M500-05-00 1 I56-314-14

M500M Monitor Module and

M500CH Control Module

INSTALLATION AND MAINTENANCE INSTRUCTIONS

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

Before Installing

This information is included as a quick reference installation

guide. Refer to the control panel installation manual for detailed

system information. If the modules will be installed in an existing

operational system, inform the operator and local authority that

the system will be temporarily out of service. Disconnect power to

the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this

equipment.

General Description

M500M Monitor Modules provide a two-wire, or fault-tolerant,

initiating circuit for normally open contact fire alarm and supervi-

sory devices, or either normally open or normally closed security

devices. The LED indicator can be latched on or returned to the

normal mode by code command from the panel. Convenient ro-

tary decade switches are used to set the address of each module.

M500CH Control Modules allow a compatible control panel to

switch discrete contacts by code command. The control module

has a status LED that can be latched on or returned to the normal

mode by code command from the panel. Rotary decade switches

are used to set the address of each module.

The control module offers two modes of switching operation. As

shipped, the module is configured for switching an external

power source to notification appliances. The external power

source can be a DC power supply or an audio amplifier (up to

70.7 Vrms). In this mode, the module reports supervision status of

the connected loads to the control panel. Load circuit status is re-

ported as a NORMAL, OPEN, or SHORTED circuit. Two pairs of

output termination points are available for fault-tolerant wiring.

The second mode of switching operation allows the panel to con-

trol one Form-C (SPDT) set of contacts. Circuit connections to the

contacts are not supervised by the module. This mode is enabled

by breaking two external tabs on the module.

Compatibility Requirements

To insure proper operation, these modules shall be connected to

listed compatible system control panels only.

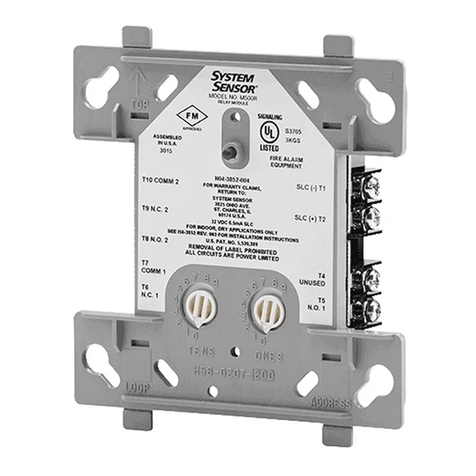

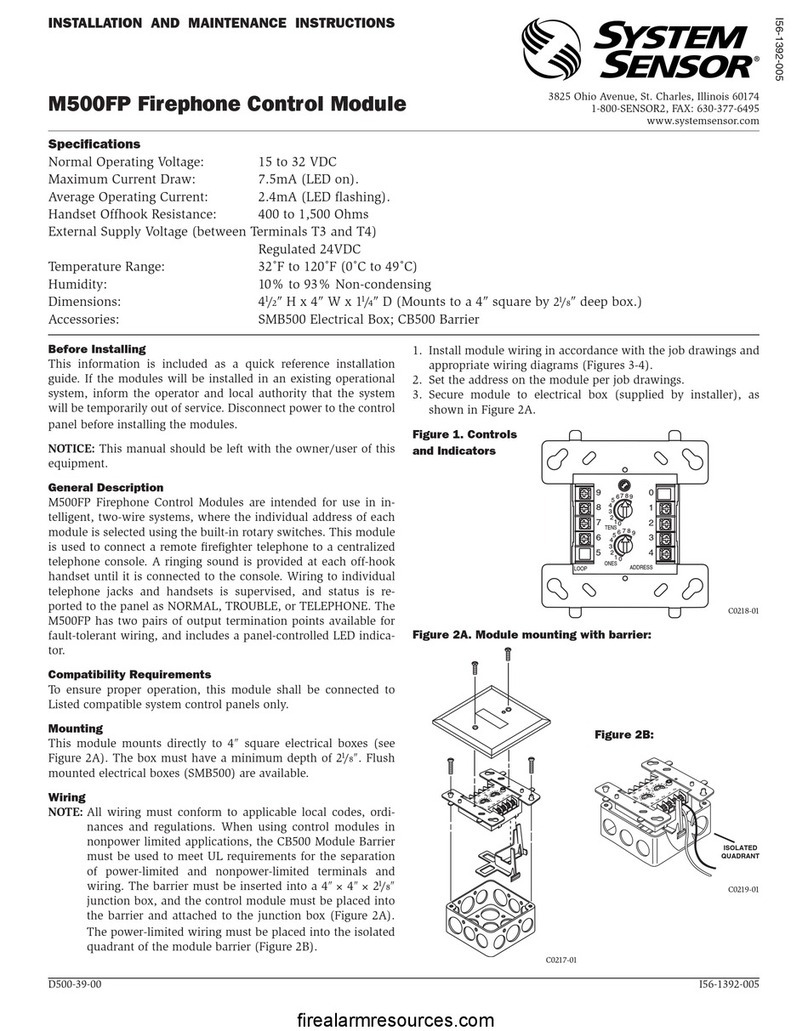

Mounting M500M and M500CH Devices

M500M and M500CH modules mount directly to 4" square electri-

cal boxes as shown in Figure 2A. The box must have a minimum

depth of 21 /8".

Wiring

NOTE: All wiring must conform to applicable local codes, ordi-

nances and regulations. When using control modules in

nonpower limited applications, the System Sensor CB500

Module Barrier must be used to meet UL requirements

for the separation of power-limited and nonpower-lim-

ited terminals and wiring. The barrier must be inserted

in a 4"x4"x21 /8" junction box, and the control module

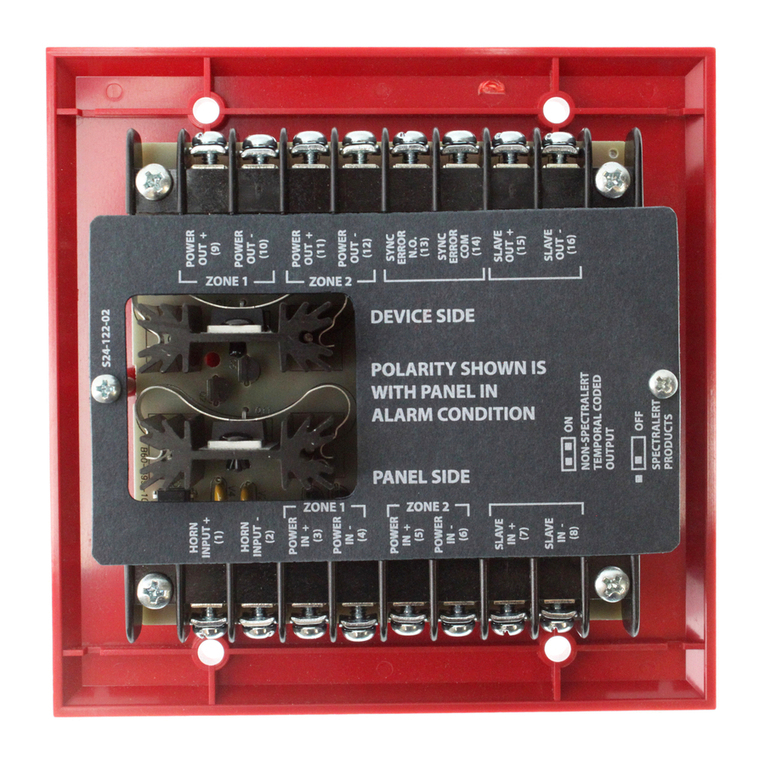

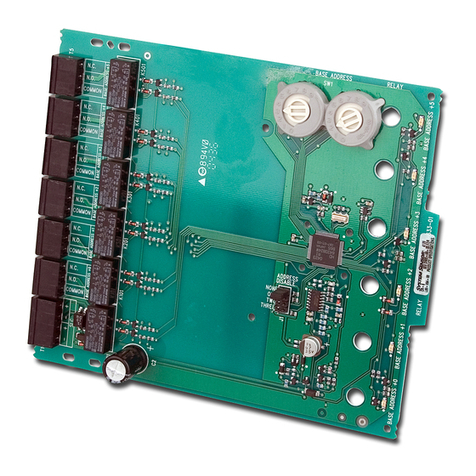

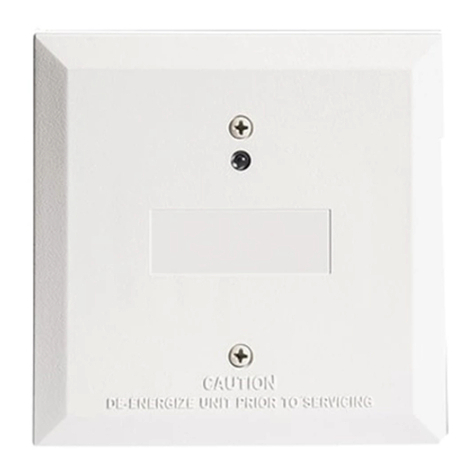

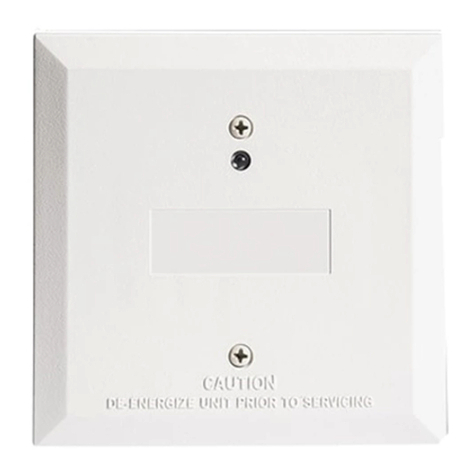

Figure 1. Monitor and control module controls and

indicators:

Figure 2A. Module mounting with barrier:

must be placed into the barrier and attached to the junc-

tion box (Figure 2A). The power-limited wiring must be

placed into the isolated quadrant of the module barrier

(Figure 2B).

1. Install module wiring in accordance with the job drawings and

appropriate wiring diagrams (Figures 3 - 9).

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as

shown in Figure 2A.

Magnet Test

The monitor and control modules can be tested with a test mag-

net available from System Sensor (M02-04-01, see Figure 1). The

magnet test checks the module electronics and connections to the

control panel. Interfaced initiating and indicating devices must be

tested independently.

STATUS LED

ROTARY DECADE

ADDRESS SWITCHES

MAGNET TEST

POSITION

27

0

1

3

4

5

6

8

9

27

0

1

3

4

5

6

8

9

ISOLATED

QUADRANT

A78-2611-00

Figure 2B:

A78-2610-00

A78-2318-00