SPECIFICATIONS

Normal Operating Voltage: 15 to 30 VDC

Standby Current: 630 µA max. average (continuous broadcasts)

Alarm Current: 2 mA (red LED on)

Maximum NAC Circuit Line Loss: 4 VDC

Power Supply Monitor

Maximum (Speakers): 70.7 V RMS. 50 W

Maximum (NAC): Regulated 24VDC

Trouble Range: 0 to 2 VDC

Max NAC Current Rating: For Class B wiring system, 3A

For Class A wiring system, 2A

Temperature Range: 32°F to 120°F (0°C to 49°C)

Humidity: 10 to 93% RH Noncondensing

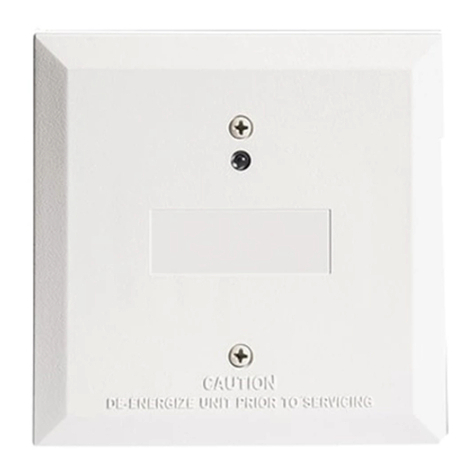

Dimensions: 4.17˝ H x 4.26˝ W x 1.22˝ D; (106 mm H x 108 mm W x 31 mm D)

Accessories: 39 kΩEnd of Line Resistor Part # A2263-00 (included)

Wall cover plate (included)

SMB500 Surface Mount Electrical Box

A2143-60 Bypass capacitor

EA-CB Control Module Barrier

D500-54-00 1 I56-2016-004

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

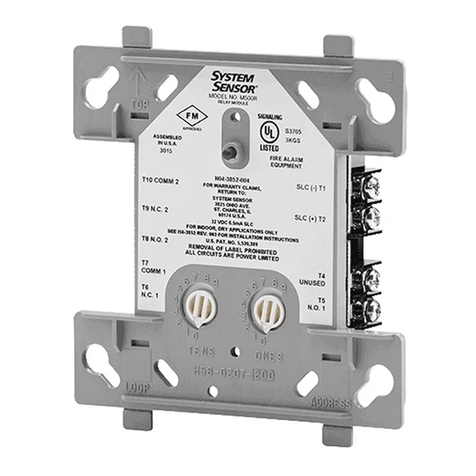

EM-1SRI Supervised Control Module

BEFORE INSTALLING

This information is included as a quick reference installa-

tion guide. Refer to the appropriate control panel installa-

tion manual for detailed system information. If the modules

will be installed in an existing operational system, inform

the operator and local authority that the system will be

temporarily out of service.

NOTICE: This manual should be left with the owner/user

of this equipment.

GENERAL DESCRIPTION

Control Module, Model EM-1SRI, is used to switch an ex-

ternal power supply or audio amplifier to notification ap-

pliances. In addition to switching the external power, the

device will monitor the wiring (while external power is

not switched to the auxiliary devices) to the auxiliary de-

vice for open and short circuits via an end of line resistor.

This module is capable of Class A or Class B operation.

The module also has on-board short circuit isolators to pre-

vent shorts on the signaling line circuit from disabling more

than one device on the intelligent loop.

The control module will also have the capability to moni-

tor the external power input for loss of power (DC volt-

age supplies only). This feature can be disabled through

device configuration programming. If the external power

is switched to the auxiliary devices and there is a loss of

the DC supply, the control module has the capability of

running an algorithm in which the device will switch back

to monitor mode and check the line for short circuits. If

no short exists, the device will reapply the external power.

This algorithm can be enabled when using a DC external

supply that is guaranteed to be above 9 volts.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected

to a listed compatible control panel.

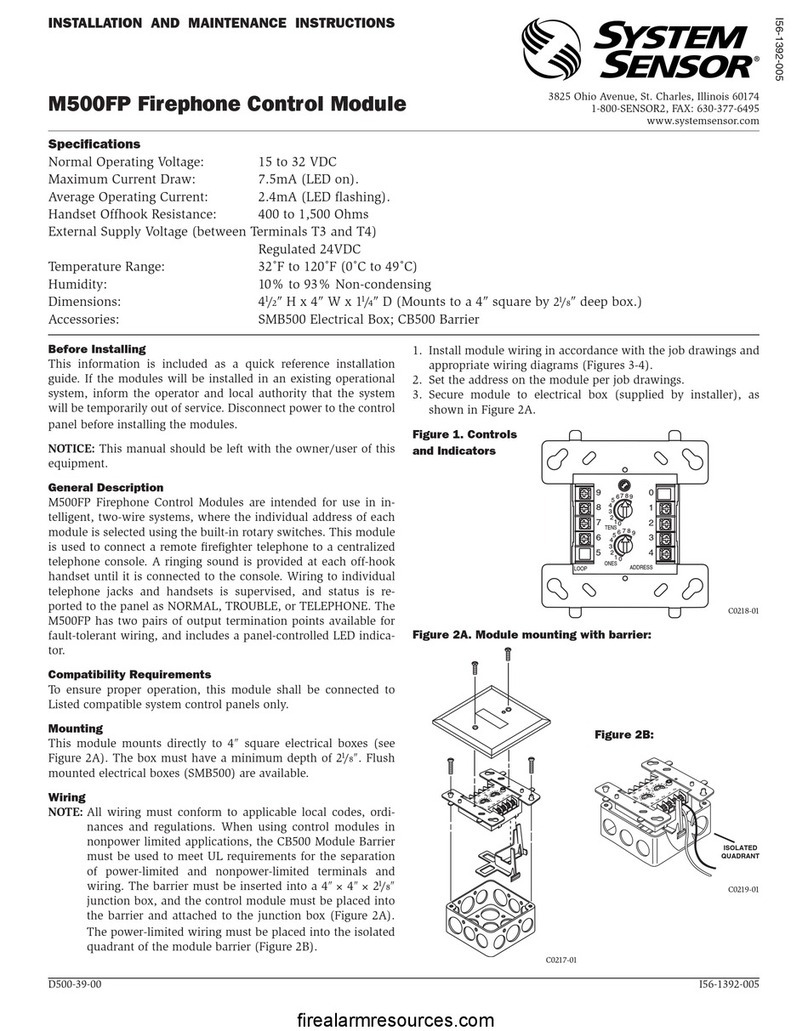

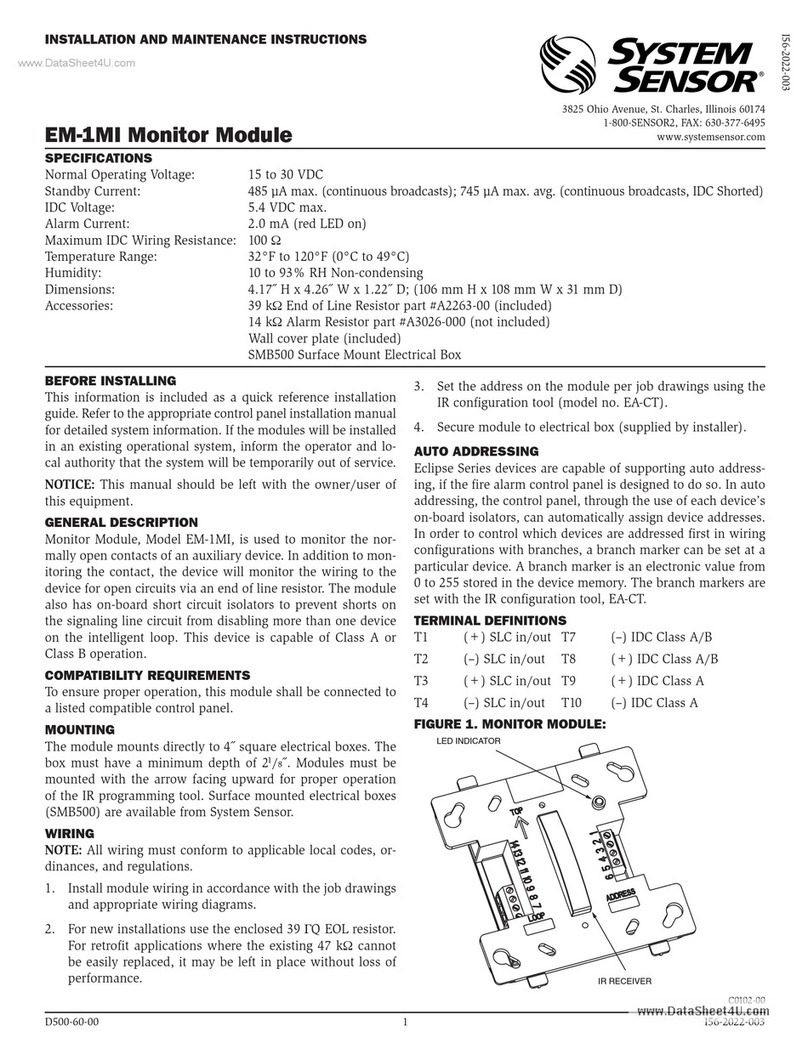

MOUNTING

The module mounts directly to 4˝ square electrical boxes.

The box must have a minimum depth of 21/8˝. Modules

must be mounted with the arrow facing upward for proper

operation of the IR configuration tool (model no. EA-CT).

Surface mounted electrical boxes (SMB500) are available

from System Sensor.

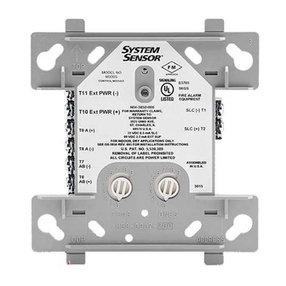

WIRING

NOTE: All wiring must conform to applicable local codes,

ordinances, and regulations.

1. Install module wiring in accordance with the job draw-

ings and appropriate wiring diagrams. Optional EA-CB

may be required to separate power limited and non

power limited wiring in the electrical box (see Figure

1B). 2. For new installations use the enclosed 39

kΩEOL resistor. For retrofit applications where the ex-

isting 47 kΩcannot be easily replaced, it may be left in

place without loss of performance.

3. Set the address on the module per job drawings using

the IR configuration tool (model no. EA-CT).

4. Secure module to electrical box (supplied by installer).

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-2016-004