Task Force Tips Master Foam Series Quick guide

Other Task Force Tips Paint Sprayer manuals

Task Force Tips

Task Force Tips Ultimatic User manual

Task Force Tips

Task Force Tips G-Force Series Quick guide

Task Force Tips

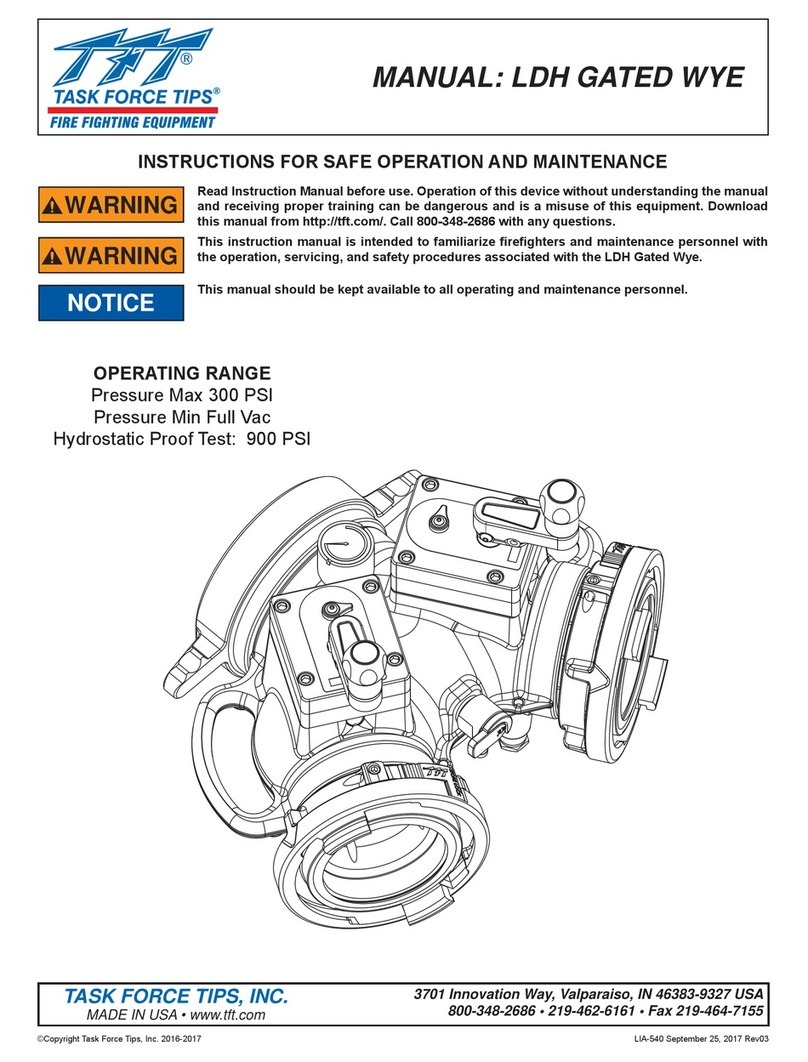

Task Force Tips LDH GATED WYE User manual

Task Force Tips

Task Force Tips METRO 1 Series Quick guide

Task Force Tips

Task Force Tips PROTECTOR Quick guide

Task Force Tips

Task Force Tips HURRICANE RC Programming manual

Task Force Tips

Task Force Tips VIT Programming manual

Task Force Tips

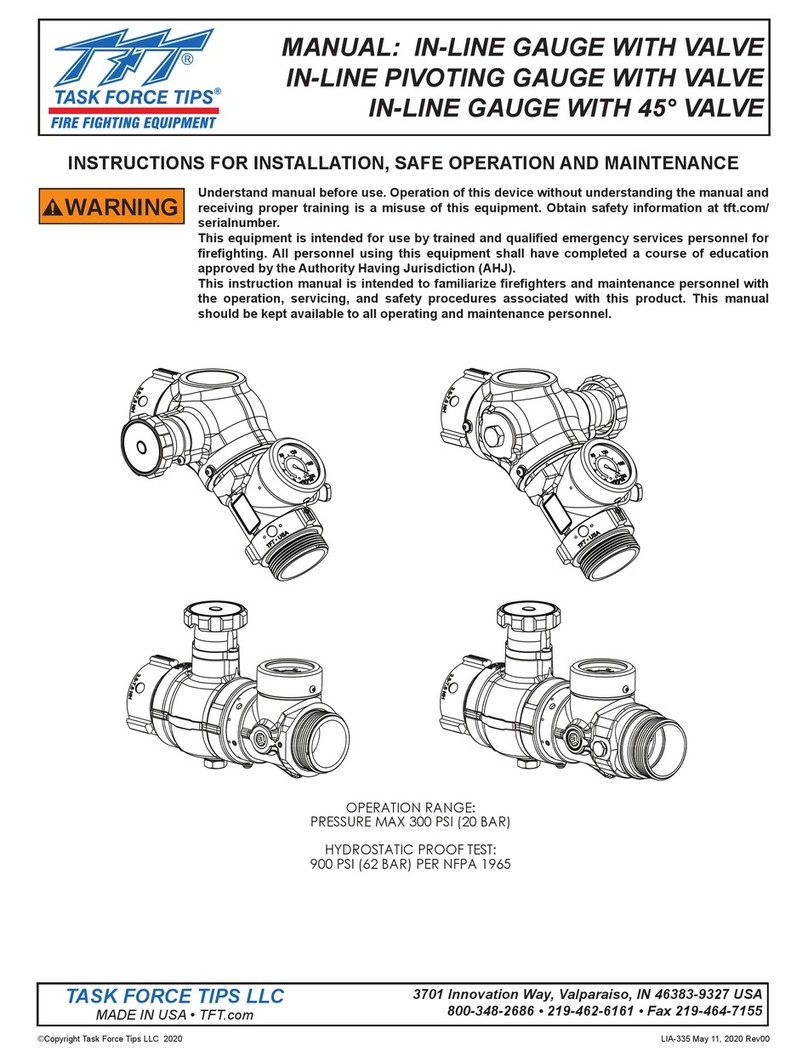

Task Force Tips IN-LINE GAUGE WITH VALVE User manual

Task Force Tips

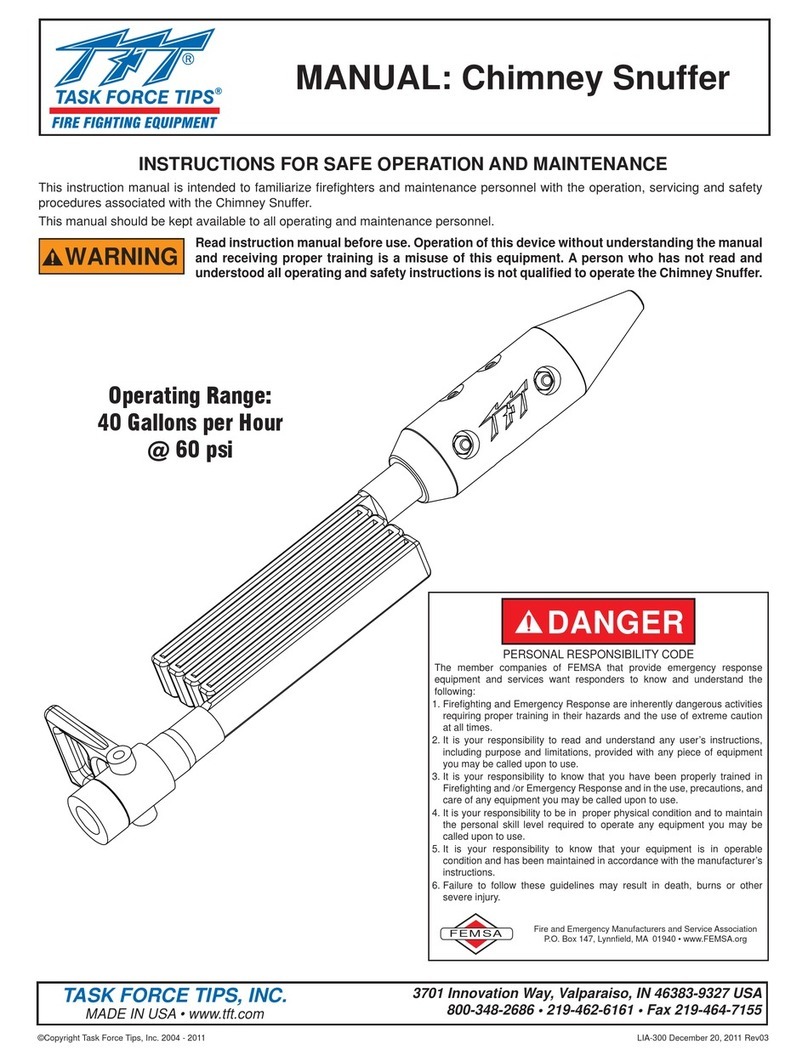

Task Force Tips Chimney Snuffer Quick guide

Task Force Tips

Task Force Tips Ultimatic Quick guide

Task Force Tips

Task Force Tips G-Force Quick guide

Task Force Tips

Task Force Tips TRANSFORMER Quick guide

Task Force Tips

Task Force Tips PRO/pak Quick guide

Task Force Tips

Task Force Tips Ultimatic Programming manual

Task Force Tips

Task Force Tips Mid-Force Quick guide

Task Force Tips

Task Force Tips MASTER Quick guide

Task Force Tips

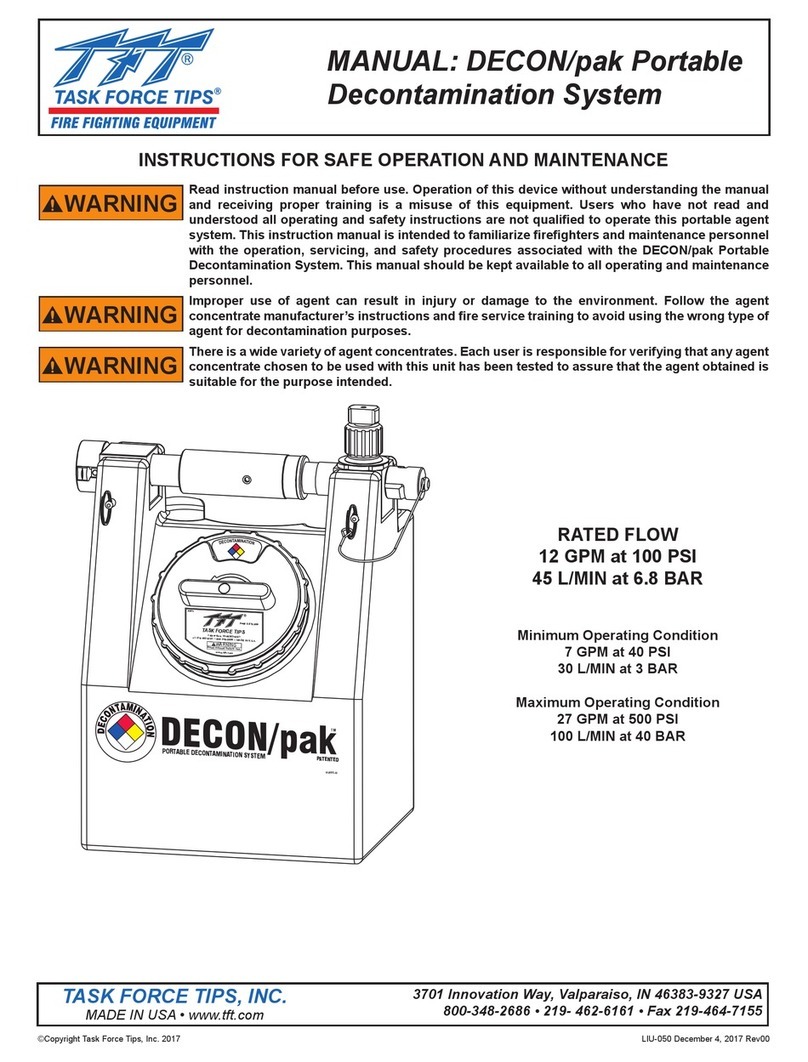

Task Force Tips DECON/pak Quick guide

Task Force Tips

Task Force Tips Masterstream Series Programming manual

Task Force Tips

Task Force Tips Masterstream Series Programming manual

Task Force Tips

Task Force Tips Twister Programming manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual