408-8851

2of 3

Rev C

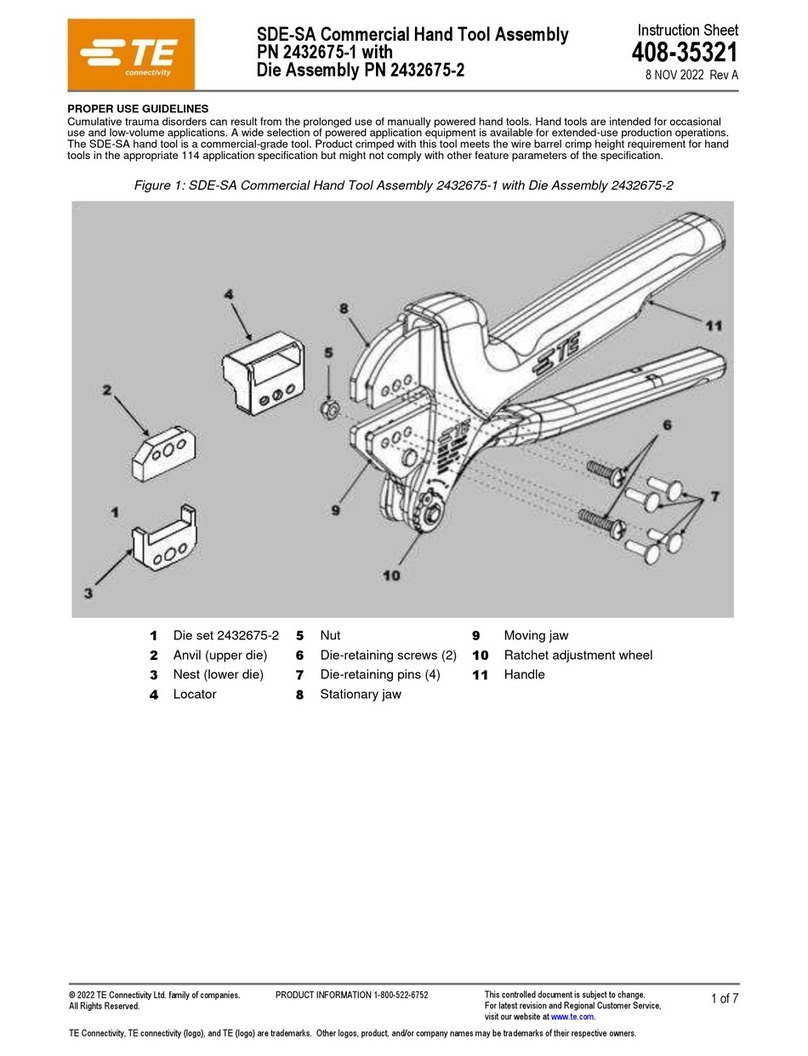

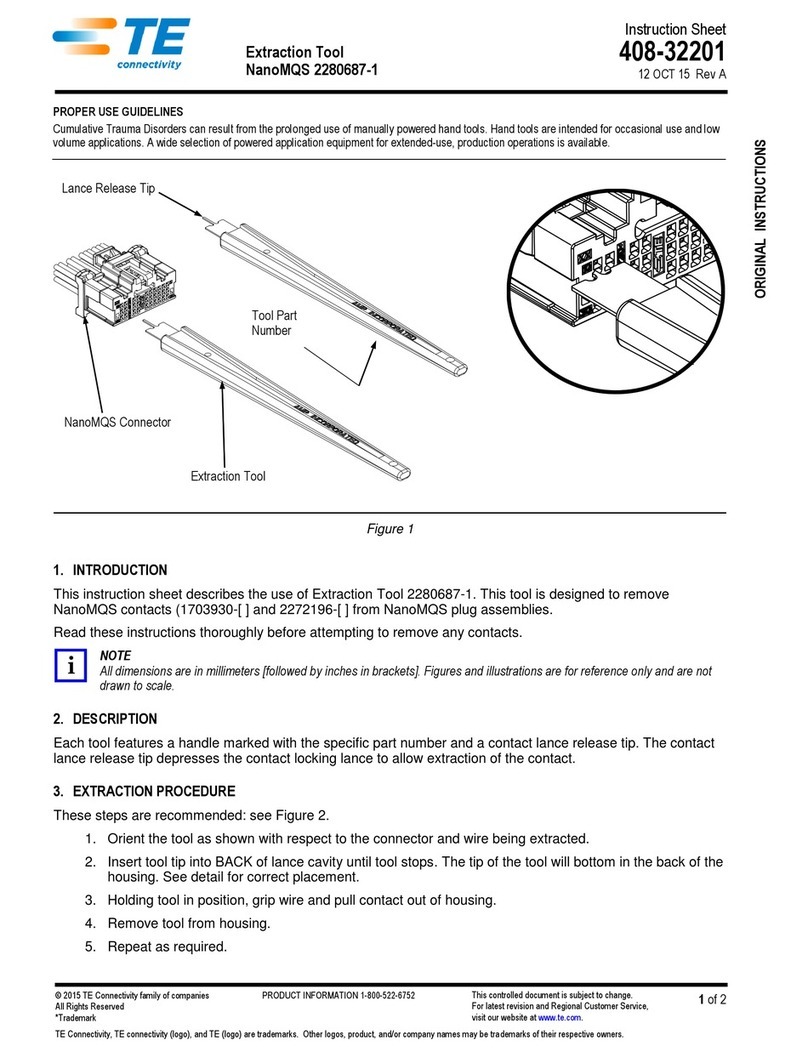

Die assemblies with center contact crimp sections

should be installed with the center contact crimp

section toward the front of the tool jaws as shown in

Figure 2. If indicated otherwise in other instructions,

follow the specific die requirements demonstrated

in that document.

3. Place the lower die in the moving jaw of the tool

frame. Install a die retention screw through the jaw

and die and tighten the screw so that the die is held

in place, but do not tighten the screw completely at

this point.

The SDE PEW 12 tool ratchet has detents that are

audible as six "clicks" as the handles are closed.

The ratchet releases on the sixth "click."

4. Slowly close the tool handles, allowing the dies to

mate and/or align. Continue closing the tool handles

until the ratchet makes the fifth "click," then tighten

both die retention screws until snug.

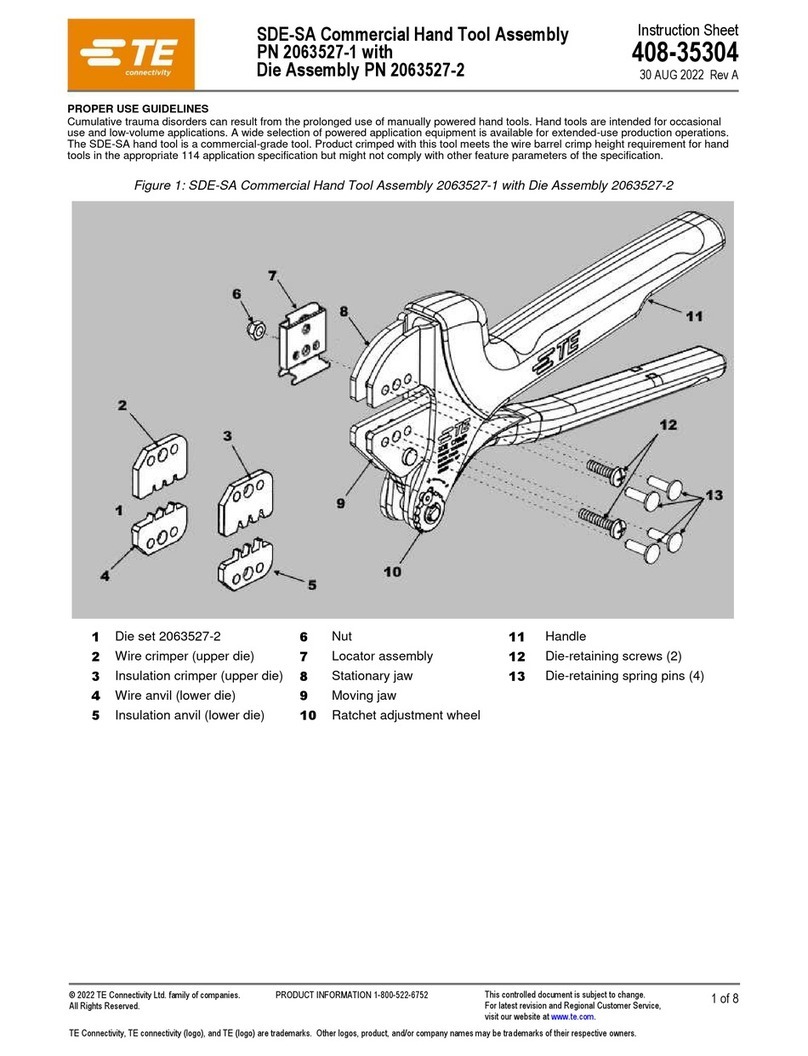

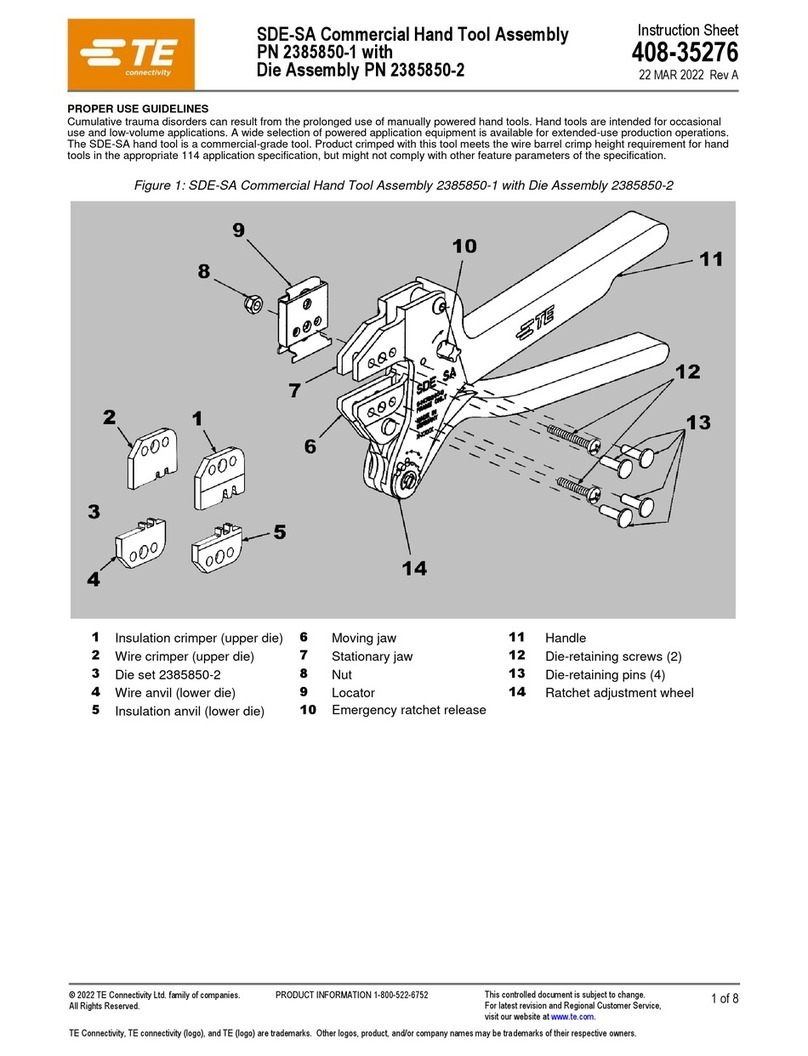

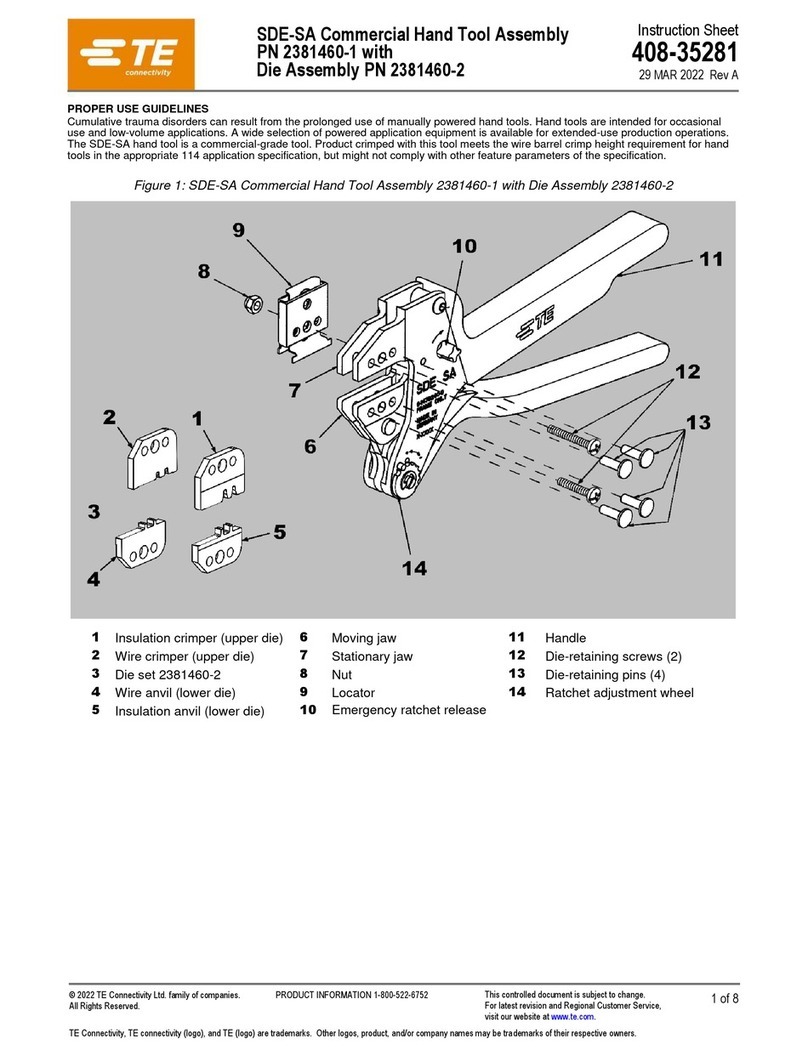

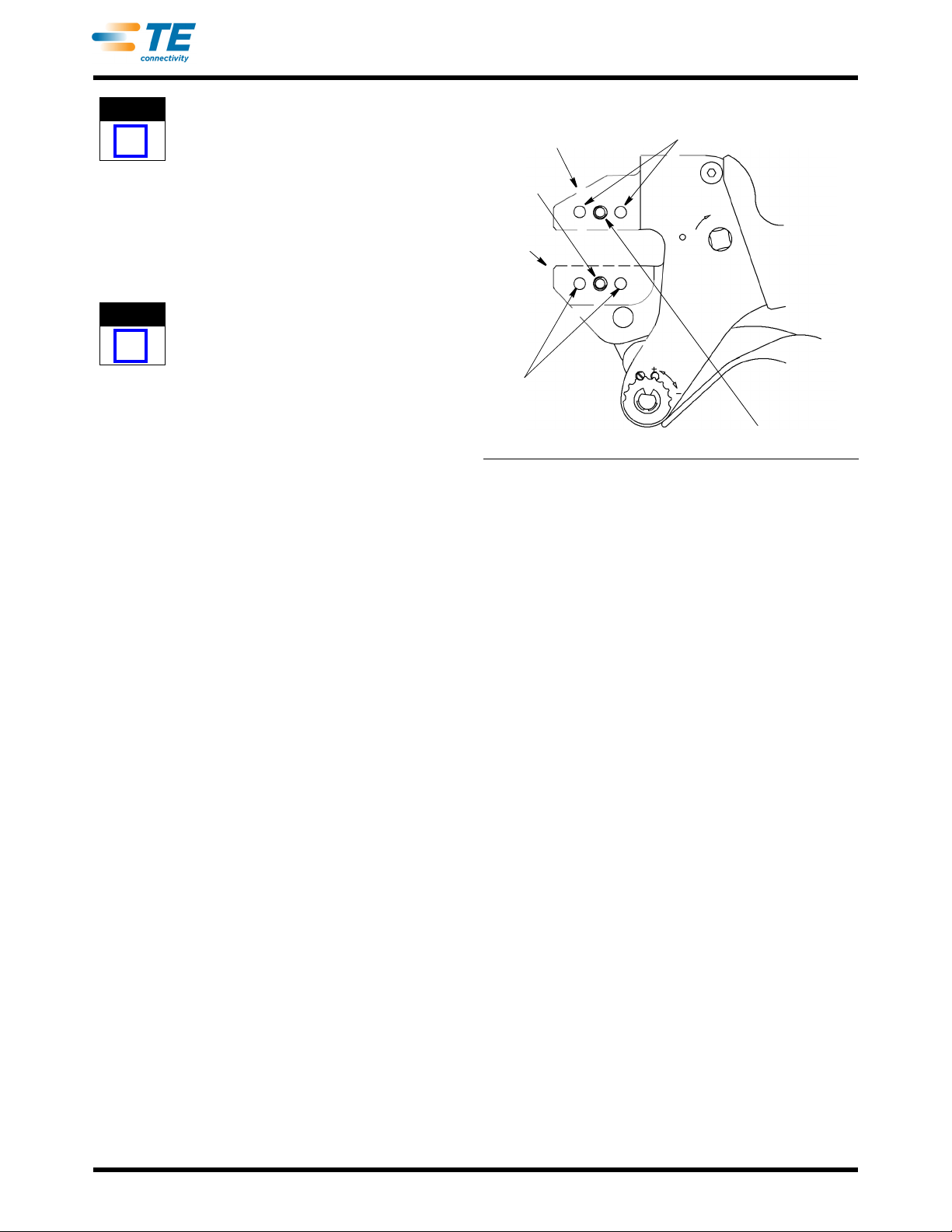

3.2. Installation of Pinned Dies (Figure 3)

1. Install the wire and insulation anvil dies with the

chamfers facing the front of the tool and the die

markings facing outward into the movable jaw of the

frame assembly.

2. Insert the die retaining pins and the short die

retention screw. Do not tighten the screw

completely.

3. Install the wire and insulation crimper dies, with

the chamfers facing the front of the tool, and with

the die markings facing outward into the stationary

jaw of the frame assembly.

4. Insert the die retaining pins and the long die

retention screw. Do not tighten the screw

completely.

5. Slowly close the tool handles allowing the dies to

mate and/or align. Continue closing the tool handles

until the ratchet makes the fifth "click," then tighten

both die retention screws until snug.

3.3. Removal

To remove the die assemblies, close the tool handles

until the tool ratchet releases, and allow the handles to

open fully. Reverse the installation procedure(s).

4. MAINTENANCE/INSPECTION

4.1. Daily Maintenance

TE recommends that operators of the tool be made

aware of, and responsible for, the following steps of

daily maintenance:

1. Remove dust, moisture, and any other

contaminants from the tool with a clean, soft brush,

or a clean, soft, lint-free cloth. Do NOT use hard or

abrasive objects that could damage the tool.

Figure 3

2. Make certain that the pivot pins are in place and

that they are secured with retaining rings.

3. All pins, pivot points, and bearing surfaces should

be protected with a thin coat of any good SAE† 20

motor oil. Do not oil excessively.

4. When the tool is not in use, keep handles closed

to prevent objects from becoming lodged in the

crimping jaws. Store the tool in a clean, dry area.

4.2. Periodic Inspection

Regular inspections of the tool should be performed

by quality control personnel. A record of scheduled

inspections should remain with the tool or be supplied

to supervisory personnel responsible for the tool.

Inspection frequency should be based upon amount of

use, working conditions, operator training and skill,

and established company standards.

1. Remove all lubrication and accumulated film by

immersing the tool (handles partially closed) in a

suitable commercial degreaser that will not affect

paint or plastic material.

2. Make certain that all pivot pins are in place and

secured with retaining rings.

3. Close tool handles until ratchet releases and then

allow them to open freely. If they do not open

quickly and fully, the spring is defective and must be

replaced.

Insert Upper Die

Insert

Lower

Die

Short Die

Retention

Screw

Die

Retaining

Pins

Die Retaining Pins

Long Die Retention Screw