THERMACUT EX-TRACK PA-1 User manual

Pipe Cutting System

Operating Instructions – EX-0-902-002/N23557

Revision 1, 27th March, 2023

EN - 2

EX-TRACK®PA-1

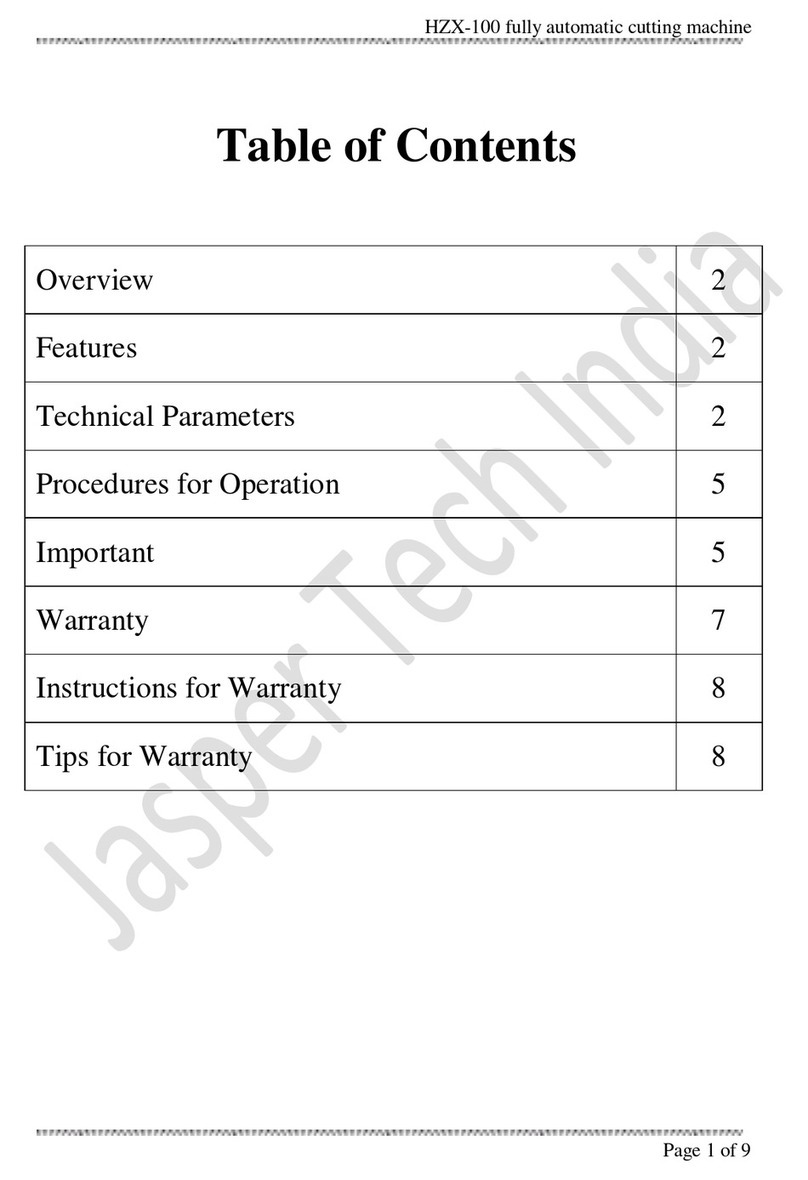

Table of contents

1 Identification ............................................................... EN-4

1.1 Marking.............................................................................................. EN-4

1.2 Identification plate ........................................................................... EN-4

1.3 Signs and symbols used.................................................................. EN-5

1.4 Classification of the warnings......................................................... EN-5

2 Safety........................................................................... EN-6

2.1 Designated use................................................................................. EN-6

2.2 Obligations of the operator............................................................ EN-6

2.3 Warning and notice signs................................................................ EN-6

2.4 Product-specific safety instructions................................................ EN-7

2.5 Safety instructions for the pipe cutter............................................ EN-7

2.6 Safety instructions for pipe cutting ................................................ EN-7

2.7 Personal protective equipment ...................................................... EN-7

2.8 Emergency information................................................................... EN-8

3 Scope of delivery......................................................... EN-8

4 Product description ..................................................... EN-9

4.1 Assembly and use ............................................................................ EN-9

4.2 Technical data................................................................................. EN-10

5 Transport and positioning .........................................EN-11

6 Setting up the device.................................................EN-12

6.1 Connecting to the gas supply....................................................... EN-12

6.2 Connecting the torch..................................................................... EN-12

6.3 Connecting the torch tip ............................................................... EN-12

6.4 Determining the correct number of chain links ......................... EN-13

6.5 Changing the wheels..................................................................... EN-13

6.6 Positioning the device on the pipe .............................................. EN-13

7 Operating the device.................................................EN-14

7.1 Selection of suitable torch tip....................................................... EN-15

7.2 Putting into operation.................................................................... EN-15

7.3 Cutting............................................................................................. EN-16

7.3.1 Bevel cutting ................................................................................... EN-17

7.4 Stopping the cutting process ....................................................... EN-17

8 Putting out of operation ............................................EN-17

9 Maintenance and cleaning ........................................EN-17

9.1 Maintenance and cleaning intervals............................................ EN-18

10 Faults and troubleshooting .......................................EN-19

11 Disposal .....................................................................EN-20

11.1 Disposal of materials...................................................................... EN-20

11.2 Disposal of consumables .............................................................. EN-20

11.3 Packaging........................................................................................ EN-20

12 Warranty ....................................................................EN-21

EX-TRACK®PA-1

EN - 3

13 Ordering information................................................ EN-22

14 Parts list..................................................................... EN-22

15 Cutting data .............................................................. EN-26

15.1 Propane cut charts..........................................................................EN-26

EN - 4

1 Identification EX-TRACK®PA-1

1 Identification

The EX-TRACK®PA-1 is a portable manual gas cutter for cutting pipes with

diameters of up to 600 mm. It is equipped with four wheels used to keep

balance as well as chains to secure the device on the pipe. The device may

be operated only with original Thermacut®parts. This documentation

exclusively describes the EX-TRACK®PA-1 gas cutter.

When used in this documentation, the term “device” always refers to the

EX-TRACK®PA-1 gas cutter.

1.1 Marking

This product fulfills the requirements that apply to the market to which it

has been introduced. A corresponding marking has been affixed to the

product.

1.2 Identification plate

The device is labeled by means of an identification plate on the housing.

For inquiries, please have at hand the device type, device number, and

year of construction per the identification plate.

Fig. 1 EX-TRACK®PA-1 identification plate

EX-TRACK®PA-1 1 Identification

EN - 5

1.3 Signs and symbols used

The following signs and symbols are used:

1.4 Classification of the warnings

The warnings are divided into four different categories and are indicated

prior to potentially dangerous work steps. The following signal words are

used depending on the type of hazard:

General instructions.

Action(s) to be carried out in succession.

Lists.

Cross-reference symbol refers to detailed, supplementary or further

information.

Caption, item description.

1

A

DANGER

Describes an imminent threatening danger. If not avoided, it may cause

severe injury or death.

WARNING

Describes a potentially dangerous situation. If not avoided, this may

result in serious injury or death.

CAUTION

Describes a potentially harmful situation. If not avoided, this may result in

slight or minor injuries.

NOTICE

Describes the risk of impairing work results or material damage and

indicates irreparable damage to the device or equipment.

EN - 6

2Safety EX-TRACK®PA-1

2Safety

This chapter warns of hazards that should be kept in mind to operate the

product safely. Non-observance of the safety instructions may result in risks

to the life and health of personnel, environmental damage or material

damage.

Observe the document entitled “Safety Instructions”.

2.1 Designated use

The device described in this document may be used only for the purpose

and manner described. The device is exclusively intended to cut pipes. Any

other use is considered improper and will lead to loss of warranty.

Unauthorized modifications or changes to enhance the performance are

not permitted and will lead to loss of warranty.

Do not exceed the maximum load data as defined by the document

supplied. Overloads lead to destruction.

Do not make any modifications or changes to this product.

Do not use or store the device outdoors where it is wet.

2.2 Obligations of the operator

Ensure that only qualified personnel are permitted to work on the

device or system.

Qualified personnel are:

— those who are familiar with the basic regulations on occupational

safety and accident prevention;

— those who have been instructed on how to handle the device;

— those who have read and understood these operating instructions;

— those who have been trained accordingly and have either of the

following qualifications:

• gas welding foreman‘s license,

• diploma of gas welding training,

• approval by the Ministry of Labor

— those who are able to recognize possible risks because of their

special training, knowledge, and experience.

Keep untrained persons out of the work area.

2.3 Warning and notice signs

The following warning, notice and mandatory signs can be found on the

product:

These markings must always be legible. They may not be covered,

obscured, painted over, or removed.

Read and observe the operating instructions.

EX-TRACK®PA-1 2Safety

EN - 7

2.4 Product-specific safety instructions

Only disassemble the device for maintenance and inspection purposes.

The device is made from aluminum alloy. Do not drop it or subject it to

heavy pressure.

Mount and position the device correctly.

Do not place the device on pipes when it is not used.

Always check the correct and free motion of the device before starting

the cutting operation.

Verify the correct chain tension before operation.

Do not mistake the top and bottom sides of the chain.

Do not use deformed, damaged or rusted chains.

Do not open any valves by force.

Do not move the device while the pre-heat flame is on.

Do not insert hands into rotary or moving sections.

2.5 Safety instructions for the pipe cutter

Verify that the gas hoses are not damaged, for example, by being driven

over, crushed or torn.

Check the gas hoses for damage and wear at regular intervals.

If it is necessary to replace the gas hoses, use only models which have

been approved by the manufacturer and which fully comply with the

local and/or national regulations.

2.6 Safety instructions for pipe cutting

Oxy-fuel cutting may cause damage to the eyes, skin, and hearing. Note

that other hazards may arise when the device is used with other cutting

components. Therefore, always wear the prescribed personal protective

equipment as defined by local regulations.

All metal vapors, especially lead, cadmium, copper, and beryllium, are

harmful. Ensure sufficient ventilation or extraction. Do not exceed the

current occupational exposure limits (OEL).

Ensure sufficient ventilation for gas cutting in order to prevent the air

from being polluted.

Adhere to the general fire protection regulations and remove

flammable materials from the vicinity of the cutting work area prior to

starting work. Provide appropriate fire extinguishing equipment in the

workplace.

Do not cut sealed containers or pressurized cylinders.

Do not use defective or contaminated pressure regulators.

Check for any leakage of gas from the distributor, the hoses or the

torch.

2.7 Personal protective equipment

Wear your personal protective equipment (PPE).

Ensure that others in close proximity are also wearing personal

protective equipment.

EN - 8

3 Scope of delivery EX-TRACK®PA-1

Personal protective equipment consists of protective clothing, safety

goggles, face protection, ear protectors, protective gloves, and safety

shoes.

2.8 Emergency information

In the event of an emergency, immediately disconnect the following

supplies at the gas inlet into the device or on the gas cylinders’ side:

—Oxygensupply

— Fuel gas supply

3 Scope of delivery

The following components are included in the scope of supply:

—1×EX-TRACK

®PA-1 body

— 1 x gas distributor incl. hoses and torch assembly

— 3× tip for propane (type 1, 2, 3)

— 2 x open wrench

— 1× consumables cleaning toolkit (needles)

— 2× gas fittings

— 1× horizontal torch holder

— 1 x vertical torch holder

— 1 x chain with 80 links

— 1× operator manual

— 2 x larger wheels (for cutting pipes with diameters in a range

between 80 – 108 mm)

The order data and ID numbers for the equipment parts and

consumables can be found at the end of this manual.

For more information about points of contact, consultation, and orders,

visit

www.ex-track.com

.

Although the items delivered are carefully checked and packaged, it is not

possible to fully rule out the risk of transport damage.

Goods-in inspection

Check for order completeness by checking the delivery note.

Check the delivered goods for damage (visual inspection).

Claim process

If goods are damaged, notify the final carrier.

Keep the packaging for possible inspection by the carrier.

Returns

Use original packaging and packing material for returns.

If you have questions concerning the packaging or how to secure the

device, contact your supplier, carrier or transport company.

EX-TRACK®PA-1 4 Product description

EN - 9

4 Product description

4.1 Assembly and use

The pipe cutter consists of the following components:

Fig. 2 Components and connections

AGas distributor

BButterfly nut

CClutch lever

DHoses

EConnector of torch holder

FUp-down hand wheel

GTorch

HButterfly screw

IWheel

JLeft-right hand wheel

KSprocket

LChain

MForward-backward hand knob

NFuel gas inlet

OOxygen inlet

Gas distributor (A) The gas distributor controls the flow of the

preheating oxygen, the fuel gas, and the

cutting oxygen.

Butterfly nut (B) The butterfly nut controls the chain tension

and through this the fit of the device on the

pipe to be cut.

Clutch lever (C) Holds the device on the pipe. If the clutch

lever is released, the device can be moved

quickly on the pipe.

Hoses (D) The three hoses are connected to the gas

distributor.

Connector of torch

holder (E)

Connects with the butterfly screw of the

lateral bar.

Up-down hand wheel (F) Moves the torch up and down.

D

I

CBA

F

E

G

H

J

I

K

L

M

N

O

EN - 10

4 Product description EX-TRACK®PA-1

4.2 Technical data

* After installation of two larger wheels it is possible to cut pipes with a

diameter between 80 – 108 mm.

Torch (G) Torch installed in the torch holder

Butterfly screw (H) Connects with the connector of the torch

holder.

Wheel (I) (4x) Provides balance and ensures cutting

precision.

Left-right hand wheel (J) Moves the device to the right or left.

Sprocket (K) Accommodates the chain. The rotation of

the sprocket moves the device.

Chain (L) Is put around the sprocket and the pipe to

hold the device in place.

Forward-backward hand

knob (M)

Moves the device forward and backward. A

clockwise turn moves the device forward, an

anti-clockwise turn moves it backward.

Fuel gas inlet (N) For the connection of the fuel gas hose.

Oxygen inlet (O) For the connection of the oxygen hose.

Table 1 Power supply specifications

Weight [kg] 12 (incl. accessories)

10.5 (without accessories)

Dimensions [mm] 325 x 325 x 425

Type of operation manual

Effective pipe cutting diameter [mm] 108* – 600

Pipe wall thickness [mm] 5 – 90

Groove I-shape and V-bevel

(angle up to 45°)

Range of vertical torch

movement [mm]

50

Range of lateral torch

movement [mm]

100

Table 2 Ambient conditions for transport and storage

Ambient temperature -20°C to +55°C

Relative humidity < 50% at +40°C

< 90% at +20°C

Table 3 Gas data

Permissible cutting gas Propane

Max. gas inlet pressure propane 3 bar / 43.5 psi

Max. gas inlet pressure oxygen 10 bar / 145 psi

EX-TRACK®PA-1 5 Transport and positioning

EN - 11

5 Transport and positioning

WARNING

Risk of injury due to improper transport and installation

Improper transport and installation can cause the device to tip or fall.

This may result in injury.

• Wear your personal protective equipment.

• Ensure that all supply lines and cables do not encroach into the area in

which employees are working.

• Note the weight of the device when lifting it.

4.2 Technical data on page EN-10

• Use an appropriate lifting tool with load handling equipment for

transporting and installing the device.

• Avoid abrupt lifting and setting down.

• Do not lift the device over individuals or other devices.

NOTICE

Risk of material damage due to improper transport and installation

The device is made from aluminum alloy. Improper transport or

installation can therefore cause material and irreparable damage to the

device.

• Protect the device against weather conditions, such as rain and direct

sunlight.

• Do not drop the device.

• Do not drop anything on the device.

• Protect the device from spatter when cutting.

• Use the device only in dry, clean, and well-ventilated rooms.

EN - 12

6 Setting up the device EX-TRACK®PA-1

6 Setting up the device

All references to parts refer to figure 2 in this document.

6.1 Connecting to the gas supply

6.2 Connecting the torch

6.3 Connecting the torch tip

1Select a suitable tip.

2Insert the tip.

3Tighten the nut with the two attached wrenches.

WARNING

Risk of injury due to explosion

The use of defective or damaged gas cylinders or hoses can cause

explosions. This can result in injury.

• Never use defective or leaking cylinders.

• Never use defective or leaking gas hoses.

• Use cylinders only for the purpose specified.

• Install cylinders in a place free from heat and open flame.

• Never cut pressurized cylinders or hermetically sealed containers.

• Ensure sufficient ventilation.

1Position the gas distributor (A) on the

device.

2Fix the gas distributor with the

hexagonal screw using a 6 mm

hexagonal key.

3Verify the hoses are correctly

connected.

4Verify there are no leaks.

1Insert the connector of torch holder

(E) into the butterfly nut casing at the

lateral bar.

2Connect the torch connector (E) to

the butterfly screw of the lateral

bar (H).

3Tighten both butterfly nuts.

4Adjust the angle and tighten the

connection.

H E

NOTICE

Risk of material damage due to incorrect installation

If the tip is tightened too much, it will heat up during operation and

become difficult to remove. Resulting damage to the tip will lead to

backfire.

• Do not overtighten the tip.

• Avoid damage to the tip.

EX-TRACK®PA-1 6 Setting up the device

EN - 13

6.4 Determining the correct number of chain links

The chain can be adapted to suit most diameters by increasing or

decreasing the number of links. The required number of links is calculated

as follows:

Let Y be the number of links and

D be the diameter of the pipe in centimeter rounded up to the next full

centimeter.

The formula then is Y = D +12.

Example:

The diameter of a pipe is 258 mm. 258 mm = 25.8 cm.

Rounded up it is 26 cm.

Y = 26+12 = 38 links.

6.5 Changing the wheels

6.6 Positioning the device on the pipe

1Unscrew the screws on the wheels

using a Phillips screwdriver size 1.

2Remove the wheels.

3Put on new wheels.

4Fix the wheels with the screws using a

Phillips screwdriver size 1.

WARNING

Risk of crushing

Improper assembly and disassembly of components can result in

crushing of limbs.

• Do not reach into the hazardous areas.

• Check and wear your personal protective equipment.

1Calculate the required number of

links.

2Position the device on the pipe.

3Turn the butterfly nut (B) to lower the

bracket with the sprocket.

4Place the chain over the sprocket.

Let the chain hang vertical to the

pipe.

EN - 14

7 Operating the device EX-TRACK®PA-1

7 Operating the device

5Close the links.

Verify that the rounded side of the

chain faces toward the pipe!

6Turn the butterfly nut (B) clockwise to

fix the device on the pipe.

Leave a clearance of 1 to 2 mm so

that the device can run smoothly.

7Hold the device and release the

clutch lever (C).

8Move the device within a range of

120 ° and align chain.

WARNING

Risk of injury or damage due to backfire

Backfires may cause serious accidents or fire.

• When a backfire occurs, you should find the cause.

• Inspect and maintain the device correctly before using it again.

• The followings are causes of backfire:

— Improper gas pressure adjustment.

— Overheated tip.

— Dross clogging in tip.

— Damages to the tapered section of tip or torch.

— If oil or grease is used on the connections of the oxygen hose.

NOTICE

Material damage due to flashback

Flashbacks can cause fire and damage to the device. If there is a hissing

sound in the torch, proceed as follows:

• Immediately disconnect the following supplies at the gas inlet into the

device or on the gas cylinders’ side:

•Oxygensupply

• Fuel gas supply

EX-TRACK®PA-1 7Operatingthedevice

EN - 15

7.1 Selection of suitable torch tip

1Select a tip that fits the thickness of the material to be cut.

2Insert tip into torch.

3Fix tip by tightening the nut with the two wrenches.

If the material to be cut is heavily rusted or you need a bevel cut with an

angle exceeding 20 degrees, select the tip one grade higher than

specified in the cutting data.

7.2 Putting into operation

Adjust the gas pressure on the following valves:

1Open the fuel gas valve 1/4 turn.

2Open the pre-heating oxygen valve 1/2 turn.

3Light the torch with an igniter.

4Gradually open the pre-heating oxygen valve until the standard flame

shows a white cone. The incandescent area should be uniform and have

a length about 5 to 6 mm.

5Open the cutting oxygen valve fully.

6Re-adjust the flame so it shows an orderly flow.

7Adjust the torch at a suitable distance from the surface:

Acetylene gas: 8 to 10 mm

Propane gas: 5 to 8 mm.

NOTICE

Bad cutting quality due to improper gas setting

A disorderly oxygen flow will have a serious negative impact on the

cutting surface.

• Close the pre-heating oxygen and fuel gas valve.

• Keep the cutting oxygen flowing and clean tip with a needle.

A neutral flame ensures a good quality

cut surface.

An oxygen flame shortens the flow of

the cutting oxygen and can be used for

bevel cutting. It can cause slug

deposition or melting of the upper

cutting surface.

Due to the high pressure of the cutting

oxygen, a carbonizing flame has similar

effects as the oxidizing flame.

EN - 16

7 Operating the device EX-TRACK®PA-1

7.3 Cutting

There are three ways to start cutting:

1Drill a hole and start on the edge of the hole, or

2Pierce through the material, or

3Start from the edge of the material.

Then

4Align the torch tip with the cutting start point.

5Open the valves as described in chapter 7.2.

6Ignite the torch with a lighter.

7Adjust the flame.

https://youtu.be/MCr54FVrzzY

8Pre-heat the cutting point until it is white hot.

9Open the valve for the cutting oxygen about 1/8 turn.

10 Position the torch tip about 15 to 20 mm above the surface to be cut in

order to prevent contamination of the tip.

11 Inspect the cutting state and use the knob (M) to control the cutting

speed.

12 Hold the butterfly nut (B) with one hand during operation. When the

device moves down, support it, when it moves up, lift it, as shown in the

following illustration.

13 In order to change direction, turn the knob (M).

Turning the knob clockwise moves the device forward, turning the knob

anti-clockwise moves the device backwards.

EX-TRACK®PA-1 8 Putting out of operation

EN - 17

7.3.1 Bevel cutting

The torch connector is equipped with two holes. For bevel cuts position the

torch in the lower one. Proceed as follows:

1Position the torch in the lower hole of the torch connector.

2Position the torch holder and torch in the required angle.

3Fix the torch with the butterfly nut (B).

4Choose a tip one grade larger than specified in the cutting data for the

material thickness.

5Use an oxidizing flame and reduce the speed a little bit.

7.4 Stopping the cutting process

1Close the following supplies at the gas inlet into the device or on the gas

cylinders’ side:

—Oxygenvalve

— Fuel gas valve

8 Putting out of operation

1Disconnect the device from the oxygen supply.

2Disconnect the device from the fuel gas supply.

9 Maintenance and cleaning

Scheduled maintenance and cleaning are prerequisites for a long service

life and trouble-free operation. The maintenance cycle is determined by

the work environment and the device’s maintenance intervals. If the device

is operated for more than 8 hours a day, the maintenance intervals should

be changed as needed. Always observe the provisions of DIN 31051

“Fundamentals of maintenance” and DIN EN 13306 “Maintenance -

Maintenance terminology”, as well as any local laws and regulations.

CAUTION

Risk of injury due to hot parts

Parts may still be hot after the operation. People are at a risk of burns.

• Wear your personal protective equipment.

• Allow the cutting torch to cool down for 5 – 10 minutes before

touching the parts.

CAUTION

Fire hazard due to contamination

Dust deposits inside the device can lead to a reduction in insulation. This

can cause short circuits or fires.

• Clean the device annually with dried compressed air to remove dust

and cutting fume residue.

EN - 18

9 Maintenance and cleaning EX-TRACK®PA-1

9.1 Maintenance and cleaning intervals

The specified intervals are standard values and refer to single-shift

operation. We recommend recording the inspections. The date of the

inspection, the detected defects and the name of the inspector should be

documented.

Maintenance and inspection services should always be performed by

skilled repair engineers.

WARNING

Risk of self-ignition if oil or grease is used with oxygen.

If oil or grease is used on the connections of the oxygen pipe or on the

pressure regulators, self-ignition can occur.

• Never use oil or grease together with oxygen.

Daily/every 6 hours

of cutting

Clean the four wheels with an iron wire brush.

Lubricate the rotary section of the device, i.e.

the wheels, sprocket, worm gear, handle, and

worm bearing.

Check the consumables for wear.

Clean the nozzle orifice of the tip.

Weekly Lubricate the butterfly nut and sliding sections

Every 3 months Check the device for signs of cracks.

Check the gas hose and connections for leaks.

EX-TRACK®PA-1 10 Faults and troubleshooting

EN - 19

10 Faults and troubleshooting

Contact your retailer or Thermacut®in the event of questions or

problems.

Table 4 Fault messages in the display

Error Cause Troubleshooting

Device

does not

work

Chain tension too great. Adjust the chain tension.

Worn worm gear. Clean and/or repair worm

gear.

Wheel does not rotate. Lubricate or replace, if

necessary.

Defective

surface

Worn or damaged tip. Clean the tip or replace, if

necessary.

Unsuitable gas pressure

and/or cutting speed.

Verify the correct gas

pressure and cutting speed.

Tip

The injection stream of

cutting oxygen does not

extend straight.

Replace the tip.

The injection stream of

the cutting oxygen

bifurcates.

The tip emanates a

clicking sound when

cutting.

The pre-heating flame is

not flat.

Gas leaks and/or burns at

the nut.

EN - 20

11 Disposal EX-TRACK®PA-1

11 Disposal

Disassemble equipment prior to proper disposal.

Collect components separately and recycle in an environmentally

responsible manner.

Observe local regulations, laws, provisions, standards and guidelines.

11.1 Disposal of materials

This product is mainly made of metallic materials that can be melted in

steel and iron works and are thus almost infinitely recyclable. The plastic

materials used are labeled in preparation for their sorting and separation

for later recycling.

11.2 Disposal of consumables

Oil, greases and cleaning agents must not contaminate the ground or

enter the sewage system. These substances must be stored, transported

and disposed of in suitable containers. Observe the relevant local

regulations and disposal instructions in the safety data sheets specified by

the manufacturer of the consumables. Contaminated cleaning tools

(brushes, rags, etc.) must also be disposed of in accordance with the

information provided by the consumables' manufacturer.

Observe the relevant local regulations and disposal instructions in the

safety data sheets specified by the manufacturer of the consumables.

11.3 Packaging

Thermacut®has reduced the packaging to the necessary minimum. The

ability to recycle packaging materials is always considered during their

selection.

Table of contents

Other THERMACUT Cutter manuals

Popular Cutter manuals by other brands

BrandSafway

BrandSafway Spider ProCut Operator's manual

Far Tools

Far Tools TCR 720B Original manual translation

Avantco

Avantco S30 Operator's manual for Attachment

Z.I.P.P.ER MASCHINEN

Z.I.P.P.ER MASCHINEN ZI-MOS4TA user manual

E-RM

E-RM F-121 Use and maintenance manual

Hyd-Mech

Hyd-Mech S20DSP Use and maintenance manual