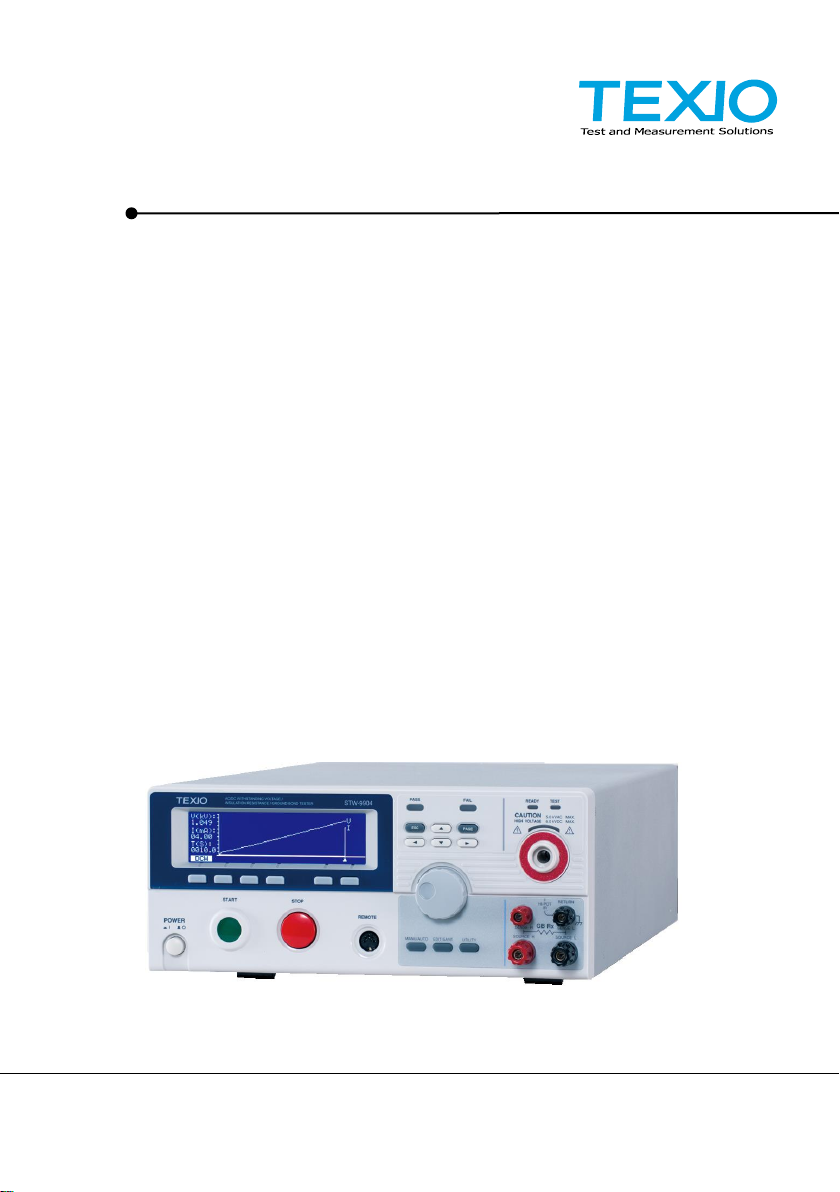

TEXIO STW-9000 Series User manual

B71-0410-11

INSTRUCTION MANUAL

WITHSTANDING VOLTAGE TESTER

STW-9000 SERIES

STW-9901

STW-9902

STW-9903

STW-9904

STW-9801

STW-9802

STW-9803

■ About Brands and Trademarks

“TEXIO” is the product brand name of our industrial electronic devices.

All company names and product names mentioned in this manual are the

trademark or the registered trademark of each company or group in each

country and region.

■ About the Instruction Manual

Permission from the copyright holder is needed to reprint the contents of this

manual, in whole or in part. Be aware that the product specifications and the

contents of this manual are subject to change for the purpose of improvement.

■About firmware version

Firmware version corresponding is this manual will be as follows.

STW-9800 Series: Ver3.00 or higher

STW-9900 Series: Ver2.00 or higher

CONTENTS

USING THE PRODUCT SAFELY ········································Ⅰ-Ⅳ

1. GETING STARTED...............................................................1

1.1 STW-9000 Series Overview......................................................... 1

1.2 Model Overview.......................................................................... 2

1.3 Main Features ............................................................................2

1.4 Accessories................................................................................2

1.5 Package Contents.......................................................................3

1.6 Appearance ................................................................................4

1.6.1 STW-9000 Front Panel...........................................................................4

1.6.2 STW-9904 Front Panel...........................................................................4

1.6.3 STW-9901/9902/9903 Rear Panel..........................................................6

1.6.4 STW-9904 Rear Panel............................................................................6

1.6.5 STW-9801/9802/9803 Rear Panel..........................................................7

1.7 Set Up........................................................................................8

1.7.1 Line Voltage Connection and Power Up.................................................8

1.7.2 Installing the Optional GP-IB Card..........................................................9

1.7.3 Workplace Precautions.........................................................................10

1.7.4 Operating Precautions..........................................................................11

1.7.5 Basic Safety Checks.............................................................................12

2. OPERATION ...................................................................... 13

2.1 Menu Tree ................................................................................ 13

2.1.1 Menu Tree Overview.............................................................................14

2.2 Test Lead Connection ............................................................... 16

2.2.1 ACW, DCW, IR Connection ..................................................................16

2.2.2 GB Connection......................................................................................17

2.3 ACW, DCW and GB Manual Testing ........................................... 17

2.3.1 Choose/Recall a Manual Test Number.................................................18

2.3.2 Edit Manual Test Settings.....................................................................18

2.3.3 Setting the Test Function......................................................................19

2.3.4 Setting the Test Voltage or Test Current...............................................19

2.3.5 Setting the Test Frequency...................................................................20

2.3.6 Setting the Upper and Lower Limits......................................................20

2.3.7 Setting a Reference Value....................................................................22

2.3.8 Setting the Test Time (Timer) ...............................................................22

2.3.9 Setting the Ramp Up Time....................................................................24

2.3.10 Creating a MANU Test File Name.......................................................24

2.3.11 Setting the ARC Mode........................................................................25

2.3.12 Setting PASS HOLD...........................................................................26

2.3.13 Setting FAIL MODE ............................................................................27

2.3.14 Setting MAX HOLD.............................................................................28

2.3.15 Setting the Grounding Mode...............................................................29

2.3.16 Saving and Exiting EDIT Status..........................................................32

2.3.17 Running a MANU Test........................................................................32

2.3.18 PASS / FAIL MANU Test ....................................................................35

2.3.19 Zeroing of the Test Leads (GB only)...................................................39

2.3.20 Special MANU Test Mode (000) .........................................................41

2.4 Automatic Tests ........................................................................ 44

2.4.1 Choose/Recall an Automatic Test.........................................................44

2.4.2 Edit Automatic Test Settings.................................................................45

2.4.3 Adding a Step to the Automatic Test.....................................................45

2.4.4 Creating an AUTO Test File Name.......................................................46

2.4.5 Saving and Exiting EDIT Status............................................................47

2.4.6 Automatic Test Page View....................................................................47

2.4.7 Running an Automatic Test...................................................................49

2.4.8 Automatic Test Results.........................................................................52

2.5 Common Utility Settings ............................................................ 55

2.5.1 LCD Settings.........................................................................................55

2.5.2 Buzzer Settings.....................................................................................56

2.5.3 Interface Settings..................................................................................57

2.5.4 Control Settings ....................................................................................58

3. EXTERNAL CONTROL ....................................................... 60

3.1 External Control Overview......................................................... 60

3.1.1 Remote Terminal Overview...................................................................60

3.1.2 Remote Controller Operation................................................................60

3.2 SIGNAL I/O Overview ............................................................... 61

3.2.1 Using the SIGNAL I/O to Start/Stop Tests ............................................62

3.2.2 Using the Interlock Key.........................................................................62

4. REMOTE CONTROL .......................................................... 64

4.1 Interface Configuration.............................................................. 64

4.1.1 USB Remote Interface..........................................................................64

4.1.2 RS-232C Remote Interface...................................................................64

4.1.3 GP-IB Remote Interface........................................................................65

4.2 USB/RS-232C Remote Control Function Check .......................... 65

4.3 Return to Panel Control............................................................. 66

4.4 Command Syntax...................................................................... 66

4.5 Command List .......................................................................... 68

4.6 System Commands ................................................................... 70

4.6.1 SYSTem:LCD:CONTrast ......................................................................70

4.6.2 SYSTem:LCD:BRIGhtness...................................................................70

4.6.3 SYSTem:BUZZer:PSOUND..................................................................70

4.6.4 SYSTem:BUZZer:FSOUND..................................................................70

4.6.5 SYSTem:BUZZer:PTIMe ......................................................................71

4.6.6 SYSTem:BUZZer:FTIMe.......................................................................71

4.6.7 SYSTem:ERRor....................................................................................71

4.6.8 SYSTem:GPIB:VERSion ......................................................................72

4.7 Function Commands ................................................................. 72

4.7.1 FUNCtion:TEST....................................................................................72

4.7.2 MEASure<x>.........................................................................................72

4.7.3 MAIN:FUNCtion....................................................................................73

4.8 Manual Commands ................................................................... 73

4.8.1 MANU:STEP.........................................................................................73

4.8.2 MANU:NAME........................................................................................74

4.8.3 MANU:RTIMe........................................................................................74

4.8.4 MANU:EDIT:MODE ..............................................................................74

4.8.5 MANU:ACW:VOLTage..........................................................................75

4.8.6 MANU:ACW:CHISet .............................................................................75

4.8.7 MANU:ACW:CLOSet ............................................................................75

4.8.8 MANU:ACW:TTIMe...............................................................................76

4.8.9 MANU:ACW:FREQuency .....................................................................76

4.8.10 MANU:ACW:REF................................................................................76

4.8.11 MANU:ACW:ARCCurrent ...................................................................77

4.8.12 MANU:DCW:VOLTage .......................................................................77

4.8.13 MANU:DCW:CHISet ...........................................................................77

4.8.14 MANU:DCW:CLOSet..........................................................................78

4.8.15 MANU:DCW:TTIMe ............................................................................78

4.8.16 MANU:DCW:REF................................................................................79

4.8.17 MANU:DCW:ARCCurrent ...................................................................79

4.8.18 MANU:IR:VOLTage ............................................................................79

4.8.19 MANU:IR:RHISet................................................................................80

4.8.20 MANU:IR:RLOSet...............................................................................80

4.8.21 MANU:IR:TTIMe .................................................................................80

4.8.22 MANU:IR:REF.....................................................................................80

4.8.23 MANU:GB:CURRent...........................................................................81

4.8.24 MANU:GB:RHISet...............................................................................81

4.8.25 MANU:GB:RLOSet .............................................................................81

4.8.26 MANU:GB:TTIMe................................................................................81

4.8.27 MANU:GB:FREQuency.......................................................................82

4.8.28 MANU:GB:REF...................................................................................82

4.8.29 MANU:GB:ZEROCHECK....................................................................82

4.8.30 MANU:UTILity:ARCMode....................................................................83

4.8.31 MANU:UTILity:PASShold....................................................................83

4.8.32 MANU:UTILity:FAILmode....................................................................83

4.8.33 MANU:UTILity:MAXHold.....................................................................83

4.8.34 MANU:UTILity:GROUNDMODE .........................................................84

4.8.35 MANU<x>:EDIT:SHOW......................................................................84

4.9 Sweep Commands .................................................................... 84

4.9.1 SWEEP:DATA:STATus ........................................................................84

4.9.2 SWEEP<X>:DATA:SHOW....................................................................85

4.9.3 SWEEP:GRAPh:SHOW........................................................................85

4.9.4 SWEEP :GRAPh:LINE..........................................................................86

4.9.5 SWEEP:STARt:TIME............................................................................86

4.10 Auto Commands...................................................................... 86

4.10.1 AUTO:STEP........................................................................................86

4.10.2 AUTO<x>:PAGE:SHOW.....................................................................87

4.10.3 AUTO:PAGE:MOVE ...........................................................................87

4.10.4 AUTO:PAGE:SWAP ...........................................................................87

4.10.5 AUTO:PAGE:SKIP..............................................................................88

4.10.6 AUTO:PAGE:DEL...............................................................................88

4.10.7 AUTO:NAME.......................................................................................88

4.10.8 AUTO:EDIT:ADD................................................................................89

4.10.9 TESTok:RETurn..................................................................................89

4.11 Common Commands ............................................................... 89

4.11.1 *CLS ...................................................................................................89

4.11.2 *IDN....................................................................................................89

4.11.3 *RMTOFF............................................................................................90

4.12 Error Messages ...................................................................... 91

5. FAQ ................................................................................... 92

5.1 The tester will not turn on.......................................................... 92

5.2 The panel keys are not working. ................................................ 92

5.3 When I press the START button the tester will not start testing?.. 92

5.4 The accuracy does not match the specification........................... 92

6. APPENDIX ......................................................................... 93

6.1 Fuse Replacement.................................................................... 93

6.2 Error Messages ........................................................................ 94

6.2.1 System Self-Test...................................................................................94

6.2.2 Test Errors............................................................................................94

6.3 STW-9000 Specifications .......................................................... 95

6.3.1 Specifications........................................................................................95

6.4 Dimensions ............................................................................ 100

6.4.1 STW-9801/9802/9803 Dimensions.....................................................100

6.4.2 STW-9901/9902/9903 Dimensions.....................................................101

6.4.3 STW-9904 Dimensions.......................................................................102

I

USING THE PRODUCT SAFELY

■ Preface

To use the product safely, read instruction manual to the end. Before using

this product, understand how to correctly use it. If you read the manuals but

you do not understand how to use it, ask us or your local dealer. After you

read the manuals, save it so that you can read it anytime as required.

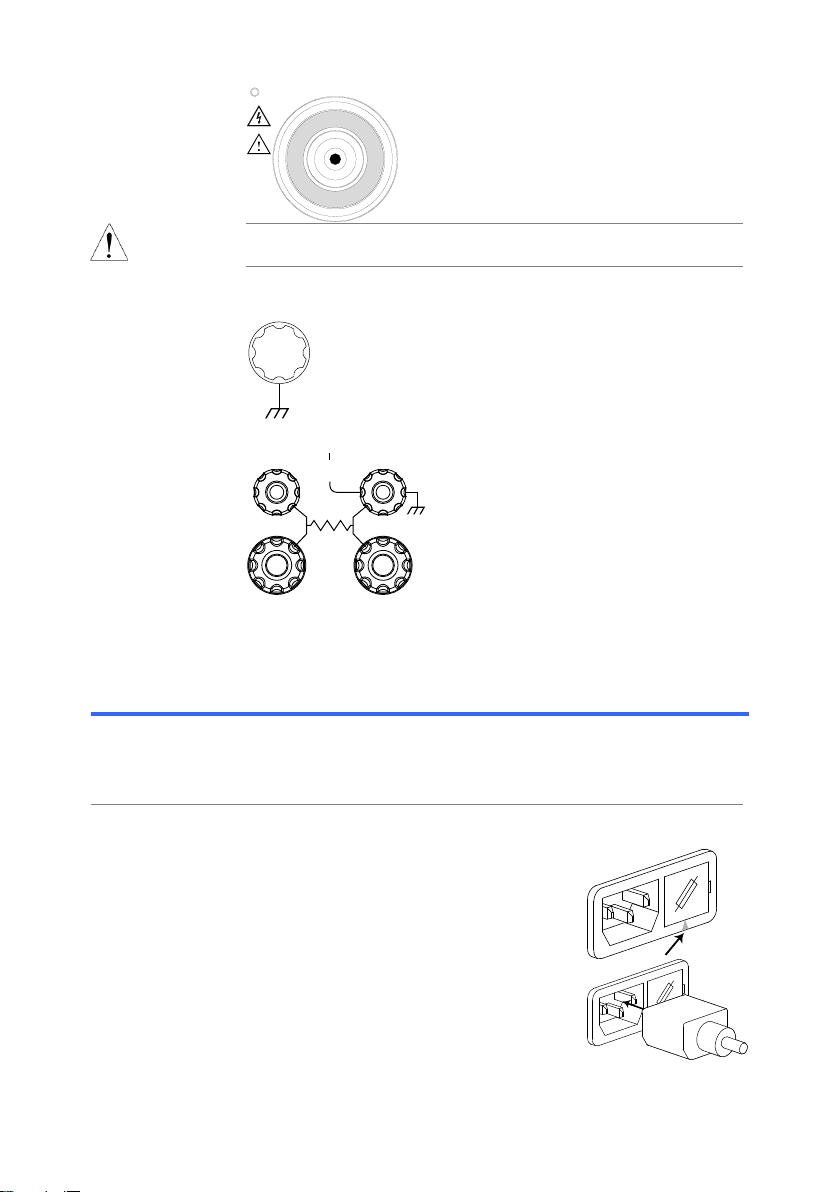

■ Pictorial indication

The manuals and product show the warning and caution items required to

safely use the product. The following pictorial indication is provided.

Pictorial

indication

Some part of this product or the manuals may show this

pictorial indication. In this case, if the product is

incorrectly used in that part, a serious danger may be

brought about on the user's body or the product. To use

the part with this pictorial indication, be sure to refer to the

manuals.

WARNING

!

If you use the product, ignoring this indication, you may get

killed or seriously injured. This indication shows that the

warning item to avoid the danger is provided.

CAUTION

!

If you incorrectly use the product, ignoring this indication,

you may get slightly injured or the product may be

damaged. This indication shows that the caution item to

avoid the danger is provided.

Please be informed that we are not responsible for any damages to the user or

to the third person, arising from malfunctions or other failures due to wrong use

of the product or incorrect operation, except such responsibility for damages as

required by law.

II

USING THE PRODUCT SAFELY

WARNING

!

CAUTION

!

■ Do not remove the product's covers and panels

Never remove the product's covers and panels for any purpose.

Otherwise, the user's electric shock or fire may be incurred.

■ Warning on using the product

Warning items given below are to avoid danger to user's body and life and

avoid the damage or deterioration of the product. Use the product, observing

the following warning and caution items.

■ Warning items on power supply

● Power supply voltage

The rated power supply voltages of the product are 100, 120, 220 and

240VAC. The rated power supply voltage for each product should be

confirmed by reading the label attached on the back of the product or by the

“rated” column shown in the instruction manual. The specification of power

cord attached to the products is rated to 125VAC for all products which are

designed to be used in the areas where commercial power supply voltage is

not higher than 125VAC. Accordingly, you must change the power cord if

you want to use the product at the power supply voltage higher than 125VAC.

If you use the product without changing power cord to 250VAC rated one,

electric shock or fire may be caused. When you used the product equipped

with power supply voltage switching system, please refer to the corresponding

chapter in the instruction manuals of each product.

● Power cord

(IMPORTANT) The attached power cord set can be used for

this device only.

If the attached power cord is damaged, stop using the product and call us or

your local dealer. If the power cord is used without the damage being

removed, an electric shock or fire may be caused.

● Protective fuse

If an input protective fuse is blown, the product does not operate. For a

product with external fuse holder, the fuse may be replaced. As for how to

replace the fuse, refer to the corresponding chapter in the instruction

manual. If no fuse replacement procedures are indicated, the user is not

permitted to replace it. In such case, keep the case closed and consult us

or your local dealer. If the fuse is incorrectly replaced, a fire may occur.

III

USING THE PRODUCT SAFELY

■ Warning item on Grounding

If the product has the GND terminal on the front or rear panel surface, be sure

to ground the product to safely use it.

■ Warnings on Installation environment

● Operating temperature and humidity

Use the product within the operating temperature indicated in the “rating”

temperature column. If the product is used with the vents of the product

blocked or in high ambient temperatures, a fire may occur. Use the product

within the operating humidity indicated in the “rating” humidity column.

Watch out for condensation by a sharp humidity change such as transfer to a

room with a different humidity. Also, do not operate the product with wet

hands. Otherwise, an electric shock or fire may occur.

● Use in gas

Use in and around a place where an inflammable or explosive gas or steam is

generated or stored may result in an explosion and fire. Do not operate the

product in such an environment. Also, use in and around a place where a

corrosive gas is generated or spreading causes a serious damage to the

product. Do not operate the product in such an environment.

● Installation place

Do not insert metal and inflammable materials into the product from its vent

and spill water on it. Otherwise, electric shock or fire may occur.

■ Do not let foreign matter in

Do not insert metal and inflammable materials into the product from its vent

and spill water on it. Otherwise, electric shock or fire may occur.

■ Warning item on abnormality while in use

If smoke or fire is generated from the product while in use, stop using the

product, turn off the switch, and remove the power cord plug from the outlet.

After confirming that no other devices catch fire, ask us or your local dealer.

IV

USING THE PRODUCT SAFELY

■ Input / Output terminals

Maximum input to terminal is specified to prevent the product from being

damaged. Do not supply input, exceeding the specifications that are indicated

in the "Rating" column in the instruction manual of the product. Also, do not

supply power to the output terminals from the outside. Otherwise, a product

failure is caused.

■ Calibration

Although the performance and specifications of the product are checked under

strict quality control during shipment from the factory, they may be deviated

more or less by deterioration of parts due to their aging or others.

It is recommended to periodically calibrate the product so that it is used with its

performance and specifications stable. For consultation about the product

calibration, ask us or your local dealer.

■ Daily Maintenance

When you clean off the dirt of the product covers, panels, and knobs, avoid

solvents such as thinner and benzene. Otherwise, the paint may peel off or

resin surface may be affected. To wipe off the covers, panels, and knobs, use

a soft cloth with neutral detergent in it.

During cleaning, be careful that water, detergents, or other foreign matters do

not get into the product.

If a liquid or metal gets into the product, an electric shock and fire are caused.

During cleaning, remove the power cord plug from the outlet.

Use the product correctly and safely, observing the above warning and caution

items. Because the instruction manual indicates caution items even in individual

items, observe those caution items to correctly use the product.

If you have questions or comments about the manuals, ask us or E-Mail us.

1

1. GETING STARTED

This chapter describes the safety tester in a nutshell, including its main features

and front / rear panel introduction. After going through the overview, please read

the safety considerations in the Set Up chapter.

1.1 STW-9000 Series Overview

The STW-9000 Series Safety Testers are AC/DC withstanding voltage, insulation

resistance and ground bond safety testers.

The STW-9901/9801 are AC withstanding voltage testers, the STW-9902/9802 are

AC/DC withstanding voltage testers and the STW-9903/9803 are AC/DC

withstanding voltage and insulation resistance testers. The STW-9904 includes all

the test functions of the other models as well as ground bond testing. All models

can operate at up to 5kVAC for AC withstanding voltage testing and at up to 6kVDC

for DC withstanding voltage testing (excluding the STW-9901/9801).

For the STW-9000 models, the testing terminals are also mirrored on the rear panel

for added safety and for more permanent safety testing environments. They also

include an innovative sweep function to view test results as a graph.

The STW-9000 Series can store up to 100 manual tests, as well as run up to 16

manual tests sequentially as an automatic test, allowing the safety testers to

accommodate any number of safety standards, including IEC, EN, UL, CSA, GB,

JIS and others.

Note: Throughout this user manual, the terms ACW, DCW, IR and GB refer to AC

Withstanding, DC Withstanding, Insulation Resistance and Ground Bond testing,

respectively.

2

1.2 Model Overview

Model name

ACW

DCW

IR

GB

Sweep

Rated Load

STW-9901

500VA/100W

STW-9902

500VA/100W

STW-9903

500VA/100W

STW-9904

500VA/100W

STW-9801

200VA/50W

STW-9802

200VA/50W

STW-9803

200VA/50W

1.3 Main Features

Performance

ACW: 5kVAC

DCW: 6kVDC

IR: 50V~1000V (50V steps)

GB: 3A~32A (STW-9904)

Features

Ramp up time control

Safety discharge

100 test conditions (MANU mode)

100 automatic tests (AUTO mode)

Over temperature, voltage and current protection

Pass, Fail, Test, High Voltage and Ready indicators

PWM output (90% efficiency, increased reliability)

Interlock (configurable).

Sweep Function.

Interface

Remote control start/stop interface terminal

RS-232C/USB interface for programming

Optional GP-IB interface for programming

Signal I/O port for pass/fail/test monitoring and start/stop

control/interlock

1.4 Accessories

Standard

Accessories

Part number

Description

GHT-114

Test lead

Power cord

Region dependent

GTL-115

GB Test leads (STW-9904 only)

N/A

Remote terminal male plug

N/A

N/A

Interlock key

Accessories CD

(Instruction manual, USB Driver)

3

Optional

Accessories

Part number

Description

GHT-205

High Voltage Test Probe

GHT-113

High Voltage Test Pistol

GTL-232

RS-232C cable

GTL-248

GP-IB cable

GTL-247

USB cable(A-A)

GRA-417

Rack Adapter Panel (19”,4U)

(STW-9901/02/03/9801/9802/9803)

Options

Part number

Description

Opt.1 GP-IB Interface

GP-IB module

1.5 Package Contents

Check the contents before using the STW-9000.

Opening the box

Contents

(single unit)

STW-9000 unit

Accessories CD (Instruction manual, USB Driver)

Power cord x1 (region dependent)

GHT-114 test leads x1

GTL-115 test leads x1(STW-9904)

Remote terminal male plug

Interlock key

Note

Keep the packaging, including the box, polystyrene foam

and plastic envelopes should the need arise to return the

unit to TEXIO TECHNOLOGY.

4

1.6 Appearance

1.6.1 STW-9000 Front Panel

POWER

START STOP

REMOTE

MANU/ AUTO EDIT/SAVE UTILITY

ESC PAGE

Tester

HIGH VOLTAGE

CAUTION 5. 0kVAC MAX.

6. 0kVDC MAX.

AC/ DC Withstanding Voltage/

Insulation Resistance

RETURN

PASS FAIL READY TEST

PASS/FAIL indicators

Directional keysFunction keys

HIGH VOLTAGE

indicator

RETURN

terminal

REMOTE terminal

STOP button

START button

POWER

button

Display

Scroll wheel

Configuration keys

READY indicator

TEST indicator

HIGH VOLTAGE output

terminal

1.6.2 STW-9904 Front Panel

POWER

START STOP

REMOTE

MANU/AUTO EDIT/SAVE UTILITY

ESC PAGE

HIGH VOLTAGE

CAUTION 5.0 kVAC MAX.

6.0 kVDC MAX.

GB Rx

SENSE H

SOURCE H

SENSE L

SOURCE L

RETURN

PASS FAIL READY TEST

HI-POT

IR

G P T - 9 9 0 4 Tester

AC / DC Withstanding Voltage /

Insulation Resistance / Ground Bond

SOURCE L

SENSE L &

RETURN Terminal

SENSE H

SOURCE H

Display

240 X 64 dot matrix display (LCD)

Function keys

The function keys correspond to the soft-keys directly above

on the main display.

Pass/Fail

indicators

PASS

FAIL

The PASS and FAIL indicators light up upon

a PASS or FAIL test result at the end of a

manual test or automatic test.

ESC key

ESC

The ESC key is used to exit out of a menu

or cancel a setting.

PAGE key

PAGE

The PAGE key is used to view automatic

test information and test results.

Directional arrow

keys

The directional arrow keys are used to

navigate menus and parameter settings.

READY indicator

READY

The READY indicator is lit when the tester

is ready to begin testing. The STOP button

is used to put the tester into READY status.

TEST indicator

TEST

The TEST indicator is lit when a test is on.

The START button is used to put the tester

into TEST status.

HIGH VOLTAGE

indicator

HIGH VOLTAGE

CAUTION 5.0 kVAC MAX.

6.0 kVDC MAX.

The HIGH VOLTAGE indicator will light up

when an output terminal is active. Only

after the test has finished or stopped will

the indicator turn off.

5

HIGH VOLTAGE

output terminal

HIGH VOLTAGE

CAUTION 5.0 kVAC MAX.

6.0 kVDC MAX.

The HIGH VOLTAGE terminal output is

used for outputting the testing voltage. The

terminal is recessed for safety. This

terminal is used in conjunction with the

RETURN terminal.

WARNING

USE EXTREME CAUTION.

Do not touch the HIGH VOLTAGE terminal during testing.

RETURN terminal

Except STW-9904

RETURN

The RETURN terminal is used for IR,

DCW and ACW tests.

RETURN, SENSE

and SOURCE

terminals

Only STW-9904

SOURCE H

SENSE H

SOURCE L

SENSE L

GB Rx

RETURN

HI-POT

IR

The RETURN terminal is used for IR,

DCW and ACW tests.

The SOURCE H, SOURCE L, SENSE

H and SENSE L terminals are used

for GB tests.

Scroll wheel

The scroll wheel is used to edit parameter

values.

UTILITY key

UTILITY

Used to enter the MANU Utility or Common

Utility menu.

EDIT/SAVE key

EDIT/SAVE

Used to start editing MANU/AUTO tests as

well as save settings and parameters.

MANU/AUTO key

MANU/AUTO

The MANU/AUTO key is used to select

manual tests (MANU) or automatic tests

(AUTO).

REMOTE terminal

REMOTE

The REMOTE terminal is used to connect

to a remote controller.

STOP button

STOP

The STOP button is used to stop/cancel

tests. The STOP button will also put the

safety tester in the READY status to begin

testing.

6

START button

START

The START button is used to start tests.

The START button can be used to start

tests when the tester is in the READY

status. Pressing the START button will put

the tester in the TEST status.

POWER switch

POWER

Turns the power on. The safety tester will

always start up with the last test setting

from when the instrument was last powered

down.

1.6.3 STW-9901/9902/9903 Rear Panel

TO AVOID ELECTRIC SHOCK THE POWER CORD

PROTECTIVE GROUNDING CONDUCTOR MUST BE

ONLY WITHSPECIFIEDTYPE AND RATEDFUSE.

NO OPERATOR SERVICEABLE COMPONENTS INSIDE.

DO NOT REMOVE COVERS. REFER SERVICING TO

FORCONTINUEDFIRE PROTECTION.REPLACE

CONNECTED TO GROUND.

QUALIFIED PERSONNEL.

WARNING

AC

LINE VOLTAGE

100V

230V

220V

120V

SELECTION

207~250V

RANGE

90~110V

198~242V

108~132V

(50/60Hz)

250V

250V

T 10A

FUSE

T 6.3A

MAX.

1000VA

GND

ENSURE THE POWER IS REMOVED FROM

THE INSTRUMENT BEFORE REPLACING THE FUSE

POWER

SIGNAL I / O RS232

GPIB

HIGH VOLTAGE

CAUTION

MAX.

6.0 kVDC

5.0 kVAC

RETURN

SER. NO. LB

Signal I/ O, RS232

& USB port Fan vents

Fuse selectorLine voltage

Optional GPIB port

High voltage terminal

GND

Return

terminal

1.6.4 STW-9904 Rear Panel

TO AVOID ELECTRIC SHOCK THE POWER CORD

PROTECTIVE GROUNDING CONDUCTOR MUSTBE

ONLY WITHSPECIFIEDTYPE AND RATED FUSE.

NO OPERATOR SERVICEABLE COMPONENTS INSIDE.

DO NOT REMOVE COVERS. REFER SERVICING TO

FORCONTINUEDFIRE PROTECTION. REPLACE

CONNECTED TO GROUND.

QUALIFIED PERSONNEL.

WARNING

AC

LINE VOLTAGE

100V

230V

220V

120V

SELECTION

207~250V

RANGE

90~110V

198~242V

108~132V

(50/60Hz)

250V

250V

T 10A

FUSE

T 6.3A

MAX.

1000VA

GND

ENSURE THE POWER IS REMOVED FROM

THE INSTRUMENT BEFORE REPLACING THE FUSE

POWER

SIGNAL I / O RS232

GPIB

GB Rx

SENSE H

SOURCE H

SENSE L

SOURCE L

RETURN

HI-POT

IR

HIGH VOLTAGE

CAUTION

MAX.

6.0 kVDC

5.0 kVAC

SER. NO. LB

High voltage terminal

Signal I/ O, RS232

& USB port Fan vents

Fuse selectorLine voltage

Optional GPIB port

GND

Return, Sense

and Source

terminals

7

1.6.5 STW-9801/9802/9803 Rear Panel

SIGNAL I/O USB A port RS-232Cport Fan

Fuse selector

Line voltage

Optional GP-IB port

GND

TO AVOID ELECTRIC SHOCK THE POWER CORD

PROTECTIVE GROUNDING CONDUCTOR MUST BE

ONLY WITH SPECIFIED TYPE AND RATED FUSE .

NO OPERATOR SERVICEABLE COMPONENTS INSIDE

.

DO NOT REMOVE COVERS REFER SERVICING TO

FOR CONTINUED FIRE PROTECTION .

REPLACE

CONNECTED TO GROUND .

QUALIFIED PERSONNEL.

WARNING

AC

LINEVOLTAGE

100V

230V

220V

120V

SELECTION

207~250V

RANGE

90~110V

198~242V

108~132V

(50/60 Hz)

T5A

250V

FUSE

POWER MAX.

500VA

GND

SIGNAL I/O RS232

SER. NO .LB

ENSURE THEPOWERISREMOVED FROM

THEINSTRUMENTBEFOREREPLACING THEFUSE

GPIB

T2.5A

250V

SIGNAL I/O port

SIGNAL I / O

The SIGNAL I/O port is used to monitor the

tester status (PASS, FAIL, TEST) and input

(START/ STOP signals). It is also used with

the Interlock key.

USB A port

Used for remote control.

RS-232C interface

port

RS232

Used for remote control and firmware

updates.

Fan/Fan Vents

Exhaust fan. Allow enough room for the fan

to vent. Do not block the fan openings.

GND

GND

Connect the GND (ground) terminal to the

earth ground.

Line voltage input

220

230

100

120

Line voltage input: 100/120/220/230VAC

±10%

Line voltage fuse

220

230

100

120

Line voltage selector and fuse:

STW-9900

STW-9800

100V/120V

T10A 250V

T5A 250V

220V/230V

T6.3A 250V

T2.5A 250V

Optional GP-IB

port

GPIB

Optional GP-IB interface for remote control.

8

HIGH VOLTAGE

output terminal

CAUTION

HIGH VOLTAGE

MAX.

5.0 kVAC

6.0 kVDC

The HIGH VOLTAGE terminal output

is used for outputting the testing

voltage.

WARNING

USE EXTREME CAUTION.

Do not touch the HIGH VOLTAGE terminal during testing.

RETURN terminal

STW-9901/9902/9903

RETURN

The RETURN terminal is used for IR,

DCW and ACW tests.

RETURN/

SENSE and

SOURCE

terminals

Only STW-9904

GB Rx

SENSE H

SOURCE H

SENSE L

SOURCE L

RETURN

HI-POT

IR

The RETURN terminal is used for IR,

DCW and ACW tests.

The SOURCE L/H AND SENSE L/H

terminals are for GB tests only.

1.7 Set Up

1.7.1 Line Voltage Connection and Power Up

Background

Before powering up the STW-9000 ensure the correct

voltage has been selected on the rear panel. The

STW-9000 supports line voltages of 100V/120V/220V and

230V.

Steps

1. Check the line voltage and the fuse in

the fuse holder.

Page 93

The desired line voltage should line up

with the arrow on the fuse holder.

220

100

120

230

2. Connect the power cord to theAC

voltage input.

22

0

100

120

230

9

3. If the power cord does not have an

earth ground, ensure the ground

terminal is connected to an earth

ground.

GND

Warning

Ensure the power cord is connected to an earth ground.

Failure could be harmful to the operator and instrument.

4. Press the Power button.

POWER

5. When the unit is powering up, all the LED indicators will

light. Check to make sure all 5 LED indicators are working.

6. Check to make sure the System Self-Test passes without

errors.

S y s e mt

H a r w a rd e C

h

C h e c i g . .n .

F i r w a rm e C h

SYS T E

SM E L F T E

S T

k

e c i g . .n .k

e c i g . .n .k

After the System Self-Test completes, the tester will go

into VIEW status and be ready to operate.

I R G BA CW D CW

E

F R E Q = 0 H z6

0

100k V

EIV

MT I E = 0 0 1 . 0 SR

0 0 m AER F =# 0 .0

1 . 0 0 m AIH ES = 0T

0 0 . 1 S0A M P =R

W

VIEW status

MM A UN N A_2M A N U = * * * - 0 0

m A

WARNING

See the Appendix on page 94 for details if a self-test error

is detected.

1.7.2 Installing the Optional GP-IB Card

Background

The optional GP-IB is a user-installable option. Follow the

instructions below to install the GP-IB card.

WARNING

Before installing the optional GP-IB card ensure the

STW-9000 is turned off and disconnected from power.

Steps

1. Remove the screws from the rear panel cover plate.

10

2. Insert the GP-IB card into the two slots on either side of

the opening. Push the card gently until it is fully inserted.

1.7.3 Workplace Precautions

Background

The STW-9000 is a high voltage instrument that outputs

dangerous voltages. The following section describes

precautions and procedures that must be followed to

ensure a safe work environment.

WARNING

The STW-9000 generates voltages in excess of 5kVAC or

6kVDC. Follow all safety precautions, warnings and

directions given in the following section when using the

instrument.

1. Only technically qualified personnel should be allowed to

operate the safety tester.

2. The operating workplace must be fully isolated, especially

when the instrument is in operation. The instrument

should be clearly labeled with appropriate warning

signage.

3. The operator should not wear any conductive materials,

jewelry, badges, or other items, such wrist watches.

4. The operator should wear insulation gloves for high

voltage protection.

5. Ensure the earth ground of the line voltage is properly

grounded.

6. Ensure any devices that are adversely affected by

magnetic fields are not placed near the tester.

This manual suits for next models

9

Table of contents

Other TEXIO Test Equipment manuals