7

13/10/2016

A Ground Breaking Company Since 1923

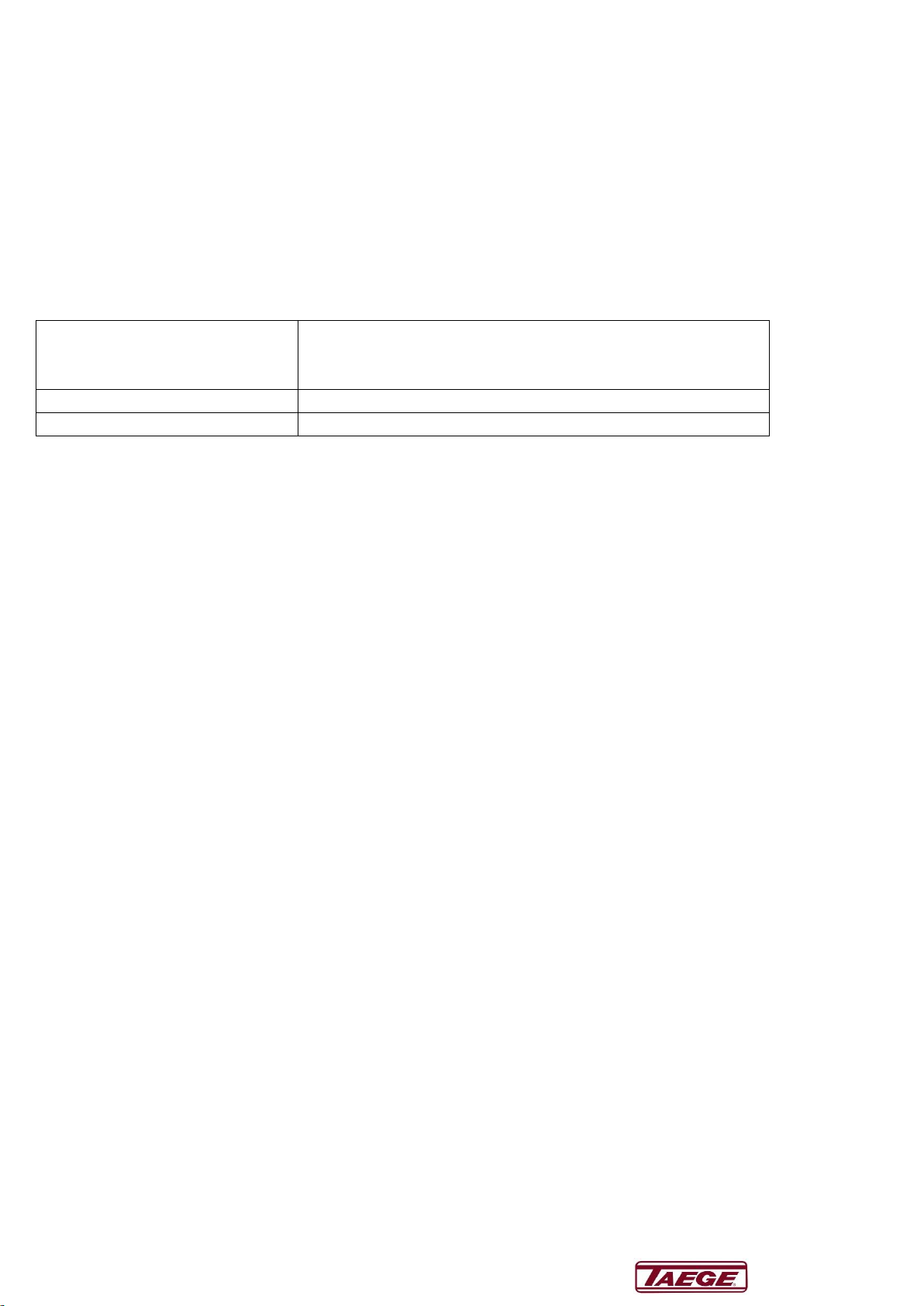

Configuration

On start up for the first time, ensure the controller is configured to the correct sowing width

and the distance settings entered if your unit has a ground speed input device. (jockey wheel.

encoded wheel or radar). This is called configuration.

Manual ground speed is available on some controllers

Please check with your Taege Dealer.

Calibration

When the operator needs “to accurately measure the weight of the seed or product” during

calibration. This is done by reading and following the instructions about calibration in the

Controller Manual.

It is most important that this is accurate, that the scales provided be used. These scales

measure in one gram increments. Care must be taken to prime the hopper before calibrating,

to make sure that no bridging occurs during calibration.

Comment: When calibrating a Taege M3 Mini Hopper, ensure that sufficient seed is weighed.

E.g. Grass at least 1.00Kg

The Air Assist Blower must be turned OFF during calibration.

Go to the Controller Owners Manual and follow the instructions about QUICK CALIBRATION

Always disconnect the power source when the controller is not in use.

Always disconnect the power source and controller when welding on the machine.

Fan Speed

If your TAEGE M3 Mini Hopper is fitted with an electric air assist blower, it is important that

this is operated continuously when seeding.

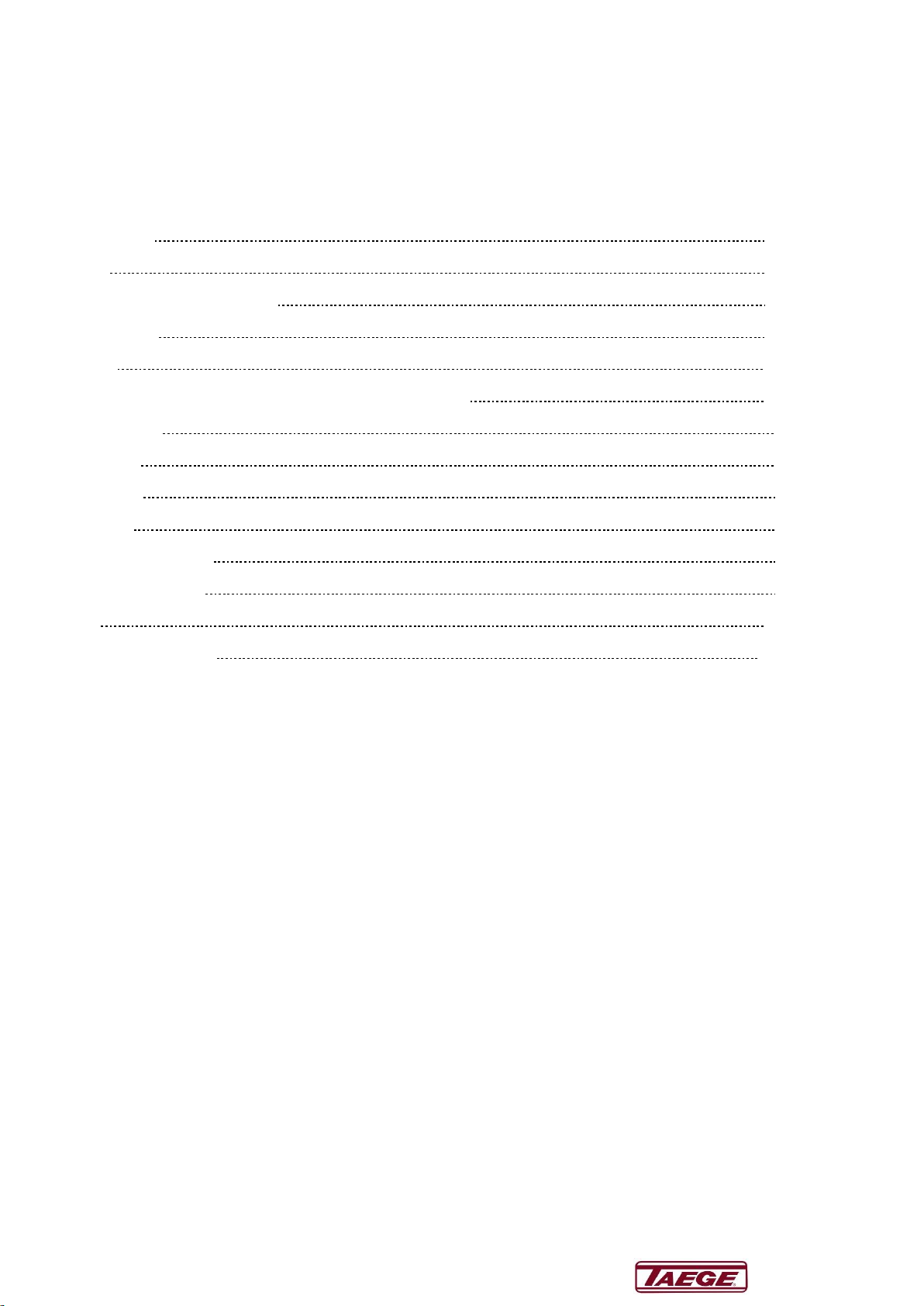

M3 Hopper Operation

Once you have set up and calibrated the machine, turn the air assist blower on (if fitted).

Press the “GO” button on the controller.

You will see a moving indicator on the top of the controller screen.