MaxQ 5000 Shaker 2-1Thermo Scientific

Section 2 Specifications

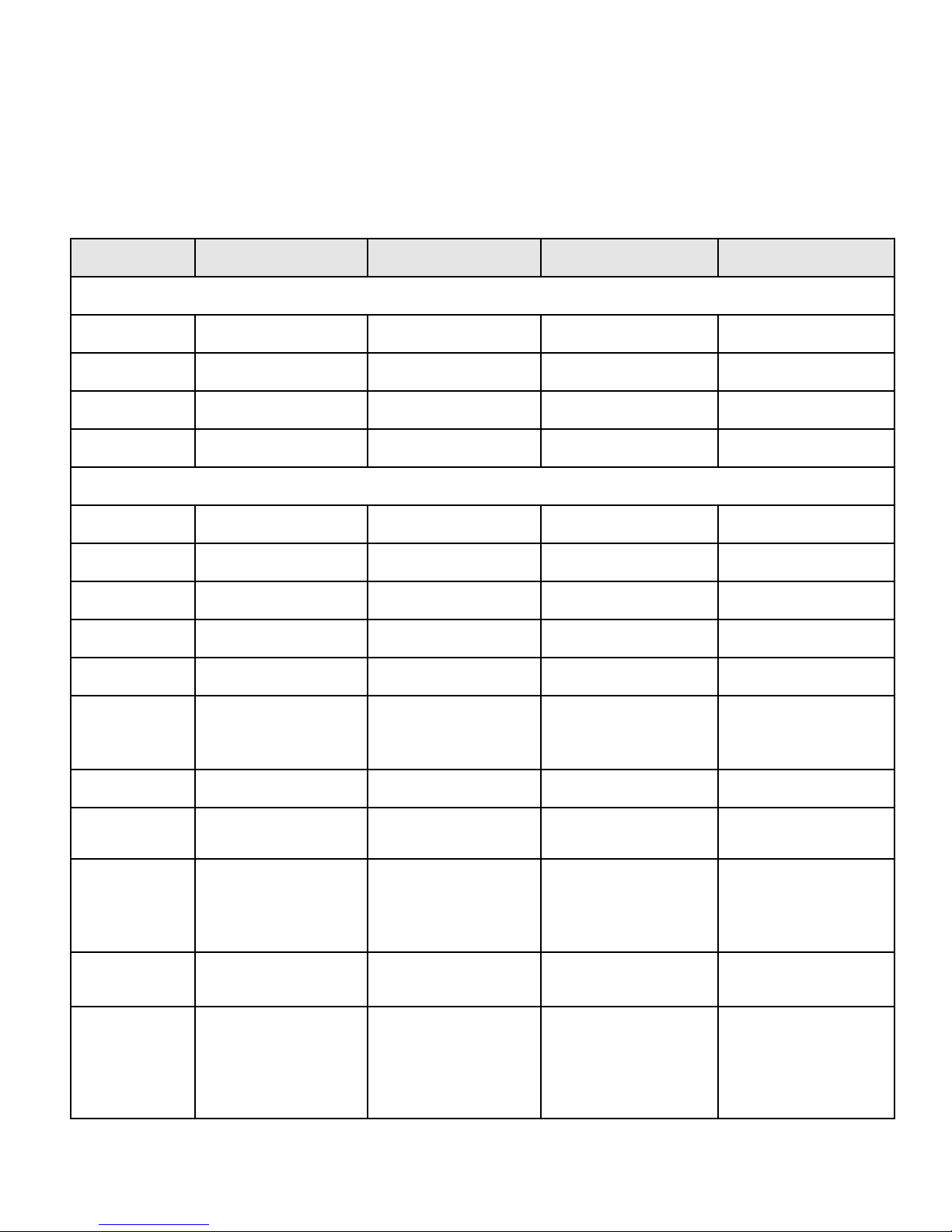

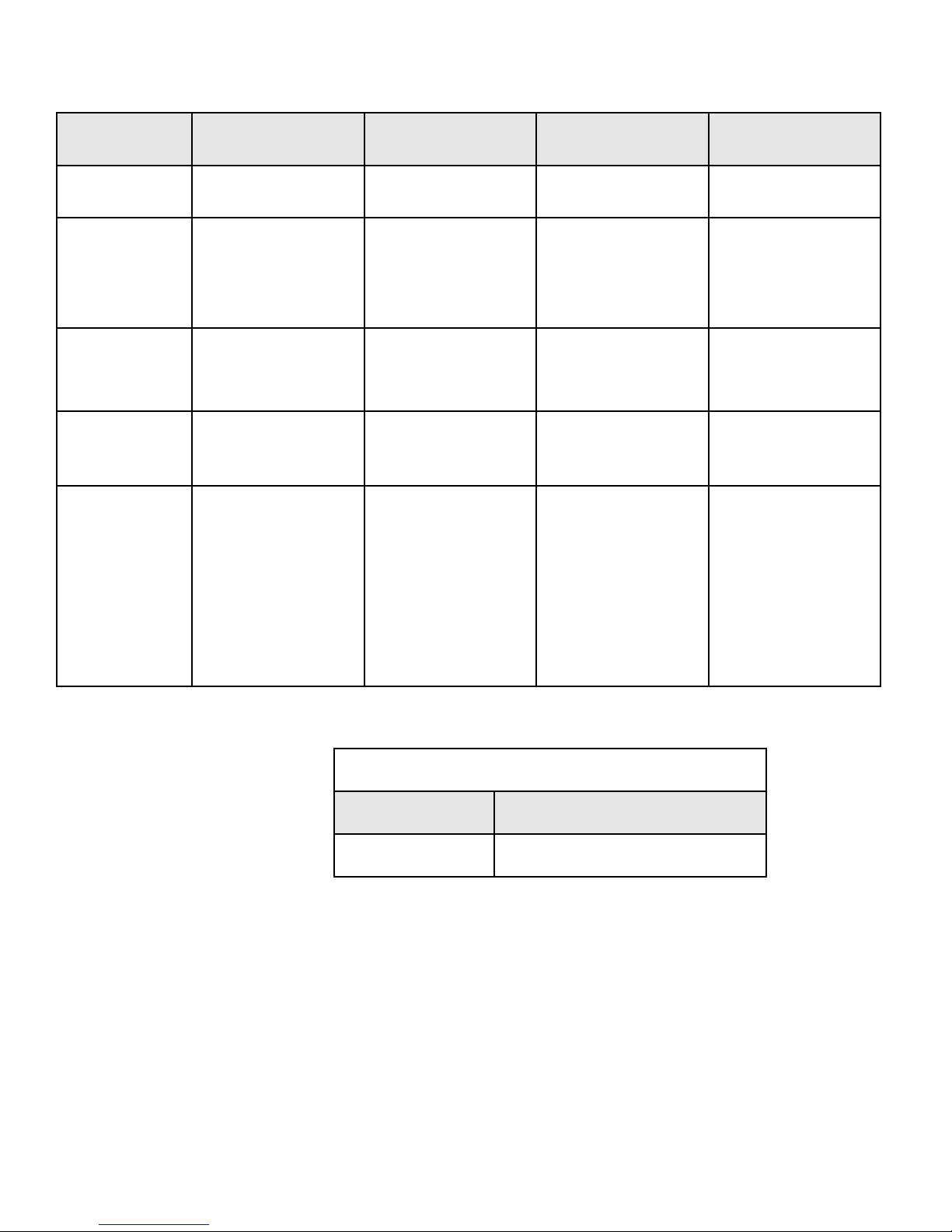

Model No. 4348/4354 4349/4355 4350/4356 4351/4358

Exterior Unit Dimensions in. (cm)

Width 41” (104.1 cm) 41” (104.1 cm) 41” (104.1 cm) 41” (104.1 cm)

Height 41” (104.1 cm) 41” (104.1 cm) 41” (104.1 cm) 41” (104.1 cm))

Length 32” (81.3 cm) 32” (81.3 cm) 32” (81.3 cm) 32” (81.3 cm)

Weight lbs (kg) 476 (215.9) 476 (215.9) 512 (232.2) 512 (232.2)

Electrical: Standard Temperature/Refrigerated - Dedicated Power Source

Volts (AC) 120/120 220-240/220-240 120/120 220-240/220-240

Amps 12.0/14.0 6.5/8.0 7.5/14.0 6.5/8.0

Watts 1450/1600 1500/1840 900/1600 1500/1840

Freq. 50/60 (both models) 50/60 (both models) 50/60 (both models) 50/60 (both models)

Speed 40 to 400 rpm, ±10 rpm 40 to 400 rpm, ±10 rpm 15 to 500 rpm, +1 rpm 15 to 500 rpm, +1 rpm

Timer Continuous or timed from 1-

60 mins

Continuous or timed from 1-

60 mins

Continuous or timed from 0.1-

999 hours or 0.1-999 mins

Continuous or timed from 0.1-

999 hours or 0.1-999 mins

Recorder Output None None None None

RS232 Interface None None Monitor speed and time with

a computer

Monitor speed and time with

a computer

Display Analog tachometer displays

speed in rpm

Analog tachometer displays

speed in rpm

2 individual LED displays indi-

cate time and speed simulta-

neously. 3 characters height

1/2 inch (1.27 cm)

2 individual LED displays indi-

cate time and speed simulta-

neously. 3 characters height

1/2 inch (1.27 cm)

Soft Start Feature None None Software algorithms prevent

sudden start/stops

Software algorithms prevent

sudden start/stops

Mutable Alarms None None

Audible portion of the alarm

can be silenced for a 1 hr.

period without deactivating

the actual alarm condition by

depressing any key

Audible portion of the alarm

can be silenced for a 1 hr.

period without deactivating

the actual alarm condition by

depressing any key