Construction and Industrial Equipment Product Safety

It is the responsibility of the owner of the construction and industrial equipment products to

be knowledgeable about federal, state and local regulations that effect the total usage of

his equipment, and responsibility to working personal and the public. Since regulations are

subject to change, and also differ from one local to another, this manual makes no attempt

to provide such information.

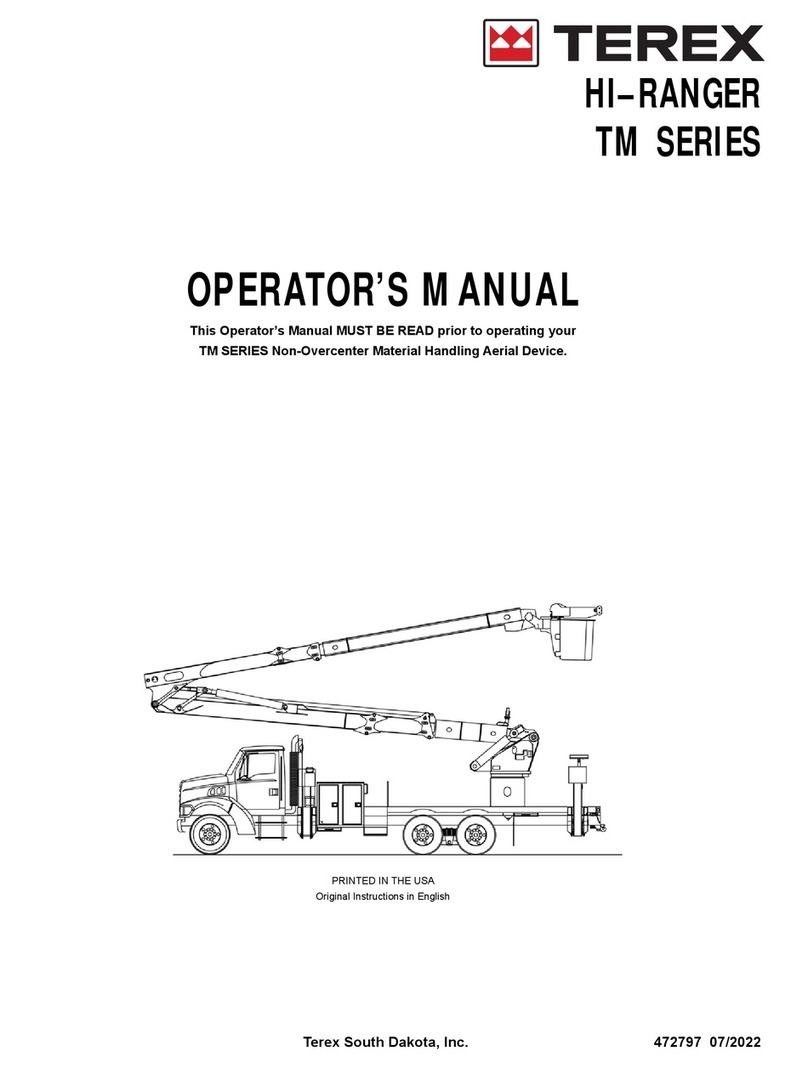

Terex Cranes provides appropriate operation and maintenance manuals for various

construction and industrial equipment products that it manufactures and sells. In addition,

where applicable, appropriate national consensus standards, industry standards and safety

related manuals are included with the Terex manuals in the shipment of each product. It is

company policy to provide this information for the owner or user of the equipment. It is

expected that the owner or user will utilize these manuals and standards to provide the

appropriate information and training to those people who are to operate, maintain and

supervise the use of equipment in a proper and safe manner.

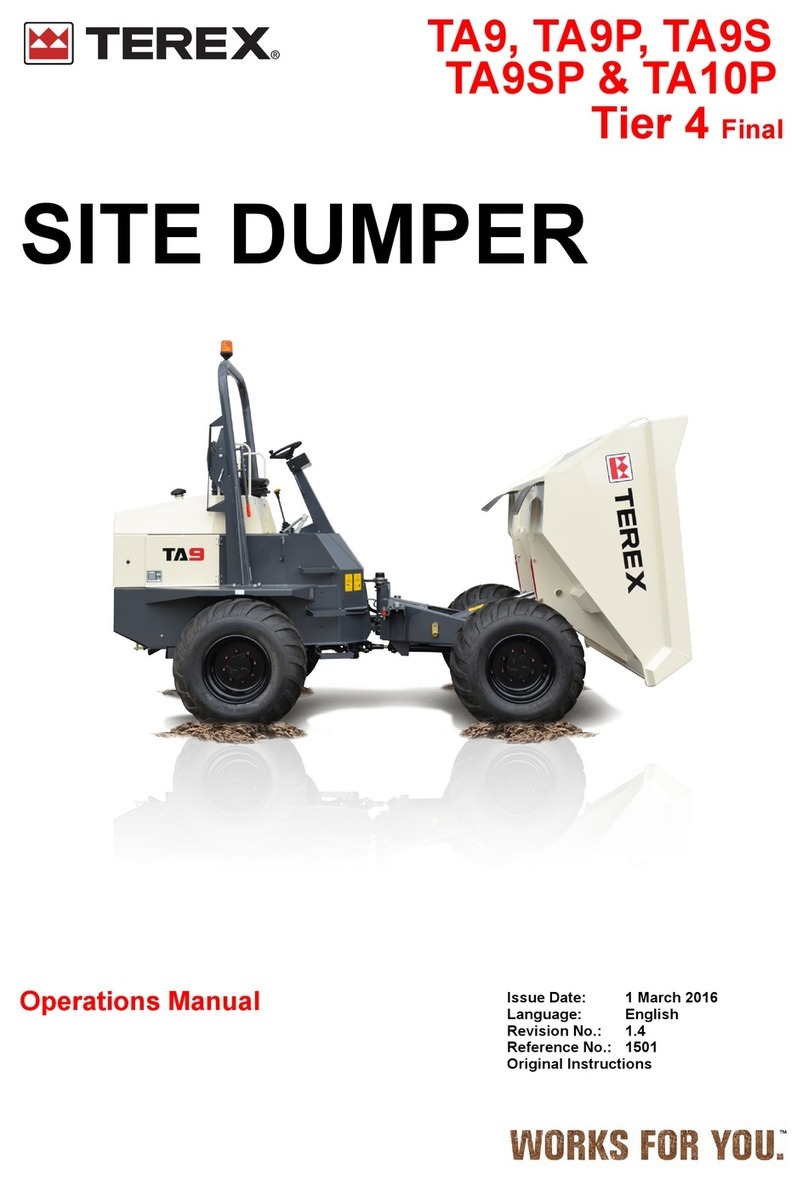

Construction and industrial equipment is designed and manufactured to perform heavy-

duty work. Under normal usage, the equipment will wear. For this reason it is essential that

the owner/user establish and perform a periodic inspection of the equipment. The objective

of inspection programs is to prevent accidents, reduce downtime and keep the equipment

working efficiently. These inspection programs should be designed to discover worn,

cracked, broken or deteriorated parts and loose or missing fasteners before they result in a

problem.

Proper training and inspection programs are essential to avoiding injury to persons,

damage to property and excessive maintenance costs.

Read and understand the manuals provided with this equipment. Assistance is available

from the distributors of your Terex product and from the Terex manufacturing facility.

When operating a hydraulic crane, the operator should realize that hydraulic and

structural competence, NOT TIPPING LOAD, is often the determinant of lifting

capacity. Therefore, THE OPERATOR MUST BE GUIDED SOLELY BY THE

APPROPRIATE MANUFACTURER’S LOAD RATING CHART when considering

load weights. The manufacturers rated loads must never be exceeded.

Follow the recommended operating and maintenance procedures and keep your machine

operating at MAXIMUM EFFICIENCY. Use the Suggested Crane Periodic Inspection Check

List provided. In addition, we STRONGLY URGE that a MAINTENANCE LOG be kept in

conjunction with all maintenance performed on the machine.

If you desire any special information regarding the care and operation of the machine, we

will gladly furnish it upon request. Because we build various types of equipment, we ask

that you include your machine model and serial number in all correspondence so that we

can provide the correct information.

The information, specifications, and illustrations in this publication are based on the

information in effect at the time of approval for printing. We reserve the right to make

changes at any time without obligation.

Introduction

5REVISED: