Thermo Forma 3911 Operating instructions

This manual suits for next models

3

Table of contents

Other Thermo Laboratory Equipment manuals

Thermo

Thermo 1284 Operating instructions

Thermo

Thermo IEC Centra CL5 User manual

Thermo

Thermo ThermoFlex 900 User manual

Thermo

Thermo 2210 User manual

Thermo

Thermo Centra CL2 User manual

Thermo

Thermo SORVALL RC-12BP User manual

Thermo

Thermo Orbitrap Fusion Series User manual

Thermo

Thermo 4862 Operating instructions

Thermo

Thermo 8600 Series Operating instructions

Thermo

Thermo 3413 User manual

Thermo

Thermo Luminoskan Ascent User manual

Thermo

Thermo IEC Centra CL3 User manual

Thermo

Thermo LabSystems Multiskan RC User manual

Thermo

Thermo iCAP 6000 Series User manual

Thermo

Thermo Savant SpeedVac SPD121P User manual

Thermo

Thermo 1284 Operating instructions

Thermo

Thermo Varioskan User manual

Thermo

Thermo FINNPIPETTE DIGITAL User manual

Popular Laboratory Equipment manuals by other brands

Alfa Network

Alfa Network Color Lab Operator's manual

Agilent Technologies

Agilent Technologies 280-DS MQS Operator's manual

Analytik Jena

Analytik Jena Biometra TAdvanced Series operating manual

Ocean Optics

Ocean Optics SpectroClip-R Installation and operation manual

Sanuvox

Sanuvox SANUVAIR S1000 OZD instruction manual

Endress+Hauser

Endress+Hauser analytikjena CyBio QuadPrint HQ Assembly instructions

Koehler

Koehler KV3000 Operation and instruction manual

NuAire

NuAire LabGard NU-640-400 Operation and maintenance manual

UVITEC Cambridge

UVITEC Cambridge FIREREADER MAX User & service manual

BioLAB

BioLAB BHMS-104 Operation manual

Piezotronics

Piezotronics IMI Sensors 699B06 Installation and operating manual

IKA

IKA ULTRA-TURRAX T 18 digital manual

Yamato

Yamato IL603 instruction manual

Hall Research Technologies

Hall Research Technologies 511-POH-30W user manual

Heidolph

Heidolph Smart S-biosystems 801620 operating instructions

Hach

Hach ISECL181 user manual

Teledyne Lecroy

Teledyne Lecroy ZD500 Getting started manual

Macherey-Nagel

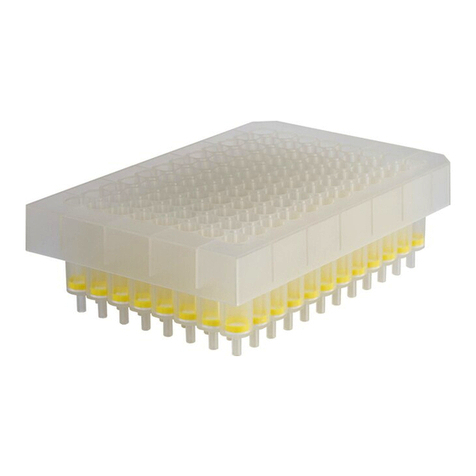

Macherey-Nagel NucleoMag 96 PCR user manual