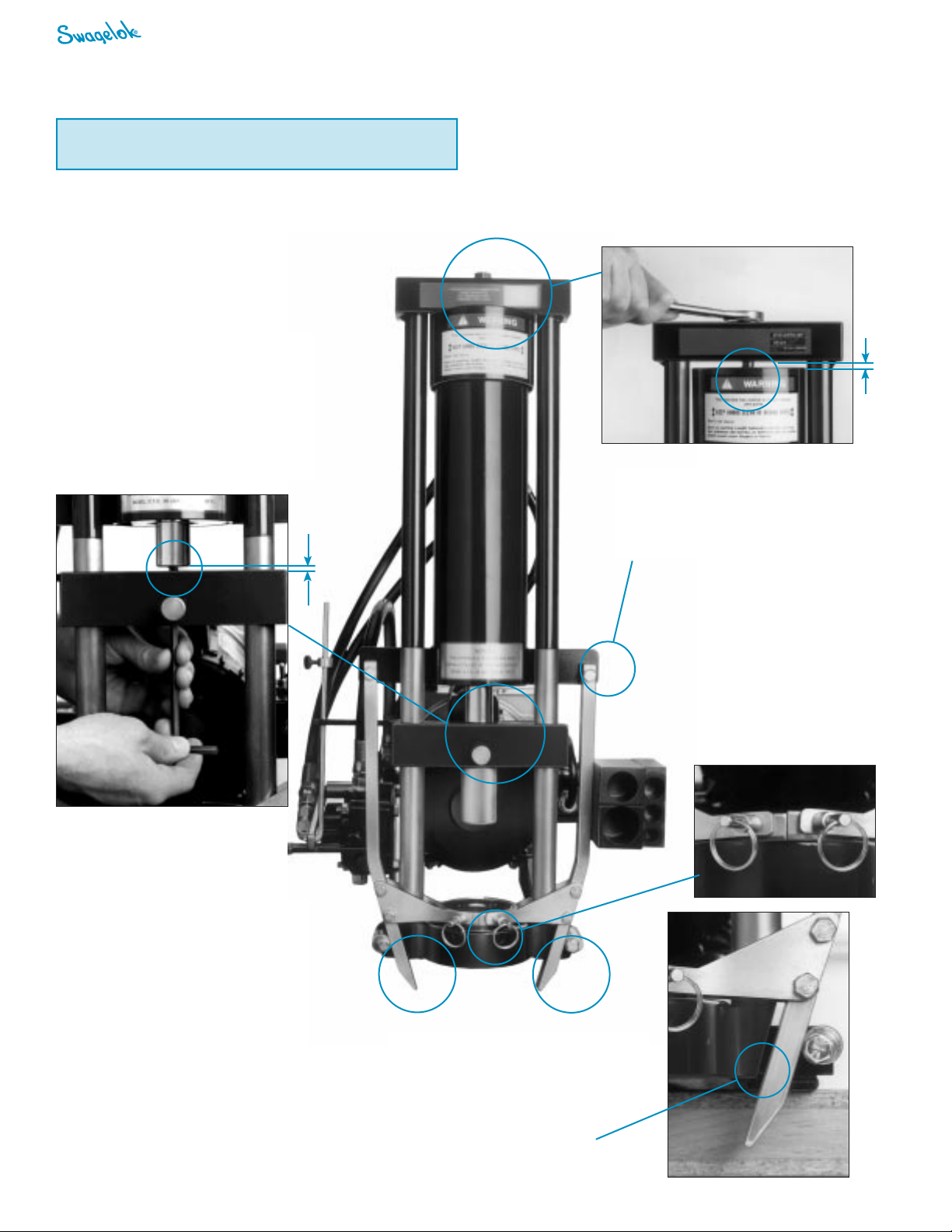

Breather Cap Installation

The breather cap is shipped in the bag attached to the swager.

1. Remove the plug from the oil reservoir. Note: Do not discard

the plug. To reduce loss of hydraulic oil through the breather

cap, reinstall the plug when shipping the swager or when

tilting it or placing it on its side.

2. Check the hydraulic fluid level. It should be 1 to 1 1/2 in.

(25 to 38 mm) below the breather hole. Note: The swager

is shipped with the proper type and amount of oil in the

reservoir. However, if additional fluid is required, it should be

equivalent to Mobil®D.T.E. 26 (325 SUS at 100°F, 37°C)

3. Install the breather cap.

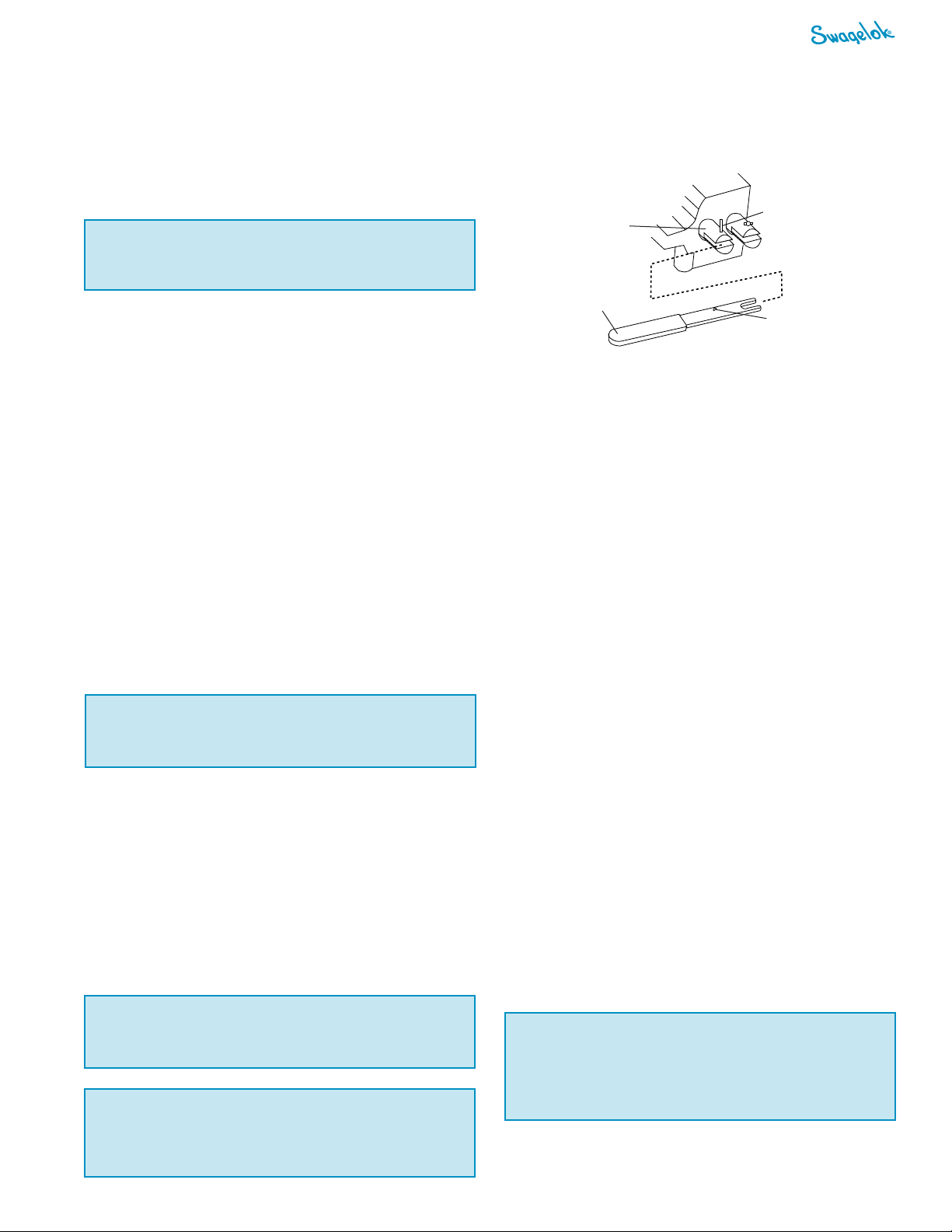

Note: The valve is on the left side of the swager.

2. Position the valve handle so that the hole is in line with the

roll pin in the valve stem. (See drawing above.)

3. Use a hammer to carefully tap the roll pin down through

the hole in the handle until the pin is flush with the top of

the stem.

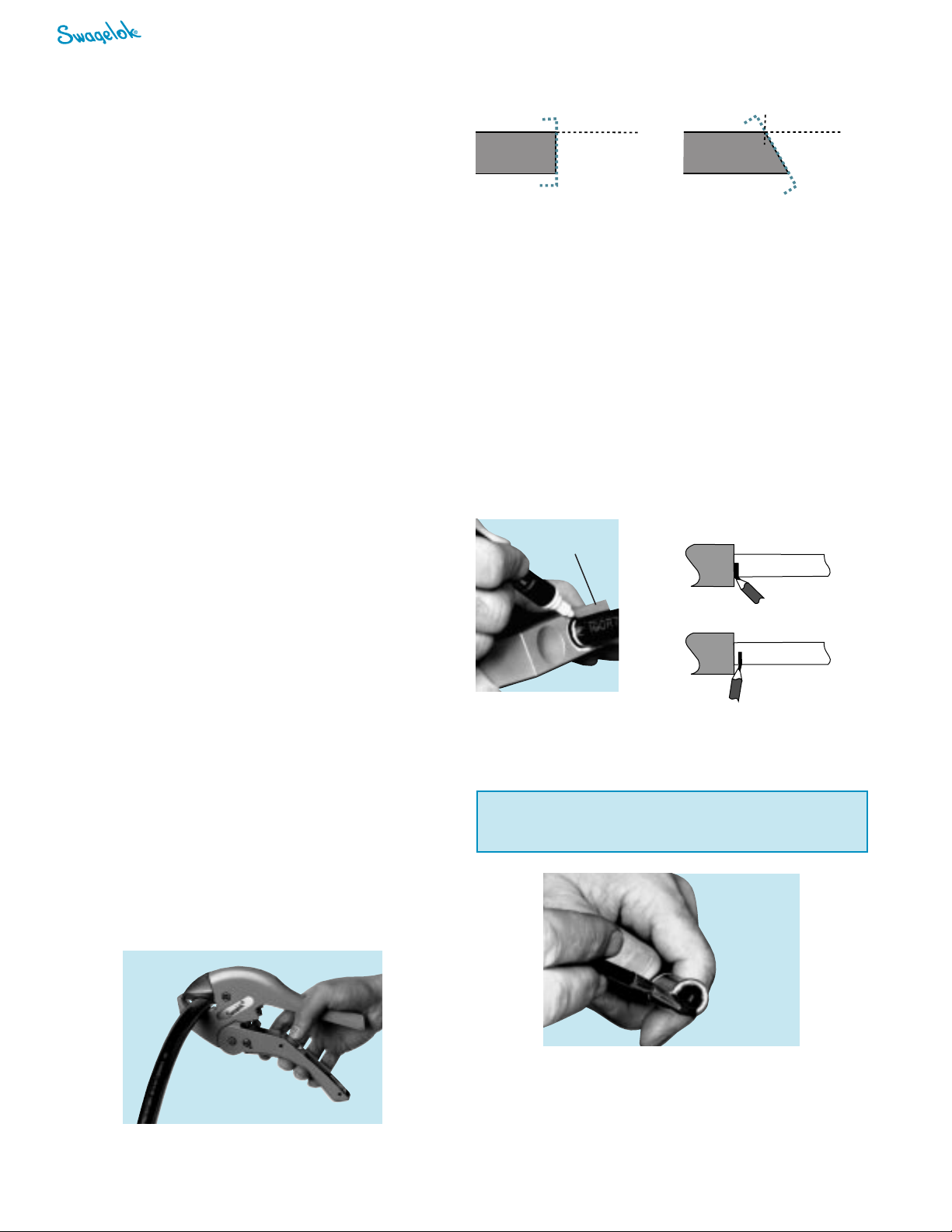

Dies and Pushers

Use the chart in Section II to determine the proper dies and

pushers needed for each end connection. The dies have been

adapted to fit in the die lifting fingers on the swager.

Adjustment of the Automatic

Return Stop Position

1. Install the proper dies and pusher for the hose and end

connection desired.

2. Turn on the swager.

3. Pull the valve handle toward you to bottom the pusher onto

the dies.

4. Push the valve handle in the opposite direction, raising the

pusher.

5. Insert the hose and end connection assembly up between

the dies and so that it can be held in the pusher. Note: See

Section II for hose pre-assembly instructions.

6. Push or pull the valve handle so that the bottom of the end

connection shell is 3/4 to 1 in. (19 to 25 mm) above the top

of the dies.

7. Loosen the thumb screw on the trip rod collar.

8. Allow the trip rod collar and trip rod to descend to the low-

est position.

9. Tighten the thumb screw.

10. Remove the hose and connection.

11. Run the swager a full cycle to make sure the trip rod prop-

erly releases the valve handle.

The swager is now ready for use.

Note: Different sizes and types of hose and end connections

may require additional adjustments.

Valve Handle Installation

The handle is shipped in the bag attached to the swager.

1. Raise and secure the trip rod mechanism (2, 3, 4, 8,

and 12) out of the way of the swager.

!Caution

Always adjust the trip rod collar so that the return

stop functions before the pusher block retracts into

the bottom of the cylinder.The swager may be

damaged otherwise.

!Caution

Do not lift or move the swager by its die lifting fingers,

arms, or hydraulic hoses.

!Caution

Never connect the green or green/yellow wire to a live

terminal!

!Caution

The motor should always be disconnected from the

power source whenever servicing the machine or

performing troubleshooting.

Roll pin hole

Valve handle

Valve

stem

Roll pin

Setup

1. Place the swager on a sturdy platform or table.

2. Position the swager so the die bowl clears the platform or

table to allow clearance for the moving parts of the swager.

3. Secure the swager with suitable fasteners through the bolt

holes located in the angle iron supports on the base of the

swager.

Electrical Requirements

■The electrical requirements for the swager are as follows:

■110/220 V (ac)

■13/6 A

■1 phase 60 Hz, wired for 110 V

■The swager must be grounded to guard against electrical

shock. The unit is equipped with a three-wire conductor and

three-prong plug to fit a grounded receptacle.

■When turning on the swager unit for the first time, verify that

the motor is rotating in the direction of the arrow on the

motor.

■A swager’s voltage can be changed from 110 to 220 V using

the wiring diagram on the inside of the switch cover. (It is

recommended that a qualified electrician perform this task.)

!Caution

Do not operate the swager without the breather cap

in place.