INSTALLATION AND MAINTENANCE INSTRUCTIONS

M902M Input Module

For Two-wire Conventional Detector

Before Installing

This information is included as a quick reference installation guide. Refer to the appropriate installation manual for detailed system information. If

the modules will be installed in an existing operational system, inform the operator and local authority that the system will be temporarily out of

service. Disconnect power to the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

The M902M Input Module allows intelligent panels to interface and monitor two-wire conventional smoke detectors.

The module address should be set by the model CP900M from 101to 199. When the module is interrogated, it transmits the status of one zone of

two-wire detectors to an intelligent control panel. Status conditions are reported as normal, open, or alarm.

A status LED indicator is provided and is controlled by code command from the control panel. (

).

Compatibility Requirements

To insure proper operation, this module shall be connected to

compatible intelligent control panels only. Conventional two-wire

smoke detectors must be compatible with the interface module. The

external power 24VDC which supplies the power to the detector must be

reset.

The input module includes the following items:

(1) Two-wire interface module

(1) 3.9K ohm end-of-line resistor

(1) Off-white cover plate

(1) Screw pack for cover plate

NOTE: All wiring must conform to applicable local codes, ordinances

and regulations. When using control modules in nonpower limited

applications, the CB500 Module Barrier must be used to meet the

requirements for the separation of power limited and nonpower-limited

terminals and wiring. The barrier must be inserted in a 100mmsquare by 50mm

deep electrical boxes, and the control module must be placed into the

barrier and attached to the junction box (Figure 2A). The power-limited

wiring must be placed into the isolated quadrant of the module barrie.

The M902M Input Module mounts directly to 100mm square electrical

boxes as shown in

A.The box must have a minimum depth of

50mm.

1. Install module wiring in accordance with the job drawings and

appropriate wiring diagrams (Figure 3.).

2. Set the address on the module per job drawings.

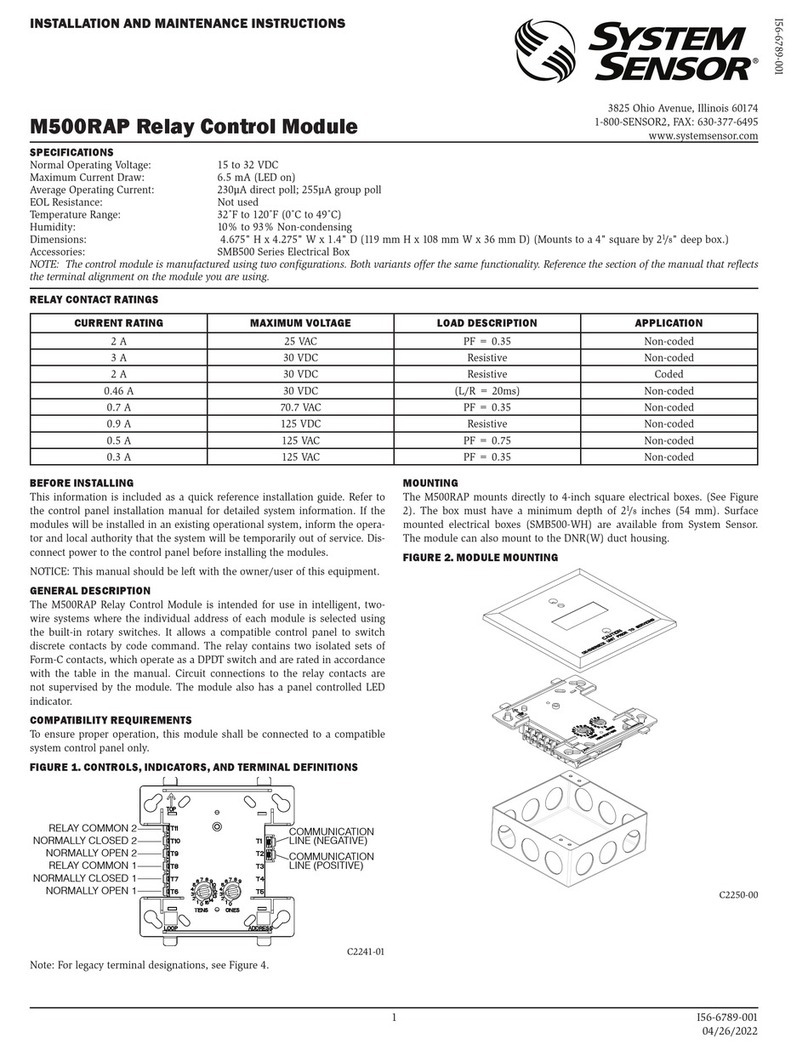

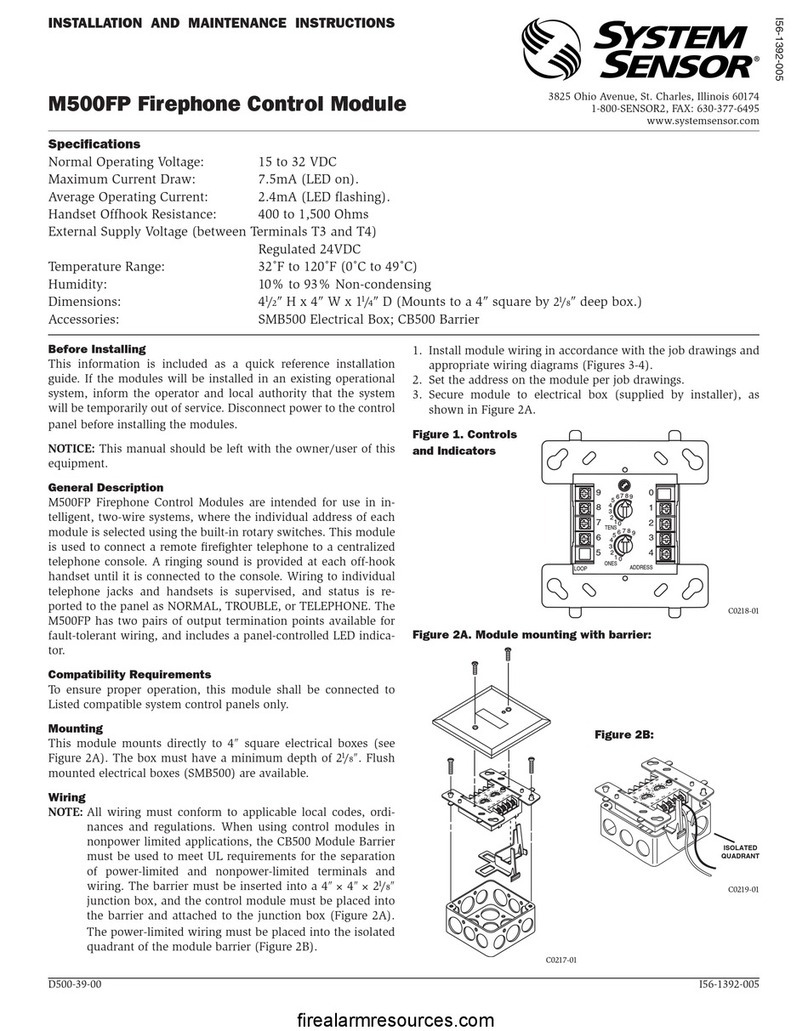

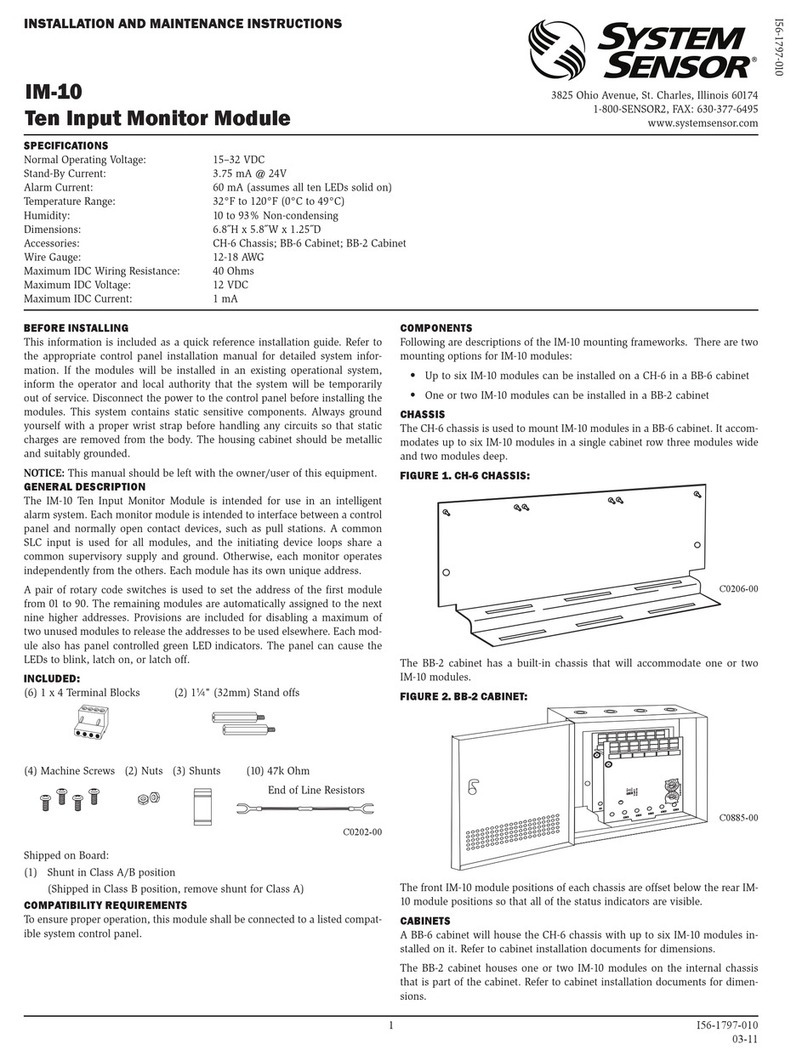

Figure 1. Input Module and Indicator

detailing Mounting Arrangement

Temperature: -10° C to 55° C (14°F to 131° F) External Power Supply Requirements-Terminals 3 & 4

Humidity: 5% to95%RH Noncondensing Voltage:18 to 29 VDC (filtered, regulated, and power-limited)

Weight: 0.2bs (92 g) Ripple: 100mV RMS Max

124.6mm L x 124.6mm W x62mm H (with the

mountingplate andthe junctionbox, seeFigure 2B ) Current:102 mA per module

Accessories: SMB500/W Surface Mount Box for 900 series

modules

(Power must be interrupted to reset detectors. The interface module

must have a minimum of 18 VDC at terminals 3 and 4 to function

properly. Ground fault detection must be accomplished by the

control panel.)

Communication Line-Terminals 1 & 2

Voltage: 15 – 32 VDC Loop Impedance: 40¡Max

Current: 850µA Max @ 24 VDC, no communication

1.8 mA Max 24V (LED latched on)

Initiating Device Circuit (IDC) – Terminals 5 & 6

Current: 102 mA Max Detector Current in Standby: Up to 2.4 mA

Standby Current: 12 mA Max @ maximum IDC voltage Style: Style B (class B)

IDC Loop Impedance: 25¡Max EOL Resistance: 3.9K ohm nominal

Alarm Current: 18 mA minimum

(Detector loop current is sufficient to ensure operation of one alarmed detector per zone.)

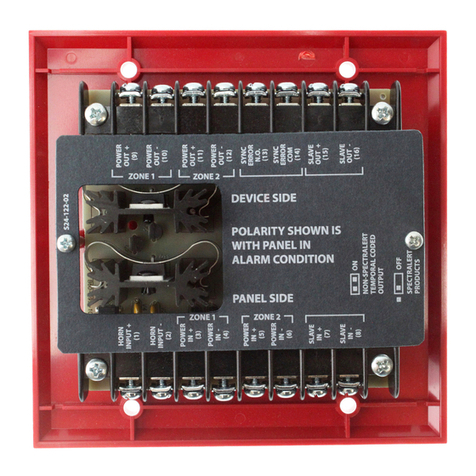

Figure 3. M902M Input Module Wiring Diagrams

with B401/B801 Base:

CONNECT MODULES TO LISTED

COMPATIBLE CONTROL

PANELS ONLY.

FROM PANEL OR

TERMINAL WIRING MUST BE

POWER LIMITED

IS RECOMMENDED

COMMUNICATION LINE

32 VDC MAX

TWISTED PAIR

RESISTOR

(INCLUDED)

DO NOT LOOP WIRE UNDER TERMINALS BREAK WIRE

RUN TO PROVIDE SUPERVISION OF CONNECTIONS.

DETECTORS MUST BE UL LISTED COMPATIBLE WITH

MODULE.

INSTALL DETECTORS PER MANUFACTURE’S

INSTALLATION INSTRUCTIONS.

OPTIONAL BRANCH CIRCUIT

TO NEXT INTERFACE MODULE

MODULE SUPERVISED SUPPLY

VOLTAGE AND DETECTOR LOOP.

POWER TO THE INTERFACE MODULE

MUST BE EXTERNALLY SWITCHED TO

RESET THE DETECTORS. A CONTROL CMX-7

MODULE CAN BE USSED TO SWITCH

POWER FROM A STANDARD POWER

SUPPLY.

18-29 VDC

2-WIRE CONVENTIONAL DETECTOR

INITIATING DEVICE CIRCUIT (IDC)-NFPA STYLE B

POWER LIMITED 102mA MAX:29VDC MAX

IDC INSTALLATION WIRING MUST NOT EXCEED

25 OHMS, 12-18AWG

DO NOT MIX FIRE ALARM INITIATING SUPERVISORY.

OR SECURITY DEVICES ON THE SAME MODULE

Three-Year Limited Warranty

Xi'an System Sensor warrants its enclosed products to be free from defects in materials and workmanship under normal use and service for a period

of three years from date of manufacture. The company’s obligation of this Warranty shall be limited to the repair or replacement of any art of the

product, which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the

date of manufacture.

The Company shall not be obligated to repair or replace units which are found to be defective because of damage, unreasonable use, modifications,

or alterations occurring after the date of manufacture.

Compatible Two-wire System Sensor Smoke Detectors for Use with M902M : A

3. Secure module to electrical box (supplied by installer), as shown in Figure 2A.

Standard: GB16806-2006 Certification:

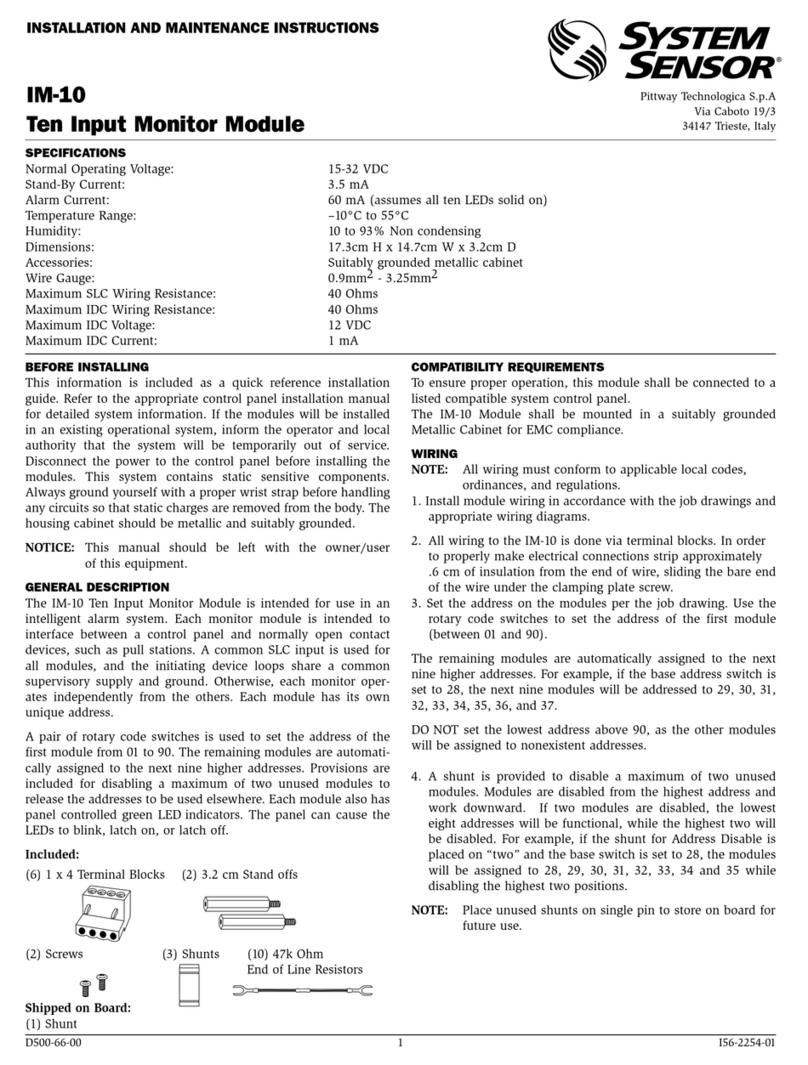

Figure2A. Exploded View of Typical Module

Figure2B. Module Mounting Size:

Dimensions:

Detector

Model Detector

TypeBase

Model Max

Detector

JTY-LZ-881 Ionization DZ-B801 25

JTY-GD-882 Photoelectric DZ-B801 25

JTW-SD-885 Thermal DZ-B801 25

JTY-GD-2451 Photoelectric DZ-B401/B 20

JTY-LZ-1451 Ionization DZ-B401/B 20

JTW-BCD-5451 Thermal DZ-B401/B 20

JTY-LZ-1151 Ionization DZ-B401 20

JTY-GD-2151 Photoelectric DZ-B401 20

Product Nameplate Date Code Note:

XX X X

Stands for: The end number of the producing year the producing month the week of the month