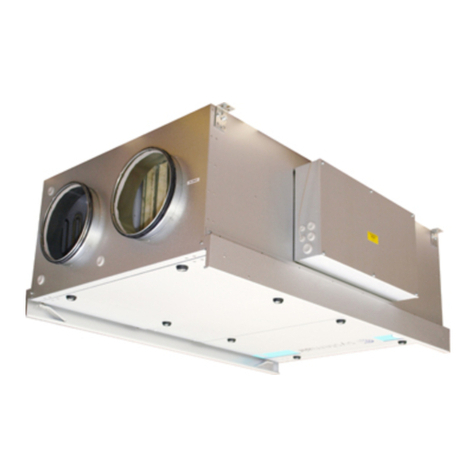

4 | HHCompact Air Handling Units

Safety Considerations

1.1 - General

TheHHCompactairhandlingunits(AHUs)havebeen

designedandmanufacturedinaccordancewiththeCE

machinedirective.Inordertoguaranteesafeoperation

anduseoftheunit,pleasecarefullyreadandobservethe

instructionsinthisdocumentandpayspecialattentionto

thewarningsthatapplytothisunit.Anymodicationsin

thedesignand/orinstallationoftheAHUthatarecarried

outwithoutpriordiscussionwithSystemairB.V.and

withoutadvancewrittenagreementwillresultintheloss

oftherighttoanywarrantyclaimsandanyclaimforinjury

topersonnelasaresultofthesemodications.

Allworkmustbecarriedoutbysufcientlytrained

personnel. All applicable personal safety devices must be

usedtoensuresafeworkingconditions.Safetyglovesand

glassesmustbewornforallmaintenanceoperations.A

respiratoryprotectionmaskmustbewornwhenchanging

thelters.TheA-weightedequivalentcontinuoussound

pressurelevelcanbeabove80dB(A),dependingonthe

motorsize,fansize,fanspeedandtheAHUinstallation

location.Thismeansthateardefendersmustbeworn,

whenthefanisrunning.

Alldoorsandhatchesmusthaveatleastonelockthat

canonlybeopenedwithaspecialdevice.Heatingand

cooling coils are manufactured and supplied in accordance

withguidelinesofthePressureEquipmentDirective(PED).

Donotwalkontheroofpanelsofunitsinstalledinsideor

outside.

Onlysufcientlyqualiedpersonnelisallowedtowork

on(electrical)components.Allpowersuppliestothe

unitmustbedisconnected,beforeanyworkcanbe

carriedout.Switchoffthesupplyvoltageusingthemain

disconnectswitch.

CAUTION:Ingeneralelectricheatershaveaseparate

supplyandmustbeswitchedoffseparately.

Ifworklightingisrequired,useonlylightingwith24V

maximum.Useofelecticalequipmentwithavoltage

above48Visonlypermittedifanearthleakageswitchis

installedthatcomplieswithlocalandnationalregulations.

1.2 - Applications

TheAHUisdesignedforthemovementandconditioning

ofair,unlessotherwiseagreedduringthedesignstage.

FromJanuary1st,2016AHUsmustcomplywithEU

regulation 1253/2014 implementing ErP directive

2009/125/EC,iftheyarewithinthescopeofthe

regulationandthedirective.

EUregulation1253/2014ispartoftheCE-marking.

Thisregulationappliesfor:

• ‘ventilation unit’ (VU) means an electricity driven

applianceequippedwithatleastoneimpeller,one

motor and a casing and intended to replace utilised air

by outdoor air in a building or a part of a building.

WhereanAHUisregardedasa:

• ‘non-residential ventilation unit’ (NRVU) means a

ventilationunitwherethemaximumowrateofthe

ventilationunitexceeds250m3/h,and,wherethe

maximumowrateisbetween250and1000m3/h,

themanufacturerhasnotdeclareditsintendeduseas

beingexclusivelyforaresidentialventilationapplication.

Theregulationdenestwotypesofventilationunits.

Thesemustbeplacedonthemarketorputintoservice,in

accordancewiththerequirementsofthisregulation.

• ‘unidirectional ventilation unit’ (UVU) means a

ventilationunitproducinganairowinonedirection

only,eitherfromindoorstooutdoors(exhaust)orfrom

outdoorstoindoors(supply),wherethemechanically

producedairowisbalancedbynaturalairsupplyor

exhaust

‘bidirectional ventilation unit’ (BVU) means a ventilation

unitwhichproducesanairowbetweenindoorsand

outdoorsandisequippedwithbothexhaustandsupplyfans

ThefollowingunitcombinationsareconsideredasaBVU:

• TwoormoreunitscombinedwithaRACheatrecovery

system

• Twoormoreunitsdirectly(withoutbuilding-side

ductwork)connectedwithamixingchamber.

Iftwoormoreunitsarecombinedasdescribedabove

on-siteinthebuildingbyathirdparty(forexampleinstaller),

aBVU(basedonCE-markedUVUs)willbe“putintoservice”.

Thismeansthethirdpartyhastodeclareproductconformity

withtherequirementsofaBVUandCEmarking.

Unitscanbesuppliedwithoutaccessoriesthatare

indicatedasmandatoryinregulation1253/2014.These

accessoriesmustbesuppliedandinstalledbyathirdparty.

Theaccessoriesthatarenotsuppliedbutmandatoryare

indicatedinthetechnicalspecicationoftheAHU,e.g.

fanswithvariablespeeddrive,thermalbypassdevice,heat

recovery,visualsignalingoralteralarm(2018regulation).

1.3 - Instruction types

Thefollowingwarningpictogramsandlabelswithtextare

used.

Lifting point

ThispictogramshowswheretheAHUmustbeliftedandis

positionedonthesupportbeam.