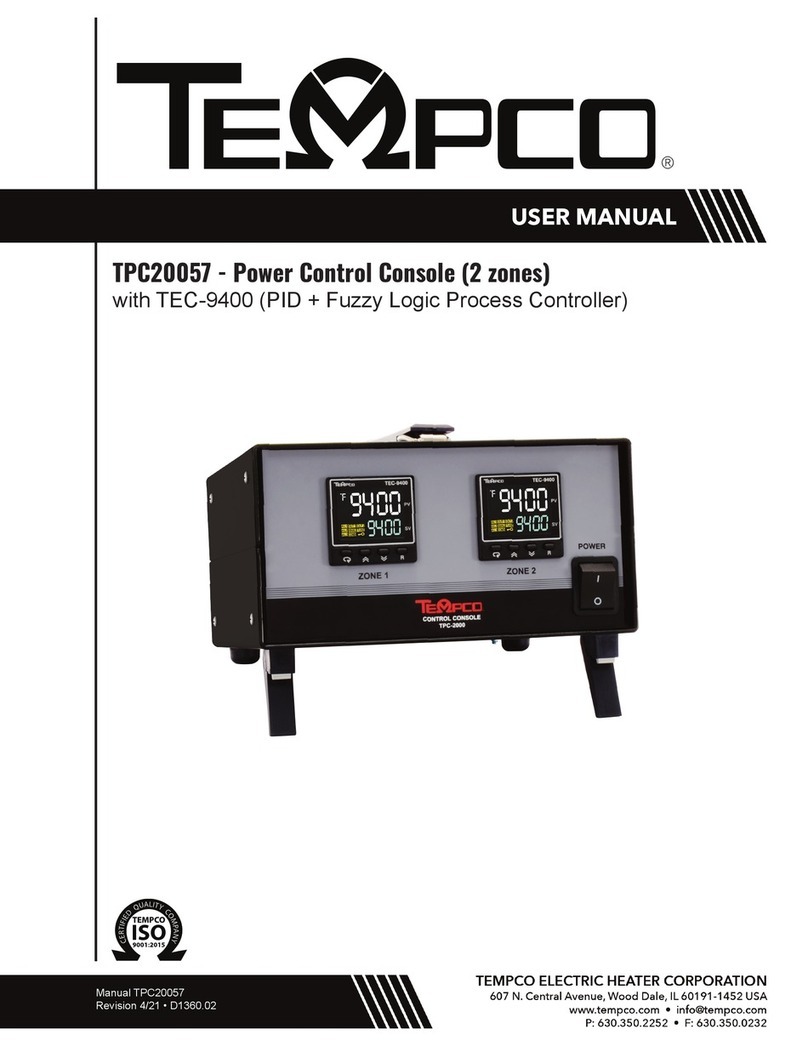

Tempco TPC-1000 User manual

TPC-1000/2000/3000/4000 - 12 Amp

with TEC-9400 (PID + Fuzzy Logic Process Controller)

D1306.TE-401-402-404-405 Revision 2/22/2019

USER MANUAL

Manual TPC-1000/2000/3000/4000 - 12 Amp

Revision 7/19 • D1340

Page 1of 18

SPECIFICATIONS

Temperature Controller: Model TEC-9400, 1/16 DIN Dual Display with PID Auto-tuning

Sensor Input: Type “J”, type “K” thermocouple or RTD, dependent on model ordered

(Alternative inputs available for special order)

Note: Connector body colors are as follow:

Type “J” T/C: Black

Type “K” T/C: Yellow

RTD: White

Power Cord/voltage Input: 120VAC or 240VAC (dependent on model ordered) –

Check rear label for indentification

Heater Output: 12A max for 1-zone consoles

6A max per zone for 2-zone consoles

4A max per zone for 3-zone consoles

3A max per zone for 4-zone consoles

Output Device: Solid State Relay

Main Power Switch: Located on front panel

Fuse Main Power: See replacement parts list (located inside power inlet module)

Fuse Control Power: See replacement parts list (located on back panel)

WARNINGS

1. Air vents located on top and bottom of console must not be blocked! To prevent an overheating condition

the internal components must remain as close to room temperature (75ºF / 24ºC) as possible.

2. Dangerous voltage capable of causing injury or death is present within this console. Power to all

equipment must be disconnected before installation or beginning any troubleshooting procedures. Heater

output wiring and component replacement must be made by qualified personnel only.

3. To minimize the possibility of fire or shock, do not expose this console to rain or excessive moisture.

4. Do not use this console in areas where hazardous conditions exist such as excessive shock, vibration,

dirt, corrosive gases, oil or where explosive gases or vapors are present.

5. It is strongly recommended that a process should incorporate a Limit Control like a Tempco TEC-901

which will shut down the equipment at a preset process condition in order to avoid possible damage to

products or systems.

WIRING (For safety, disconnect all power sources prior to wiring)

1. Attach the leads from your type thermocouple to the mini-plug provided. Take care to note the correct

polarity. The red lead is (-) negative.

2. The heater output current is sourced directly through the line cord. The rear console output receptacle and

mating Hubbell plug provides live controlled power for direct connection to your heater(s). Connect one lead

from your heater to one prong of the Hubbell plug (not ground). Connect the other lead from your heater to

the other prong. Connect heater ground (if applicable) to the ground connection (G) on the plug.

Page 2of 18

OPERATION

1. Verify the power switch is in the off position. Plug your heater & thermocouple into the rear connectors. Plug the provided line

cord from the console into a standard outlet. Switch on the console.

2. Set your desired temperature setpoint by using the up and down arrow buttons on the TEC-9400 temperature controller.

3. Refer to the following pages for complete operation and auto-tuning of the TEC-9400 temperature controller.

SPARE/REPLACEMENT PARTS

Tempco Description

Part Number

EHD-124-276 (for 1, 2, and 3-zone units) Fuse (1), rated 1 Amp/ 250V, ¼" x 1¼", fast acting,

BUSS ABC-1-R. Used for TEC-9400 Controller (located inside rear panel mounted fuseholder)

EHD-124-290 (for 4-zone units) Fuse (1), rated 1.5 Amp/ 250V, ¼" x 1¼", slow acting, BUSS

ABC-1 .5-R. Used for TEC-9400 Controller (located inside rear panel mounted fuseholder).

EHD-124-300 (for 2-zone units) Fuses (2), rated 8 amps, 250V, ¼" x 1¼", fast acting, BUSS ABC-8-R.

EHD-124-279 (for 3-zone units) Fuses (3), rated 5A, 250V, ¼" x 1¼", fast acting, BUSS ABC-5-R.

EHD-124-282 (for 4-zone units) Fuses (4), rated 4 amps, 250V, ¼" x 1¼", fast acting, BUSS ABC-4-R.

EHD-102-113 (for 120V units) Power output plug (1 per zone), Hubbell HBL4720C, 15A 125V Twist-Lock.

EHD-102-121 (for 240V units) Power output plug (1 per zone), Hubbell HBL4570C, 15A 250V Twist-Lock.

(Type of plug dependent on console model ordered)

TCA-101-104 Type “K” thermocouple mini plug (1 per zone), yellow

TCA-101-105 Type “J” thermocouple mini plug (1 per zone), black

TCA-101-136 Type “CU” mini-plug, white (for 2-wire RTD)

NOTE: For all fuses, use listed BUSS part numbers or equivaliant.

Page 3of 18

2-1.TEC-9400 Front Panel Keys and Display

Page 4of 18

1.1 Menu Flowchart

The Menu has been divided in to 5 groups. They are as follows:

1. User Menu

2. Setup Menu

3. Manual Mode Menu

4. Auto-Tuning Mode Menu

5. Calibration Mode Menu

User Menu Setup

Menu

Manual Mode

Auto-Tuning Mode

Calibration Mode

5 Sec 6.2 Sec 7.4 Sec 8.6 Sec 9.8 Sec

5 Sec 5 Sec 2 Sec Min

3 Sec Max

To access a

parameter

In the User Menu,

Refer to

Section 1.1.1.1,

page 5

To access a

parameter in

the Setup Menu,

Refer to

Section 1.1.1,

Starting on Page 5.

8 Sub-menu options

are available for the

setup menu.

- Basic Menu

- Output Menu

- Alarm Menu

- Event Input Menu

- User Select Menu

To start

Manual

Control

Mode, Refer to

Section 1.1.2

Page 7 & 18

To start

Auto-Tuning

Mode, Refer to

Section 1.1.3

Page 7, 15 & 16

To access

Calibration Mode,

Refer to

Section 2.5

Page 14

Press for the next parameter

Press and key to return to the previous parameter.

Page 5of 18

*Not Applicable

1.1.1 Setup Menu

The setup menu has been categorized in to eight categories. They are listed below.

1. Basic Menu (pg 5) *5. User Select Menu

2. Output Menu (pg. 6) *6. Communication Menu

*3. Alarm Menu *7. Current Transformer Menu

*4. Event Input Menu *8. Profile Menu (Ramp and Soak)

1.1.1.1 Basic Menu (bASE)

In the setup menu, when the upper display says “SET”, Use the or keys to get “bASE” in the lower display.

Then, use the key to cycle through the “bASE” menu parameters (Note Chart on pg. 8).

or

SET bASE

OFS1

OFS2

OFS3

INPT

UNIT

DP

INLO

INHI

SP1L

SP1H

FILT

DISP

PB

TI

TD

RAM P

RR

RET Y

RELO

REHI

RMSP

RINL

RINH

CODE

OFST L

OFST H

CALO

CAHI

SFT

SFL1

SFL2

SFtH

Page 6of 18

1.1.1.2 Output Menu (oUT)

In the setup menu, when the upper display says “SET”, use the or key to get “oUT” in the lower

display. Then, use the key to cycle through the “oUT” menu parameters (Note Chart on pg. 9).

or

SET OUT

OUT 1

O1T Y

O1FT

O1HY

CYC1

OFST

OUT 2

O2T Y

O2FT

CYC2

CPB

DB

PL1L

PL1H

PL2L

PL2H

Page 7of 18

1.1.2 Manual Mode Menu – (Use for Temporary Operation if Sensor Fails)

Press and hold the “ ” key for approx. 6sec until the “HAND” parameter is shown in the upper display.

Then, press and hold the “ ” key for an additional 5 sec. until an “MANU” led starts to flash in the lower left

of the display. Then, use the “ ” key to cycle through the available options.

User is able to manually set the out output to be energized from 0-100% of the cycle time.

“Hx.xx” is used to adjust output 1.

“Cx.xx” is used to adjust output 2.

You are able to exit manual mode by pressing and holding the key.

1.1.3 Auto-Tuning Mode – (Tunes PID Parameters to Your Application)

Press and hold the “ ” key for approx. 7sec until the “A-T” parameter is shown in the upper display.

Press and hold the “ ” key for 5 seconds to activate Auto-Tuning Mode. Continue to hold the “ ” key for

an additional 3 seconds, else the display will revert to a “User Menu” parameter.

Auto-tuning allows the controller to find its own optimal control parameters (PID) by measuring the speed of

your thermal process.

HANd

5 Sec

M V1

M V2

FILE

Press key 5 Sec To execute the selected default program

Page 8of 18

1.2 Parameter Description

(*Parameters that are not applicable are not shown)

Register

Address

Parameter

Notation Parameter Description Range Default

Value

0 SP1

Set Point 1

(Used for Output 1)

Low: SP1L

High: SP1H

77.0°F

8 INPT

(See Pg. 11) Input sensor selection

0 J_tC: J type Thermocouple

1 K_tC: K type Thermocouple

2 T_tC: T type Thermocouple

3 E_tC: E type Thermocouple

4 B_tC: B type Thermocouple

5 R_tC: R type Thermocouple

6 S_tC: S type Thermocouple

7 N_tC: N type Thermocouple

8 L_tC: L type Thermocouple

9 U_tC: U type Thermocouple

10 P_tC: P type Thermocouple

11 C_tC: C type Thermocouple

12 D_tC: D type Thermocouple

13 Pt.dN: PT100 ΩDIN curve

14 Pt.JS: PT100 ΩJIS curve

15 4-20: 4-20mA linear current input

16 0-20: 0-20mA linear current input

17 0-5V: 0-5VDC linear voltage input

18 1-5V: 1-5VDC linear voltage input

19 0-10: 0-10VDC linear voltage

input

0, 1 or 13

(Depends on

Model Ordered)

9 UNIT Input unit selection

0 oC:°C unit

1 oF:°F unit

2 Pu:Process unit

1

10 DP Decimal point selection

0 No.dP: No decimal point

1 1-dP: 1 decimal digit

2 2-dP: 2 decimal digit

3 3-dP: 3 decimal digit

0

13 SP1L Low limit of set point 1

(Span Value)

Low: -19999

High :SP1H 0.0° F

14 SP1H High limit of set point 1

(Span Value)

Low: SP1L

High: 45536 1000.0°F

15 FILT

Filter damping time constant of

PV Sensor

(See Pg. 14)

0

0

: 0 second time constant

1 0.2: 0.2 second time constant

2 0.5: 0.5 second time constant

3 1: 1 second time constant

4 2: 2 second time constant

5 5: 5 second time constant

6 10: 10 second time constant

7 20: 20 second time constant

8 30: 30 second time constant

9

60

: 60 second time constant

2

Page 9of 18

(*Parameters that are not applicable are not shown)

Register

Address

Parameter

Notation Parameter Description Range Default

Value

16 DISP Secondary display selection

0

None: No Display

1 MV1: Display MV1

2 MV2: Display MV2

3 tIMR: Display Dwell Time

4

PRoF: display Profile Status

0

17 PB Proportional band value

(See Pg. 17)

Low: 0.0

High: 500.0°C (900.0°F)

10.0° C

(18.0° F)

18 TI Integral time value

(See Pg. 17)

Low: 0

High: 3600 sec 100

19 TD Derivative time value

(See Pg. 17)

Low: 0.0

High: 360.0 sec 25

20 OUT1 Output 1 function

0 REVR: Reverse (heating) control

action

1 dIRt : Direct (cooling) control

action

0

21

O1TY

FACTORY

SET, DO

NOT

CHANGE

Output 1 signal type

0 RELY: Relay output

1 SSrd: Solid state relay drive

output

2 4-20: 4-20mA linear current

3 0-20: 0-20mA linear current

4 0-5V: 0-5VDC linear voltage

5 1-5V: 1-5VDC linear voltage

6

0-10

: 0-10VDC linear voltage

1

22 O1FT Output 1 failure transfer mode

(See Pg. 15)

Select BPLS (Bumpless transfer), or

0.0 ~ 100.0 % to continue output 1

control function if the sensor fails, or

select OFF (0) or ON (1) for ON-OFF

control

0

23 O1HY Output 1 ON-OFF control

hysteresis. PB=0

Low: 0.1°C (0.2°F)

High: 50.0°C (90.0°F)

0.1° C

(0.2 °F)

24 CYC1 Output 1 cycle time Low: 0.1

High: 90.0 sec. 1.0

26 RAMP Ramp function selection

(See Pg. 13)

0 NoNE: No Ramp Function

1 MINR: Use ⁰/minute as Ramp Rate

2 HRR: Use ⁰/hour as Ramp Rate

0

Page 10 of 18

(*Parameters that are not applicable are not shown)

Register

Address

Parameter

Notation Parameter Description Range Default

Value

27 RR Ramp rate

(See Pg. 13)

Low: 0.0

High: 900.0°F 0

61 PL1L Output 1 Low Power limit Low: 0

High:PL1H or 50% 0

62 PL1H Output 1 High Power limit Low: PL1L

High: 100 % 100

94 PASS Password entry

(See Next Page)

Low: 0

High: 9999 0

Page 11 of 18

2 Programming

Press and hold for 5 seconds, then release to enter the setup menu. Press and release to cycle

through the list of parameters. The upper display indicates the parameter symbol, and the lower display

indicates the value of the selected parameter.

2.1 User Security

There are two parameters, PASS (password) and CODE (security code), which will control the lockout

program.

CODE Value

PASS Value

Access Rights

0

Any Value

All parameters are changeable

1000

=1000

All parameters are changeable

≠1000

Only user menu parameters changeable

9999

=9999

All parameters are changeable

≠9999

Only SP1 to SP7 are changeable

Others

=CODE

All parameters are changeable

≠CODE

No parameters can be changed

2-1.User Access Rights

2.2 Signal Input

INPT: Select the desired sensor type or signal type for the signal input. Factory set.

DO NOT CHANGE

UNIT: Select the desired process unit

Options: °C, °F, PU (Process unit). If the unit is neither °C nor °F, then is set to PU.

DP: Select the desired resolution (decimal points) for the process value.

Page 12 of 18

2.3 Control Output

There are 4 kinds of control modes can be configured as shown below.

2.3.1 Heat Only ON-OFF Control – (Used for Solonoids and Valves)

Select REVR for OUT1, Set PB to 0. O1HY is used to adjust the hysteresis for ON-OFF

control. The output 1 hysteresis (O1HY) setting is only available when PB = 0. The heat only ON-OFF

control function is shown below.

2-1.Heat Only ON-OFF Control

ON-OFF control may cause excessive process oscillations even if the hysteresis is set to the smallest value.

If ON-OFF control is used (i.e. PB = 0), TI, TD, CYC1, OFST, CYC2, CPB, DB will no longer be applicable

and will be hidden. Auto-Tuning mode and Bumpless transfer are not possible in on/off mode.

2.3.2 Heat only P or PD Control – (Used for Electric Heaters)

Select REVR for OUT1, set TI = 0, OFST is used to adjust the control offset (manual reset). If PB ≠0 then

O1HY will be hidden.

OFST Function: OFST is measured in % with a range of 0 - 100.0 %. When the process is stable, let’s say

the process value is lower than the set point by 5°F. Let’s also say that 20.0 is used for the PB setting. In

this example, 5°F is 25% of the proportional band (PB).

By increasing the OFST value by 25%, the control output will adjust itself, and the process value will

eventually coincide with the set point.

When using Proportional (P) control (TI = 0), Auto-Tuning will be unavailable. Refer to the “manual tuning"

section for the adjustment of PB and TD. Manual reset (OFST) is usually not practical because the load may

change from time to time; meaning the OFST setting would need to be constantly adjusted. PID control can

avoid this problem.

Page 13 of 18

2.3.3 Heat only PID Control – (Default for Electric Heaters)

Select REVR for OUT1. PB and TI should not be zero. Perform Auto-Tuning for initial startup. If the control

result is not satisfactory, use manual tuning or try Auto-Tuning a second time to improve the control

performance.

2.3.4 Cool only Control

ON-OFF control, Proportional control, and PID control can be used for cooling control. Set “OUT1” to DIRT

(direct action).

NOTE: ON-OFF control may result in excessive overshoot and undershoot in the process. Proportional

control could result in a deviation of the process value from the set point. It is recommended to use PID

control for Heating or Cooling control to produce a stable process value.

When selecting parameters, all of the above parameters may not be available. The number of visible

parameters depends on the configuration of the controller.

2.4 Ramp

The ramping function is performed during power up or any time the set point is changed. Choose “MINR”

(ramp in minutes) or “HRR” (ramp in hours) for the “RAMP” setting, and the controller will perform the

ramping function. The ramp rate is programmed by adjusting the “RR” setting. The ramping function is

disabled whenever the controller enters Failure mode, Manual control mode, Auto-Tuning mode or

Calibration mode.

2.4.1 Ramping Example without Dwell Timer

Set the “RAMP” setting to “MINR” to ramp in minutes.

Set the ramp rate (RR) to 10.

The starting temperature is 30°C.

The setpoint is initially set to 200°C.

After the process warms up, the user changed the setpoint to 100°C after 30 minutes.

After power up, the process will behave as shown below.

2-2.Ramp Function

Page 14 of 18

Note: When the ramp function is used, the lower display will show the current ramping value. However, it will revert to

show the set point value as soon as the up or down key is touched for adjustment. The ramp rate is initiated at power

on and/or whenever the Set point is changed. Setting the “RR” setting to zero means no ramping function is used.

2.5 User Calibration

Each unit is calibrated in the factory before shipment. The user can still modify the calibration in the field.

The basic calibration of the controller is highly stable and set for life. User calibration allows the user to offset

the permanent factory calibration in order to:

v Calibrate the controller to meet a user reference standard.

v Match the calibration of the controller to that of a particular transducer or sensor input.

v Calibrate the controller to suit the characteristics of a particular installation.

v Remove long term drift in the factory set calibration.

There are two parameters: Offset Low (OFTL) and Offset High (OFTH) for adjustment to correct an error in

the process value.

There are two parameters for the sensor input. These two signal values are CALO and CAHI. The input

signal low and high values are to be entered in the CALO and CAHI parameters respectively.

Refer to section 1.6 for key operation and section 1.7 for the operation flowchart. Press and

hold the key until the setup Menu page is obtained. Then, press and release the key to navigate to

the calibration low parameter OFTL. Send your low signal to the sensor input of the controller, then press

and release the key. If the process value (the upper display) is different from the input signal, the user

can use and keys to change the OFTL value (the lower display) until the process value is equal to the

value the user needs. Press and hold the key for 5 seconds to complete the low point calibration (the

display should blink once). The same procedure is applied for high scale calibration.

As shown below, the two points OFTL and OFTH construct a straight line. For the purpose

of accuracy, it is best to calibrate with the two points as far apart as possible. After the user calibration is

complete, the input type will be stored in the memory. If the input type is changed, a calibration error will

occur and an error code is displayed.

2-3.Two Point User Calibration

2.6 Digital Filter

In certain applications the process value is too unstable to be read. To improve this, a

programmable low pass filter incorporated in the controller can be used. This is a first order filter with a time

constant specified by the FILT parameter. A value of 0.5 seconds is used as a factory default. Adjust FILT

to change the time constant from 0 to 60 seconds. 0 seconds represents no filter applied to the input signal.

The filter is characterized by the following diagram.

Page 15 of 18

Note: The Filter is available only for the process value (PV), and is performed for the displayed value only.

The controller is designed to use an unfiltered signal for control even when a filter is applied. If a lagged

(filtered) signal is used for control; it may produce an unstable process.

2-4.Filter Characteristics

2.7 Failure Transfer

The controller will enter failure mode if one of the following conditions occurs:

1. An SBER error occurs due to an input sensor break, an input current below 1mA for 4-20mA, or an

input voltage below 0.25V for 1-5 V.

2. An ADER error occurs due to the A-D converter failing.

Output 1 and Output 2 will perform the failure transfer (O1.ft & O2.ft) function as the controller enters failure mode.

2.7.1 Output 1 Failure Transfer

If Output 1 Failure Transfer is activated, it will perform as follows:

1. If output 1 is configured as proportional control (PB≠0), and BPLS is selected for O1FT, then output

1 will perform a Bumpless transfer. After that, the previous average value of of the output will be

used for controlling output 1.

2. If output 1 is configured as proportional control (PB≠0), and a value of 0 to 100.0 % is set for O1FT,

then output 1 will perform failure transfer. After that the value of O1FT will be used for controlling

output 1.

3. If output 1 is configured as ON-OFF control (PB=0), then output 1 will transfer to an off state if OFF

is set for O1FT, or it will transfer to an on state if ON is set for O1FT.

2.8 Auto-Tuning

The Auto-Tuning process will be performed at the set point (SP1). The process will oscillate around the

set point during the tuning process. Set a set point to a lower value if overshooting beyond the normal

process value will cause damage. It is usually best to perform Auto-Tuning at the Set point the machine is

expected to be operated at, with the process running normally (i.e. material in the oven, etc.)

Auto-Tuning is generally applied in the following cases:

v Initial setup for a new process

v The set point is changed substantially from the previous Set point when Auto-Tuning was performed.

v The control result is unsatisfactory

Page 16 of 18

2.8.1 Auto-Tuning Operation Steps

1. The system is set up to run under real-world conditions.

2. “PB and “TI” settings should not be set to zero.

3. The LOCK parameter should be set to NONE.

4. Set the set point to a normal operating value, or a lower value if overshooting beyond the

normal process value will cause damage.

5. Press and hold the key until appears on the upper display. Continue to hold the

“ ” key for an additional 3 seconds, else the display will revert to a “User Menu”

parameter.

6. Press and hold the key until the TUNE indicator begins to flash.

7. The Auto-Tuning process has begun.

NOTE:

During Auto-Tuning, the output will stay on until the Process Value reaches the setpoint. This is likely to

cause the temperature to exceed the setpoint.

Then, the output will remain off until the process value falls below the setpoint.

This will occur at least two times while the controller “learns” how to control your process.

Procedures:

Auto-Tuning can be applied either as the process is warming up (Cold Start) or as the

process has been in steady state (Warm Start). After the Auto-Tuning process is completed, the TUNE

indicator will stop flashing and the unit will revert to PID control by using its new PID values. The PID values

obtained are stored in nonvolatile memory.

2.8.2 Auto-Tuning Error

If Auto-Tuning fails, an ATER message will appear on the upper display in any of the following

cases.

v If PB exceeds 9000 (9000 PU, 900.0°F or 500.0°C)

v If TI exceeds 1000 seconds

v If the set point is changed during the Auto-Tuning process

2.8.3 Solution for an Auto-Tuning Error

1. Try Auto-Tuning once again.

2. Avoid changing the set point value during the Auto-Tuning process.

3. Ensure PB and TI are not set to zero.

4. Use manual tuning.

5. Touch RESET key to reset the message.

Page 17 of 18

2.9 Manual Tuning

In certain applications, using Auto-Tuning may be inadequate for the control requirement, or, the process

moves too slowly to Auto-tune accurately.

If this is the case, the user can try manual tuning.

If the control performance by using Auto-Tuning is still unsatisfactory, the following guidelines can be applied

for further adjustment of PID values.

ADJUSTMENT SEQUENCE

SYMPTOM

SOLUTION

Proportional Band ( PB )

Slow Response

Decrease PB

High overshoot or Oscillations

Increase PB

Integral Time ( TI )

Slow Response

Decrease TI

Instability or Oscillations

Increase TI

Derivative Time ( TD )

Slow Response or Oscillations

Decrease TD

High Overshoot

Increase TD

2-2.PID Parameter Adjustment Guide

2-5. Effects of PID Adjustment

Page 18 of 18

2.10 Manual Control

To enable manual control, ensure the LOCK parameter is set to NONE.

Press and hold until (Hand Control) appears on the display. Press and hold until

the “MANU” indicator begins to flash. The lower display will show .

Indicates the output control variable for output 1, and indicates the control variable for

output 2. The user can use the up-down keys to adjust the percentage values for the heating or cooling

output. This % value is based on the CYC1 and CYC2 settings, where the associated output will stay on for

the % of time the CYC1 & CYC2 values are set for.

Example: If CYC1 is set to 20seconds, and the controller is set to “H50.0”, the output will be on for

10seconds, then turn off for 10 seconds.

The controller performs open loop control and ignores the input sensor as long as it stays in manual control

mode

2.10.1 Exit Manual Control

Pressing the key will revert the controller to its normal display mode.

2.11 Setting Controller to Factory Default

The controller’s parameters can be loaded with default values listed in the parameter description table . In

certain situation it is desirable to retain these values after the parameters values has been changed. The

below procedure to be followed to reload the default values.

1. Ensure the LOCK parameter is set to NONE.

2. Press and hold until (Hand Control) appears on the display.

3. Press and release the key to cycle through the manual mode menu to reach “FILE”.

4. Press and hold for 5 seconds or until the upper display FILE flash for a moment.

607 N. Central Avenue Wood Dale, IL 60191-1452 USA

P: 630-350-2252 Toll Free: 800-323-6859

www.tempco.com

Band Heaters

Cast-In Heaters

Radiant Heaters

Flexible Heaters

Process Heaters

Temperature Control

Cartridge Heaters

Coil & Cable Heaters

Strip Heaters

Tubular Heaters

Instrumentation

Temperature Sensors

HEAT THINGS UP!

With Thousands of Design Variations

We Make Everything You Need.

Custom Manufacturer Since 1972

ELECTRIC HEATING ELEMENTS • TEMPERATURE CONTROLS • SENSORS • PROCESS HEATING SYSTEMS

© Copyright 2019 TEHC. All Rights Reserved

This manual suits for next models

4

Table of contents

Other Tempco Controllers manuals