IFR COM-120B User manual

MAINTENANCE

MANUAL

coM r 1208

COMMUNICATION SERUICE MONITOR

ffir=ETm

,E,E'.E.EiI

"E'E'Etril

'E,E'EtrII

m

IIEH

ll r-r R

lll.|?^rt I o

llt* lA

iltl

BJ

6-fiilI

t@l

I towrar I

[^-" I

6

^A-

,4=}

\-l

@

tm;l

@i

tr9tr

L-JEL

RF RECETVT IEFRY: REC.00

RF: UX-UU IiA

m -n mLST

l?UT:T/R ATTEII$dB

FFI-TER r0O Xllr

D€I(X)I FI

AT.|I,() / OATA FT.TER EET

AUTIIO / OATA OE}I OUT TET

rO}C/ DATACOOC:

I rlt RBCEIYEDGOOET

lF FREO(EI5Y: XXXX lt DEIORT|OIt XX- T

RF ERROR

(Avrrt .rrrtr

FI!p1ITd

-l 0+l

l-T,T--l

FIOfER

(F{) rr faT?r

oa

|-T-----_---r

ocvtlTprl

arEl rotEl

tAvnl

.tO 0 +tO

t f #T fuco*l2oB

t to c666666

ffiJ.' X;.,trj: #"^JE X-* r"^

10200 West York Street / Wichita, Kansas 67215 U.S.A. / (316) 5224981/ FAX (316) 524-2623

1002-060G,300

-

\'---_--11

MAINTENANCE

MANUAL

COM

-1208

COMMUNICATION

SERVICE

MONITOR

--

--

10200 West York Street / Wichita, Kansas 67215 U.S.A. / (316) 522-4981 / FAX (316) 524-2623

1002-0600-300

DIGITALY REMASTERED

OUT OF PRINT- MANUAL SCANS

By

Artek Media

18265 200th St.

Welch, MN 55089

www.artekmedia.com

“High resolution scans of obsolete technical manuals”

If your looking for a quality scanned technical manual in PDF format please visit

our WEB site at www.artekmedia.com or drop us an email at

manuals we have available.

If you don’t see the manual you need on the list drop us a line anyway we may

still be able to point you to other sources. If you have an existing manual you

would like scanned please write for details. This can often be done very

reasonably in consideration for adding your manual to our library.

Typically the scans in our manuals are done as follows;

1) Typed text pages are typically scanned in black and white at 300 dpi.

2) Photo pages are typically scanned in gray scale mode at 600 dpi

3) Schematic diagram pages are typically scanned in black and white at 600

dpi unless the original manual had colored high lighting (as is the case for

some 70’s vintage Tektronix manuals).

4) Most manuals are text searchable

5) All manuals are fully bookmarked

All data is guaranteed for life (yours or mine … which ever is shorter). If for ANY

REASON your file becomes corrupted, deleted or lost, Artek Media will replace

the file for the price of shipping, or free via FTP download.

Thanks

Dave & Lynn Henderson

Artek Media

PUBLISHED BY

IFR SYSTEMS INC

WICHITA, KANSAS

COPYRIGHT @ 1996 by IFR SYSTEMS, lNC.

All rights reserved. Printed in the United States of America. No part of this

publication may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without

the prior permission of the publisher.

PUBLISHED BY

IFR

SYSTEMS INC

WICHITA, KANSAS

COPYRIGHT

©

1996

by

IFR

SYSTEMS,

INC.

All

rights

reserved.

Printed

in

the

United

States

of

America.

No

part

of

this

publication

may

be

reproduced,

stored

in a

retrieval

system,

or

transmitted

in

any

form

or

by

any

means,

electronic,

mechanical,

photocopying,

recording

or

otherwise

without

the

prior

permission

of

the

publisher.

TABLE OF CONTENTS

SECTION .1 - CALIBRATION

1-1 GENERAL

1-1-1 SAFETY PRECAUTIONS

1-1-2 ESD PRECAUTIONS

1-2 TEST EQUIPMENT REQUIREMENTS

1-3 DISASSEMBLYREQUIREMENTS

1.4 CALIBRATION ADJUSTMENTS

1-5 CONTROLS, CONNECTORS AND INDICATORS

1-6 COMPLETION OF CALIBRATION TEST PROCEDURES

1-7 CALIBRATION RECORD

1.8 CALIBRATIONPROCEDURES

1-8-1 POWER SUPPLY CALIBRAT]ON

1-8-2 TCXO/OCXOCALIBRATION

1-8-3 DVM CALIBRATION

1-8-4 GENERATOR OUTPUT LEVEL CALIBRATION

1-8.5 DISTORTIONMETERCALIBRATION

1-8-6 SINAD METER CALIBRATION

1.8-7 RF GENERATE FM DEVIAT]ON CALIBRATION

1.8.8 RF GENERATE PM DEVIATION CALIBRATION

1-8-9 RF GENERATE AM MODULATION CALIBRATION

1-8-10 RF GENERATE EXTERNAL MODULATION CALIBRATION

1-8-11 SPECTRUM ANALYZER CALIBRATION

1-8-12 MIXER NULL CALIBRATION

1-8-13 FM DEVIATION METER CALIBRAT]ON

1-8-14 PM DEVIATION METER CALIBRATION

1.8.15 AM MODULATION METER CALIBRATION

1.8.16 POWER METER CALIBRATION

SECTION 2 - PC BOARDS AND SCHEMATICS

PRODUCT STRUCTURE 1ST LO ASSEMBLY

INTERCONNECT DIAGRAM 2ND LO ASSEMBLY

COMPOSITE ASSEMBLY 3RD LO ASSEMBLY

CASE ASSEMBLY BASE BAND ASSEMBLY

LID ASSEMBLY GENERATOR TRAY

FRONT PANEL ASSEMBLY AM FM MODULATOR ASSEMBLY

KEYBOARD CONTROLLER ASSEMBLY GEN CONVERTER ASSEMBLY

AUDIO BOARD ASSEMBLY ANALYZER ASSEMBLY

EL D]SPLAY INTERFACE ASSEMBLY POWER SUPPLY ASSEMBLY

ATTENUATOR CONTROL ASSEMBLY REFERENCE FREQ. STD.

POWER TERMINATION ASSEMBLY RECEIVER TRAY STD.

GENERATOR OUTPUT ASSEMBLY FRONT END BLOCK

MOTHERBOARD ASSEMBLY IF AMP/DEMOD ASSEMBLY

PCMCIA INTERFACE ASSEMBLY RECEIVER TRAY OPT. 03

VIDEO CNTR/FCTN GEN ASSEMBLY DIGITAL TRAY OPT. 04

CONTROLLER TRAY AUXILIARY AMP OPT. 05

SYNTHESIZER TRAY RECEIVER TRAY OPT. 08

TABLE

OF

CONTENTS

SECTION

1 -

CALIBRATION

1-1

GENERAL

1-1-1

SAFETY

PRECAUTIONS

1-1-2

ESD

PRECAUTIONS

1-2

TEST

EQUIPMENT

REQUIREMENTS

1-3

DISASSEMBLY

REQUIREMENTS

1-4

CALIBRATION

ADJUSTMENTS

1-5

CONTROLS,

CONNECTORS

AND

INDICATORS

1-6

COMPLETION

OF

CALIBRATION

TEST

PROCEDURES

1-7

CALIBRATION

RECORD

1-8

CALIBRATION

PROCEDURES

1

-8-1

1-8-2

1-8-3

1-8-4

1-8-5

1-8-6

1-8-7

1-8-8

1-8-9

1-8-10

1

-8-11

1

-8-12

1-8-13

1

-8-14

1

-8-15

1-8-16

POWER

SUPPLY

CALIBRATION

TCXOIOCXO

CALIBRATION

DVM

CALIBRATION

GENERATOR

OUTPUT

LEVEL

CALIBRATION

DISTORTION

METER

CALIBRATION

SINAD

METER

CALIBRATION

RF

GENERATE

FM

DEVIATION

CALIBRATION

RF

GENERATE

PM

DEVIATION

CALIBRATION

RF

GENERATE

AM

MODULATION

CALIBRATION

RF

GENERATE

EXTERNAL

MODULATION

CALIBRATION

SPECTRUM

ANALYZER

CALIBRATION

MIXER

NULL

CALIBRATION

FM

DEVIATION

METER

CALIBRATION

PM

DEVIATION

METER

CALIBRATION

AM

MODULATION

METER

CALIBRATION

POWER

METER

CALIBRATION

SECTION

2 -

PC

BOARDS

AND

SCHEMATICS

PRODUCT

STRUCTURE

INTERCONNECT

DIAGRAM

COMPOSITE

ASSEMBLY

CASE

ASSEMBLY

LID

ASSEMBLY

FRONT

PANEL

ASSEMBLY

KEYBOARD

CONTROLLER

ASSEMBLY

AUDIO

BOARD

ASSEMBLY

EL

DISPLAY

INTERFACE

ASSEMBLY

ATTENUATOR

CONTROL

ASSEMBLY

POWER

TERMINATION

ASSEMBLY

GENERATOR

OUTPUT

ASSEMBLY

MOTHERBOARD

ASSEMBLY

PCMCIA

INTERFACE

ASSEMBLY

VIDEO

CNTR/FCTN

GEN

ASSEMBLY

CONTROLLER

TRAY

SYNTHESIZER

TRAY

1

ST

LO

ASSEMBLY

2ND

LO

ASSEMBLY

3RD

LO

ASSEMBLY

BASE

BAND

ASSEMBLY

GENERATOR

TRAY

AM

FM

MODULATOR

ASSEMBLY

GEN

CONVERTER

ASSEMBLY

ANALYZER

ASSEMBLY

POWER

SUPPLY

ASSEMBLY

REFERENCE

FREQ.

STD.

RECEIVER

TRAY

STD.

FRONT

END

BLOCK

IF

AMPIDEMOD

ASSEMBLY

RECEIVER

TRAY

OPT.

03

DIGITAL

TRAY

OPT.

04

AUXILIARY

AMP

OPT.

05

RECEIVER

TRAY

OPT.

08

Scans by ArtekMedia © 2008

SECTION 1 . CALIBRATION

1 .1 G EN ERAL

This section contains calibration procedures for the following assemblies and systems:

PARA TITLE PAGE

1-8-1

1-8-2

1-8-3

1-B-4

1-8-5

1-8-6

1-8-7

1-8-8

1-8-9

1-8-10

1-8-1 1

1-8-12

1-8-13

1-8-14

1-8-15

1-8-16

These

POWER SUPPLY CALIBRATlON

TCXO/OCXO CALIBRATION

DVM CALIBRATION

GENERATOR OUTPUT LEVEL CALIBRATION

DISTORTION METER CALlBRATION

SINAD METER CALIBRATION

RF GENERATE FM DEVIATION CALIBRAT]ON

RF GENERATE PM DEVIATION CALIBRAT]ON

RF GENERATE AM MODULATION CALIBRATION

RF GENERATE EXTERNAL MODULATION CALIBRATION

SPECTRUM ANALYZER CALIBRATION

MIXER NULL CALIBRATION

FM DEVIATION METER CALIBRATION

PM DEVIATION METER CALIBRATION

AM MODULATION METER CALIBRATION

POWER METER CALIBRATION

1-5

1-7

1-9

1-1 1

1-14

1-16

1-18

1-21

1-23

1-25

1-29

1-36

1-38

1-41

1-43

1-45

procedures should be performed as a result of one or more of the following conditions:

O lf, during the course of normal operation, the COM-1208 or any major function thereof

fails to meet the performance specifications.

O lf a module is found to be defective and requires replacement.

O lf the recommended 12 month calibration interval is due.

Figure 1-1 lists the calibration procedures required based on the replacement of a specific

module. All procedures must be performed for the annual calibration.

1-1-1 SAFETY PRECAUTIONS

As with any piece of electronic equipment, extreme caution should be taken when working with

'live" circuits. When performing the calibration procedures in this section, be sure to observe

the f ollowing precautions:

WARNING: REMOVE ALL JEWELRY BEFORE PERFORMING ANY CALIBRATION

PROCEDURES INVOLVING LIVE CIRCUITS.

HEED ALL WARNINGS AND CAUTIONS CONCERNING MAXIMUM VOLTAGES

AND POWER INPUTS.

1-1

SECTION

1 -

CALIBRATION

1-1

GENERAL

This

section

contains

calibration

procedures

for

the

following

assemblies

and

systems:

PARA

1-8-1

1-8-2

1-8-3

1-8-4

1-8-5

1-8-6

1-8-7

1-8-8

1-8-9

1-8-10

1

-8-11

1-8-12

1-8-13

1-8-14

1-8-15

1-8-16

TITLE

POWER

SUPPLY

CALIBRATION

TCXOIOCXO

CALIBRATION

DVM

CALIBRATION

GENERATOR

OUTPUT

LEVEL

CALIBRATION

DISTORTION

METER

CALIBRATION

SINAD

METER

CALIBRATION

RF

GENERATE

FM

DEVIATION

CALIBRATION

RF

GENERATE

PM

DEVIATION

CALIBRATION

RF

GENERATE

AM

MODULATION

CALIBRATION

RF

GENERATE

EXTERNAL

MODULATION

CALIBRATION

SPECTRUM

ANALYZER

CALIBRATION

MIXER

NULL

CALIBRATION

FM

DEVIATION

METER

CALIBRATION

PM

DEVIATION

METER

CALIBRATION

AM

MODULATION

METER

CALIBRATION

POWER

METER

CALIBRATION

PAGE

1-5

1-7

1-9

1-11

1-14

1-16

1-18

1-21

1-23

1-25

1-29

1-36

1-38

1-41

1-43

1-45

These

procedures

should

be

performed

as

a

result

of

one

or

more

of

the

following

conditions:

•

If,

during

the

course

of

normal

operation,

the

COM-120B

or

any

major

function

thereof

fails

to

meet

the

performance

specifications.

•

If

a

module

is

found

to

be

defective

and

requires

replacement.

•

If

the

recommended

12

month

calibration

interval

is

due.

Figure

1-1

lists

the

calibration

procedures

required

based

on

the

replacement

of

a

specific

module.

All

procedures

must

be

performed

for

the

annual

calibration.

1-1 -1

SAFETY

PRECAUTIONS

As

with

any

piece

of

electronic

equipment,

extreme

caution

should

be

taken

when

working

with

"live"

circuits.

When

performing

the

calibration

procedures

in

this

section,

be

sure

to

observe

the

following

precautions:

WARNING:

REMOVE

ALL

JEWELRY

BEFORE

PERFORMING

ANY

CALIBRATION

PROCEDURES

INVOLVING

LIVE

CIRCUITS.

HEED

ALL

WARNINGS

AND

CAUTIONS

CONCERNING

MAXIMUM

VOLTAGES

AND

POWER

INPUTS.

1

-1

1-1-2 ESD PRECAUTIONS

CAUTION: THESE CALIBRATION PROCEDURES SHOULD ONLY BE PERFORMED lN AN ESD

ENVIRONMENT AND ALL PERSONNEL PERFORMING THIE PROCEDURES

SHOULD KNOW ACCEPTED ESD PRACTICES OR BE ESD CERTIFIED.

fi cAU'oN t?

L.--r \t/

ll

THIS EQUIPMENT CONTAINS PARTS

SENSIT]VE TO DAMAGE

BY ELECTROSTATTC DTSCHARGE (ESD)

1.2 TEST EOUIPMENT REQUIREMENTS

Table 1-1 contains a comprehensive list of test equipment suitable for performing any of the

procedures listed in this manual. Any other equipment meeting the specifications listed in

Table 1-1 may be substituted in place of the recommended models.

NOTE: For certain procedures contained in this manual, the equipment listed in Appendix A may

exceed the minimum required specif ications.

1.3 DISASSEMBLY REQUIREMENTS

To perform the calibration procedures, the case assembly must be removed.

1.4 CALIBRATION ADJUSTMENTS

Before making adjustments, always observe the measurement. lf the measurement is within the

tolerances given, do not proceed with the adjustment. When an adjustment is required, attempt

to obtain a precise measurement, instead of just within tolerance.

1.5 CONTROLS, CONNECTORS AND INDICATORS

The front and rear panel controls, connectors and indicators specified in the calibration

procedures are followed by an item number. Refer to Figures 3-1 and 3-2 in the COM-1208

Operation Manual for the location of these items.

1.6 COMPLETION OF CALIBRATION TEST PROCEDURES

Upon completion of a specific calibration procedure, the calibration procedure may be

terminated. Control settings, operating commands and test equipment do not carry over from

one procedure to another and are not assumed at the beginning of a procedure.

1.7 CALIBRATION RECORD

A Calibration Record is provided for recording the results obtained while performing the

Calibration Procedures. lt is recommended the technician reoroduce the Calibration Record.

rather than use the copy in this manual.

1-2

1-1-2

ESD

PRECAUTIONS

CAUTION:

THESE

CALIBRATION

PROCEDURES

SHOULD

ONLY

BE

PERFORMED

IN AN

ESD

ENVIRONMENT

AND

ALL

PERSONNEL

PERFORMING

THIE

PROCEDURES

SHOULD

KNOW

ACCEPTED

ESD

PRACTICES

OR BE

ESD

CERTIFIED.

\.~

CAUTION

THIS EQUIPMENT CONTAINS PARTS

SENSITIVE

TO

DAMAGE

BY

ELECTROSTATIC DISCHARGE (ESD)

1-2

TEST

EQUIPMENT

REQUIREMENTS

Table

1-1

contains

a

comprehensive

list

of

test

equipment

suitable

for

performing

any

of

the

procedures

listed

in

this

manual.

Any

other

equipment

meeting

the

specifications

listed

in

Table

1-1

may

be

substituted

in

place

of

the

recommended

models.

NOTE:

For

certain

procedures

contained

in

this

manual,

the

equipment

listed

in

Appendix

A

may

exceed

the

minimum

required

specifications.

1-3

DISASSEMBLY

REQUIREMENTS

To

perform

the

calibration

procedures,

the

case

assembly

must

be

removed.

1-4

CALIBRATION

ADJUSTMENTS

Before

making

adjustments,

always

observe

the

measurement.

If

the

measurement

is

within

the

tolerances

given,

do

not

proceed

with

the

adjustment.

When

an

adjustment

is

required,

attempt

to

obtain

a

precise

measurement,

instead

of

just

within

tolerance.

1-5

CONTROLS,

CONNECTORS

AND

INDICATORS

The

front

and

rear

panel

controls,

connectors

and

indicators

specified

in

the

calibration

procedures

are

followed

by

an

item

number.

Refer

to

Figures

3-1

and

3-2

in

the

COM-120B

Operation

Manual

for

the

location

of

these

items.

1-6

COMPLETION

OF

CALIBRATION

TEST

PROCEDURES

Upon

completion

of

a

specific

calibration

procedure,

the

calibration

procedure

may

be

terminated.

Control

settings,

operating

commands

and

test

equipment

do

not

carryover

from

one

procedure

to

another

and

are

not

assumed

at

the

beginning

of

a

procedure.

1-7

CALIBRATION

RECORD

A

Calibration

Record

is

provided

for

recording

the

results

obtained

while

performing

the

Calibration

Procedures.

It is

recommended

the

technician

reproduce

the

Calibration

Record,

rather

than

use

the

copy

in

this

manual.

1-2

Scans by ArtekMedia © 2008

Type Model Specif icatlons

Digital Multimeter (DMM) HP34401A or equivalent

Calibrator Fluke 5100B or equivalent

Audio Analyzer HP8903B or equivalent Frequency Range:

20 Hz to 20 kHz

Accu racy

r0.1 dB

Frequency Counter Phillips PM6669

or equivalent Frequency:

'lO Hz to 1.3 GHz

Reso lution :

>7 digits

Measuring Receiver

HP8902A (opt. 30, 32,371

or equivalent RF Power:

-20 to +30 dBm

RF Power Range:

.1 to 1 GHz

RF Level:

Tuned 0 to -127 dBm

RF Power Accuracy:

10.1 dB

Measuring Receiver Sensor HP11722A or equivalent

Modulation Analyzer

HP8901A or equivalent FM Meter Range:

20 Hz to 200 kHz

FM Meter Accuracy:

t1% t1 digit

Phase Meter Range:

to 200 Radians

Phase Meter Accuracy:

t3"/" t1 digit

10 MHz Standard Accu racv:

t2 X 10-e

(Traceable to NIST)

COM-120 Maintenance Kit P/N 7001-8743-800

Signal Generator HP8657A or equivalent

10 W RF Amplif ier Amplifier Research

10w1000

or equivalent

Gain:

40 dB Nominal

Bandwidth:

1 MHz to 1 GHz

200 W RF Amplifier ENI 5100L or equivalent Gain:

50 dB Nominal

Bandwidth:

1.5 to 150 MHz

Table 1-1 Test Equipment Requirements

Type

Model

Specifications

Digital

Multimeter

(DMM)

HP34401

A

or

equivalent

Calibrator

Fluke

5100B

or

equivalent

HP8903B

or

equivalent

Frequency

Range:

Audio

Analyzer

20

Hz

to

20

kHz

Accuracy

±0.1

dB

Phillips

PM6669

Frequency:

Frequency

Counter

or

equivalent

10Hzt01.3GHz

Reso

luti

on:

~7

digits

HP8902A

(opt.

30,

32,

37)

RF

Power:

or

equivalent

-20

to

+30

dBm

RF

Power

Range:

Measuring

Receiver

.1t01GHz

RF

Level:

Tuned

0

to

-127

dBm

RF

Power

Accuracy:

±0.1

dB

Measuring

Receiver

Sensor

HP11722A

or

equivalent

HP8901

A

or

equivalent

FM

Meter

Range:

20

Hz

to

200

kHz

FM

Meter

Accuracy:

Modulation

Analyzer

±1 % ±1

digit

Phase

Meter

Range:

to

200

Radians

Phase

Meter

Accuracy:

±3%

±1

digit

Accuracy:

10

MHz

Standard

±2

X

10-

9

(Traceable

to

NIST)

COM-120

Maintenance

Kit

PIN

7001-8743-800

Signal

Generator

HP8657A

or

equivalent

Amplifier

Research

Gain:

10

W RF

Amplifier

10W1000

40

dB

Nominal

or

equivalent

Bandwidth:

1

MHz

to

1

GHz

ENI

51

OOL

or

equivalent

Gain:

200

W

RF

Amplifier

50

dB

Nominal

Bandwidth:

1.5t0150MHz

_._-

-------~-.---

-. _

...

-------

----

-----~.-

Table

1-1

Test

Equipment

Requirements

Scans by ArtekMedia © 2008

THE

FOLLOWING

a:

I

a: a: a:

I

z W W W I

CALIBRATION

z I

~

W Z N l- I- Z

0

...J

I- z

a:z

wZz

wZz

wOz

wOz

~Z

Wz

Wz

o Z !

a:

Z

PROCEDURES

o..Z

OZ

i=

a:wz

...J

z

o..Q

xQ

0>0

Wo

wo

~Qo

~Qo

1--0

~i=0

«Q

...Jo

::EO

::EO

i=

0

Wo

IF

THIS

«

::E-

«~-

1--

MUST

BE

I-w-

1--

a:1-i= a:1-i=

a:~i=

~~

::J-

zi= zi=

~a:i=

~~

::J~

O~

0::

«...J~

Zl-

w~

0::

I-

Z~

ASSEMBLY

IS

PERFORMED

co

0«

w~«

w~«

w::J«

w::J«

O<t

0«

::J

w«

f/)o::

Qo::

:::::i

O::I-a: _0::

::Ea:

z>a:

z>a:

zOO::

zoO::

::EO::

0::0::

-0::

-a:

otiio::

a:

0::

REPAIRED

OR

\..

a:

co

Oco « W::Jco

I-CO

oco

wwco wwco wOco

woco

::J!!!

WCO

I-co I-co O::E!!! w!!!

w-

x-

zo..-

o:::::::i

«-

(!)O:::::i (!)O:::::i

(!)::E:::::i

X:::::i

«-

«-

REPLACED

~~

0...J 0 wl-...J z...J

(!)::E:::::i

0::...J

-...J -...J

::E

~

~...J

•

1-«

(!)::J«

0«

-«

u..::E« u..::E«

~::E(3

u..!><<(

1-«

-«

>« >«

0«

00

0

::E

0°

1-0

000

a:u.. 0

0::0..

0

0::

0

00

::EO

Wo

Wo

::E

0 0.. 0

0..

>

~

0 0

0 « W w

::E ::E

«

0 0..

f/)

u..

0..

1-8-1

1-8-2 1-8-3 1-8-4 1-8-5 1-8-6 1-8-7 1-8-8 1-8-9 1-8-10

1-8-11

1-8-12 1-8-13 1-8-14 1-8-15 1-8-16

•

MOTHERBOARD

PC

BOARD

ASSEMBLY

ATTENUATOR

CONTROL

PC

BOARD

ASSEMBLY

f--------

"---

I--------~---

f----------

---------

--

FRONT

PANEL

ASSEMBLY

DIGITAL

TRAY

•

CONTROLLER

TRAY

ANAL

VZER

TRAY

• •

RECEIVER

TRAY

• • •

SYNTHESIZER

TRAY • • • • • • • • • • • • •

GENERATOR

TRAY

• • • • •

POWER

TERMINATION

ASSEMBLY

•

GENERATOR

OUTPUT

ASSEMBLY

• • • • •

CONVERTER

ASSEMBLY

• • • • • •

REFERENCE

FREQUENCY

ASSEMBLY

•

FAN

ASSEMBLY

POWER

SUPPLY

ASSEMBLY

• • • • • • • • • • • • • • • •

8702001

Figure

1-1

Module

Replacement

and

Calibration

Requirements

•

1-4

Scans by ArtekMedia © 2008

1.8 CALIBRATION PROCEDU RES

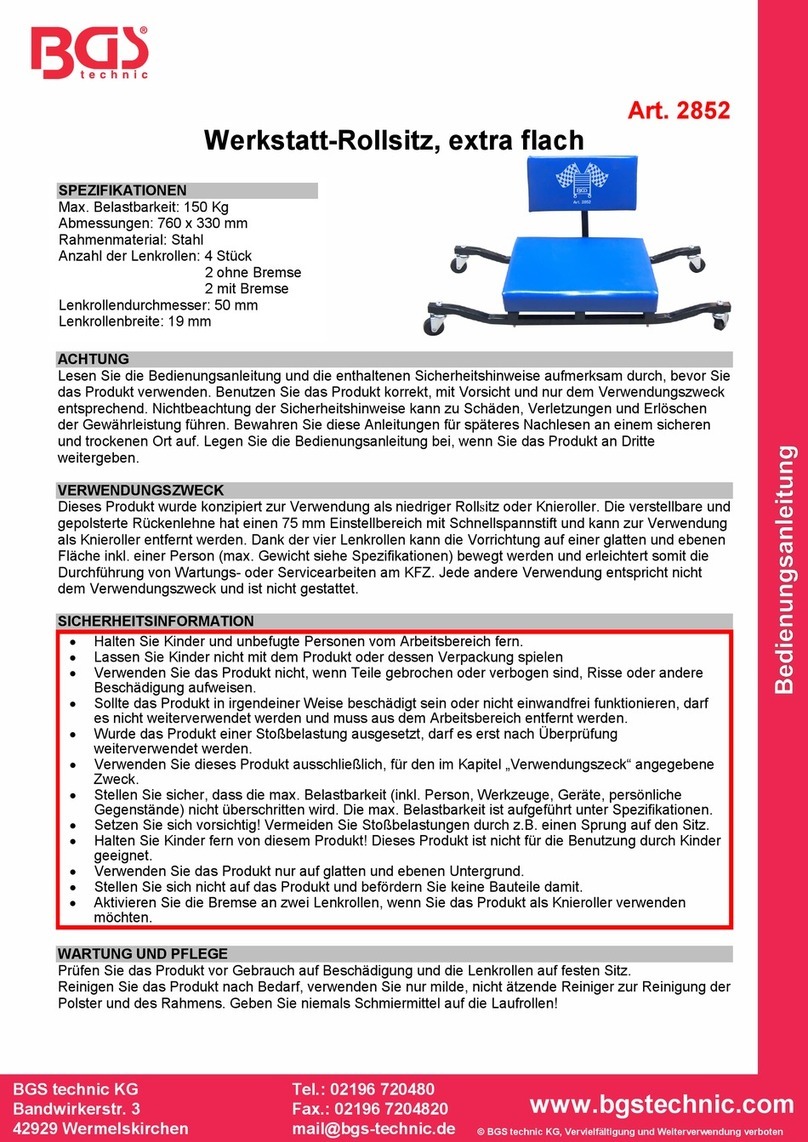

1-8-1 POWER SUPPLY CALIBRATION

PREREQUISITES: NONE

EQUIPMENT REOUIRED: 1 Dlc|TAL MULTTMETER (DMM)

FIG URES: 1-2

STEP PROCEDURE

1. Apply Power to COM-12O8. Ailow 30 minute warm-up period.

2. Verify Voltages at Motherboard Connector 87A6J10 per Table 1-2 using DMM. Refer to

Figure 1-2 tor pin locations. Use Chassis f or ground.

Supply Voltage Locatlon

+13 V+13 Vdc (10.25 V) 8746J10 PtN 1.13

+35 V+35 Vdc (t1 V) 87A6J10 PtN 2.14

10.5 V-10.5 Vdc (t0.5 V) 8746J10 PtN 3.15

+10.5 V+10.5 Vdc (10.25 V) 87A6J10 PIN 4.16

+5 V Analog +5 Vdc (+0.2 V/-0.0 V) 87A6J10 PIN 5.17

+5 V Digital +5 Vdc (+0.2 V/-0.0 V) 8746J10 PrN 7,19

+12 V EL +12 Vdc (10.25 V) 87A6J10 PrN 9.21

Table 1-2 Power Supply Voltages and Locations

3. Set COM-1208 to OFF and disconnect test equipment.

1-5

1-8

CALIBRATION

PROCEDURES

1-8-1

POWER

SUPPLY

CALIBRATION

PREREQUISITES:

NONE

EQUIPMENT

REQUIRED:

DIGITAL

MULTIMETER

(DMM)

FIGURES:

1-2

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

30

minute

warm-up

period.

2.

Verify

Voltages

at

Motherboard

Connector

87A6J10

per

Table

1-2

using

DMM.

Refer

to

Figure

1-2

for

pin

locations.

Use

Chassis

for

ground.

Supply

Voltage

Location

+13

V +

13

Vdc

(±0.25

V)

87A6J10

PIN

1,13

~~------

----,----,

f--~-~-~~---

~~

-

---

-~

-"-~-----

+35

V

+35

Vdc

(±1 V)

87A6J10

PIN

2,14

-10.5

V

-10.5

Vdc

(±0.5

V)

87A6J10

PIN

3,15

+

10.5

V

+10.5

Vdc

(±0.25

V)

87A6J10

PIN

4,16

+5

V

Analog

+5

Vdc

(+0.2

V/-O.O V)

87A6J10

PIN

5,17

+5

V

Digital

+5

Vdc

(+0.2

V/-O.O V)

87A6J10

PIN

7,19

+12VEL

+12

Vdc

(±0.25

V)

87A6J10

PIN

9,21

Table

1-2

Power

Supply

Voltages

and

Locations

3.

Set

COM-120B

to

OFF

and

disconnect

test

equipment.

1-5

Scans by ArtekMedia © 2008

dlilltd-lllti{l

@@ :f -o-

-l I

\;

lo o o o

l.=

foooo,

l-

I

/F

oli

\x:x:

\ oooor

rooooooooorroor I

roo.o.o..o..... I

rooooorooorroot I

,aoooao.o.ooo.. I

roo.o.ooo..oo.. I

)aoooaoooooaaol I

raaoooaoooaaooe I

D..o.o.oao..oa.l

-t

oO

@

12

87A6J10

8707009

Figure 1-2 Power Supply Voltage Locations (87A0J10)

IO

oo

oo

oo

OO

oo

ao

oo

oo

oo

oo

ao

1-6

1-

6

•••••••••••••••••••

•••••••••••••••••••

.......•...........

..................•

................

....•...•.••••..

......•..••••••.

~

••••••••••••••••••••

••••••••••••••••••••

•••••••••••••••••••

87A6J10

Figure

1-2

Power

Supply

Voltage

Locations

(87A6J10)

8707009

Scans by ArtekMedia © 2008

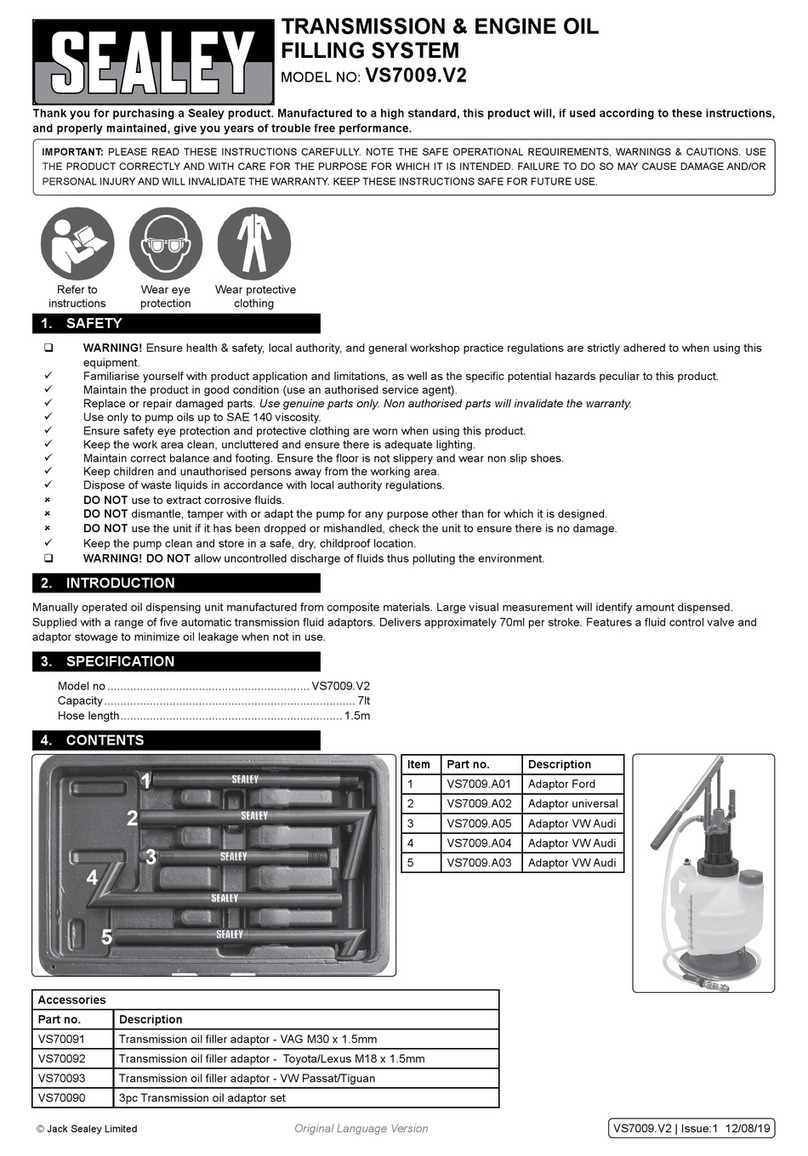

1-8-2 TCXO/OCXO CALIBRATION

PREREQUISITES: 1-8-1 POWER SUPPLY CALIBRATION

EOUIPMENT REQUIRED: 1 FREQUENCY COUNTER

FIGURES: 1-3

STE PPROCEDURE

1. Apply Power to COM-1208. Allow 5 minute warm-up period.

2. Connect Frequency Gounter to AUX RF OUT Connector (13).

3. Press GEN Test Mode Key (3) to access RF Generate Operation Screen.

4. Set RF Field to 998.0000 HHz.

5. Set Output to AUX and Output Level to -13 dBm-

6. Set all Modulation Sources to OFF.

7. lf OCXO is installed, go to Step 10.

8. Verify Frequency Counter reads 998.0000 (1199.6 Hz). Adjust 87A16A1R1 as required

(Figure 1-3).

9. Set COM-1208 Power to OFF and disconnect test equipment.

10. lf OCXO is installed, verify Frequency Counter reads 998.0000 (110 Hz). lf not, go to Step

12.

11. Set COM-1208 Power to OFF and disconnect test equipment.

12. Remove Protected Screw from OCXO to access adjustment. Adjust OCXO until Frequency

Counter reads 998.0000 (t10 Hz).

13. Replace Protected Screw, set COM-1208 Power to OFF and disconnect test equipment.

1-7

1-8-2

TCXO/OCXO

CALIBRATION

PREREQU

IS

ITES:

1-8-1

POWER

SUPPLY

CALIBRATION

EQUIPMENT

REQUIRED:

FREQUENCY

COUNTER

FIGURES:

1-3

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

5

minute

warm-up

period.

2.

Connect

Frequency

Counter

to

AUX

RF

OUT

Connector

(13).

3.

Press

GEN

Test

Mode

Key

(3)

to

access

RF

Generate

Operation

Screen.

4.

Set

RF

Field

to

998.0000

MHz.

5.

Set

Output

to

AUX

and

Output

Level

to

-13

dBm.

6.

Set

all

Modulation

Sources

to

OFF.

7.

If

OCXO

is

installed,

go

to

Step

10.

8.

Verify

Frequency

Cou

nter

reads

998.0000

(±199.6

Hz).

Adjust

87

A

16A

1

R1

as

required

(Figure

1-3).

9.

Set

COM-120B

Power

to

OFF

and

disconnect

test

equipment.

10.

If

OCXO

is

installed,

verify

Frequency

Counter

reads

998.0000

(±10

Hz).

If

not,

go

to

Step

12.

11.

Set

COM-120B

Power

to

OFF

and

disconnect

test

equipment.

12.

Remove

Protected

Screw

from

OCXO

to

access

adjustment.

Adjust

OCXO

until

Frequency

Counter

reads

998.0000

(±10

Hz).

13.

Replace

Protected

Screw,

set

COM-120B

Power

to

OFF

and

disconnect

test

equipment.

1-

7

Scans by ArtekMedia © 2008

PROTECTED SCREW

87A1 6A1 R1

Figu re 1 -3 TCXO/OCXO Adjustments

1-B

PROTECTED SCREW

i

""-,,,

/

V

I

I

8718012

0 0

0 0 0

0 0

~

a

~

0

a a a

o o

o

oe

o

o

87A16A1R1

87070H

Figure

1-3

TCXO/OCXO

Adjustments

1-8

Scans by ArtekMedia © 2008

1-8-3 DVM CALIBRATION

PREREQUISITES: 1-8-1 POWERSUPPLYCALIBRATTON

EOUIPMENT REQUIRED: 1 CALIBRATOR

FIGURES: NONE

STEP PROCEDURE

1. Apply Power to COM-120B. Allow 5 minute warm-up period.

2. Connect Calibrator to SCOPE/DVM Connector (20).

3. Press MTRS Instruments Key (4).

4. Select "3. DVM" on Meters Menu.

5. Set Peak Hold to OFF.

6. Set Average to OFF.

7. Set Source to SC/DVM AC.

8. Set Meter Reading Units to Vrms.

9. Set Range as shown in Table 1-3. For each Range setting, set Calibrator for stated input.

Verify Meter Reading matches input within specified tolerance. lf not, go to Step 13.

Range Callbrator Input Frequency Readlng Tolerance

200 v190 Vrms 50 Hz 110.1 V

20v 19 Vrms 1 kHz 11.02 V

2V 1.9 Vrms 2O kHz 1106 mV

Table 1-3 SC/DVM AC Range Settings

10. Set Source to SC/DVM DC.

11. Set Range as shown in Table 1-4. For each Range setting, set Calibrator for stated input.

Verify Meter Reading matches input within specified tolerance. lf not, go to Step 13.

Range Callbrator Input Readlng Tolerance

200 v 1 90 Vdc +10.1 V

20v 19 Vdc 11.02 V

2V 1.9 Vdc t106 mV

Table 1-4 SC/DVM DC Range Settings

1-9

1-8-3

DVM

CALIBRATION

PREREQUISITES:

1-8-1

POWER

SUPPLY

CALIBRATION

EQU

IPMENT

REQUIRED:

CALIBRATOR

FIGURES:

NONE

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

5

minute

warm-up

period.

2.

Connect

Calibrator

to

SCOPE/DVM

Connector

(20).

3.

Press

MTRS

Instruments

Key

(4).

4.

Select

"3.

DVM"

on

Meters

Menu.

5.

Set

Peak

Hold

to

OFF.

6.

Set

Average

to

OFF.

7.

Set

Source

to

SCIDVM

AC.

8.

Set

Meter

Reading

Units

to

Vrms.

9.

Set

Range

as

shown

in

Table

1-3.

For

each

Range

setting,

set

Calibrator

for

stated

input.

Verify

Meter

Reading

matches

input

within

specified

tolerance.

If

not,

go

to

Step

13.

Range

Calibrator

Input

Frequency

Reading

Tolerance

200

V

190

Vrms

50

Hz !

±1

O.

1 V

20

V 19

Vrms

1

kHz

±1.02

V

2V

1.9

Vrms

I

20

kHz

±106

mV

I

Table

1-3

SC/DVM

AC

Range

Settings

10.

Set

Source

to

SCIDVM

DC.

11.

Set

Range

as

shown

in

Table

1-4.

For

each

Range

setting,

set

Calibrator

for

stated

input.

Verify

Meter

Reading

matches

input

within

specified

tolerance.

If

not,

go

to

Step

13.

Range

Calibrator

Input

Reading

Tolerance

200

V

190

Vdc

±10.1

V

20

V 19

Vdc

±1.02

V

2 V

1.9

Vdc

±106

mV

Table

1-4

SC/DVM

DC

Range

Settings

1-9

Scans by ArtekMedia © 2008

STEP PROCEDURE

12. Set COM-1208 to OFF and disconnect test equipment.

PERFORM THE FOLLOWING ONLY WHEN REQUIRED.

13. Press SETUP MEMORY Key (21).

14. Select "1. Calibration" f rom Setup Screen.

15. Press ENTER Key to access Password Field. Press SHIFT, F, M, Y, S, V, C, D and SHIFT

Data Entry Keys (5). Press ENTER Key.

16. Select "1. DVM" to access DVM METER CALIBRATION Screen.

17. Move cursor to AC RANGE X1.

18. Set Calibrator to 1.000 Vrms at 60 Hz.

19. Press ENTER Key twice and wait until current Field displays CALIBnATED.

20. Move cursor to AC RANGE X10.

21. Set Calibrator to 10.00 Vrms at 60 Hz.

22. Press ENTER Key twice and wait until current Field displays CALIBBATED.

23. Move cursor to AC RANGE X100.

24. Set Calibrator to 100.0 Vrms at 60 Hz.

25. Press ENTER Key twice and wait until current Field displays CALIBRATED.

26. Move cursor to DC RANGE X1.

27. Set Calibrator to 2.000 Vdc.

28. Press ENTER Key twice and wait until current Field displays CALIBRATED.

29. Press RETURN Soft Function Key F6.

30. Press MTRS lnstruments Key (4).

31. Select "3. DVM" on Meters Menu.

32. Proceed at Step 7.

1-10

STEP

PROCEDURE

12.

Set

COM-120B

to

OFF

and

disconnect

test

equipment.

PERFORM

THE

FOLLOWING

ONLY

WHEN

REQUIRED.

13.

Press

SETUP

MEMORY

Key

(21).

14.

Select

"1.

Calibration"

from

Setup

Screen.

15.

Press

ENTER

Key

to

access

Password

Field.

Press

SHIFT,

F, M, Y, S,

V,

C,

D

and

SHIFT

Data

Entry

Keys

(5).

Press

ENTER

Key.

16.

Select

"1.

DVM"

to

access

DVM

METER

CALIBRATION

Screen.

17.

Move

cursor

to

AC

RANGE

X1.

18.

Set

Calibrator

to

1.000

Vrms

at

60

Hz.

19.

Press

ENTER

Key

twice

and

wait

until

current

Field

displays

CALIBRATED.

20.

Move

cursor

to

AC

RANGE

X10.

21.

Set

Calibrator

to

10.00

Vrms

at

60

Hz.

22.

Press

ENTER

Key

twice

and

wait

until

current

Field

displays

CALIBRATED.

23.

Move

cursor

to

AC

RANGE

X100.

24.

Set

Calibrator

to

100.0

Vrms

at

60

Hz.

25.

Press

ENTER

Key

twice

and

wait

until

current

Field

displays

CALIBRATED.

26.

Move

cursor

to

DC

RANGE

X1.

27.

Set

Calibrator

to

2.000

Vdc.

28.

Press

ENTER

Key

twice

and

wait

until

current

Field

displays

CALIBRATED.

29.

Press

RETURN

Soft

Function

Key

F6.

30.

Press

MTRS

Instruments

Key

(4).

31.

Select

"3.

DVM"

on

Meters

Menu.

32.

Proceed

at

Step

7.

1-10

Scans by ArtekMedia © 2008

1.8-4 GENERATOR OUTPUT LEVEL CALIBRATION

PREREQUISITES: 1-8-1 POWER SUPPLY CALIBRATION

EQUIPMENT REOUIRED: 1 MEASURING RECEIVER

FIGURES: NONE

STEP PROCEDURE

1. Apply Power to COM-1208. Allow 5 minute warm-up period.

2. Press GEN Test Mode Key (3) to access RF Generate Operation Screen.

3. Set RF Field to 405.5000 MHz.

4. Set all Modulation Sources to OFF.

5. Set Output to T/H and connect Measuring Receiver to T/R Connector. Set Measuring

Receiver for Automatic Tuning and Tuned RF Level Measurement.

6. Set Output Level to -20 dBm. Verify Measuring Receiver reads -20 dBm (t2 dB). lf not,

go to Step 14.

7. Set Output Level to -9O dBm. Verify Measuring Receiver reads -90 dBm (t2 dB). lf not,

go to Step 14.

8. Set Output Level to -130 dBm. Verify Measuring Receiver reads -130 dBm (12.5 dB). lf

not, go to Step 14.

9. Set Output to AUX and connect Measuring Receiver to AUX RF OUT Connector (13).

10. Set Output Level to -20 dBm. Verify Measuring Receiver reads -20 dBm (12 dB). lf not,

go to Step 14.

11. Set Output Level to -9O dBm. Verify Measuring Receiver reads -90 dBm (t2 dB). lf not,

go to Step 14.

12. Set Output Level to -130 dBm. Verify Measuring Receiver reads -130 dBm (42.5 dB). lf

not, go to Step 14.

13. Set COM-120B to OFF and disconnect test equipment.

PERFORM THE FOLLOWING ONLY WHEN REOUIRED.

14. Press SETUP MEMORY Key (21).

15. Select "1. Calibration" f rom Setup Screen.

16. Press ENTER Key to access Password Field. Press SHIFT, F, M, Y, S, V, C, D and SHIFT

Data Entry Keys (5). Press ENTER Key.

17. Select "6. RF GENERATOR - OUTPUT LEVEL" to access RF GENERATOR LEVEL

CALIBRATION Screen.

1-11

1-8-4

GENERATOR

OUTPUT

LEVEL

CALIBRATION

PREREQUISITES:

1-8-1

POWER

SUPPLY

CALIBRATION

EQUIPMENT

REQUIRED:

1

MEASURING

RECEIVER

FIGURES:

NONE

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

5

minute

warm-up

period.

2.

Press

GEN

Test

Mode

Key

(3)

to

access

RF

Generate

Operation

Screen.

3.

Set

RF

Field

to

405.5000

MHz.

4.

Set

all

Modulation

Sources

to

OFF.

5.

Set

Output

to

TIR

and

connect

Measuring

Receiver

to

T/R

Connector.

Set

Measuring

Receiver

for

Automatic

Tuning

and

Tuned

RF

Level

Measurement.

6.

Set

Output

Level

to

-20

dBm.

Verify

Measuring

Receiver

reads

-20

dBm

(±2

dB).

If

not,

go

to

Step

14.

7.

Set

Output

Level

to

-90

dBm.

Verify

Measuring

Receiver

reads

-90

dBm

(±2

dB).

If

not,

go

to

Step

14.

8.

Set

Output

Level

to

-130

dBm.

Verify

Measuring

Receiver

reads

-130

dBm

(±2.5

dB).

If

not,

go

to

Step

14.

9.

Set

Output

to

AUX

and

connect

Measuring

Receiver

to

AUX

RF

OUT

Connector

(13).

10.

Set

Output

Level

to

-20

dBm.

Verify

Measuring

Receiver

reads

-20

dBm

(±2

dB).

If

not,

go

to

Step

14.

11.

Set

Output

Level

to

-90

dBm.

Verify

Measuring

Receiver

reads

-90

dBm

(±2

dB).

If

not,

go

to

Step

14.

12.

Set

Output

Level

to

-130

dBm.

Verify

Measuring

Receiver

reads

-130

dBm

(±2.5

dB).

If

not,

go

to

Step

14.

13.

Set

COM-120B

to

OFF

and

disconnect

test

equipment.

PERFORM

THE

FOLLOWING

ONLY

WHEN

REQUIRED.

14.

Press

SETUP

MEMORY

Key

(21).

15.

Select

"1.

Calibration"

from

Setup

Screen.

16.

Press

ENTER

Key

to

access

Password

Field.

Press

SHIFT,

F, M, Y,

S,

V, C, D

and

SHIFT

Data

Entry

Keys

(5).

Press

ENTER

Key.

17.

Select

"6.

RF

GENERATOR

-

OUTPUT

LEVEL"

to

access

RF

GENERATOR

LEVEL

CALIBRATION

Screen.

1-11

Scans by ArtekMedia © 2008

STEP PROCEDURE

18. Press LEVEL Soft Function Key F2, if displayed.

19. Connect Measuring Receiver to T/R Connector.

20. Move cursor to -20 dBm Field. Press ENTER Key to access Data Field.

21. Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading closest to

-20 dBm.

22. Press ENTER Key and wait until -20 dBm Field displays CALIBRATED.

23. Move cursor to -22 dBm Field. Press ENTER Key to access Data Field.

24. Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading closest

-22 dBm.

25. Press ENTER Key and wait until -22 dBm Field displays CALIBBATED.

26. Move cursor to -24 dBm Field. Press ENTER Key to access Data Field.

27. Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading closest

-24 dBm.

28. Press ENTER Key and wait until -24 dBm Field displays CALIBRATED.

29. Move cursor to -26 dBm Field. Press ENTER Key to access Data Field.

30. Edit Data Field using DATA SCROLL Keys (17), tor Measuring Receiver reading closest

-26 dBm.

31. Press ENTER Key and wait until -26 dBm Field displays CALIBRATED.

32. Move cursor to -28 dBm Field. Press ENTER Key to access Data Field.

33. Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading closest

-28 dBm.

to

to

to

to

to

34. Press ENTER Key and wait until -28 dBm Field

35. Move cursor to -29.9 dBm Field. Press ENTER

36. Edit Data Field using DATA SCROLL Keys (17)

-29.9 dBm.

displays CALIBRATED.

Key to access Data Field.

f or Measuring Receiver reading closest

37. Press ENTER Key and wait until -29.9 dBm Field displays CALIBRATED.

38. Press T/R Soft Function Key F3. Set Measuring Receiver for RF Power Measurement.

t-tz

STEP

PROCEDURE

18.

Press

LEVEL

Soft

Function

Key

F2,

if

displayed.

19.

Connect

Measuring

Receiver

to

T/R

Connector.

20.

Move

cursor

to

-20

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

21.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-20

dBm.

22.

Press

ENTER

Key

and

wait

until

-20

dBm

Field

displays

CALIBRATED.

23.

Move

cursor

to

-22

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

24.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-22

dBm.

25.

Press

ENTER

Key

and

wait

until

-22

dBm

Field

displays

CALIBRATED.

26.

Move

cursor

to

-24

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

27.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-24

dBm.

28.

Press

ENTER

Key

and

wait

until

-24

dBm

Field

displays

CALIBRATED.

29.

Move

cursor

to

-26

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

30.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-26

dBm.

31.

Press

ENTER

Key

and

wait

until

-26

dBm

Field

displays

CALIBRATED.

32.

Move

cursor

to

-28

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

33.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-28

dBm.

34.

Press

ENTER

Key

and

wait

until

-28

dBm

Field

displays

CALIBRATED.

35.

Move

cursor

to

-29.9

dBm

Field.

Press

ENTER

Key

to

access

Data

Field.

36.

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-29.9

dBm.

37.

Press

ENTER

Key

and

wait

until

-29.9

dBm

Field

displays

CALIBRATED.

38.

Press

T/R

Soft

Function

Key

F3.

Set

Measuring

Receiver

for

RF

Power

Measurement.

1-1 2

Scans by ArtekMedia © 2008

STEP PROCEDURE

39. Access each Data Field for f requencies 0.2500 to 999.9999 MHz. For each Data Field,

perform following:

O Press ENTER Key to access Data Field.

O Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading

closest to -20 dBm.

a Press ENTER Key and wait until current Field displays CALIBnATED.

O Continue with next Field.

40. Press AUX Soft Function Key F4.

41. Connect Measuring Receiver to AUX RF OUT Connector (13).

42. Access each Data Field for f requencies 0.2500 to 999.9999 MHz. For each Data Field,

perform following:

a Press ENTER Key to access Data Field.

a Edit Data Field using DATA SCROLL Keys (17) tor Measuring Receiver reading

closest to -13 dBm.

O Press ENTER Key and wait until current Field displays CALIBRATED.

O Continue with next Field.

43. lf Optional Amplifier is installed, press AUX AMP Soft Function Key F5.

44. Access each Data Field for f requencies 0.2500 to 999.9999 MHz. For each Data Fietd,

perform following:

a Press ENTER Key to access Data Field.

O Edit Data Field using DATA SCROLL Keys (17) for Measuring Receiver reading

closest to 0.0 dBm.

O Press ENTER Key and wait until current Field displays CALIBRATED.

O Continue with next Field.

45. Press RETURN Soft Function Kev F6.

46. Press GEN Test Mode Key (3).

47. Continue at Step 2.

1-'13

STEP

PROCEDURE

39.

Access

each

Data

Field

for

frequencies

0.2500

to

999.9999

MHz.

For

each

Data

Field.

perform

following:

•

Press

ENTER

Key

to

access

Data

Field.

•

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-20

dBm.

•

Press

ENTER

Key

and

wait

until

current

Field

displays

CALIBRATED.

•

Continue

with

next

Field.

40.

Press

AUX

Soft

Function

Key

F4.

41.

Connect

Measuring

Receiver

to

AUX

RF

OUT

Connector

(13).

42.

Access

each

Data

Field

for

frequencies

0.2500

to

999.9999

MHz.

For

each

Data

Field.

perform

following:

•

Press

ENTER

Key

to

access

Data

Field.

•

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

-13

dBm.

•

Press

ENTER

Key

and

wait

until

current

Field

displays

CALIBRATED.

•

Continue

with

next

Field.

43.

If

Optional

Amplifier

is

installed.

press

AUX

AMP

Soft

Function

Key

F5.

44.

Access

each

Data

Field

for

frequencies

0.2500

to

999.9999

MHz.

For

each

Data

Field.

perform

following:

•

Press

ENTER

Key

to

access

Data

Field.

•

Edit

Data

Field

using

DATA

SCROLL

Keys

(17)

for

Measuring

Receiver

reading

closest

to

0.0

dBm.

•

Press

ENTER

Key

and

wait

until

current

Field

displays

CALIBRATED.

•

Conti

nue

with

next

Field.

45.

Press

RETURN

Soft

Function

Key

F6.

46.

Press

GEN

Test

Mode

Key

(3).

47.

Continue

at

Step

2.

1

-13

Scans by ArtekMedia © 2008

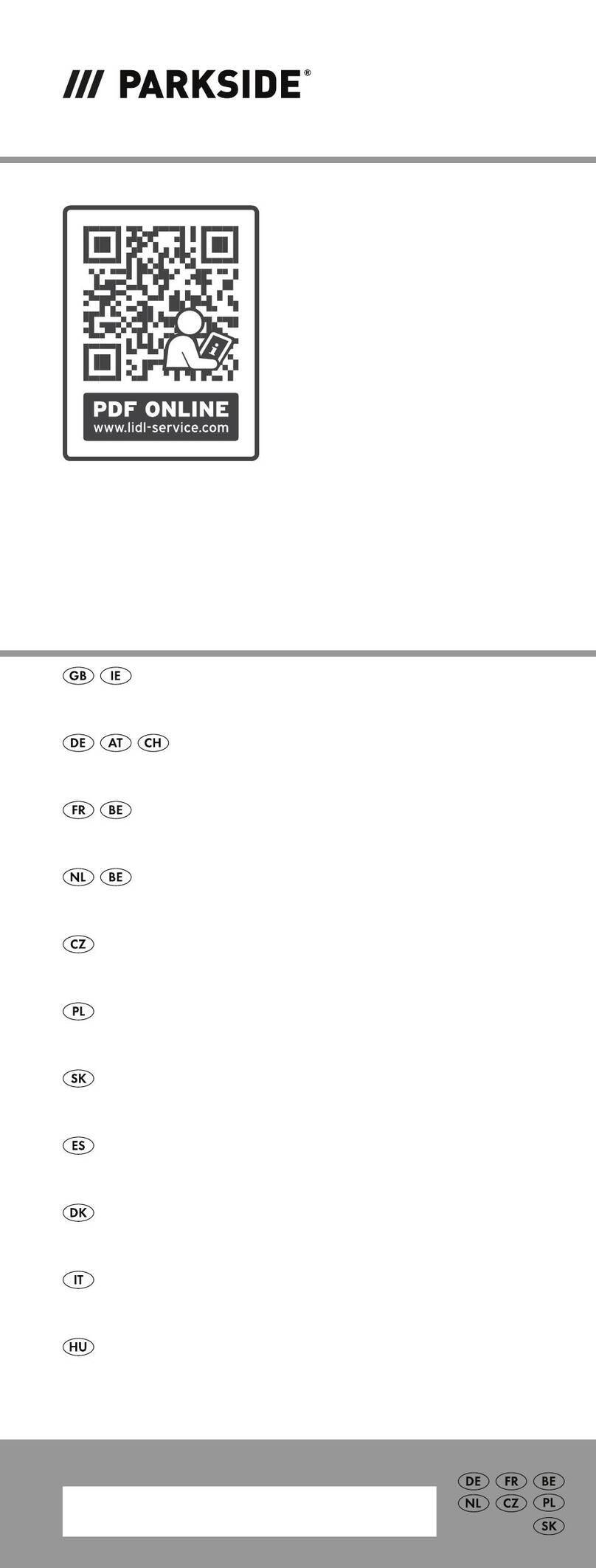

-8-5 DISTORTION METER

PREREQU ISITES:

EQU IPMENT REOUIRED:

FIG U RES:

CALIBRATION

1-8-1 POWER SUPPLY CALIBRATION

'l

AA

AUDIO ANALYZER

AUDIO/DATA

Figure 1-4 Distortion/SINAD Meter Test Equipment Setup

STEP PROCEDURE

1. Apply Power to COM-1208. Allow 5 minute warm-up period.

2. Connect Test Equipment as shown in Figure 1-4.

3. Press AUDIO GEN lnstruments Key ( ).

4. Set Audio Generator 2 to ON.

5. lf Optional Audio Generator 2 is installed, set Tone Frequency tor 1000.0 Hzand Shape to

S'NE.

6. Set Audio Generator 2 Level tor 1.41 Vp.

7. Set Audio Generator 1 to OIV.

8. Set Audio Generator 1 Format to TONE.

9. Set Audio Generator 1 Tone Frequency to 2800.0 Hz.

10. Set Audio Generator 1 Shape to SINE.

11. Set Audio Generator 1 Level to 0.14 Vp.

12. Set Audio Generator 1 Mode to CON]..

coM-1208

(1e) (14)

AUDIO ANALYZER

AUDIO/DATA GEN

1 1A

t-t+

1-8-5

DISTORTION

METER

CALIBRATION

PREREQUISITES:

1-8-1

POWER

SUPPLY

CALIBRATION

EQUIPMENT

REQUIRED:

AUDIO

ANALYZER

FIGURES:

1-4

COM-120B AUDIO ANALYZER

(19)

(14)

AUDIO/DATA

IN

AUDIO/DATA

GEN

HIGH

IMPEDANCE

INPUT

00603001

Figure

1-4

Distortion/SINAD

Meter

Test

Equipment

Setup

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

5

minute

warm-up

period.

2.

Connect

Test

Equipment

as

shown

in

Figure

1-4.

3.

Press

AUDIO

GEN

Instruments

Key

(4).

4.

Set

Audio

Generator

2

to

ON.

5.

If

Optional

Audio

Generator

2

is

installed.

set

Tone

Frequency

for

1000.0

Hz

and

Shape

to

SINE.

6.

Set

Audio

Generator

2

Level

for

1.41

Vp.

7.

Set

Audio

Generator

1

to

ON.

8.

Set

Audio

Generator

1

Format

to

TONE.

9.

Set

Audio

Generator

1

Tone

Frequency

to

2800.0

Hz.

10.

Set

Audio

Generator

1

Shape

to

SINE.

11

.

Set

Audio

Generator

1

Level

to

0.14

Vp.

12.

Set

Audio

Generator

1

Mode

to

CONT.

1-1 4

Scans by ArtekMedia © 2008

STEP PROCEDURE

13. Set Audio Analyzer to measure Distortion with all filters off .

14. Verify Audio Analyzer reads approximately 10% Distortion.

15. Press MTRS Instruments Key (4).

16. Select Distortion Meter Operation.

17. Set Distortion Meter Source to AUDIO/DATA-IN.

18. Set Peak Hold to OFF.

19. Set Average to OFF.

20. Set Low-Pass Filter to 20 kHz.

21. Verify Distortion Meter Reading matches Audio Analyzer (10.6%). lf not, go to Step 23.

22. Set COM-1208 Power to OFF and disconnect test equipment.

PERFORM THE FOLLOWING ONLY WHEN REQUIRED,

23. Set Audio Generator 2 tor 1.41 Vp.

24. Set Audio Generator 1 tor 0.14 Vp.

25. Press SETUP MEMORY Key (21).

26. Select "1. Calibration" f rom Setup Screen.

27. Press ENTER Key to access Password Field. Press SHIFT, F, M, Y, S, V, C, D and SHIFT

Data Entry Keys (5). Press ENTER Key.

28. Select "2. O ISTORTION METER" to access DISTORTION METER CALIBRATION Screen.

29. Enter Audio Analyzer Reading using DATA ENTRY Keys (5). Press ENTER Key.

30. Go to Step 15.

1-15

STEP

PROCEDURE

13.

Set

Audio

Analyzer

to

measure

Distortion

with

all

filters

off.

14.

Verify

Audio

Analyzer

reads

approximately

10%

Distortion.

15.

Press

MTRS

Instruments

Key

(4).

16.

Select

Distortion

Meter

Operation.

17.

Set

Distortion

Meter

Source

to

AUDIO/DATA-IN.

18.

Set

Peak

Hold

to

OFF.

19.

Set

Average

to

OFF.

20.

Set

Low-Pass

Filter

to

20

kHz.

21.

Verify

Distortion

Meter

Reading

matches

Audio

Analyzer

(iO.6%).

If

not,

go

to

Step

23.

22.

Set

COM-120B

Power

to

OFF

and

disconnect

test

equipment.

PERFORM

THE

FOLLOWING

ONLY

WHEN

REQUIRED.

23.

Set

Audio

Generator

2

for

1.41

Vp.

24.

Set

Audio

Generator

1

for

0.14

Vp.

25.

Press

SETUP

MEMORY

Key

(21).

26.

Select

"1.

Calibration"

from

Setup

Screen.

27.

Press

ENTER

Key

to

access

Password

Field.

Press

SHIFT,

F, M, Y, S, V, C, D

and

SHIFT

Data

Entry

Keys

(5).

Press

ENTER

Key.

28.

Select

"2.

DISTORTION

METER"

to

access

DISTORTION

METER

CALIBRATION

Screen.

29.

Enter

Audio

Analyzer

Reading

using

DATA

ENTRY

Keys

(5).

Press

ENTER

Key.

30.

Go

to

Step

15.

1

-15

Scans by ArtekMedia © 2008

1-8-6 SINAD METER CALIBRATION

PREREOUISITES: 1-8-1 POWER SUPPLY CALIBRATION

EQUIPMENT REQUIRED: 1 AUDIO ANALYZER

FIG U RES:

STEP

1-4

PROCED URE

1. Apply Power to COM-1208. Allow 5 minute warm-up period.

2. Connect Test Equipment as shown in Figure 1-4.

3. Press AUDIO GEN Instruments Key (a).

4. Set Audio Generator 2 to ON.

5. ff Optional Audio Generator 2 is installed, set Tone Frequency for 10A0.0 Hz and Shape to

srwE.

6. Set Audio Generator 2 Level tor 1.41 Vp.

7. Set Audio Generator 1 to OIV.

8. Set Audio Generator 1 Format to IONE.

9. Set Audio Generator 1 Tone Frequency to 2800.0 Hz.

10. Set Audio Generator 1 Shape to SIIVE.

11. Set Audio Generator 1 Level to 0.14 Vp.

12. Set Audio Generator 1 Mode to CONT.

13. Set Audio Analyzer to measure SINAD with filters off .

14. Verify Audio Analyzer reads approximately 20 dB SINAD.

15. Press MTRS Instruments Key (a).

16. Select SINAD Meter Operation.

17. Set SINAD Meter Source to AUDIO/DATA-IN.

18. Set Peak Hold to OFF.

19. Set Average to OFF.

20. Set Low-Pass Filter to 20 kHz.

21. Verify SINAD Meter Reading matches Audio Analyzer (11.1 dB). lf not, go to Step 23.

22. Set COM-120B Power to OFF and disconnect test equipment.

1-16

1-8-6

SINAD

METER

CALIBRATION

PREREQUISITES:

1-8-1

POWER

SUPPLY

CALIBRATION

EQUIPMENT

REQUIRED:

AUDIO

ANALYZER

FIGURES:

1-4

STEP

PROCEDURE

1.

Apply

Power

to

COM-120B.

Allow

5

minute

warm-up

period.

2.

Connect

Test

Equipment

as

shown

in

Figure

1-4.

3.

Press

AUDIO

GEN

Instruments

Key

(4).

4.

Set

Audio

Generator

2

to

ON.

5.

If

Optional

Audio

Generator

2

is

installed,

set

Tone

Frequency

for

1000.0

Hz

and

Shape

to

SINE.

6.

Set

Audio

Generator

2

Level

for

1.41

Vp.

7.

Set

Audio

Generator

1

to

ON.

8.

Set

Audio

Generator

1

Format

to

TONE.

9.

Set

Audio

Generator

1

Tone

Frequency

to

2800.0

Hz.

10.

Set

Audio

Generator

1

Shape

to

SINE.

11

.

Set

Audio

Generator

1

Level

to

0.14

Vp.

12.

Set

Audio

Generator

1

Mode

to

CONT.

13.

Set

Audio

Analyzer

to

measure

SINAD

with

filters

off.

14.

Verify

Audio

Analyzer

reads

approximately

20

dB

SINAD.

15.

Press

MTRS

Instruments

Key

(4).

16.

Select

SINAD

Meter

Operation.

17.

Set

SINAD

Meter

Source

to

AUDIO/DATA-IN.

18.

Set

Peak

Hold

to

OFF.

19.

Set

Average

to

OFF.

20.

Set

Low-Pass

Filter

to

20

kHz.

21.

Verify

SINAD

Meter

Reading

matches

Audio

Analyzer

(±1.1

dB).

If

not,

go

to

Step

23.

22.

Set

COM-120B

Power

to

OFF

and

disconnect

test

equipment.

1

-1

6

Scans by ArtekMedia © 2008

Other manuals for COM-120B

1

Table of contents

Other IFR Service Equipment manuals