D770-53-00 1 I56-2617-001R

WFDE Vane-type Waterflow Detector

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Important

Please Read Carefully And Save

This instruction manual contains important information about the instal-

lation and operation of waterflow detectors. Purchasers who install wa-

terflow detectors for use by others must leave this manual or a copy of it

with the user.

Read all instructions carefully before beginning. Follow only those instruc-

tions that apply to the model you are installing.

Use vane-type waterflow detectors in wet-pipe systems only. DO NOT USE

IN DRY-PIPE, DELUGE, OR PRE-ACTION SYSTEMS. The sudden inrush of

water in such systems may break the vane or damage the mechanism.

Do not use in potentially explosive atmospheres. Do not leave unused

wires exposed.

Principles of Operation

Vane type waterflow detectors mount to water-filled pipes in sprinkler sys-

tems. Waterflow in the pipe deflects a vane. Deflection of the vane pro-

duces a switched output, usually after a specified delay. All WFDEs have

a pneumatically controlled mechanical delay mechanism. Delays are non-

cumulative; they reset if the flow of water stops or drops below minimum

triggering flow rate before the entire delay has elapsed. All detectors will

activate on a sustained flow of water greater than the maximum specified

in Table 1, but will not activate if the flow rate is less than the minimum

specified in Table 1.

Steel Pipe Compatibility

DO NOT USE THE ABOVE MODELS ON COPPER PIPE. The clamping

forces of the mounting bolts may collapse the pipe sufficiently to prevent

the detector from functioning properly.

DO NOT INSTALL STEEL OR IRON PIPE SECTIONS IN COPPER PIPING

FOR MOUNTING A WATERFLOW DETECTOR. Incompatibility between the

dissimilar metals will cause bimetallic corrosion.

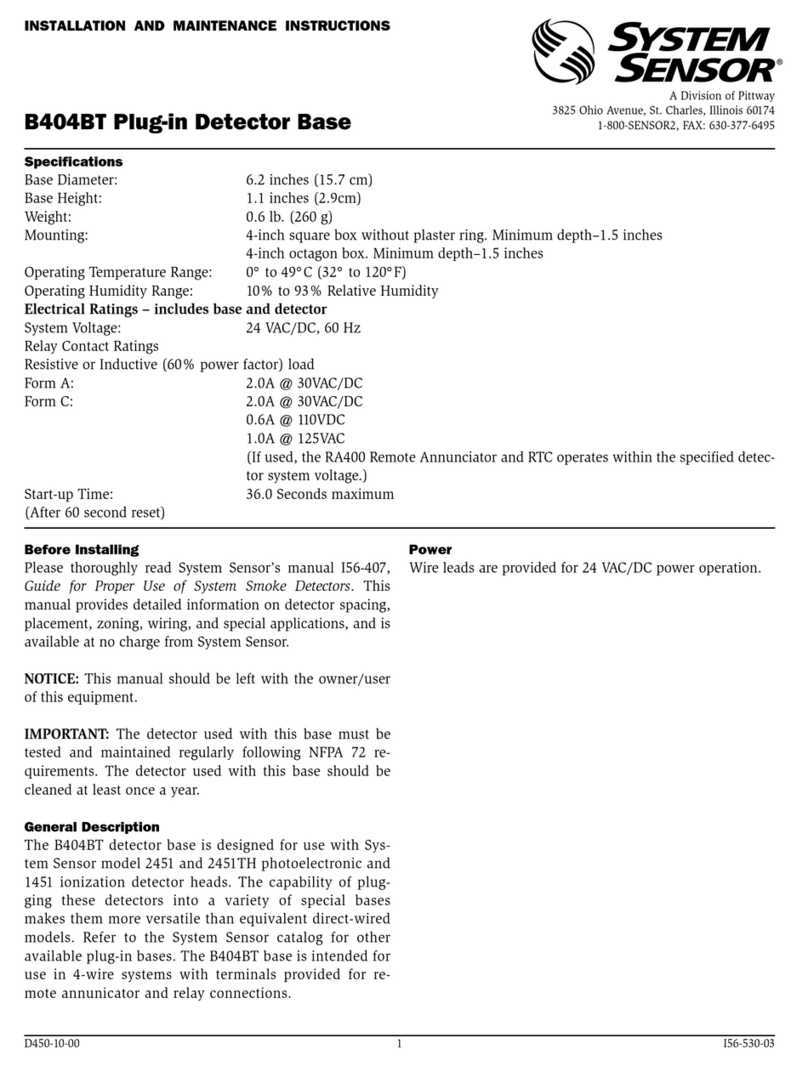

Specifications

Contact Ratings: 10 A @ 125/250 VAC

2.5 A @ 24 VDC EC–certificate Number: 0786-CPD-40151

Triggering Flow Rate: Refer to Table 1 EN12259–5

Static Pressure Rating (maximum): 17.25 bar (250 psi) (1725 KPa)

16 bar (VdS)

Operating Temperature Ranges: 0° – 68°C (32° – 155°F)

Compatible Pipe: Steel Water Pipe (Refer to Table 1)

Shipping Weight: 1.8 – 3.2 Kilograms

Enclosure Rating: Nema4/IP54

Installation Guidelines

Before installing any waterflow alarm device, be thoroughly familiar

with national codes of practice and the requirements of the authority

having jurisdiction.

Failure to follow these directions may result in failure of the device to

report a waterflow condition. System Sensor is not responsible for de-

vices that have been improperly installed, tested or maintained.

1. Mount the detector where there is adequate clearance for installation

and removal and a clear view of it for inspections. See Figure 1 for

mounting dimensions.

2. Locate the unit 1.8 – 2.1 meters above the floor to protect from damage.

3. On horizontal runs, position the detector on top or on the side of the

pipe. Do not mount it upside down because condensation may collect

in the housing and impair the operation of the detector. For vertical

flow applications, mount detector on pipe where upflow conditions

exist. Failure to do so may prevent unit from operating properly.

4. Mount detector at least 15 cm from a fitting which changes the direc-

tion of the water flow, or no closer than 61 cm from a valve or drain.

5. BE SURE DIRECTION-OF-FLOW ARROW MATCHES ACTUAL DI-

RECTION OF FLOW IN THE PIPE.

Mounting Instructions

1. Drain the pipe.

2. Cut a hole in the desired location. Center the hole in the pipe as shown

in Figure 2, and be sure the hole is perpendicular to the center of the

pipe. If the hole is off center, the vane will bind against the inside wall

of the pipe. Use a drill or holesaw to cut a hole of the proper diameter.

See Table 2 for hole size. Before drilling, use a punch or scribe to mark

the drill site to keep the bit from slipping.

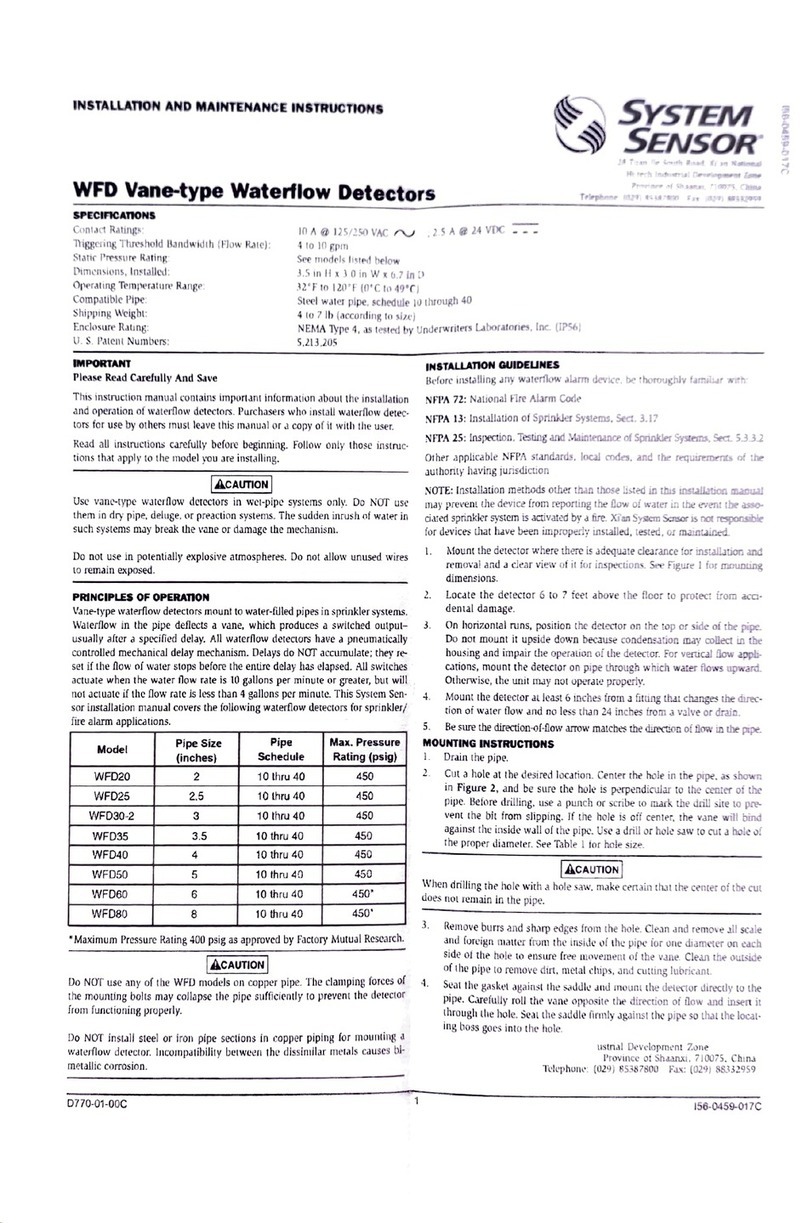

This System Sensor installation manual covers the following waterflow

detectors for sprinkler/fire alarm applications.

Table 1.

MODEL

NUMBER

DN

REF. PIPE

SIZE - mm (in)

NOMINAL

PIPE O.D.

(mm)

WALL

THICKNESS

(mm)

TRIGGERING

FLOW RATE

(liters/min)

WFD20E 50 (2) 60.3 2.3/2.9

30 – 57

WFD25E 65 (2-1/2) 76.1 2.6/2.9

WFD30-2E 80 (3) 88.9 2.9/3.2

WFD40E 100 (4) 114.3 3.2/3.6

WFD60E 150 (6) 168.3 4.0/4.5

WFD80E 200 (8) 219.1 4.5/5.9