3

BACK TO INDEX For more informaon about our products and how to contact us, please visit thermopatch.com

Copyrights ..........................................................................................................................................2

Introducon........................................................................................................................................2

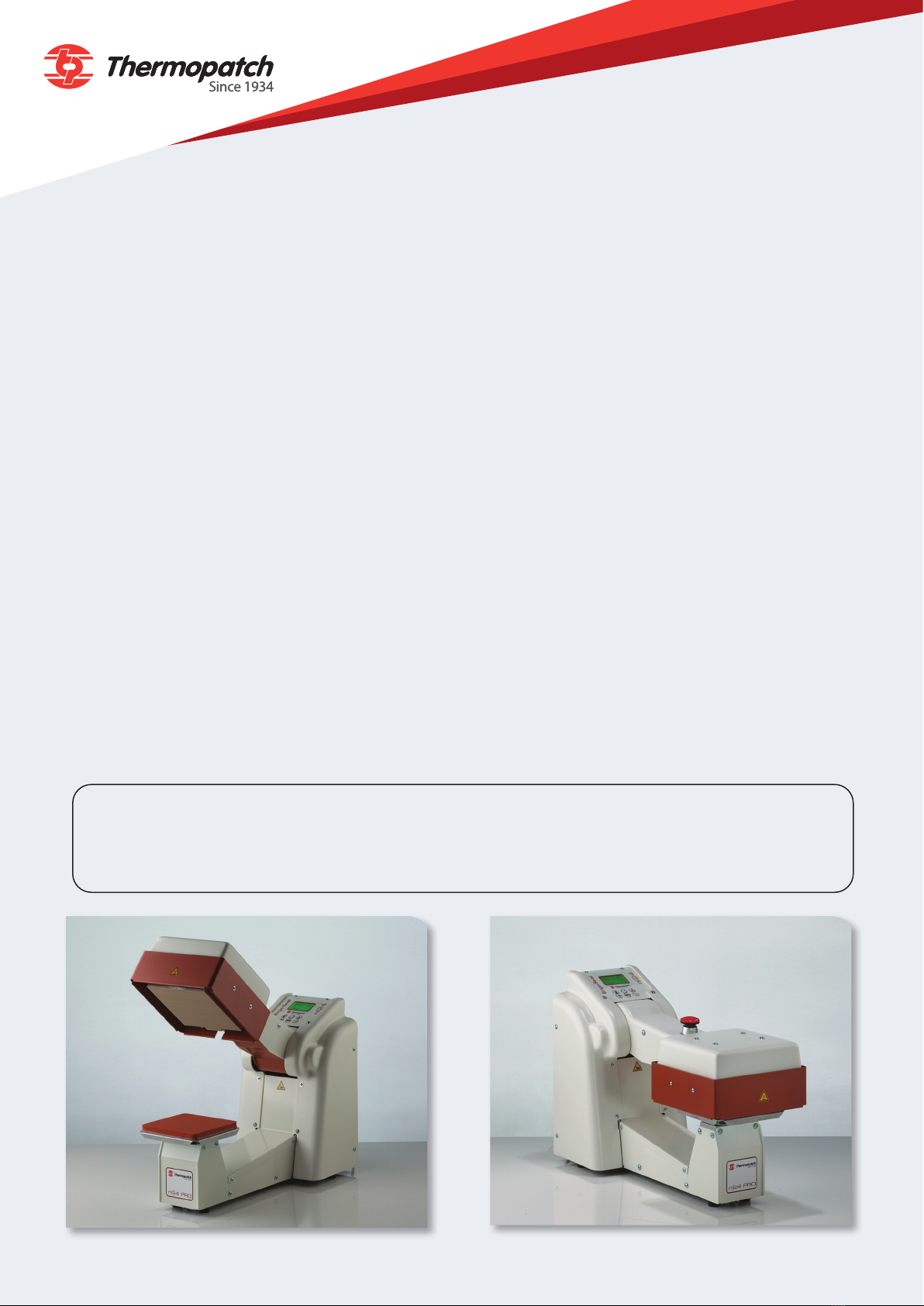

1 GeneralDescripon ..............................................................................................................5

1.1 Levering........................................................................................................................................ 5

1.2 Warranty ...................................................................................................................................... 5

2 Intended use ........................................................................................................................5

3 Assemblyandinstallaon .....................................................................................................6

3.1 Assembly and installaon ............................................................................................................ 6

4 Operanginstrucon............................................................................................................7

4.1 Operang the NL-24 Pro

4.1.1 The control unit and display ........................................................................................................ 7

4.1.2 Sengs......................................................................................................................................... 8

4.1.2.1 Temperature seng..................................................................................................................... 9

4.1.2.2 Time seng.................................................................................................................................. 9

4.1.2.3 Pressure sengs .......................................................................................................................... 9

4.2 Interrupng the work cycle of the NL-24 Pro .......................................................................... 11

4.3 Reading the counters ................................................................................................................. 11

4.4 Error messages........................................................................................................................... 11

4.4 Switching from pedal control to manual control from V 1.52................................................... 12

5 Overview of safety measures and warnings........................................................................15

5.1 Safety.......................................................................................................................................... 15

The safety frame ........................................................................................................................ 15

The emergency stop buon....................................................................................................... 15

6 Technicalspecicaons .......................................................................................................17

6.1 Specicaons of the NL-24 Pro ................................................................................................. 17

7 Transport and storage .........................................................................................................17

7.1 Transport .................................................................................................................................... 17

7.2 Storage ....................................................................................................................................... 17

8 Maintenance.......................................................................................................................18

Temperature...................................................................................................................................

Teon cover....................................................................................................................................

Sealing pad .....................................................................................................................................

Replacement of the Teon protecon and the sealing pad..........................................................

Air lter pressure regulator............................................................................................................

Contents