Tektronix 519 User manual

Other Tektronix Test Equipment manuals

Tektronix

Tektronix 7T11A User manual

Tektronix

Tektronix 7904 User manual

Tektronix

Tektronix 221 User manual

Tektronix

Tektronix MSO2000 Series User manual

Tektronix

Tektronix TDS3000 Series Troubleshooting guide

Tektronix

Tektronix 7313/R7313 User manual

Tektronix

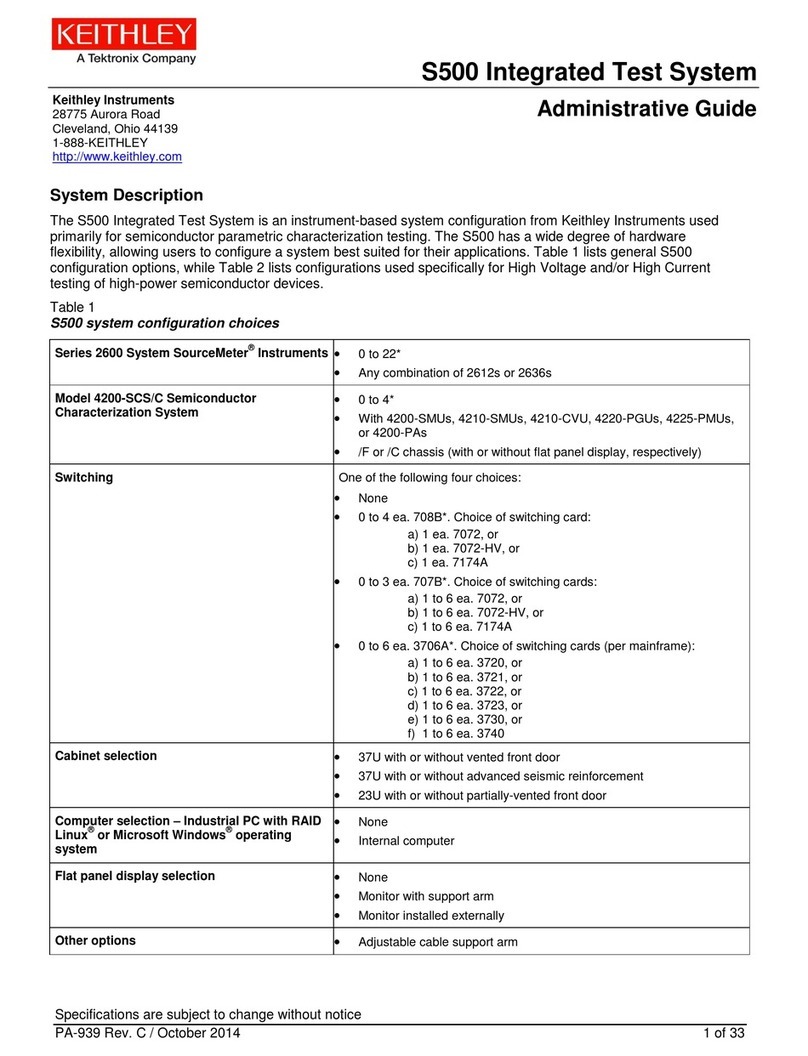

Tektronix Keithley S500 User manual

Tektronix

Tektronix 544 User manual

Tektronix

Tektronix 511A User manual

Tektronix

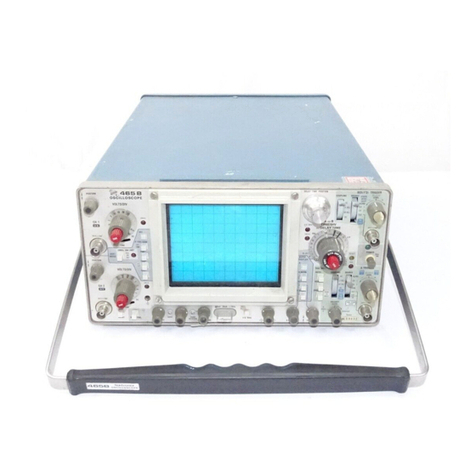

Tektronix 465B User manual

Tektronix

Tektronix MSO70000C/DX Use and care manual

Tektronix

Tektronix 314 User manual

Tektronix

Tektronix AMM768 User manual

Tektronix

Tektronix 513 User manual

Tektronix

Tektronix 7603 Operating instructions

Tektronix

Tektronix Keithley 2657A User manual

Tektronix

Tektronix P7380SMA User manual

Tektronix

Tektronix 7603 User manual

Tektronix

Tektronix 2430A User manual

Tektronix

Tektronix 5000 Series User manual