pag.

3

Industrial PC- COPILOT 21.5"

Order code 2E00xxxxNovember 2020 - Rev. 1.8

1. General Features

Copilot 21.5'' is the System Electronics operator panel

that oers performance and performance for all su-

pervisory and on-board machine applications, with an

innovative and robust design and mechanically reliable.

Made of stainless steel, resistant to dust and liquids,

Copilot 21.5'' is a PC solution adaptable to all the needs

of the latest generation industrial machines.

The 1920x1080 FullHD graphic display allows the display

of high resolution images and movies; it is equipped

with user and remote adjustable LED backlighting. The

multi-touch touch screen with up to 10 simultaneous

touches, and scratch-resistant, allows operator inte-

raction with simple gestures.

The Copilot 21.5" PC terminal, thanks to the new in-

tegrated Wireless solutions, can operate as a supervisor

of the equipment connected to the machine and with

users' portable devices.

Dierent congurations, such as solid state disks for

data storage and I/O management make the Copilot

21.5'' adaptable to all the needs of the industrial market.

2. Technical

specication

•CPU: Intel i7-7700T 7th-GEN 2.9GHz

Intel i5 Core 7500T 7th-GEN 2.7GHz

Intel J5005 Quad Core 1.5GHz GeminiLake

Intel J1900 Quad Core 2GHz Bay Trail

• RAM Memory: up to 32GB

• Operating System: Windows 10 Iot, Windows 8.1

64bit, Microsoft Widows Embedded 7, altro a richiesta

• Expansion slot: 1 x miniPCIe / 1x M.2

• LCD:

Size/model: 21,5’’ TFT Color LCD

Maximum resolution: 1920 x 1080 FullHD

Touch Screen: PCAP - 10 tocchi

Brightness: 300 cd/m2

Field of view angle:±89° H, ±89° V

Contrast: 1:5000

• Capacity:

HDD: SATA no a 1TB 2,5’’

SSD: Fino a 256GB

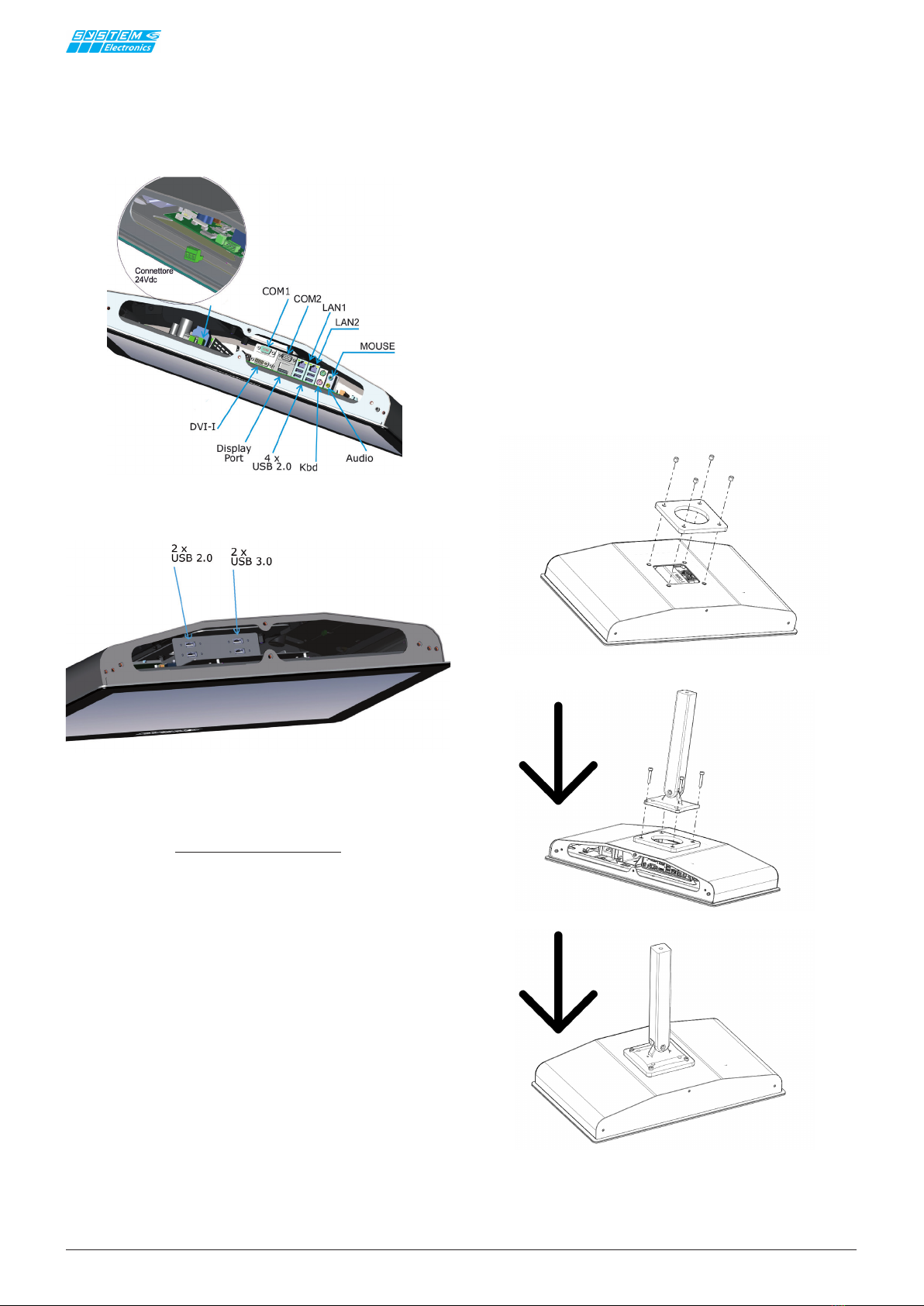

• Input/Output ports:

LAN: 2 Eth 10/100/1000

Serial port: 2 x RS232

Parallela port: internal

PS2 port: Keyboard + Mouse

USB port: Up to 8 x USB - (6 x USB 2.03 + 2 x

USB 3.0)

I/O: Available on request

Wireless connection optional: WiFi 802.11

a/b/g/n + Bluetooth 4.0

Audio: Line in / Line out

Video Output: DVI/VGA/DP

• Battery

Type and duration: UPS available on request

• Caratteristichesiche:

Weight: Max 10 Kg

Size: 545(W) x 335(H) x 85(D) mm

Protection: IP67 - Stainless Steel

Mounting: Arm / Panel

Power supply: 24 Vdc

Temperature: 0°C +50°C

(Max +60°C cooled version)

3. Description and

operation

Copilot 21.5'' can be powered at 24VDC from an exter-

nal power supply or directly from the 24Vdc power supply

of the machine to which it is connected. The PC turns on

automatically when the input power supply is present.

Copilt 21.5'' has two gigabit-ethernet networks, two

RS232 serial ports, PS2 mouse and keyboard port, 4

USB 2.0 ports, display port connection, DVI or external

VGA for a remote monitor, audio connection.

Other communication ports (such as USB3.0, parallel,

etc.) are available as an option.

The main recent operating systems can be pre-installed

on the terminal: Windows 10, Linux Debian9, Windows7

and Windows 8.1.

After the operating system shutdown you can turn on

Copilot 21.5'' again by disconnecting for 10 seconds and

reconnecting the external 24VDC power supply or by

pressing the optional power button. It is also possible

to turn on Copilot 21.5'' from Wake-On-Lan commands

from an external PC connected to the terminal's Ether-

net network.

4. Installation

4.1 Configuration of internal

connectors

- Remove the 6 M5 xing screws M5 of the Copilot

21.5'' that cover the upper and lower doors, taking care

to keep the gaskets placed in the screws themselves and

inside the mechanics, in order to reassemble them later

in the same position.

- Typically all the connection cables are connected

from the bottom side of the Copilot 21.5'': the removal of

the upper door can facilitate the insertion of the cables

allowing to control their insertion.

- Nella versione a 8 USB le 4 porte USB aggiuntive

sono poste sotto lo sportello superiore.

- The power connector is placed vertically, acces-

sible by inserting your hand inside the bottom opening.