2

2

How to Read This Guide

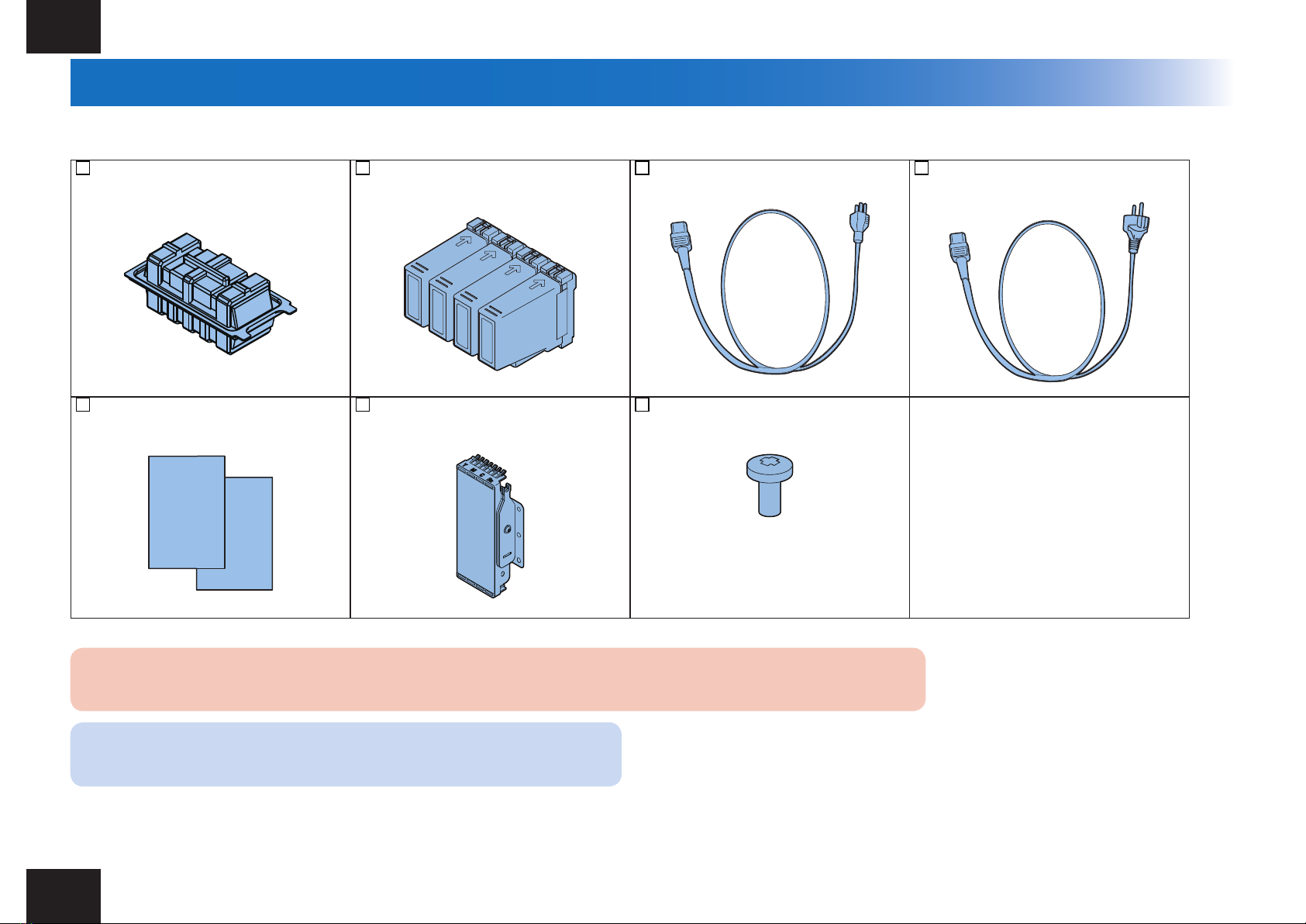

When Using the Included Parts

When the parts supplied with this product are required to be used in the installation

procedure, the following symbol indicating that the parts are supplied with the product is

shown in the illustration.

Packaged Item

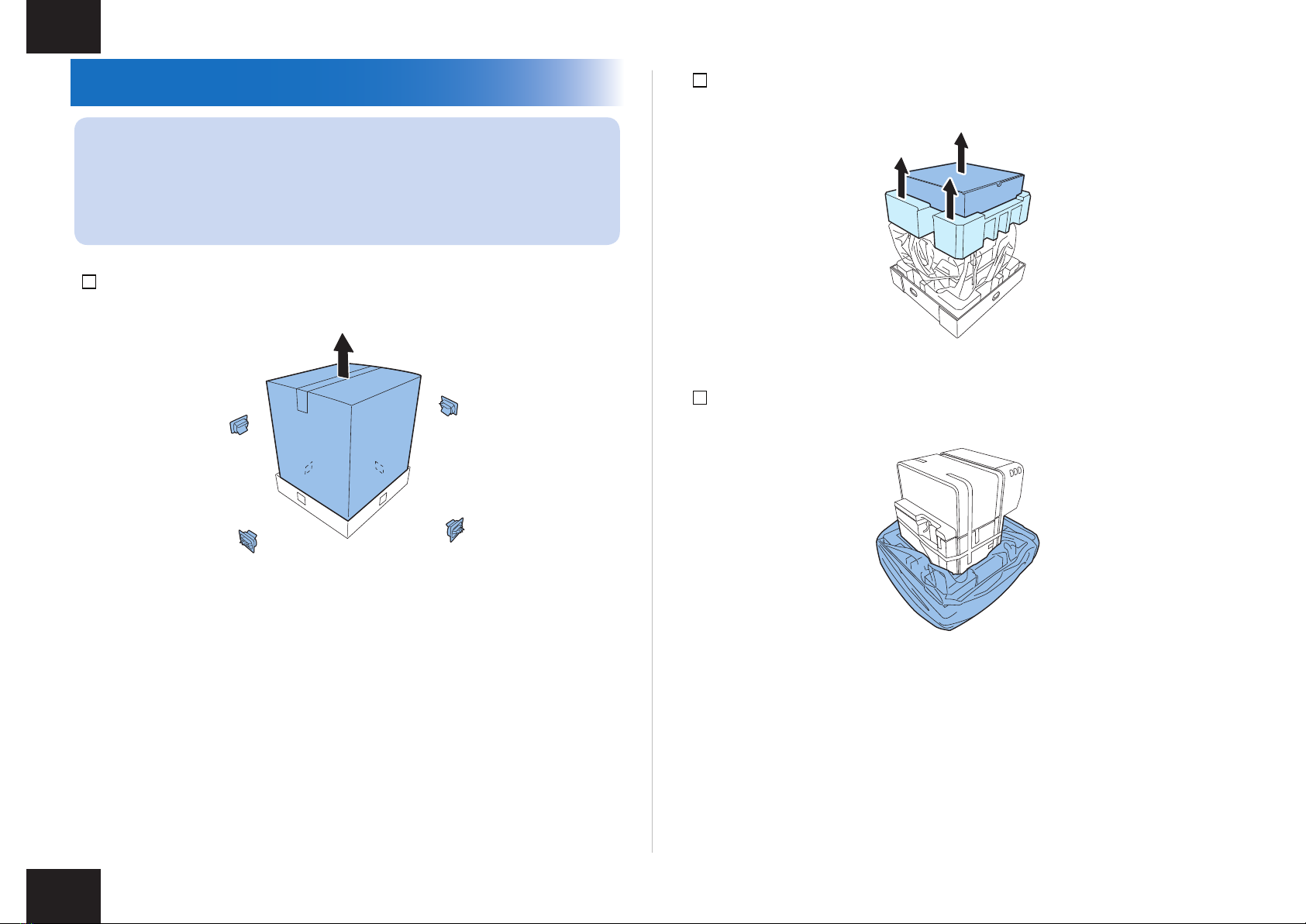

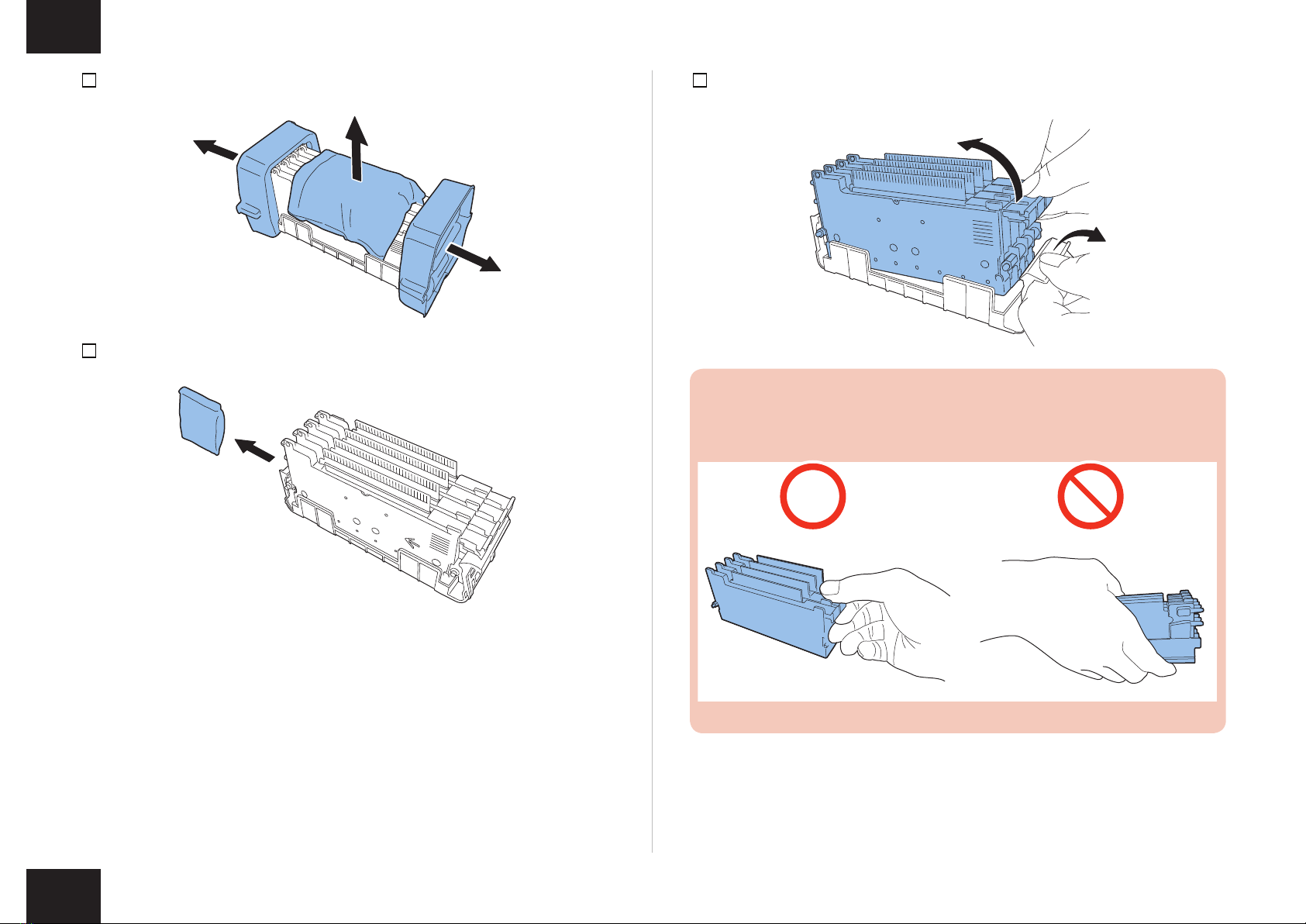

About the Symbols Used in Illustrations

In this guide, operations performed frequently are represented by the following symbols:

Connector

Disconnect

Screw

Tighten Remove Connect Secure Free

Harness

Push

Insert Plug in Turn on

Sound CheckCheck Visual Check

Claw

Remove

Checking instruction

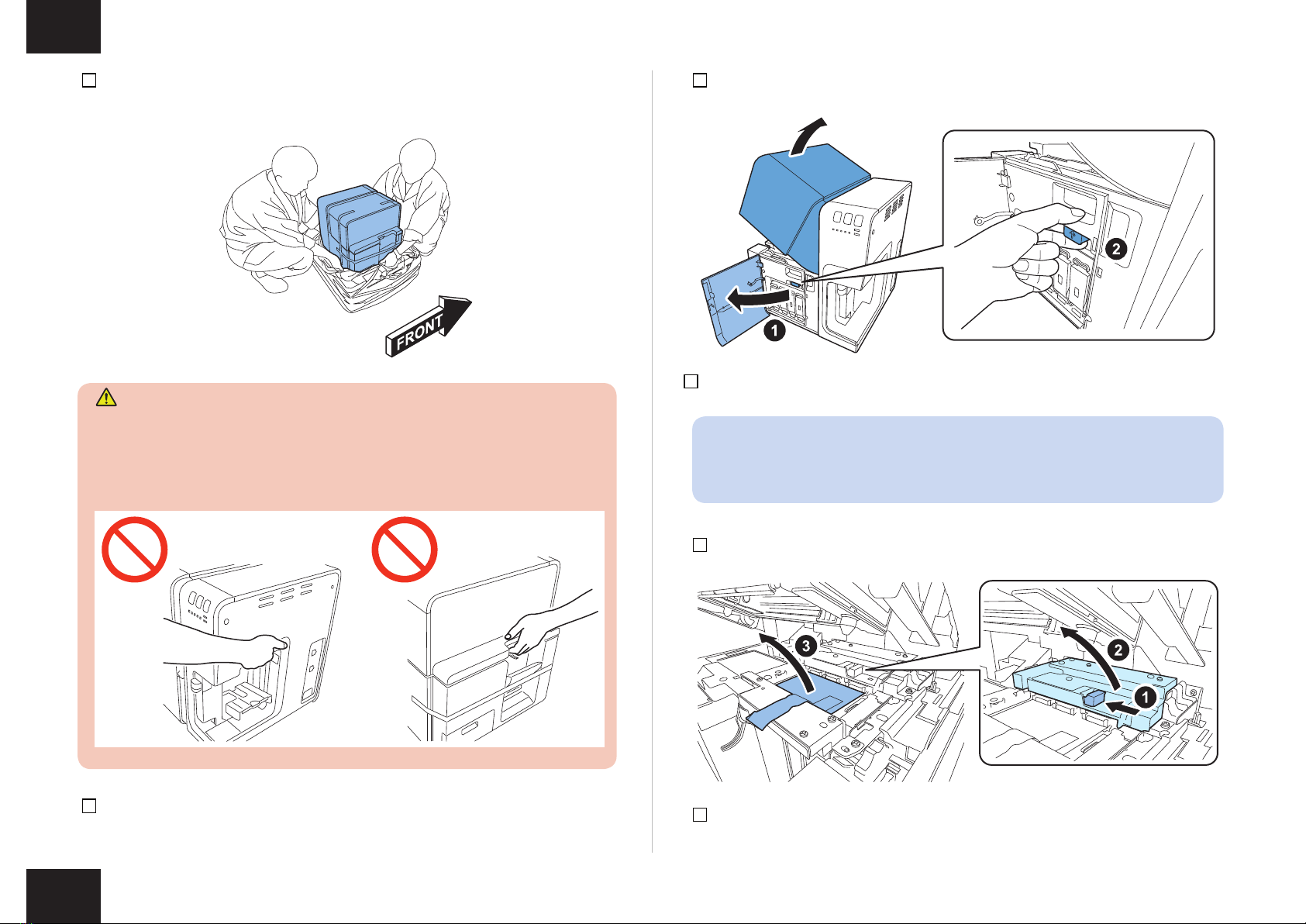

Check Before Installation

Installation requirements are listed below.

Checking the Power Supply

Power Cord of Printer must be connectable to the outlet (100V - 240V AC +10%/-15%)

exclusively.

Checking the Installation Environment

1. The installation environment must be as described below. Avoid installing Printer near the

faucet, water heater, humidier, or refrigerator.

• Operating temperature range: 5 to 35 degrees Celsius

• Operating humidity range: 10%RH to 90%RH

2. Avoid placing Printer in place exposed to high temperature and humidity, extremely low

temperature, severe temperature changes, and direct sunlight. Especially, avoid placing

Printer near re, out of doors, in distribution warehouse, or in refrigerator.

3. Avoid installing Printer in an area subject to dust.

4. The room must be well-ventilated properly.

5. None of Printer feet should oat. The machine must be held level constantly.

6. When placing Printer on desk, table or the like, it must be sturdy and stable enough to

support weight of Printer.