9.2 Commissioning VPPI-...-A.../-V...-S1BT

The product variants VPPI-...-A.../-V...-S1BT have a Bluetooth interface for param-

eterisation. Parameterisation takes place via the Festo Automation Suite plug-in

and is described in the manual VPPI-...-A.../-V...-S1BT è 1 Applicable documents.

The Bluetooth interface is permanently active. The Bluetooth connection must

therefore be secured against unauthorised access.

• Protect the Bluetooth connection with a password.

The password function in the plug-in in the Festo Automation Suite is described in

the manual VPPI-...-A.../-V...-S1BT è 1 Applicable documents.

9.3 Commissioning VPPI-...-LK/-PT-S1

The product variants VPPI-...-LK/-PT-S1 have an IO-Link/I-Port interface for param-

eterisation and process data transmission. Parameterisation and the required

configuration files are described in the manual VPPI-...-LK/-PT-S1 è 1 Applicable

documents.

10 Malfunctions

10.1 Diagnostics

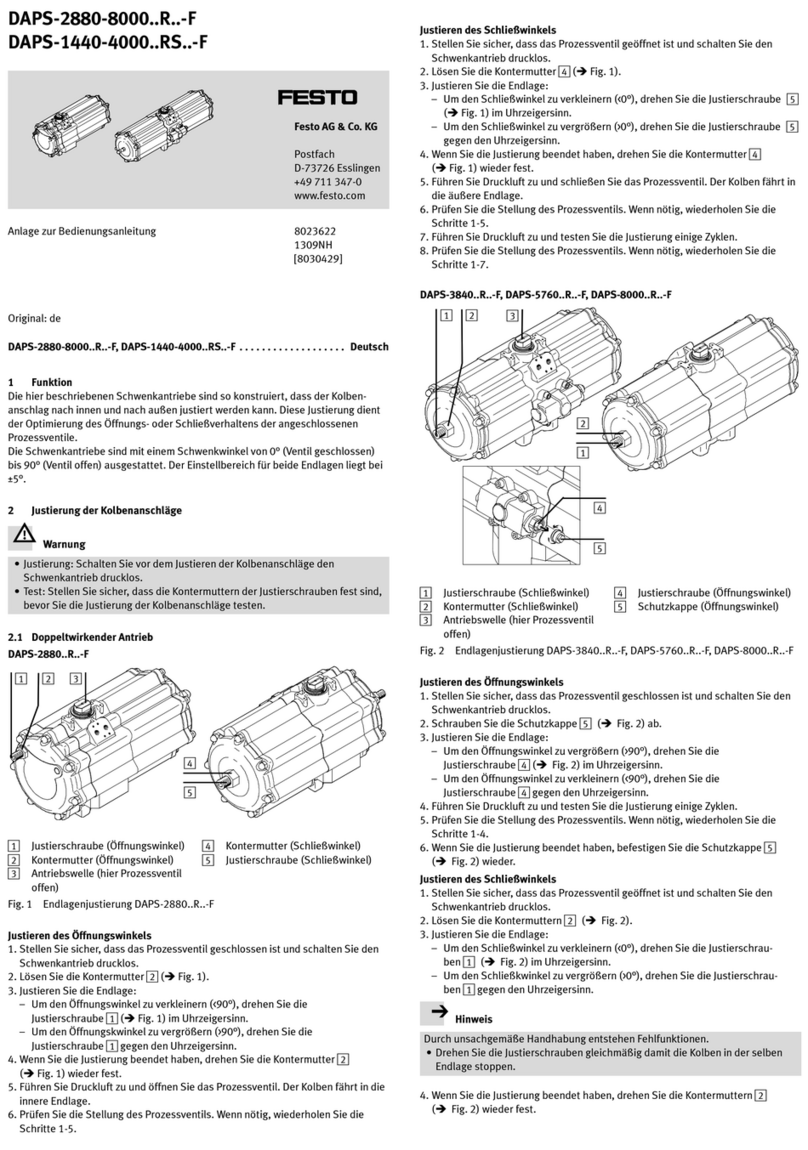

The following table describes the diagnostics with the LED operating status è Fig.

1, [7].

The product variants VPPI-...-PT-S1 with I-Port interface do not have LEDs. Infor-

mation on the operating status is displayed by the connected CTEU bus node

è Documentation of the CTEU bus node.

LED Status and meaning

LED lights green:

–The operating voltage is present and within the permissible range.

–Setpoint signal lies within the permissible range (0 … 10.8 V or 2.5 … 20.5 mA).

LED lights red:

–Working temperature is too high.

–Valve is in temperature shut-off.

LED flashes red:

–Supply voltage is too high

LED flashes alternately red and green in the ratio 1:1:

–Analogue setpoint value is too high.

–Cable break setpoint input

LED flashes alternately red and green in the ratio 1:5:

–Temperature is critical

–Power reduction active

LED is off:

–No operating voltage.

–The operating voltage is below the permissible range (< 20.4 V).

LED flashes green at a ratio of 1:9, VPPI-...-LK-S1:

–IO-Link connected

LED flashes green at a ratio of 1:1, VPPI-...-S1BT:

–Bluetooth connected

Tab. 6: Operating status LED

10.2 Fault Clearance

Error description Cause Remedy

Valve does not respond. Operating voltage not applied. Check the operating voltage

connection.

No setpoint voltage. Check the controller and con-

nection.

Working temperature is too

high. Valve is in temperature

shut-off.

Switch off the valve, let it cool

down and restart.

Reduce ambient temperature

and / or temperature of

medium.

Valve normally open:

The working pressure at (2)

falls to the level at (3) (ambient

pressure or vacuum).

Cable break setpoint input Check connection to setpoint

generator.

Replace supply cable.

Valve normally closed:

The working pressure at (2)

deviates upwards or down-

wards from the setpoint value

(working pressure is neither

pressurised nor exhausted).

Cable break setpoint input Check connection to setpoint

generator.

Replace supply cable.

Setpoint value not reached. Input pressure at (1) is too low. Increase input pressure at (1).

Maintain permissible maximum

operating pressure è 12 Tech-

nical data.

Tab. 7: Fault Clearance

11 Disassembly

1. Specify setpoint value 0 bar (0 MPa).

2. Switch off compressed air supply.

3. Switch off operating voltage.

4. Remove electrical connecting cables.

5. Remove compressed air lines.

6. Dismantle the product.

12 Technical data

An individual test report is created for products of the variant VPPI -...- T. This

test report can be found in the Support Portal (FoX) by entering the product key

www.festo.com/sp.

General technical data

Valve function 3-way proportional-pressure regulator

Mounting position any

Product weight [g] 370

Approvals RCM

KC

Materials

Seals HNBR

Housing Reinforced PA

Tab. 8: General technical data

Operating and ambient conditions

Ambient temperature [°C] 0 … 50

Storage temperature [°C] –20 … +70

Temperature of medium [°C] 0 … 50

Degree of protection IP65

Operating medium Compressed air in accordance with

ISO 8573-1:2010 [7:4:4]

Inert gas

Information on the operating

medium

lubricated operation not possible

Climate class in accordance

with EN 60721

3k3

Nominal operating altitude < 3000 m above MSL

Vibration resistance/shock resistance (in accordance with IEC 60068)

Note Explanation of the severity levels (SL) è Tab. 10 Type

of severity level (SL)

Vibration (part 2-6) Individual valve fastened with screws: SL2

Individual valve on H-rail: SL1

Linkage of max. 3 valves with lateral screw mounting:

SL2

Linkage of max. 5 valves with lateral screw mounting:

SL1

Shock (part 2 – 27) Individual valve fastened with screws: SL2

Individual valve on H-rail: SL1

Linkage of max. 3 valves with lateral screw mounting:

SL2

Linkage of max. 5 valves with lateral screw mounting:

SL1

Tab. 9: Operating and ambient conditions

Type of severity level (SL)

Vibration load

Frequency range [Hz] Acceleration [m/s2]Deflection [mm]

SL1 SL2 SL1 SG2 SL1 SL2

2 … 8 2 … 8 – – ±3.5 ±3.5

8 … 27 8 … 27 10 10 – –

27 … 58 27 … 60 – – ±0.15 ±0.35

58 … 160 60 … 160 20 50 – –

160 … 200 160 … 200 10 10 – –

Shock load

Acceleration [m/s2]Duration [ms] Shocks per direction

SL1 SL2 SL1 SL2 SL1 SL2

±150 ±300 11 11 5 5

Continuous shock load

Acceleration [m/s2]Duration [ms] Shocks per direction

±150 6 1000

Tab. 10: Type of severity level (SL)

Characteristic pneumatic values

Product type Input pressure at (1)1) Operating pressure at (1)2)

[MPa] [bar] [MPa] [bar]

VPPI-...-1V0H-... 0 … 0.6 0 … 6 0 … 0.2 0 … 2

VPPI-…-1V1H-… 0 … 0.6 0 … 6 0.1 … 0.2 1 … 2

VPPI-…-0L2H-… 0 … 0.6 0 … 6 0.2 … 0.4 2 … 4

VPPI-…-0L6H-… 0 … 1.3 0 … 13 0.6 … 0.8 6 … 8