Tegam 840A User manual

840A, 845, 850, 855

Digital Temperature Calibrator - Thermometer

MODEL 840A, 845, 850, 855

This owner’s manual was as current as possible when this product was manufactured. However,

products are constantly being updated and improved. Because of this, some differences may occur

between the description in this manual and the product you received.

Instruction Manual

PN# 840A-901-01CD

Publication Date: November 2019

REV. M

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

I

TABLE OF CONTENTS

TABLE OF CONTENTS

General Information

Common Specifications ...................................................................... .................... 1

Unique Specifications .............................................................................................. 4

Features ............................................................................................................... 5

Manual Addenda .................................................................................................... 5

Unpacking and Inspection ....................................................................................... 6

Safety Information ................................................................................................. 6

Safety Precautions ................................................................................................. 6

Battery Installation/Replacement ..............................................................................8

Memory Backup .................................................................................................... 9

Operation with Rechargeable Battery....................................................................... 9

Operating Instructions ............................................................................................ 9

1. Diagnostics and Error Messages .................................................................... 9

2. Initial Turn On .......................................................................................... 11

3. Meter Mode Operation (Thermocouple) ........................................................ 12

4. Meter Mode Operation (RTD, Thermistor, Ohms) ........................................... 12

5. Data Logging & Recall ............................................................................... 14

6. Calibrator Mode Operation (Thermocouples) ................................................. 16

7. Calibrator Mode Operation (RTD, Thermistor, Ohms) ...................................... 17

8. Storage and Recall of Calibrator Settings ..................................................... 19

9. Step Function ........................................................................................... 20

10. Ramp Function ........................................................................................ 20

Service Information

1. Calibration Procedures ............................................................................... 21

A. Thermocouple Calibration ...................................................................21

B. Resistance Calibration ........................................................................26

2. Calibration Verification ............................................................................... 30

3. Mechanical Parts Diagram .......................................................... ............. .. 36

Warranty................................................................. .......................................... 37

Limitation of Warranty.......................................................................................... 37

Statement of Calibration .......................................................................... .............37

MAINT

E

N

A

NCE

INST

RUCT

IONS

W

I

T

H

I

N

T

HIS

M

ANUA

L

A

R

E

F

O

R

US

E

B

Y QUA

L

I

F

IED

SE

RVICE

P

E

RSO

NN

EL

O

N

L

Y

.

D

O

NO

T

AT

T

E

MPT ANY

S

E

R

V

I

C

I

N

G

OTH

E

R

THAN THAT

CO

NTAIN

E

D

IN

T

H

E

O

P

E

R

ATI

O

N

INST

RUC

T

IONS

UNLE

SS

Y

O

U

ARE

QUALIFIE

D

T

O

D

O

SO

.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1

GENERAL INFORMATION

GENERAL INFORMATION

This manual provides operating instructions and maintenance information for four temperature

instruments. These instruments are high performance calibrator-thermometers capable of

simulating and measuring a wide-variety of sensors. In addition, features such as data storage

and ramping further enhance their versatility.

It is recommended that you read this manual thoroughly, especially the sections on safety, prior

to operating these instruments.

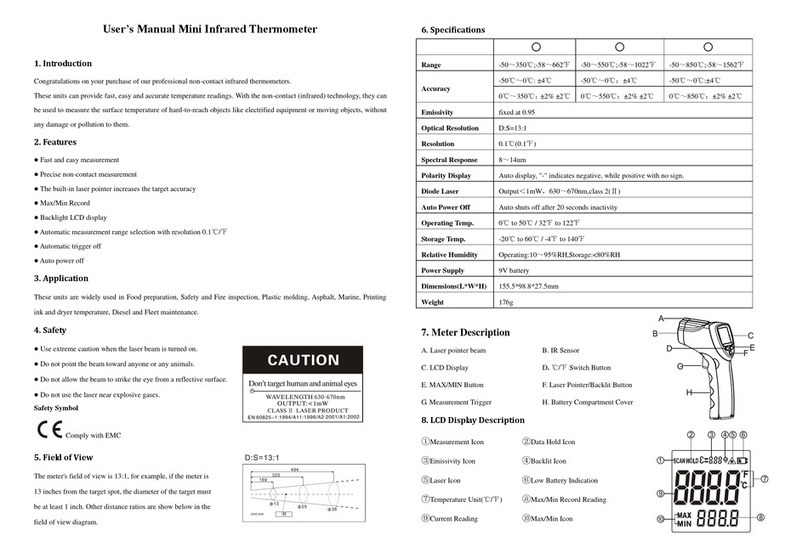

COMMON SPECIFICATIONS

THERMOMETER INPUTS: THERMOCOUPLE; Miniature TC jack. RTD, OHMS, THERMISTOR; T-

series instrumentation connector.

CALIBRATOR OUTPUTS: THERMOCOUPLE; Miniature TC jack. RTD, OHMS, THERMISTOR; T-

series instrumentation connector.

THERMOCOUPLE TYPES: K, J, T, E, N, B, R, S, G, C, D.

RTD TYPES: 100Ωplatinum (α= 0.00385)

1000Ωplatinum (α= 0.00385)

THERMISTOR TYPE: 2252Ω(YSI Series 400).

RANGES: K; -200°C to 1372°C, -328°F to 2502°F

J; -210°C to 760°C, -346°F to 1400°F

T; -200°C to 400°C, -328°F to 752°F

E; -230°C to 1000°C, -382°F to 1832°F N; -200°C to 1300°C, -328°F to 2372°F

B; 500°C to 1820°C, 932°F to 3308°F R; 0°C to 1768°C, 32°F to 3214°F

S; 0°C to 1768°C, 32°F to 3214°F

G; 300°C to 2316°C, 572°F to 4201 °F C; 0°C to 2316°C, 32°F to 4201 °F

D; 0°C to 2316°C, 32°F to 4201 °F RTD; -200°C to 850°C, -328°F to 1562°F

THERMISTOR; -40°C to 150°C, -40°F to 302°F

OHMS; 0-999.99

Ω

0-9,999.9

Ω

0-99,999

Ω

ACCURACY: All stated accuracies are exclusive of sensor errors and lead resistance induced

errors. Refer to 'UNIQUE SPECIFICATIONS' for detail accuracy specs.

RESOLUTION: TEMPERATURE; 0.1 °/1° F/C

OHMS; 0.01Ω/0.1Ω/1Ω

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2

GENERAL INFORMATION

REPEATABILITY (1 week at constant ambient temperature):

K, J, T, E, N; ±0.2°F typ.

B, R, S, G, C, D; ±1.0°F typ.

RTD, THERMISTOR; ±0.1 °F typ.

OHMS; ±0.01 % rdg typ.

METER-MODE INPUT-CURRENT (THERMOCOUPLES): 50nA typ.

METER-MODE READING-RATE: 1 reading/second typ.

METER-MODE EXCITATION-CURRENTS:

100ΩRTD; <2mA

1000ΩRTD; <200

μ

A

999.99Ω; <2mA

9999.9Ω; <200

μ

A

99999Ω; <50

μ

A

THERMISTOR; T ≤113°F <50

μ

A

T> 113°F, <2mA

CALIBRATOR MODE OUTPUT LOAD (THERMOCOUPLES): 500Ωmin.

CALIBRATOR-MODE EXCITATION-CURRENTS:

100ΩRTD; 0.5 - 1mA (0.1 - 2mA typ.)

1000ΩRTD; 50 - 100μA (10-200μA typ.)

999.99Ω; Same as 100ΩRTD

9999.9Ω; Same as 1000ΩRTD

99999Ω; 10 - 20μA (1 - 20μA typ.)

THERMISTOR; T ≤113°F, 10 - 20

μ

A

T> 113°F, 0.5- 1mA

MAXIMUM COMMON MODE VOLTAGE: 42V peak to earth.

KEYPAD: 12 momentary switches with tactile feedback select;

• On/Off

• Change/Enter

• Clear/-0

• Sensor Select/1

• °F/°C/2

• Resolution/3

• Operate/4

• Store/5

• Recall/6

• Calibrator/Meter/Up Ramp/7

• Calibrator Step/Down Ramp/8

• Calibrator Ramp/Meter Hold/9

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

3

GENERAL INFORMATION

DISPLAY: 5 digit LCD, 0.4" height, polarity indication and decimal point. Annunciators;

• Loaded Memory Locations (10 for data storage, 4 for ramp parameters)

• Low Battery (BAT)

• Number Change Mode (NUM)

• Calibrator Mode (CALIB)

• Meter Mode (METER)

• Operate Mode (OPR)

• Store Mode (STO)

• Recall Mode (RCL)

• Meter Hold (HOLD)

• Scale (°F/°C)

• Sensor Type

POWER OFF CONFIGURATION RETENTION: Instrument retains last selected;

• Sensor Type

• °F/°C Scale

• 0.1°/1° Resolution

• Calibrator/Meter Mode

• Memory Contents (data storage and ramp parameters).

DIAGNOSTICS: Display codes indicate following conditions;

• 'BAT': Low Battery

• 'OPEN': Open Input Thermocouple, RTD or Thermistor.

• 'E-1' (momentary): Invalid Keypad Entry

• 'E-2' (momentary): Ramp Function Not Installed

• 'HI': Temperature Reading or Keypad Entry Exceeds Rating

• 'LO': Temperature Reading or Keypad Entry Too Low For Accuracy

• LCD Test: During power-up, all segments and annunciators enabled momentarily

ENVIRONMENTAL LIMITS FOR OPERATING: 0°C to 50°C, less than 90% relative humidity

(R.H.) up to 35°C; reduce R.H. limit by 3%/°C from 35°C to 50°C.

ENVIRONMENTAL LIMITS FOR STORAGE: -35°C to 60°C, less than 95% relative humidity

(R.H.) up to 35°C; reduce R.H. limit by 3%/°C from 35°C to 60°C.

POWER: 9 volt alkaline battery (NEDA 1604A).

BATTERY LIFE, CONTINUOUS: 10 hrs. typical, alkaline; 3 hrs typical, Ni-Cd (rechargeable).

BATTERY INDICATOR: Display indicates BAT when less than 10% of life remains.

DIMENSIONS, WEIGHT: 7.0" x 2.9 x 1.1". Net weight 12 oz.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4

GENERAL INFORMATION

UNIQUE SPECIFICATIONS

NOTE: The specifications below are specific to the model(s) as identified by

model number. The difference specifications are in addition to the

'COMMON SPECIFICATIONS' found on pages 2-4.

• MODEL 840A:

SENSOR SELECTION: K, J, T Thermocouples

ACCURACY: (18°C to 28°C ambient, 2 years):

K, J, T; ±0.5°F (rdg ≥-50°F).

±0.04% rdg (rdg > 1250°F)

±1.0°F (rdg < -50°F)

TEMPERATURE COEFFICIENT: From 0°C to 18°C, and 28°C to 50°C;

less than ±(0.006% rdg +0.03°C)/°C.

RAMP FUNCTION: Not Included.

BATTERY LIFE, CONTINUOUS: 16 hrs typical, alkaline; 4 hrs typical, Ni-Cd (rechargeable).

• MODEL 845:

SENSOR SELECTION: K, J, T, E, N, B, R, S, G, C, D Thermocouples

ACCURACY: (18°C to 28°C ambient, 2 years):

K, J, T, E, N; ±0.5°F (rdg ≥-50°F)

±1.0°F (rdg < -50°F)

B, R, S, G, C, D; ±1.7°F

TEMPERATURE COEFFICIENT: From 0°C to 18°C, and 28°C to 50°C;

K, J, T, E, N; ±(0.002% rdg + 0.03°C)/°C

B, R, S, G, C, D; ±(0.002% rdg + 0.1°C)/°C

RAMP FUNCTION: Included.

BATTERY LIFE, CONTINUOUS: 16 hrs typical, alkaline; 4 hrs typical, Ni-Cd (rechargeable).

• MODEL 850:

SENSOR SELECTION: K, J, T, E Thermocouples

100ΩPlatinum RTD

2252ΩThermistor

1,000Ω/100,000ΩResistance

ACCURACY: (18°C to 28°C ambient, 2 years):

K, J, T, E; ±0.5 °F (rdg ≥-50°F).

±0.04% rdg (rdg > 1250°F)

±1.0°F (rdg <-50°F)

OHMS; ±0.04% range

RTD; ±0.2°F (rdg≥- 50°F) (Calibrator mode)

±0.5°F (rdg < - 50°F) (Calibrator mode)

±0.2°F ±0.04% rdg (rdg ≥ -50°F) (meter mode)

±0.5°F±0.04% rdg (rdg < -50°F) (meter mode)

Thermistor; ±0.5°F

TEMPERATURE COEFFICIENT: From 0°C to 18°C, and 28°C to 50°C;

K, J, T, E; ±(0.006% rdg + 0.03°C)/°C

RTD, THERMISTOR, OHMS; ±(0.006% rdg +0.012% rng)/°C

RAMP FUNCTION: Not Included.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5

GENERAL INFORMATION

• MODEL 855:

SENSOR SELECTION: K, J, T, E, N, B, R, S, G, C, D Thermocouples

100Ω/1000ΩPlatinum RTD

1,000Ω/10,000ΩResistance

ACCURACY: (18°C to 28°C ambient, 2 years):

K, J, T, E, N; ± 0.5°F (rdg ≥-50°F)

±1.0°F (rdg < -50°F)

B, R, S, G, C, D; ±1.7°F

RTD; ±0.2°F (rdg ≥- 50°F) (Calibrator Mode)

±0.5°F (rdg < - 50°F) (Calibrator Mode)

±0.2°F ±0.04% rdg (rdg ≥ -50°F) (meter mode)

±0.5°F ±0.04% rdg (rdg < -50°F) (meter mode)

OHMS; ±0.02% range

TEMPERATURE COEFFICIENT: From 0°C to 18°C, and 28°C to 50°C;

K, J, T, E, N; ±(0.002% rdg + 0.03°C)/°C

B, R, S, G, C, D; ±(0.002% rdg + 0.1°C)/°C

RTD, OHMS; ±(0.002% rdg + 0.004% rng)/°C

RAMP FUNCTION: Included.

FEATURES

•Combination calibrator, thermometer and datalogger.

•Function selection and numeric data entered via 12 keyswitch color coded keypad.

•Keyswitches have tactile feedback.

•5 digit LCD includes annunciators for operating modes.

•Up to 11 thermocouple types, 2 RTD types, and thermistor.

•1° or 0.1° resolution over temperature range of each sensor.

•°F and °C scales.

•Reading hold mode.

•10 memory locations for saving meter readings and/or calibrator outputs.

•Step mode for quick sequential recall of calibrator outputs from memory.

•Manual/automatic ramping for testing controller setpoints.

•Conforms to ITS-90 thermocouple & RTD tables. Refer to 'Service Information' (page 23) for

more information.

•Dust proof, splash proof, drop proof construction.

•Built-in tilt stand/hanger for bench use or hands free field measurements.

•User friendly programming.

•Retains data and programming, even when turned off.

•Performs diagnostic tests and indicates fault conditions.

•Low battery and open sensor indications.

MANUAL ADDENDA

Improvements or changes to this manual will be explained on an addendum included with the

instrument. All change information should be incorporated immediately into the appropriate

places in the manual.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

6

GENERAL INFORMATION

UNPACKING AND INSPECTION

Each instrument is inspected both mechanically and electrically before shipment. Upon receiving

your instrument unpack all items from the shipping container and check for any obvious damage

that may have occurred during transit. Report any damage to the shipping agent. Retain and use

the original packing materials if reshipment is necessary.

SAFETY INFORMATION

SAFETY SYMBOLS AND TERMS

The symbol on the instrument denotes that the user should refer to the operating

instructions.

The WARNING used in this manual explains dangers that could result in personal injury or

death.

The CAUTION used in this manual explains hazards that could damage the instrument.

SAFETY PRECAUTIONS

WARNING

These instruments are intended for use by qualified

personnel trained in the safe operation of electronic testing

equipment. Read the instruction manual thoroughly before

using, to become familiar with the instrument's operations

and capabilities.

WARNING

Do not touch a temperature probe sheath when measuring

excessively high or low temperatures, or toxic substances.

WARNING

Do not attempt to measure temperatures beyond the range

of the probe being used. Probe damage or personal injury

could result from exceeding a probe's maximum

temperature rating.

WARNING

Do not substitute a metal part for the nylon screw in the rear

case. Doing so will degrade electrical isolation of the case.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

7

GENERAL INFORMATION

WARNING

The American National Standards Institute (ANSI) states that

a shock hazard exists when probes or sensors are exposed

to voltage levels greater than 42VDC or 42V peak AC. Do

not use this instrument where voltages at the measurement

surface exceed these levels.

WARNING

The battery is accessible through a cover on the back of the

instrument. To avoid electrical shock hazard, disconnect all

temperature probes and sensors and turn the unit off before

removing the cover.

WARNING

Never use this instrument or any probe or sensor inside a

microwave oven.

CAUTION

Avoid making sharp bends in probe or sensor lead wires.

Bending lead wires at a sharp angle can damage the wire

causing probe failure.

CAUTION

Keep inputs electrically isolated from outputs. Do not

connect an external voltage source between the two

connectors, and avoid any external electrical pathways

between input and output (T2 & T1).

Failure to do so will disturb meter readings and calibrator

output levels. Damage to the instrument is also possible.

Where the meter and calibrator connectors are

simultaneously wired into a system lacking the above

isolation, it is necessary to use an "ungrounded" (i.e.

electrically isolated) probe at the thermometer input.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

8

GENERAL INFORMATION

BATTERY INSTALLATION/REPLACEMENT

A 9V alkaline battery is supplied with the instrument but not installed. Read the following

installation instructions before attempting to install or remove the battery. Replacement batteries

should also be alkaline types.

WARNING

Turn the unit off and disconnect any input/output

connections before replacing the battery. Put the cover

back into place on the battery compartment before

resuming use of the instrument.

1. Remove the cover from the battery compartment by sliding it off in the direction of the

arrow located on the battery cover.

2. Remove the old battery.

3. Place the new battery in the battery compartment. Be sure to observe proper polarity.

4. Re-install the battery cover before resuming use of the instrument.

Figure 1. Battery Installation

NOTES:

• Less than 10% of battery life remains when the BAT annunciator turns

on.

• When the battery is excessively discharged, the display is blanked.

• If the instrument is going to be stored for a long period of time or in a

high temperature environment, remove the battery to prevent leakage

damage.

• After a new battery is installed, allow approximately 5 seconds

for display turn-on the first time the unit is turned on. During

this period, microcomputer initialization is performed.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

9

GENERAL INFORMATION

MEMORY BACKUP

During battery replacement, the contents of user-programmed memory (data, operating modes,

etc.) can be saved. Prior to removing the old battery, turn off the instrument, and connect a

Model 80010 battery charger. Then exchange batteries, and disconnect the battery charger. Do

not leave the battery charger connected to instruments with non-rechargeable batteries.

OPERATION WITH RECHARGEABLE BATTERY

Model 80010 provides a 9-volt Ni-Cd battery and recharger suitable for use with the unit. This

battery provides 3-4 hours of continuous operation.

NOTE: Instrument accuracy is degraded while recharging the Ni-Cd battery, and

published specifications do not apply to measurements made during

recharging.

Turn off the instrument to recharge the battery. Allow 7 hours to recharge the battery fully. Then

unplug the recharger to avoid overcharging. Allow 20 minutes after charging before taking

measurements.

MODEL 80010 SPECIFICATIONS

Model

80010/100 80010 80010/220

Vin:

90-110 VAC

108-132 VAC

198-242 VAC

50/60 Hz

50/60 Hz

50/60 Hz

Vout: 40 VDC @ 5mA 40 VDC @ 5mA 40 VDC @ 5mA

OPERATING INSTRUCTIONS

1. DIAGNOSTICS AND ERROR MESSAGES

Unit self-diagnostics provide fault condition readouts which are described below:

PROBLEM: LIKELY CAUSE:

Blank display, unit does not power-up. (1) Improper battery installation.

Check battery polarity.

(2) Dead battery.

BAT Annunciator. (1) Low battery voltage, install a new

battery. If problem persists, consult

factory.

Display reads OPEN. (1) No thermocouple, RTD or thermistor

is plugged into the meter input.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

10

GENERAL INFORMATION

Display reads E1 momentarily. (1) This indicates that an invalid keypad

entry has been made. Review keystroke

sequence, or consult manual for input

instructions.

Display reads E2 momentarily. (1) Attempt made to activate non-

installed ramp function.

NOTE: RAMP Function enabled on Models 845 and 855 only.

Display reads HI. (1) Meter-mode input-temperature

exceeds rating of selected sensor.

(2) Calibrator-mode keypad-entry

exceeds rating of sensor type.

Display reads LO. (1) Meter-mode input-temperature

too low for accurate measurement.

(2) Calibrator-mode keypad-entry too

low for accurate simulation.

Figure 2. Keypad

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

11

GENERAL INFORMATION

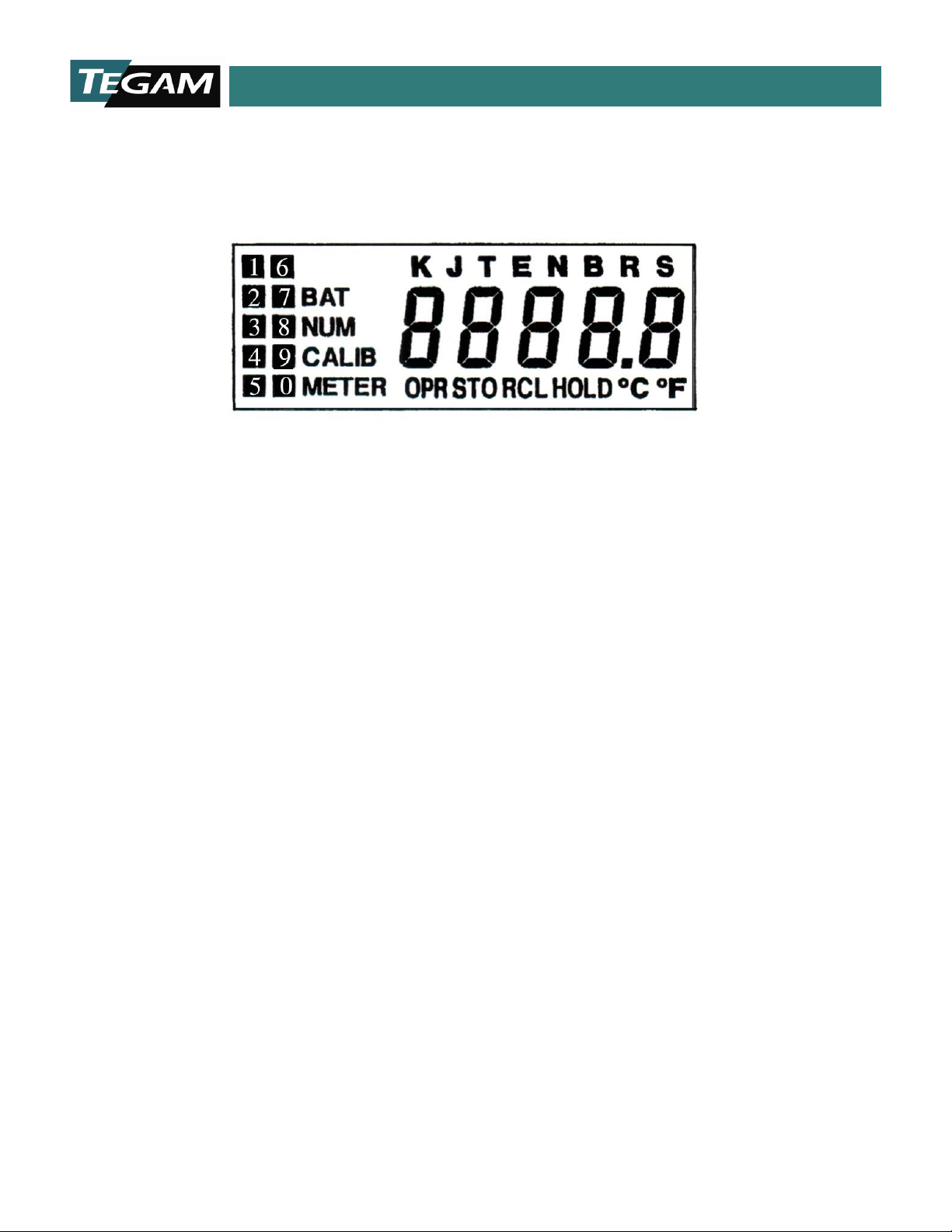

Figure 3. Display Test

2. INITIAL TURN ON

Turn on the instrument by depressing the ON-OFF keyswitch once (Figure 2). At power-up, the

unit first performs a display test. All segments and annunciators of the liquid crystal (LCD) are

momentarily turned on for visual confirmation by the user (Figure 3).

NOTE: In case of missing or poor-contrast segments, contact factory.

If the unit is turning on for the first time after a new battery is installed, it will automatically

default to the METER mode (ie. temperature measurement operation). It also defaults to K-type

thermocouples, and °F readings with 0.1° resolution. The corresponding LCD annunciators are

enabled:

METER : (Unit functioning as a thermometer)

K : (K-type thermocouple)

°F : (Fahrenheit readings)

OPR : (Instrument is operational)

If no input thermocouple is connected to the unit at this time, the numeric segments will indicate

"OPEN".

Plugging a thermocouple into the meter jack (connector T2, on the top right side) will give actual

thermocouple temperature readings.

NOTE: To obtain full accuracy, allow 1-2 minutes after connecting a

thermocouple plug, for thermal setting.

If the instrument is to be used as a thermometer or ohmmeter, refer to the Meter Mode Operation

section for detailed instructions. For use as a temperature-calibrator or ohms simulator, refer to

Calibrator Mode Operation.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

12

GENERAL INFORMATION

3. METER MODE OPERATION (Thermocouples) Set-Up:

1. Turn on instrument by depressing the ON/OFF key.

2. Check that the BAT annunciator turns off following the power-up LCD test.

If it does not turn off, less than 10% of battery remains. Refer to Battery Installation/Replacement

instructions.

3. If the meter is already in the METER mode, the METER annunciator will

be on. Otherwise the calibrator mode is enabled and the CALIB annunciator is on. Depress the

METER key to return to meter mode.

4. Connect an input thermocouple (TC) to connector T2. Select the appropriate TC Type with the

select-key. A display annunciator will indicate the selected TC-type.

NOTE: Space and legibility constraints on the display preclude the use of

dedicated annunciators for the less common tungsten- rhenium

thermocouple types (G, C & D). Instead, these types are annunciated

momentarily on the alpha-numeric display when first selected. Both T

and R annunciators remain on to indicate a Tungsten-Rhenium

selection. To recall the actual G, C, D selection, turn the unit off, then

on again for another momentary readout.

5. Select temperature scale with °F/°C key. The corresponding annunciator is enabled.

6. Select display resolution with 0.0.1 key.

NOTE: Set-up is retained during power-off.

Hold:

Meter readings can be put on hold at any time by depressing the HOLD key. At this time,

the HOLD annunciator turns on, the reading is frozen, and all keys (except ON/OFF and

HOLD) are locked out. Depress the HOLD key again to return to real-time readings, and

re-enable the keypad.

4. METER MODE OPERATION (RTD, Thermistor & Ohms) Set-Up:

1. Connect a sensor or unknown resistance to the instrument as shown in Figures 4, 5, or 6.

The 2-wire configuration is simplest, but includes lead-wire resistance in the measurement. 2-wire

measurements are generally limited to high resistance sensors (e.g. 1000-ohm RTDs, 2252-ohm

thermistors).

Lead resistance errors are compensated for in 3-wire configurations. However, full

compensation requires equal resistance in each lead. This configuration is common with 100-

ohm RTDs.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

13

GENERAL INFORMATION

In 4-wire configurations, accuracy is unaffected by lead resistance and resistance differences

between leads.

NOTE: These instruments measure input voltages on all 4 terminals, and are able

to distinguish between 2-4 and 3-wire hookups. Switching between these

measurement modes is automatic.

2. Set instrument to METER mode.

3. Use the Sensor-Select key to set the instrument to the appropriate function and range.

NOTE: Due to limited display area, 100Ωand 1000ΩRTD's are indicated on

the display by a momentary readout of "RTD-100" (or "RTD-1000")

when first selected.

Thermistors are identified by a momentary alpha-numeric readout of "Y-

400" (signifying YSI Series-400 type thermistor).

Any of these readouts can be recalled by turning the unit off and back

on.

(RTD, Thermistor, etc.)

Figure 4. 2-Wire Resistance Measurement

Figure 5. 3-Wire Resistance Measurement

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

14

GENERAL INFORMATION

Figure 6. 4-Wire Resistance Measurement

5. DATA LOGGING AND RECALL

Operating as a meter, the unit can save and recall up to 10 readings (each with independent

parameters: eg. °F/°C, TC-type and resolution) in random access memory.

To Save Readings:

1. While in the METER OPR mode, depress the STORE key. Note that the OPR annunciator is replaced

by STO.

2. Next depress one of the memory location numbers (keys 0, 1, ..., 9). The corresponding

memory annunciator turns on and the meter returns momentarily to the OPR mode, displaying

thermocouple temperature.

eg. STORE 7

NOTES:

• The enabled location annunciator indicates that the meter reading

at the instant that the location number key was pressed, was stored in

memory.

• When data is stored in a location already filed with data, the new data

replaces the old.

• Stored readings are retained during power-off.

To Recall Readings:

1. While in the METER OPR mode, readings stored earlier can be displayed by first depressing the

RECALL key. Note that the OPR annunciator is replaced by RCL, and all memory location

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

15

GENERAL INFORMATION

annunciators are blanked.

2. Next depress the keypad number corresponding to the desired location.

Note that the annunciator for this location turns on and the memory contents are displayed.

3. Several stored readings can be randomly recalled by a key sequence such as:

eg. RECALL 3

RECALL 5

RECALL 2 etc.

4. To return the meter to the operate mode, depress OPR after recalling the last reading. All

active location annunciators will turn on again, together with the OPR annunciator.

NOTE: Recalling data from unused (i.e. empty) locations will give a zero

reading.

To Erase Data Locations (Meter Mode):

1. Individual data locations can be erased by recalling the location to be cleared, followed by a

CLEAR key input. Note that the annunciator for the cleared location is turned off,and the meter

returns to OPR.

eg. RECALL 3

CLEAR

NOTE: There is no need to clear a location if new data is ready for saving in this

location. Just STORE the new data. It will write over and delete the old.

Figure 7.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

16

GENERAL INFORMATION

6. CALIBRATOR MODE OPERATION (Thermocouples) Set-Up:

1. Turn on the instrument by depressing the ON/OFF key.

2. Check that the BAT annunciator turns off after display check. If not, refer to Battery

Installation/Replacement instructions.

3. When operating as a calibrator, the display indicates CALIB. Should the instrument be

in the METER mode, press the CALIB key to change to the calibrator function.

4. Select the thermocouple type that will be used.

NOTE: Space and legibility constraints on the display preclude the use of

dedicated annunciators for the less common tungsten-rhenium

thermocouple types (G, C, & D). Instead, these types are

annunciated momentarily on the alpha-numeric display when first

selected. Both T and R annunciators remain on to indicate a

Tungsten-Rhenium selection. To recall the actual G, C, D selection,

turn the unit off, then on again for another momentary readout.

5. Select the desired temperature scale (°F/°C key).

6. Select the resolution desired (0.0.1 key).

NOTE: With 1° resolution, one less key stroke will be required to enter

calibrator output temperatures via the keypad.

7. The unit accepts numeric inputs by first changing the keypad to its number-entry mode (NUM)

by depressing the CHANGE/ENTER key once.

The numeric display will flash, the OPR annunciator will turn off, and the NUM annunciator will

turn on. Key in desired temperature value, most significant digit first. After the desired

temperature value is keyed in, press CHANGE/ENTER to return to OPR mode.

To enter a value of 212° with 0.1° resolution, the following keystrokes are used:

CHANGE/ENTER, 2, 1, 2, 0, CHANGE/ENTER

NOTES:

• Invalid numeric entries (eg. a temperature beyond the span of the

selected TC type) will cause a corresponding error code to be

displayed.

• To enter negative (ie. minus) temperatures, press the -0 key first

when in the NUM mode. The first press on this key enters the negative

sign. Subsequent presses enter zeros.

•To correct a numeric entry while in the NUM mode, press the

CHANGE/ENTER key twice. This will return number entry to the

beginning of a new number.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

17

GENERAL INFORMATION

• To return the calibrator output to 0° while in the OPR mode, press

the CLEAR key.

• The unit can be used as a convenient °F to °C or °C to °F calculator.

For example, to convert 77°F to a Celsius reading, go to the CALIB OPR mode, enter the reading

to be converted, and change scale.

eg.°F

CHANGE/ENTER

77

CHANGE/ENTER

°C (Display reads 25°C)

7. CALIBRATOR MODE OPERATION (RTD, Thermistor & Ohms)

NOTE: The 850/855 requires a steady current to function properly in the

calibration mode. Some transmitters operate with a pulsating current

which won't work with the 850/855. These devices are normally provided

with a calibration mode which when enabled stops sending pulsating

current and supplies a steady current. Disabling the mode returns the

transmitter to its normal operating state.

Set-Up:

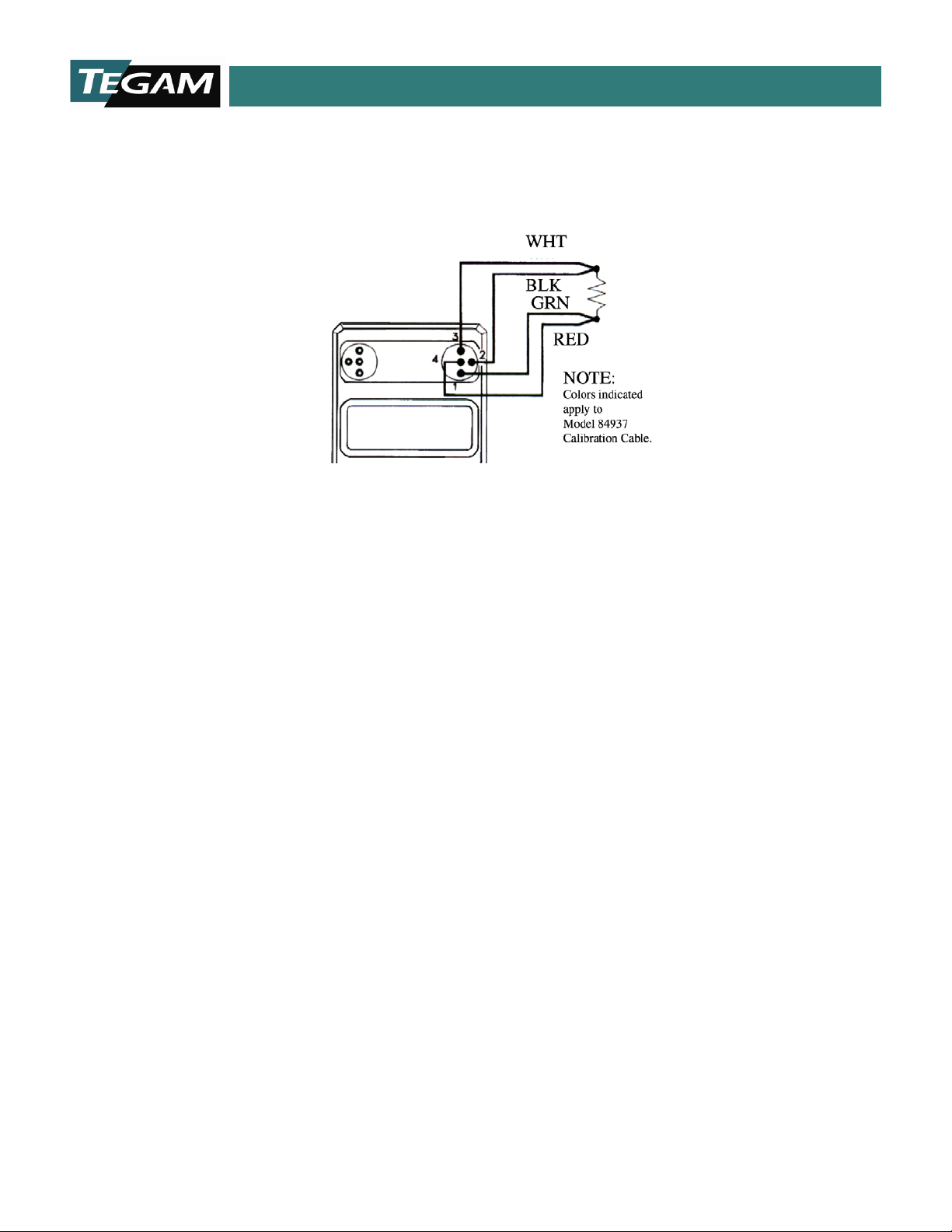

1. Connect measurement equipment under test (eg. RTD thermometer, ohmmeter etc.) to the

instrument as shown in Figures 8, 9, or 10.

The same performance tradeoffs apply to 2, 3 and 4-wire simulations as to 2, 3, and 4-wire

measurements. Refer to RTD, Thermistor and Ohms Meter-Mode section above for wiring

guidelines.

2. Set instrument to CALIBRATOR mode.

3. Use the sensor-select key to set the instrument to the appropriate function and range.

Figure 8. 2-Wire Resistance Simulation

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

18

GENERAL INFORMATION

Figure 9. 3-Wire Resistance Simulation

Figure 10. 4-Wire Resistance Simulation

NOTE: To ensure accurate calibrator outputs, observe specified limits to

excitation currents. If in doubt, check current levels with a DMM in

series with either source lead (1 or 3).

NOTE: Due to limited display area, 100Ωand 1000ΩRTD's are indicated on

the display by a momentary readout of "RTD-100" (or "RTD-1000")

when first selected.

Thermistors are identified by a momentary alpha-numeric readout of

"Y-400" (signifying YSI Series-400 type thermistor).

This manual suits for next models

3

Table of contents

Other Tegam Thermometer manuals