D450-04-00 1 I56-375-04R

B404B Plug-in Detector Base

For use with 1451, 2451, AND 2451TH detectors

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue

St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

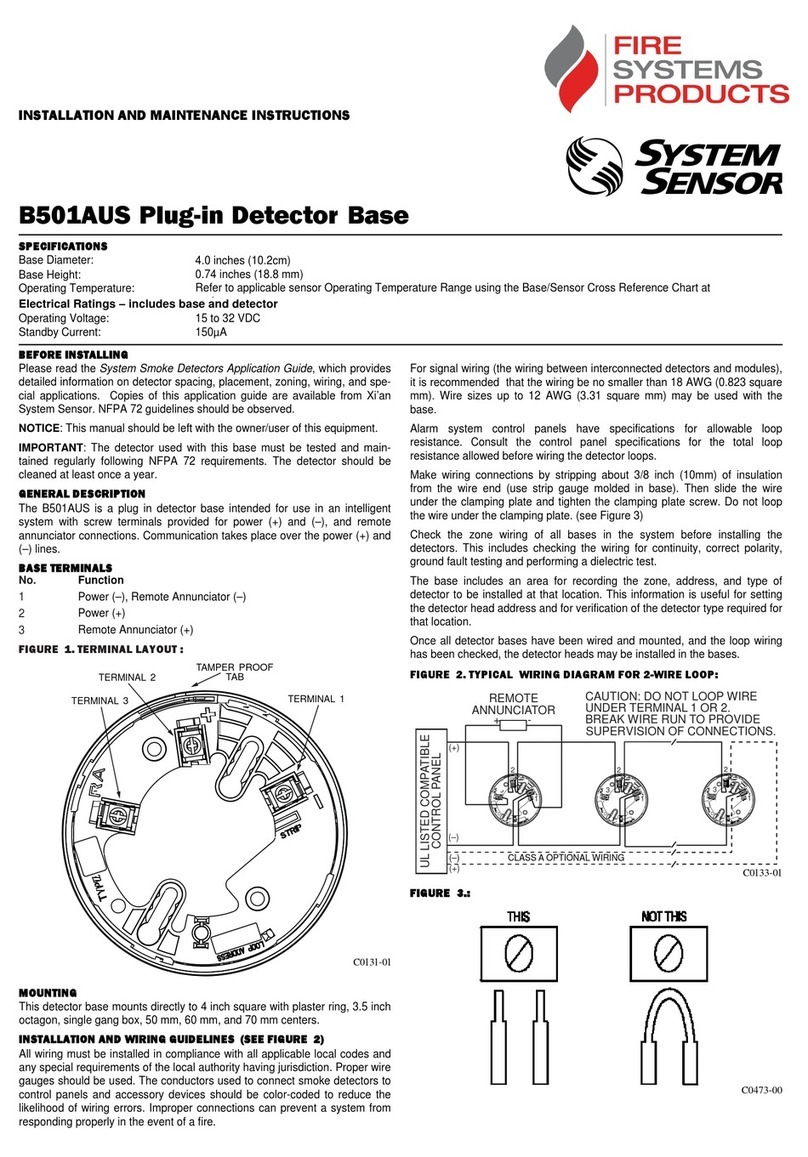

Before Installing

Please thoroughly read the System Sensor manual I56-407,

Guide for Proper Use of System Smoke Detectors. This man-

ual provides detailed information on detector spacing,

placement, zoning, wiring, and special applications, and is

available at no charge from System Sensor. (For installation

in Canada, refer to CAN/ULC-S524, Standard for the

Installation of Fire Alarm Systems and CEC Part 1, Sec. 32.)

NOTICE: This manual should be left with the owner/user

of this equipment.

IMPORTANT: The detector used with this base must be

tested and maintained regularly following NFPA 72 require-

ments. The detector should be cleaned at least once a year.

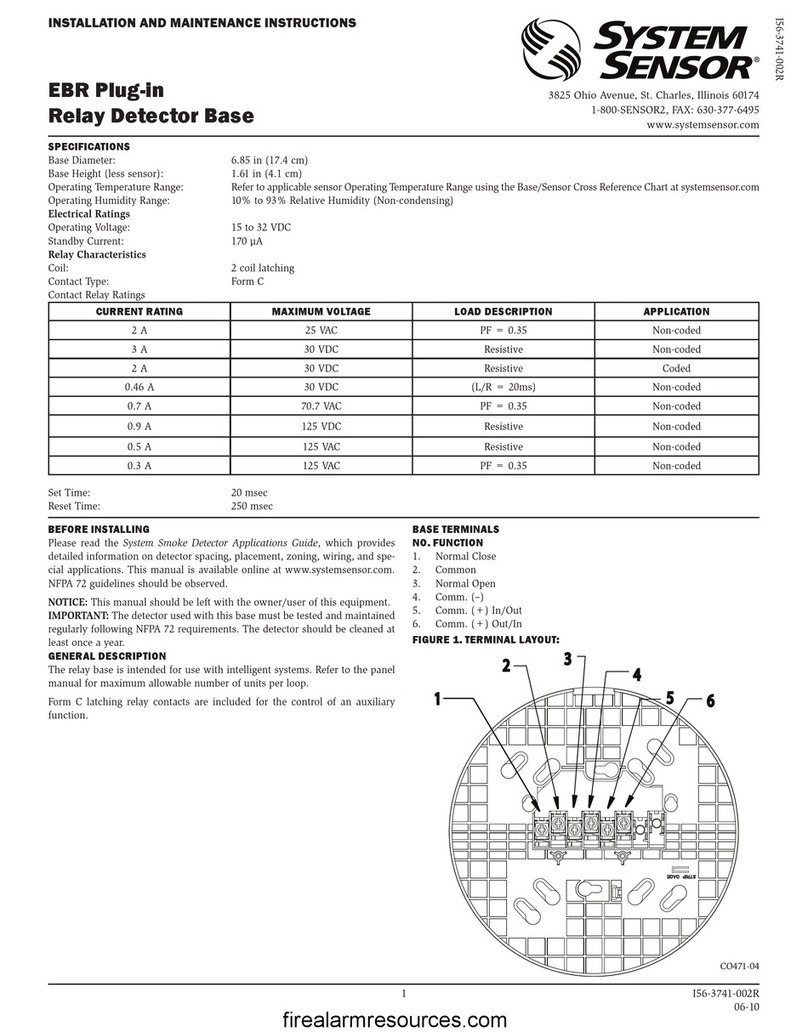

Specifications

Base Diameter: 6.2 inches (15.7 cm)

Base Height: 0.95 inches (2.9cm)

Weight: 0.6 lb. (260 g)

Mounting: 4-inch square box with or without plaster ring. Min. depth–1.5 inches

4-inch octagon box. Min. depth–1.5 inches

31⁄2-inch octagon box. Min. depth–1.5 inches

Operating Temperature Range: 0° to 49°C (32° to 120°F)

Operating Humidity Range: 10% to 93% Relative Humidity

Electrical Ratings - includes base and detector

System Voltage: 120 VAC, 60 Hz

Relay Contact Ratings

Resistive or Inductive (60% power factor) load

Form A: 2.0A @ 30VAC/DC

Form C: 2.0A @ 30VAC/DC

0.6A @ 110VDC

1.0A @ 125VAC

(If used, the RA400 Remote Lamp operates within the specified detector system voltage.)

Start-up Time: 36.0 Seconds maximum

(After 60 second reset)

General Description

The B404B detector base is designed for use with System

Sensor model 2451 and 2451TH photoelectronic and 1451

ionization detector heads. The capability of plugging these

detectors into a variety of special bases makes them more

versatile than equivalent direct-wired models. Refer to the

System Sensor catalog for other available plug-in bases.

The B404B base is intended for use in 4-wire systems with

terminals provided for power, remote annunicator, and

relay connections. This base also contains a resistor to pro-

vide current limiting in the alarm state.