Taxitronic TX30 User manual

INTERFACOM, S.A. 22/12/2016

I3000100.DOC 26.02.96

INSTALLATION MANUAL

OF

TAXIMETER

TAXITRONIC TX30

INTERFACOM, S.A.

I3000100.DOC 2

GENERAL INDEX

1. ASSEMBLY

2. ELECTRICAL INSTALLATION

3. SEALING

4. MAINTENANCE

5. TECHNICAL CHARACTERISTICS

6. IMPULSE GENERATOR

7. ADAPTER FOR ELECTRONIC PANNEL

INTERFACOM, S.A.

I3000100.DOC 3

1. ASSEMBLY (Drawing 1)

The mechanical installation of the TX30 taximeter is very simple due to its small

size 180 x 50 x 32 mm.

It can be built in and also assembled directly on the panel or on any type of

bracket. For the assembly there are anchorages for self threading screws on the

rear part, located on the connector cover, that will enable many assembly

possibilities: wether with two screws directly onto the frontal part of the dash

board or on a support or with a unique screw located in the center of the

connector cover. (See drawing 1)

IMPORTANT:

Notice that to assembly the taximeter onto the frontal part of the

dashboard, you do not need any support: the TX30 taximeter was

designed so that it could be assembled by fixing the connector cover

directly to the dashboard, using screws fixed from the inside of the

cover. Then when the cables have been connected to the taximeter,

it is fitted back into the connector cover and the whole installation is

sealed.

The electrical installation connection outlet on the taximeter can be either on the

rear or on the lower part of the equipment, improving and facilitating assembly. It

is most important that no cable nor connection should be visible.

Try to assemble the taximeter on a rigid support with as little vibration as

possible, as in the long run this can cause a break in the contacts.

INTERFACOM, S.A.

I3000100.DOC 4

2. ELECTRICAL INSTALLATION (Drawings 2,3,4 and 5)

The electrical installation of the TX30 taximeter is similar to the one for the

previous models.

To reach the connectors, you only have to remove the CONNECTOR COVER

( First it is necessary to take out the central screw of the three screws that are on

the front of the TX30).

The TX30 has four differentiated connectors: cables and connectors for the

power supply, impulse generator and external lights are supplied with the

equipment; For the data transmission connector, the cables depend on the

external equipment to be connected.

In Drawing 2 the complete electrical installation of the TX30 is explained. The list

of the conectors from the left to the right as seen on Drawing 2 is the following:

EXTERNAL LIGHTS CONNECTOR (8 tracks)

Contact 1............. Light 6

Contact 2............. Light 5

Contact 3............. Light 4

Contact 4............. Light 3

Contact 5............. Light 2

Contact 6............. Light 1

Contact 7............. Position lights (output)

Contact 8............. Common return

FEED CONNECTOR (10 tracks)

Contact 1, 2..............Negative battery ..............................Black

Contact 3,4...............Positive battery 12V.........................Red

Contact 5..................Input................................................Yellow

Contact 6..................Input................................................Blue

Contact 7..................Light 1 .............................................Green

Contact 8..................External signal or passenger...........Violet

Contact 10................External signal.................................Brown

IMPULSE GENERATOR CONNECTOR (4 tracks)

Contact 1....................Ground...................Mesh

Contact 2....................5 V..........................Red

Contact 3....................Signal.....................Green

Contact 4....................Signal.....................Blue

DATA TRANSMISSION CONNECTOR

NOTE: The TX30-S does not have any external lights connector, since it can

control only one external light through the green cable of the feed

connector.

INTERFACOM, S.A.

I3000100.DOC 5

Drawing 3 gives an example of the simplified installation of a taximeter

controlling only an external light “FREE” or ”TAXI”. It also shows the possibility in

the case of a radio-taxi company to use the light connector L6 to inform the

central of the state of the taximeter.

Drawing 4 and 5 gives two examples of installation with a connection box and

armoured cables, which prevent to access to the installation without destroying

the seals of this connection box.

RECOMMENDATIONS FOR THE INSTALLATION OF A TAXIMETER IN A CAR:

Disconnect the positive terminal on the battery until the whole electrical

installation is completed.

Any manipulation of the taximeter or of the external lights must be done with the

taximeter desconnected from the feeding.

Always take the positive and negative of the battery direct in order to avoid false

contacts and to obtain a more filtered feed.

Always connect the cables to the battery by means of a terminal, never by

winding the wires on to the contact.

If the cables cross a plate to reach the taximeter they should go through a

protective rubber casing.

If the cables are too long they should be cut to the required length and not rolled

up under any circumstances.

Please verify that the sparking plug cables are made out of graphite, so that no

interference affect the equipment.

If the vehicle has a radio endeavor to separate its installation from that of the

taximeter as far as this is possible.

Always inspect the earth connection of the aerial and the connectors.

If it is possible no element that is connected to the taximeter should be fixed to

the same support as the aerial of the radio.

INTERFACOM, S.A.

I3000100.DOC 6

EXTERNAL LIGHTS CONNECTOR

If the external lights connector is used, each one of the cables must be welded to

the connector in such a position that they have a good contact:

RECOMMENDATIONS FOR THE PROGRAMMING OF A TAXIMETER IN A CAR:

When the installation of the taximeter in the vehicle is completed proceed to

program it using the tariff charger.

Please always connect the charger in the right position, since a wrong position

may block the microchip of the taximeter and the CPU plate.

The programming sequence is as follows:

The programming is started up with the taximeter in the For Hire

position pressing the O pushbutton in the taximeter.

Calculate the constant K by doing a trial run or introducing it directly.

Adjustment of the calendar-clock if necessary.

Tariff recording.

To have more information, see “Operation Manual for the TX30 Tariff Charger”.

INTERFACOM, S.A.

I3000100.DOC 7

3. SEALING (Drawing 6)

3.1.- SEALS OF THE TX30

The sealing of the taximeter TX30 is totally made on the left of the frontal part of the

taximeter, preventing from reaching the screws that block the accesses.

See details of the taximeter drawing below:

1 2 3

Seal Nº1: corresponds to the sealing of the box of the taximeter. Therefore it

seals the electronic plate.

Seal Nº2: seals the back cover of the connectors, that is, it seals the whole

installation of the taximeter, assembly, as well as electrical installation.

Seal Nº3: seals the cover of the tariff charger connector, which is located just on

the right hand side of this seal.

3.2.- TYPES OF SEALS (Drawing 6)

In order to adapt to all legislations, there are two options of sealing, that can be

used for any of the 3 seals of the TX30 taximeter.

A OPTION: Stamped lead seal and / or plastic seal

- For this type of seal, a flat square has to be used, in which the

stamped lead or plastic seal has to be fitted.

- The sealed screw cannot be reached without breaching the seal.

B OPTION: with seal for cable

- For this type of seal, you have to use a seal plate together with a screw

with a pierced head.

- A cable is passed through the pierced hole of each element and is

then sealed.

- The sealed screw cannot be reached without breaching the cable that

goes through the screw with pierced head.

INTERFACOM, S.A.

I3000100.DOC 8

- In Drawing 6 you can observe different sealing methods:

- Drawing 6, example 1.- Plastic seals and/or stamped lead seals to seal the box

(item1), the connector cover (item 2) and the tarif connector

cover plate (item 3).

- Drawing 6, example 2.- Cable seal to seal the box (item 1), and another to seal

together connector cover and tarif connector cover plate

(item2).

- Drawing 6, example 3.- Combination of plastic and/or lead seals and cable seals.

INTERFACOM, S.A.

I3000100.DOC 9

4. MAINTENANCE (Drawing 7 and 8))

When the TX30 does not work, the box must be opened to substitute the defective

CPU plate with an asistance plate

To open the taximeter box, there are two possibilities:

4.1. opening with the hands

4.2. opening with a tool

4.1.- OPENING WITH THE HANDS (Drawing 7)

It is the normal way to open the box.

As you see on the drawing 7, you have got to take out the screws corresponding to

the box (item 1) and to the connector cover (item 2). Afterwards you can open the

box from the side where there are the seals, following the indicated direction of the

arrows of the drawing.

4.2.- WITH A TOOL (Drawing 8)

In some cases the opening by hand (see above) is not possible because some of

the TX30 have a box that will not allow that.

In this case take the screws out from the front face, take the connector cover down

and process as indicated in Drawing 8.

TO OPEN A TAXIMETER PLEASE:

take into account that even if the taximeter is desconnected from the external

feeding source, the CPU plate is internally fed with a battery and that any short cut

could damage a component.

pay attention not to touch the plate with the hand to prevent the mirco chip to block

itself and consume all the battery.

INTERFACOM, S.A.

I3000100.DOC 10

5. TECHNICAL CHARACTERISTICS

The general technical characteristics of the TX30 are as follows:

Feed voltage nominal = 12 V

maximum = 16 V

minimum = 8 V

Maximum consumption without external lights = 250 mA

Maximum consumption taximeter off = 25 mA

Maximum consumption inside battery = 5 A

Maximum power 36 W for each external light of 60 W in case that 3 outputs are

connected in parallel.

Impulse generator feed = 5 V

Impulse generator inlet signal: level 0 = -1 to 2,5 V

level 1 = from 4 to 25 V

Maintenance of the information disconnected from the vehicle’s battery = 5 years

45 V surges with a duration of 10 ms.

Resistance to electrostatic shocks of 7 kv.

Protection against inverse incorporated connection

Internal protective fuse of 6,3 A and 1 for protecting the CPU of 400 mA.

External fuse of 4 A.

Operational temperature - 20 to +70º C

Storage temperature for keeping the information - 40 to + 85º C

Dimensions 180 x 50 x 32

Approximate weight 204 gr.

"K” constant of the device from 400 until 80000 pulses per Km/ml.

NOTE: For the TX30-S the maximum power for the external light is: 36 W.

INTERFACOM, S.A.

I3000100.DOC 11

6. IMPULSE GENERATOR

6.1.- INTRODUCTION

For the vehicles with mechanical speedometer, you have to use a pulse generator

that is managed by the taximeter.

The pulse generator is inserted in the cable of the speedometer and converts the

mechanical movement of this cable in an electrical signal, which is amplified and

filtered by the taximeter.

6.2.- INSTALLATION (Drawing 9 and 10)

6.2.1. ASSEMBLY OF THE SPEEDOMETER CABLE AND PULSE GENERATOR

(Drawing 9)

First of all part of the protecting cover of this cable must be removed and the cable

must be cut (Drawing 9, item1)

A fixing ring must be put in each of the two extremities of the cable (Drawing 9,

item 2 ) and a square end (Drawing 9 item 3) on both parts that will be fixed by

pressing them on the part indicated in Drawing 9 item 4 with the appropriate pincers

(Drawing 9 item 7) in position “A” or “B“ of depending on the size of the square end.

Afterwards put the cover ends (Drawing 9 item 5) and press them on the part

indicated in Drawing 9 item 6 in the position “C” of the pliers.

Finally all pieces are assembled screwing together the two fixing rings (Drawing 9

item 9) taking into account that the separating space indicated in item 8 Drawing 9

must be sufficient.

6.2.2. CABLE CONNECTION, COVER CLOSING AND PULSE GENERATOR

SUPPORT (Drawing 10)

To connect the pulse generator cable it is necessary to open the pulse generator

cover (Drawing 10 item 1) after taking the closing screw out and moving the cover

in the right direction indicated by the arrow. Connect the cable as indicated on the

Drawing 10 item 2 taking into account the polarity of the connector.

Finally put the pulse generator cover back, fix it or seal it, if it is necessary (Drawing

10 item 3) and place the pulse generator in the corresponding holder (Drawing 10

item 4).

INTERFACOM, S.A.

I3000100.DOC 12

6.3.- SEALING (Drawing 11)

The pulse generator also has got different sealing possibilities. Three of these

possibilities are showed in Drawing 11.

6.4.- TECHNICAL CHARACTERISTICS

The main technical characteristics of the pulse generator are:

sensor type: Hall effect cell

Number of pulses / revolution: 4 with double impulses train

Feeding voltage: 4 to 18 V

Consumption at 5 V: 10 mA

INTERFACOM, S.A.

I3000100.DOC 13

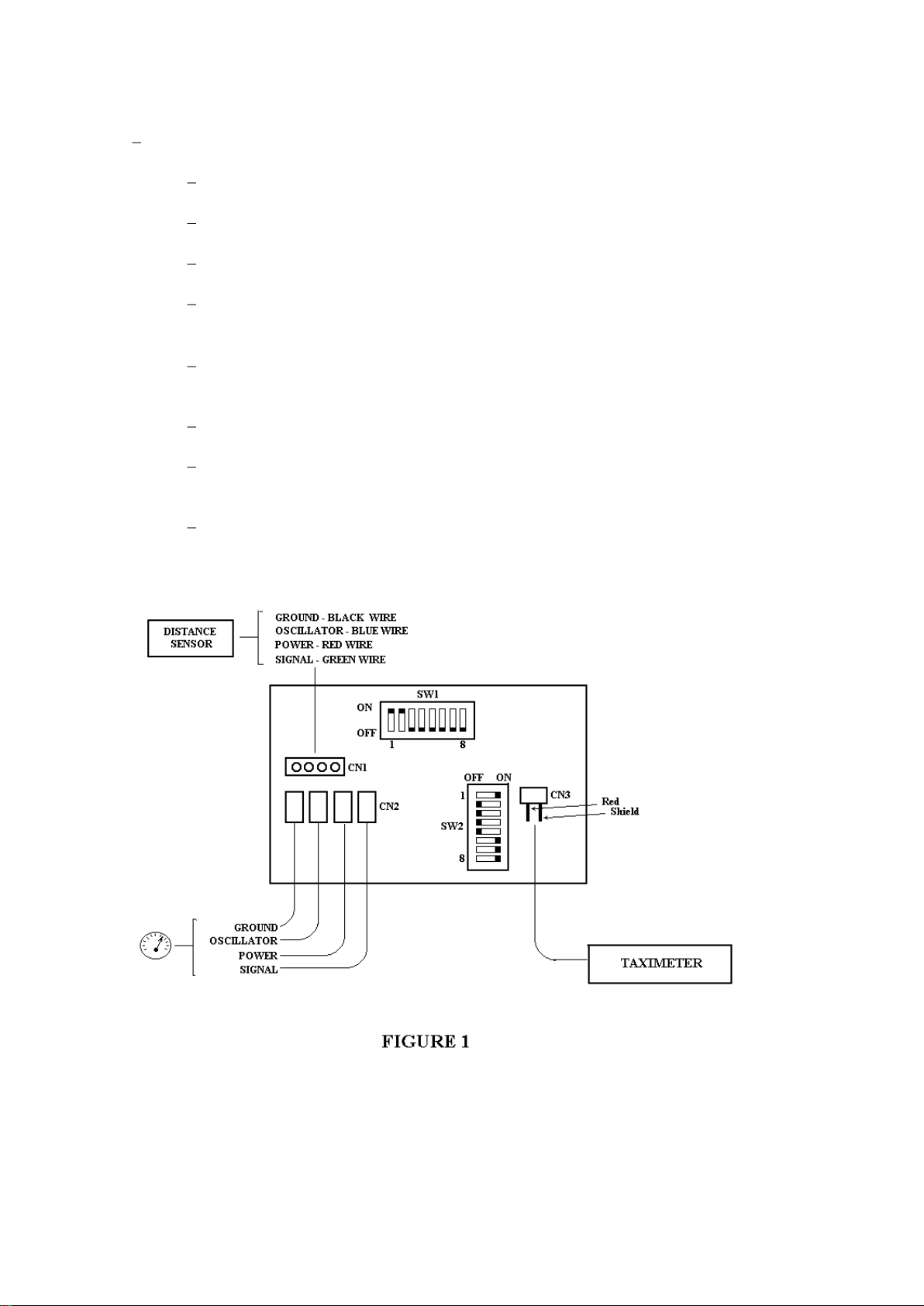

7.- VEHICLES WITH ELECTRONICAL SPEEDOMETER

7.1.- INTRODUCTION

In the case of the vehicles equiped with electronical speedometer, the taximeter can

be connected to these sensors with a sealable adaptor, which ensures the fiability of

the system.

This equipment consists of one circuit which is inserted between the distance sensor of the

car and its speedometer. This circuit gets the signal which is sent by the distance sensor,

sends an identical signal to the speedometer and another signal to the taximeter according to

its input characteristics.

Usually the distance sensor is placed in the gearbox. In some cars, it can also be placed in

the transmission differential.

7.2.- INSTALLATION.

Before connecting the equipment to the car, you have to make the following:

Localize the distance sensor of the vehicle.

Identify the cables that connect this sensor to the car speedometer.

Search which of these cables corresponds to the ground, the power and the

distance signal in order to connect them correctly to the adapter.

Some cars have a cable which has a signal (oscillator) that the sensor uses

like a carrier to modulate it in amplitude.

See which kind of signal sends the sensor to the speedometer to configurate

the adapter jumpers in order it works correctly. Diagram 1 shows the

different signals that adapters can give.

Figure 1 shows the printed circuit of the adapter indicating the jumpers and

connections of the cables to the circuit.

INTERFACOM, S.A.

I3000100.DOC 14

Equipment installation is made as follows:

Disconnect the cable which joins the vehicle sensor to the speedometer by

the side of the sensor. Usually, it is placed in the gearbox.

Put the rubber washer enclosed in the adapter circuit in this cable in order it

remains well fixed.

This cable must be solded in the contacts foreseen in the adapter circuit

(CN2).

These contacts are: Ground, Oscillator, Power and Signal. If the car sensor

does not have one of these signals, the corresponding contacts will

remain empty.

Connect the cable that is delivered with the adapter, to the CN1 connector

and at the other end the distance sensor, making the same contacts that you

have done previously.

Cover the connections made with the thermoretractable cable enclosed and

apply heat to seal it and prevent modifications.

Connect the taximeter to the adapter circuit in connector CN3 by means of

the cable enclosed. The cable must be connected leaving the shield and the

red cables at the top part.

Verify that the taximeter works correctly and adjust the constant "K" of the

taximeter with the tariff charger.

INTERFACOM, S.A.

I3000100.DOC 15

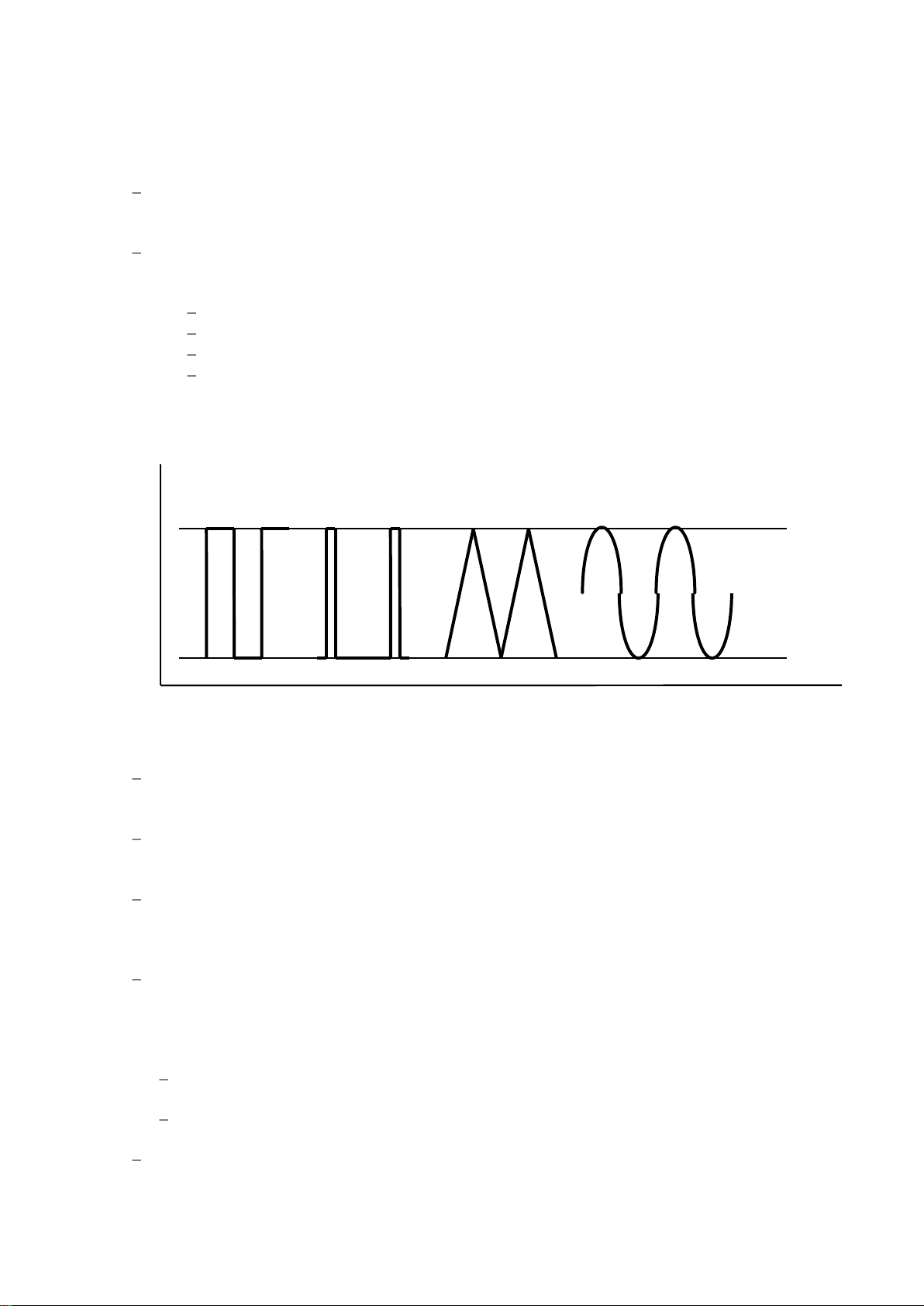

7.3.- JUMPERS CONFIGURATION.

The equipment is configurated with the jumpers in order it can be adapted to the

different sensors which are in the vehicles.

The adapters delivered from the factory are configurated in order to work correctly

with a signal of the following characteristics:

Level 0 < 1,5 v.

Level 1 > 3,5 v.

Hysteresis = 2 v.

The signal can have any shape (Squared, Impulses, Senoydal, Triangular,

etc.) if the levels 0 and 1 are between the values described above.

LEVEL1

LEVEL0

SQUARED IMPULSES TRIANGULAR SINE

D IAG R AM 1

DIFFERENTSSHAPESOFTHESIGNAL:

If the levels 1 or 0 are not the above described, jumper SW2-P8 must be removed

in order the adapter looks for the average value of the signal internally.

If the signal given by the sensor is very weak, jumper SW2-P7 must be removed in

order to reduce the Hysteresis of the circuit.

Jumper SW1-P1 must be only made when the sensor doesn't have the correct

ground, when there are potential differences between the taximeter ground and the

sensor ground.

After having connected the sensor to the adapter circuit as described, we have to

check if the distance signal has still the same tension and if the impulses appear

correctly. If this signal disappears or the tension is not correct you will have to make

the following:

If the signal wire remains fixed in level 0 (between 0 and 1 volts), make jumpers

SW1-P3, SW1-P7 and remove jumper SW1-P2.

If the signal wire is fixed in level 1 (between 5 and 12V), make jumper SW1-P5.

If the signal given by the sensor is moduled in amplitude (diagram 2) jumper SW2-

P1 must be removed and jumper SW2-P2 must be made.

INTERFACOM, S.A.

I3000100.DOC 16

D IAG R A M 2

SIGNALMODULEDINAMPLITUDE

Some vehicles Renault use a coil in distance sensor and then need an oscillator to

operate the coil correctly. To install the adapter in these cars you have to make the

following:

Make jumpers SW1-P1, SW1-P2, SW1-P4, SW1-P6, SW1-P8, SW2-P1

and SW2-P6.

Remove the other jumpers.

Connect the sensor coil in CN1 connector, by one side to the power and by

the other side to the oscillator. Connect the shield of the distance sensor

cable to the ground of CN1.

Connect the signal cable of the pannel in connector CN2. Connect the shield

of the pannel cable to the ground of CN2.

If the constant "K" of the vehicle is bigger than the maximum permitted by the

taximeter, the internal impulses divisor will have to be used. Jumpers configuration

of this diviser is as follows:

Without being divided SW2-P6

Divided by 2 SW2-P3

Divided by 4 SW2-P4

Divided by 8 SW2-P5

Only one of these four jumpers can be made.

Figure 1 shows the standard configuration of jumpers. If any of the jumpers has

been changed and it still does not work, we recommend to put again the standard

configuration before making more proves, because some jumpers configurations

are incompatibles.

7.4.- SEALING (Drawing 12)

The adaptor for electronic pannel has got two sealing possibilities that are showed

in Drawing 12.

Table of contents

Other Taxitronic Measuring Instrument manuals