Contents

1. Safety precautions ................................................................. 1

Explanation of pictograms ............................................................. 1

List of symbols ....................................................................... 2

Warning・Cautions ................................................................... 3

2. Before operating the unit ........................................................... 4

Precautions when installing the unit ..................................................... 4

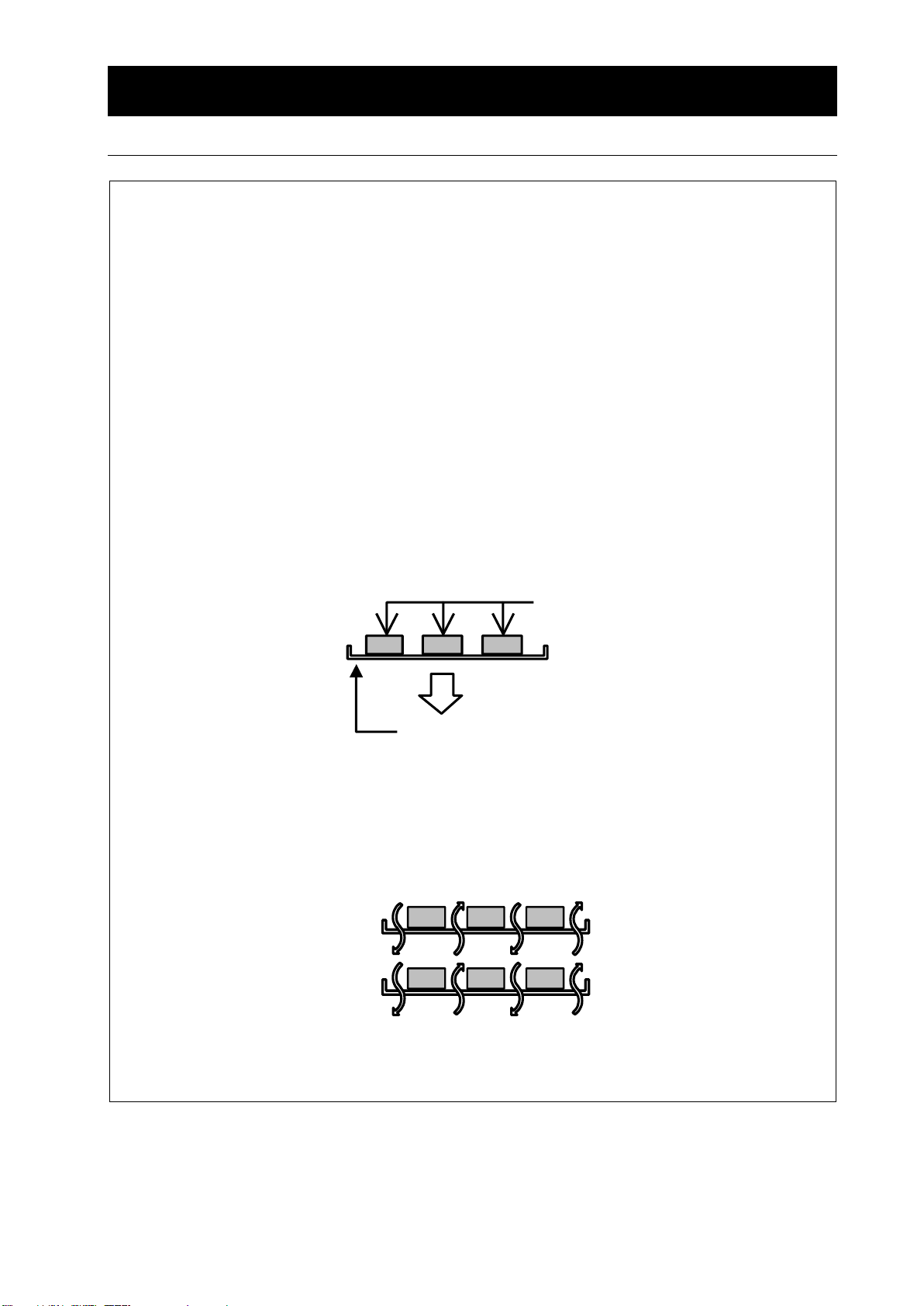

Installation procedures/precautions...................................................... 8

About defrosting of the freezer......................................................... 10

3. Names and functions of parts ...................................................... 12

Main unit ........................................................................... 12

Operation panel ..................................................................... 13

Characters of the Controller ........................................................... 15

4. Operation Method................................................................. 16

Operation Mode and Function List ..................................................... 16

Operation Mode, Function Setting Key, and Characters ................................... 20

Setting of Overheating Prevention Device ............................................... 21

Fixed Temperature Operation.......................................................... 23

Quick Auto Stop Operation............................................................ 25

Auto Stop Operation ................................................................. 27

Auto Start Operation ................................................................. 29

Calibration Offset Function............................................................ 31

Lock Function....................................................................... 32

Freezer operation mode function....................................................... 33

Temperature rise/fall characteristics .................................................... 34

Introduction of optional parts .......................................................... 35

Temperature Output Terminal.......................................................... 36

RS485 Communication Function....................................................... 38

5. Cautions on handling.............................................................. 50

6. Maintenance procedures........................................................... 52

Daily inspection/maintenance.......................................................... 52

7. When the unit is not to be used for a long time or when disposing ..................... 54

When the unit is not to be used for a long time or when disposing........................... 54

Notes about disposition............................................................... 54

8. Troubleshooting .................................................................. 55

Safety device and error codes......................................................... 55

When a malfunction is suspected ...................................................... 56

9. After sales service and warranty.................................................... 57

When requesting a repair ............................................................. 57

10. Specifications ................................................................... 58

11. Wiring diagram .................................................................. 59

12. Replacement parts list............................................................ 60

13. List of dangerous materials....................................................... 61

14. Standard installation manual ...................................................... 62