[SM‑277346‑A] −2−

DESIGN AND SELECTION

1)Inferior quality air will deteriorate the product characteristics and affect its durability

badly. Use an air dryer, filter and sub micron filter to eliminate solid material, moisture

and tar and thus provide clean air from the pressure source.

In the case where the secondary side air pressure is reduced, the secondary side air

flows through the model ER100 and will be discharged from the exhaust port. The

inside of the secondary piping and that of the load side should be kept clean.

Otherwise, similar conditions such as deteriorated product characteristics result.

2)The products response capability will be affected by the working pressure and load

volume. When a stable response is required, regulate the working pressure.

3)When the product is used with the secondary side being opened to the atmosphere

as in the case of air blowing, air pressure may vary depending on conditions of piping

and air blowing. In such a case, be sure to test the product under actual using

conditions or contact us in advance.

4)Select only the dryer, air filter, oil mist filter and regulator having the flow rate higher

than that used for PARECT units.

5) Maximum current consummation of the voltage input type unit is 20mA or less for

the model ER150, and 25mA or less for the model ER170.

MOUNTING, INSTALLATION AND ADJUSTMENT

1)Basically, the attitude of installation shall be vertical (i.e., the black portion of the coil

should face upward). In the event of the horizontal installation, the unit should be

re-adjusted for zero point as well as span.

2)Install the unit in a place where the vibration is 2m/s2, 10Hz or less.

3)Avoid operating the product in places where it may be affected by direct sunlight,

water or oil.

4)Flush air into the pneumatic pipes employed in the PARECT electro-pneumatic

regulator before connection

5)The model ER100 always bleeds the secondary air pressure from the relief hole

provided on the side, generating a bleeding sound. This bleeding sound is normal

although it grows as the secondary side pressure increases.

6)For the input signal specifications, the model ER100 is available in the voltage input

type (0 to 10V) and the current input type (4 to 20mA). Check the type of your

model before use.

USAGE AND MAINTENANCE

1)When the primary side pressure is applied to the unit, do not loosen the screw

securing the orifice. Otherwise, the orifice will fly out.

2)Do not disassemble the unit because it will fail. Operations of the disassembled unit

will not be guaranteed.

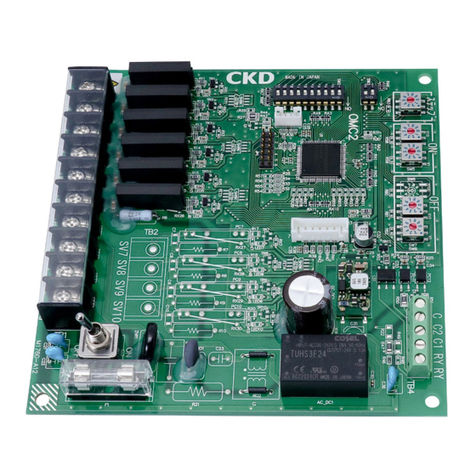

Recommended air circuit

Air filter

5μ m

Regulator

Pressure

Oil mist filter

Air dryer

Pneumatic

equipment

ER100

Fig1

!

!

!WARNING