Thiele Streamfeeder EFS Pro User manual

Manual

EFS Pro

Part Number 904537

© 2016 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on a retrieval system, or transmitted without the

express written consent of Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

315 27th Avenue NE

Minneapolis, MN 55418 USA

Tel:(763) 502-0000

Fax:(763) 502-0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

i

EFS Pro Manual

Contents

Before You Begin.................................................................................ii

Message Conventions ................................................................................................................................. ii

Safety ......................................................................................................................................................... iii

Specications .....................................................................................iv

Section 1: About the Machine .......................................................1

Section 2: Set Up ............................................................................3

Section 3: How to Operate ...........................................................10

Section 4: Troubleshooting .........................................................13

Section 5: Inspection and Care ...................................................15

Section 6: Mechanical Components ...........................................23

Section 7: Electrical Diagrams ....................................................43

Envelope Sealing System Parts Manual..........................................46

ii EFS Pro Manual

Message

Conventions

DANGER signies an action or specic equipment area that can result in

serious injury or death if proper precautions are not taken.

WARNING signies an action or specic equipment area that can result in

personal injury if proper precautions are not taken.

CAUTION signies an action or specic equipment area that can result in

equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signies an action or specic equipment area that

can result in personal injury or death from an electrical hazard if proper pre-

cautions are not taken.

Before You Begin

TECHNICIAN

OPERATOR

TIP signies information that is provided to help minimize problems in the

installation or operation of the feeder.

NOTE provides useful additional information that the installer or operator

should be aware of to perform a certain task.

CHECK signies an action that should be reviewed by the operator before

proceeding.

IMPORTANT alerts the installer or operator to actions that can potentially

lead to problems or equipment damage if instructions are not followed prop-

erly.

TECHNICIAN indicates that a qualied technician should be alerted to the

corresponding tasks and information.

OPERATOR indicates that an operator should be alerted to the corresponding

tasks and information.

WARNING LABELS afxed to this product signify an action or specic

equipment area that can result in serious injury or death if proper precautions

are not taken.

iii

EFS Pro Manual

Make sure you thoroughly read this section to become familiar with

all the safety issues relating to the safe operation of this product.

Please read all of the warnings that follow to avoid possible injury.

Although Thiele-Streamfeeder has made every effort to incorporate

safety features in the design of this feeder, there are residual risks that

an installer or operator should be aware of to prevent personal injury.

Please read all of the cautions that follow to prevent damage to this

product. This product is built with the highest quality materials.

However, damage can occur if the system is not operated and cared for

within design guidelines as recommended by Thiele-Streamfeeder.

To insure proper machine operation make sure that all the safety de-

vices are installed properly and functioning. If the feeder has the me-

dia sensor on the side guides insure that these are properly installed.

Do not attempt to defeat a safety interlock or safety feature.

Equipment interior contains incoming 115 or 230VAC electrical

power. Bodily contact with these high voltages can cause electro-

cution, which can result in serious injury or death.

safetY

Danger

TECHNICIAN

OPERATOR

iv EFS Pro Manual

speCifiCations

Maximum Product Size: ............................. 10 in. W x 13 in. L (254 mm x 330 mm)*

Minimum Product Size: ............................. #9 envelope, 3-7/8 in. W x 8-7/8 in. L (98 mm x 225 mm)*

Min/Max Product Thickness: .................... .003 in. to .25 in. (.076 mm - 6.35 mm)

Belt Speed: ................................................... 1,800 in/min (46 m/min)

Utilities: ........................................................ 115vac, 50/60Hz, 3A

Weight: ......................................................... 90 lbs. (41 kg)

Warranty: .................................................... One year limited

*Short edge leading

v

EFS Pro Manual

1EFS Pro Manual

1About the Machine

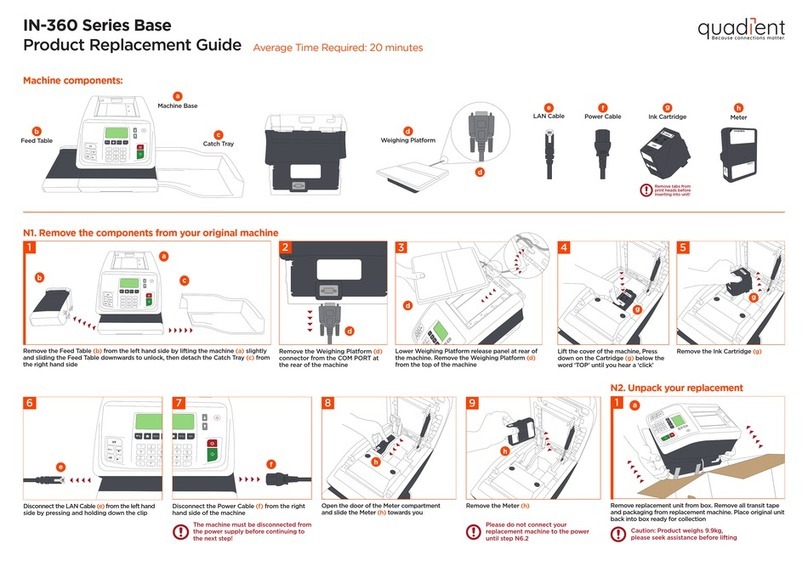

Main Assemblies

Moistening

Device

Hold

Down

Counter

Back

Wedge Side

Guide

Separator

Table

Top

On/Off

Switch

Feed/Discharge

Carriages

Sealing

Roller

Assembly

Catch

Tray

Variable

Speed

Control

The EFS Pro is an automatic envelope ap sealer, reducing the time

and mess of manually sealing envelopes. From a #9 envelope to a

10x13, and with various aps, the EFS Pro will provide consistent

feeding and ap sealing quality. Convenient and easy to set-up, along

with quick changeover from one job to another.

Familiarizing yourself with names and locations of feeder parts and

adjustments will help to prepare you for initial setup.

2

EFS Pro Manual

Main Assemblies Feature Descriptions

Feature Description

Moistening Device Assembly is used to separate the ap from the envelope, allowing the ap

portion of the envelope to pass and to come in contact with moistening brush.

The assembly also can be manually adjusted with the use of a lever to allow

envelopes to bypass the opening mechanism.

Sealing Roller Assembly Final roller assembly (downstream from moistening device). Applies pressure

on moistened and sealed envelope, securing ap closure to envelope.

Counter Digital and resettable with the use of the reset button.

Variable Speed Control Adjustment of this potentiometer type control will change the feed speed of the

unit. Turning the knob counter-clockwise decreases speed; clockwise increas-

es speed.

On/Off Switch Rocker style switch toggles AC power On or Off.

Table Top One piece shell for mounting of all sub-assemblies and components.

Back Wedge Lifts the envelopes to keep them off the table top, reduces excessive contact

with the feed belts, and helps push the envelopes against the curvature of the

separator assembly.

Side Guide Allows lateral adjustment from side for different size envelopes.

Separator Single separator mounted above the carriage housing the feed belts. This

device provides a curvature to help preshingle stacked envelopes. When

properly adjusted, a clearance is created to help singulate and feed envelopes.

Non-Adjust Hold Down Provides the friction and motion necessary to pull envelopess away from the

separator assembly. Positioned above discharge belts. Assists in creating gap

between envelopes in discharge section.

Removable Feed/Discharge

Carriages

Houses the feed belts which provides the friction and motion necessary to pull

individual envelopes from the bottom of the stack and through the separator

assembly. Easy to remove for feed belt replacement.

3EFS Pro Manual

2Set Up

Prepare the machine for operation. To do so, set up the envelopes you

are going to be feeding. Do a test run with the envelopes to verify it is

set correctly before you begin cycling the feeder.

You will have to perform this procedure for envelopes you plan to feed.

When performing initial feeder adjustments

prior to operation, always make sure you turn

Off the main power switch and disconnect all

equipment from the electrical power source.

Failure to do so can expose you to a potential

start-up and moving parts which can cause

serious injury.

Do not attempt to make any adjustments while

the feeder and machine of application are

running. Failure to do so can expose you to

moving parts which can cause serious injury.

Do not wear loose clothing when operating the

feeder.

Avoid making adjustments with loose or

unsecured parts. This can potentially damage

parts.

STEP 1:

Separator Adjustment

Review

The separator assembly provides the curvature to help preshingle

envelopes and the proper gap to help the feed belts pull envelopes

through the separator assembly area — one at a time. The downward

pressure (or weight) of the stack in the hopper will provide the force to

help push the envelopes against the curvature of the separator assem-

bly, and help it contact the feed belts. This preshingling will allow the

separator assembly to efciently separate (and singulate) envelopes.

To achieve the optimum separation, you have to use the adjustment

knob to either increase (clockwise) or decrease (counterclockwise) the

gap between the separator assembly and the feed belts.

Objective

Adjust the separator assembly for minimum gap, with minimum

pressure on the envelopes. Your objective is to adjust the clearance so

that a single envelope passes without resistance. The optimum setting

should be a gap adjustment of 1.5 thickness of an envelope.

Keep in mind the separator assembly works with

the wedge to provide the proper lift, curvature of

the envelopes, and proper belt/envelopes contact

to separate and feed one piece at a time.

Hopper refers to the space where the envelope is

stacked (made up of the side guides).

Feeding problems will occur with either too

much envelopes in the hopper, or too large a

gap between the separator assembly and the

envelopes.

The adjustments you must make (in order) are as follows:

1: Separator adjustment

2: Side guide adjustment

3: Back wedge adjustment

4: Manual test to verify

5: Envelope Moistening Device Setup

4

EFS Pro Manual

Excessive lowering of the separator assembly can damage envelopes

or lead to premature wear of the O-rings or feed belts.

A wider gap between envelopes and belt provides

the highest tolerance for curled and bent edges.

Feeding problems will occur with either too

many envelopes in the hopper, or too large a

gap between the separator assembly and the

envelope.

STEP 1:

Separator Adjustment

(continued)

1. Slide a single envelope between the feed belt and the separator.

2. Rotate the separator adjustment knob either up or down until the

envelopes can be pulled from under the separator assembly with a

slight amount of drag.

3. Repeat the drag tests and adjust as needed to achieve acceptable

clearance.

Separator

Adjustment

Knob

5EFS Pro Manual

STEP 2:

Side Guide Adjustment

1. Loosen the side guide knob. This will allow you to move the side

guide from side to side.

Register the envelopes

to be run on the wide

belt and position against

left side frame

Loosen knob

Move side guide

laterally

2. Register the envelopes to be run on the wide belt and position

against left side frame.

3. Place a handful of pre-shingled envelopes in the hopper and

against the separator.

4. Test run to assure proper feeding and singulation.

5. Tighten the side guide lock knob to secure the position.

6

EFS Pro Manual

Moving the back wedge too far forward to the

separator assembly can create a pinch point

between the tip of the triangle wedges and the

envelopes.

STEP 3:

Back Wedge Adjustment

Procedure

Adjust the back wedge for proper positioning following these steps:

1. Grasp a handful of envelopes, approximately 2 to 2.5 in. (5 to

6 cm) thick, and preshingle the edges with your thumb.

2. Place the pre-shingled envelopes in the hopper so that the

front edges rest against the curvature of the separator assem-

bly. The envelopes should be loaded ap side down with the

hinge portion against the feeder side frame.

3. Loosen the wedge adjustment lock knob.

4. Move the wedge back and forth until the bottom envelope is

not touching the table top. (see photo)

5. Make sure the wedge assembly is parallel with the edge of the

envelopes stack. Adjust as required and tighten the lock knob.

6. Wedge adjustments for wider envelopes can be achieved with

lateral adjustment. (See photo below)

Keep in mind that the back wedge works with

the separator assembly to provide the proper

lift, curvature of the envelopes, and proper belt/

envelopes contact to separate and feed one sheet

at a time.

There are a number of feeding problems which

can be solved by simply adjusting the back wedge

to different positions. Some of these problems

include double feeds, skewing, twisting, poor

singulation and jamming at the separator

assembly area.

7EFS Pro Manual

STEP 4:

Manual Test to Verify

STEP 5:

Envelope Moistening

Device Setup

Now that you have made all the necessary adjustments for operation,

it is recommended that you verify envelopes singulation and separa-

tion at the feeder for your particular application. Before you power-up

and run your machine with a full hopper, manually feed several pieces

of envelopes through the separator assembly area.

Prepare your test by loading the hopper with approximately 2 to 2.5 in.

(5 to 6 cm) of envelopes. Make sure you preshingle the stack so that

envelopes rests against the curvature of the separator assembly.

1. With the power off, manually feed several pieces of envelopes

slowly through the separator assembly area.

2. Observe how individual envelopess enter and exit the separa-

tor assembly area. Remember, a properly set gap will allow

each new piece to enter at about the center line of the cylinder

while the bottom piece is exiting the separator assembly area.

3. If feeding doubles, then move the wedge in towards the sepa-

rator assembly. Test again.

4. If pieces are overlapping excessively or, if the machine is

feeding doubles, then reduce the gap slightly by moving the

separator(s) adjustment knob about 1/8 turn counter-clock-

wise. Test again.

5. As envelopes moves through the hold-down area, check for

any skewing or jamming. Also check for damage to the enve-

lopes.

6. If this or other feeding problems still persist (slipping, skew-

ing, jamming), then review all the adjustment procedures in

“Preparing for Operation”.

Remove cap from bottle and ll with either water or ap sealing solu-

tion. Replace cap tight to prevent air leaks which could result in over-

lling and leaking within reservoir. Quickly tip bottle upside-down

and insert into top of reservoir until rmly latched.

If the separator assembly is too tight, the feeder

will have difculty pulling the envelopes through

the separator assembly area. This will cause

“missed” feeds.

Moving the back wedge too far forward to the

separator assembly can create a pinch point

between the tip of the triangle wedges and

the envelopes. If moving the back wedge in is

not effective, then an optional wedge may be

required.

For certain types of envelopes, you may have to

position the envelopes “off-center” to prevent

any skewing affect.

8

EFS Pro Manual

The moistening device runs in two different modes. The selection of

these two modes is achieved with the use of a lever. One is what is

called the production or ap opening mode. In this mode the envelope

is fed ap down with the hinge portion of the envelope up against the

left side frame of unit (also used for left side guide and registration).

Production or ap opening mode

When the envelope passes through the moistening device, a divert tab

(shoe) located above the envelope applies slight pressure from the top

side of the envelope. When this pressure is applied, the envelope ap

is deected down and under a knife device that leads to the sealing

brush. With the ap somewhat open and away from the body of the

envelope, the sealing brush is allowed to apply moisture to the ap.

STEP 5:

Envelope Moistening

Device Setup

(continued)

The second mode is the by-pass mode. The divert tab or shoe is in the

retracted or up position, not in the direct path of envelopes as they

pass over the moistening device.

Bypass mode

9EFS Pro Manual

“Thin/Thick” adjustment bracket in the down

position (factory) should be used for running

thinner stuffed envelopes.

“Thin/Thick” adjustment bracket in the up

position (factory) should be used for running

thicker stuffed envelopes.

STEP 5:

Envelope Moistening

Device Setup

(continued)

Additional adjustment may be needed on the divert tab when running

thicker envelopes (up to ¼” maximum).

With the use of a 5/64” Allen Wrench you can reposition the adjust-

ment bracket to the up position. This adjustment should be completed

when running thicker envelopes.

“Thin/Thick” adjustment bracket in the

down position (factory).

“Thin/Thick” adjustment bracket in the

up position (factory).

10

EFS Pro Manual

3How to Operate

Sequence of

Operation

Successful power-up and operation is assured if you apply the follow-

ing sequence of steps:

1: Loading envelopes in the hopper

2: Determining stack height

3: Powering On feeder

4: Setting/adjusting speed

5: Final check

STEP 1:

Loading Envelopes

in the Hopper

Preshingling prevents multiple pieces from

jamming under the separator assembly at startup.

1. Start by preshingling by hand a small stack of envelopes so

that it conforms to the curvature of the separator assembly.

Push in gently to make sure lead edges touch the separator as-

sembly and front edges of the pre-separator bars.

2. At the back wedge, notice how it helps lift the trailing edges

of the envelopes off the table top and feed belts. Also notice

how the lifting helps to push the preshingled edges against the

curvature of the separator assembly.

This section provides a sequence of operation for the feeder. It also

provides information for clearing a jam and for shutdown.

STEP 2:

Determining Stack

Height

1. Gradually add more envelopes to the hopper after the initial

stack is formed around the separator assembly. The stack

height will have a preferred minimum and a maximum, you

will have to experiment to determine effective range of height.

2. Make sure the envelopes are loaded in the hopper as straight

as possible. Before adding to hopper, “jog” each handful of

envelopes on a at surface to make sure lead edges are as

even as possible. As you add each handful, gently push in

each stack so that lead edges rest rmly against front of side

guides. "Fanning" the stack prior to loading it into the hopper

may reduce double feeds.

Stack height affects the downward pressure on

the feed belts. Greater downward pressure can

increase the chances for double feeds.

11 EFS Pro Manual

STEP 4:

Setting/Adjusting Speed

1. Set the variable speed control to the lowest speed (counter-

clockwise). Feeder motor stops if turned completely counter-

clockwise.

2. Start by slowly turning the control clockwise to gradually

increase feeder speed to coincide with the desired speed.

Turn the feeder power On by pushing the horizontal line (—) at the

Power On/Off rocker switch.

STEP 3:

Powering On Feeder

Make sure:

• Proper separation is occurring at separator assembly area.

• Envelopes is not skewing.

• Effective preshingling is occurring at curvature of separator assem-

bly.

• Envelopes is not being damaged during cycling.

• Feeder is secured and will not move during operation.

STEP 5:

Final Check

12

EFS Pro Manual

If a jam occurs during operation, follow these steps:

1. Turn the feeder power Off by pushing the circle (O) at the

rocker Power On/Off rocker switch.

2. Remove jammed envelopes from feeder. While doing so, try

to determine the cause of the jam (see “Troubleshooting”).

3. Verify whether any adjustments are loose. If so, refer to “Pre-

paring for Operation”, for proper adjustment procedures.

4. Turn the feeder power back On by pushing the horizontal line

(—) at the Power On/Off rocker switch.

Should you not be using the feeder for long periods of time, follow

these steps to ensure safe and secure storage:

1. Turn the feeder power Off by pushing the circle (O) at the

rocker Power On/Off rocker switch.

2. Disconnect the feeder power cord from the AC power source.

If installed, disconnect external run input from feeder control

panel.

3. Remove water bottle.

4. Cover the feeder with a cloth or plastic tarp to prevent dust.

Shutdown

Clearing a Jam

13 EFS Pro Manual

4Troubleshooting

This table is intended to provide you with quick solutions to the more common day-to-day problems you may

encounter.

Problem

No AC power to

feeder

1. On/Off switch in "Off" (or "O" position).

2. Power cord loose or not plugged into

outlet (or AC power source).

3. Female end of power cable loose or not

plugged into AC power inlet at rear of

feeder.

1.

Separator assembly improperly adjusted

(possibly more than one envelope thickness).

2. Back wedge improperly adjusted.

3. Worn O-rings (or angled edge).

4. Envelopes interlocking.

5. Static buildup.

1. Envelopes stack height is too low when

stack height is down, resulting in reduc-

tion of down pressure.

2. Binding in side guides.

3. Loss of friction on feed belts.

4. Sheet adhesion or interlocking between

the bottom and next envelope.

Move switch to "On" (or "—" position).

Check and secure power cord at AC

outlet.

Check and secure cord at AC power

inlet at rear of machine.

Review separator adjustment proce-

dure.

Review back wedge adjustment proce-

dure.

Rotate O-rings. If applicable, replace

angled edge. If wear is excessive, con-

sult with a qualied technician.

Check envelopes and source.

Check envelopes and source.

Review envelopes loading procedure.

Adjust side guides further apart to allow

freedom of movement between enve-

lopes.

Refer to "Cleaning Feed and Discharge

Belts".

Review envelopes loading procedure

and back wedge adjustment procedure.

Feeding doubles

Feed belts are op-

erating, but enve-

lopes not feeding

Cause Solution

Table of contents

Popular Postal Equipment manuals by other brands

Neopost

Neopost ij25 user guide

SSS Siedle

SSS Siedle BG/SR 611 Series Product information

Pitney Bowes

Pitney Bowes SendPro C Operator's guide

Pitney Bowes

Pitney Bowes F731 Operator's guide

Pitney Bowes

Pitney Bowes 1E42/W1110 SendKit installation instructions

SSS Siedle

SSS Siedle CLASSIC Product information