Thomas Industries Rietschle Thomas SK2660 User manual

MODEL SK2660

COMPRESSOR SERVICE KIT

For use on 2660 and 2680 Model Compressors

CAUTION: Improper assembly or use of damaged parts may lead

to premature failure. To avoid frequent repairs follow the recom-

mended assembly procedures.

Part No.642648A 0605

NOTE: Before you begin, read these instructions thoroughly and

assemble the necessary tools. You will need:

1/4” Hex Socket attachment for torque wrench

Torx T-27 attachment for torque wrench (for retainer screws)

Torx T-25 attachment for torque wrench (for head screws)

5/32” Allen® wrench for torque wrench (eccentric screw)

Flat Screwdriver (2)

Clean Cloths

WARNING: Unplug the compressor before beginning disassembly.

This kit includes the following parts:

NOTE: All parts in kit may not apply to your specific model.

625175 Head Screw (8)

625776 Screw-Piston Cup (2)

618114 Cylinder Sleeve (2)

625094 Flapper Screw (4)

624677 Piston Cup (2)

623143 Head Gasket (2)

623137 O-Ring (2)

621485 Valve Flapper (4)

617562 Valve Keeper (4)

A Thomas Industries Company

1419 Illinois Avenue

Sheboygan, Wisconsin 53082 USA

(920) 457-4831 www.rtpumps.com

621647 Valve Backer (4)

626392 Piston Cup Retainer(2)617177 Valve Restraint (2)

DISASSEMBLY

NOTE: To avoid confusion, service one end of the compressor at a time.

STEP 1. Clean loose dirt from the outside of the compressor.

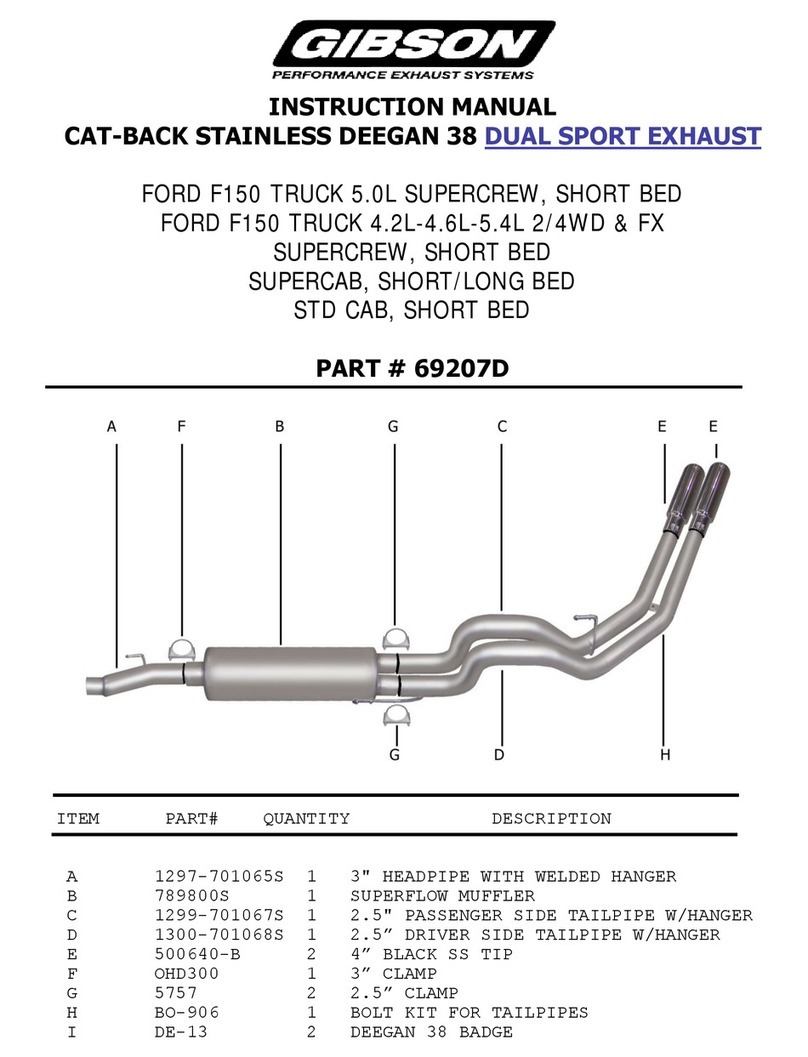

STEP 2. Loosen the 8 head screws (1) and remove the compressor head (2). Note orientation

of head and valve plates for reassembly (very important). Discard head screws.

Caution: Place capacitor off to side leaving it connected to

lead wires.

STEP 3. Carefully remove the valve plates (4) from the bottom of the head, or cylinder

sleeves

STEP 4. Remove the head gasket O-rings (3) and discard them. Turn the valve plates over.

Remove the valve plate O-rings (5) and discard them. Note orientation for reassembly.

1

Figure 1

Caution

To avoid property damage

or personal injury, always

try rotating the fan by HAND

prior to connecting the

unit to the power source.

Check for suction at the air

inlet port by placing your

finger over the port as you

turn the fan. You should

feel a slight suction with

each rotation of the fan. If

you don’t feel suction, or if

you feel or hear a thump as

you turn the fan, DO NOT

CONNECT THE UNIT TO A

POWER SOURCE; review

the assembly procedure for

possible error.

Numbers indicate tightening sequence

Power Leads

Head Assembly

5 3 7 1

4 6 2 8

STEP 2. Place head on the valve plates, making sure the same letter orientation is

as it was before disassembly. Torque the head screws to 55 inch lbs. in a criss-cross

pattern.

STEP 3. Push the fan guards into the housing until the release tabs “pop” into the

mounting holes in the compressor housing.

6

Note the tabs on

the valve plate

which indicate

exhaust side.

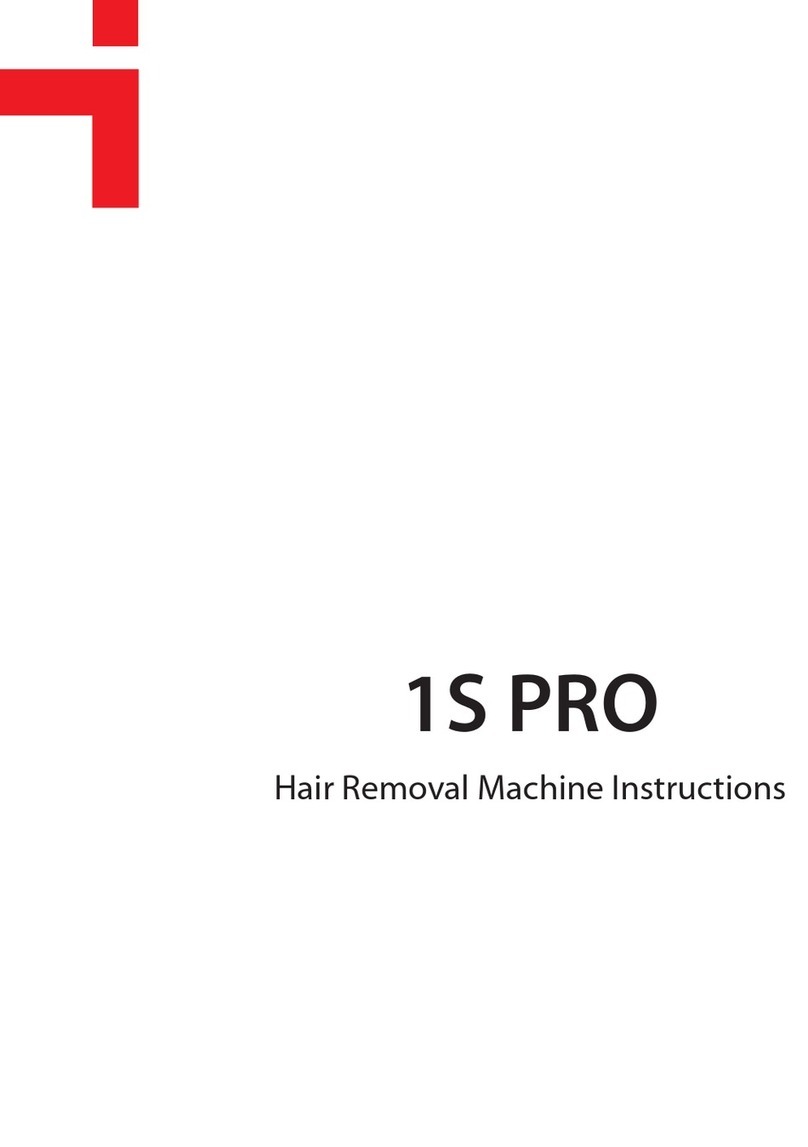

STEP 5. Remove the intake valve flapper

(1), keeper (2), restraint (3) if assembled,

and screw from the bottom of the valve plate

and discard. Clean the bottom of the plate

with a clean, soft cloth. Install the new intake

valve flapper, restraint, if one was removed,

and keeper. The valve keeper should be

placed on top of the flapper so that the word

“UP” is visible (See Fig. #2).

NOTE: Pay close attention to valve

assembly. Some parts in kit may not be for

your model.

NOTE: Torque new flapper screw to 18

inch-pounds.

STEP 6. Install the new O-ring, seating it

firmly into the groove with your finger or

blunt object. (See Fig. #2).

Figure 2

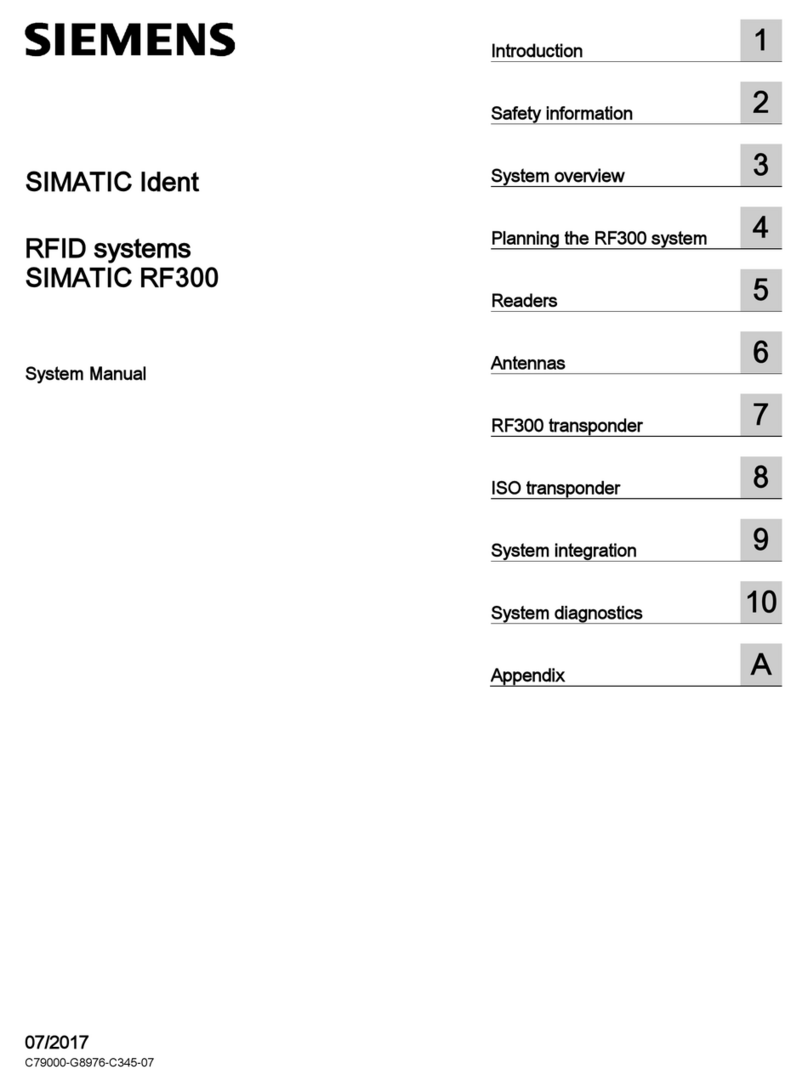

Figure 3

STEP 7. Remove the exhaust valve flapper

(1), restraint (2) and valve keeper (3)from

the top of the valve plate and discard them.

Clean the top of the plate with a clean, soft

cloth. Install the new exhaust valve flapper,

restraint and keeper. The valve keeper

should be placed on top of the flapper so

that the word “UP” is visible (See Fig. #3).

NOTE: Torque flapper screw to 18 inch-

pounds.

STEP 8. Install the new head gasket,

seating it firmly into the groove with your

finger or blunt object. (See Fig. #3). Set

aside. Repeat steps 5 thru 8 to service other

end of compressor.

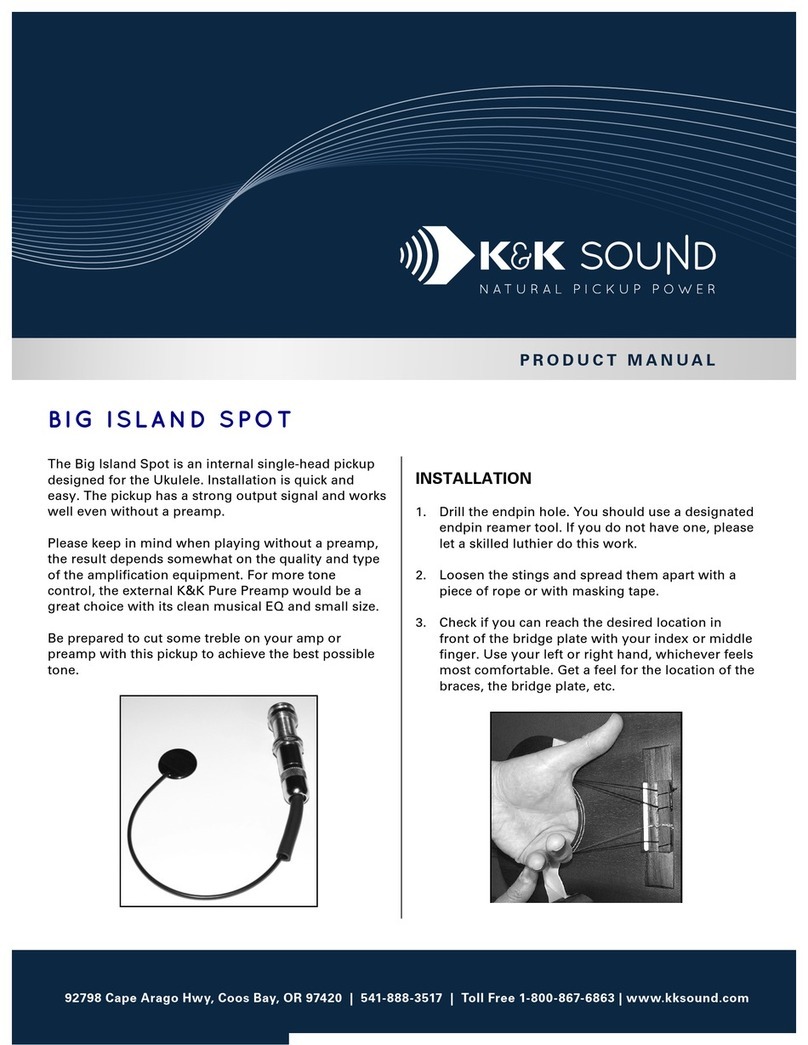

STEP 9. Remove the fan guard by depressing

the 4 tabs on the side of the housing.

STEP 10. Remove the fan by using two flat

blade screwdrivers to pry off, making sure

screwdriver contact is made with hub back,

and not the fan blades. Note fan orientation

for reassembly.

2

Figure 4

O-Ring Groove

O-Ring Groove

Release Tab

View of fan

with spring

clip facing in.

CAUTION: Make sure gasket

is not twisted when seated in

groove.

REASSEMBLY

STEP 1. With the sleeves firmly seated on the housing, replace the valve plates

in same manner as they were. (See Fig. #8). Make sure the top edge of the

sleeve locates in the O-ring groove in the bottom of the valve plate.

Figure 8

5

1 2

3

1

3

2

4

STEP 14. Rotate the rotor shaft so that flat faces up (12:00). Position piston cup at bot-

tom dead center of cylinder sleeve.

STEP 15. Slide the connecting rod assembly onto the shaft until the eccentric face

positivly stops against the bearing. Align the eccentric setscrew with the flat of the shaft.

Rotate the eccentric and shaft 90 degrees so the set screw is visable through the access

hole in the housing, and tighten set screw to 125in•lbs.

STEP 16. Align the flat on the fan with

the flat on the motor shaft and slide the

fan back onto the motor shaft, making

sure you position the fan clip in the

same orientation as it was before you

removed it. Incorrect orientation of the

fan will not provide adequate cooling of

the compressor.

Figure 7

Hold the sleeve down against the

housing with one hand, and slowly

rotate the fan with the other hand to

ensure all components are lined up

properly. As the piston travels up and

down it will also rock from side to side.

This is a feature of the WOB-L Piston.

Repeat steps 9-16 on the other side of

compressor.

STEP 11. Insert the 5/32” allen wrench into

the access hole in the compressor hous-

ing. Loosen the set screw 1/4 turn. Rotate

connecting rod to top dead center (180°)

and slide the connecting rod/eccentric

assembly off the shaft and through the

opening in the housing.

3

Eccentric

Set Screw

Access

Hole

Eccentric

Set Screw

Figure 5

STEP 12. Secure the rod assembly in a fixture.

Remove the sleeve (1 - discard) from the con-

necting rod. Remove the screw (2 - discard )

from the cup retainer (3-retain for reassembly).

Remove the piston cup (4 - discard) and wipe

debris from the top of the connecting rod and

retainer with a clean damp cloth.

STEP 13. Carefully place new sleeve (1) over

connecting rod top. Place new cup (4) in center

of connecting rod top. Do not damage the cup.

Place retainer (3) on top of cup (counterbore

up), making sure that the cup inside diameter

is seated properly over retaining boss. Note

that the retainer has a locating boss that must

insert into rod top pilot. Drive new retainer screw

to 100 in•lbs. Carefully push sleeve up forming

the cup. Stop pushing the cylinder sleeve up

when the piston cup is positioned midway inside

the sleeve.

1

4

3

2

Figure 6

CHECK OPERATION

4

STEP 14. Rotate the rotor shaft so that flat faces up (12:00). Position piston cup at bot-

tom dead center of cylinder sleeve.

STEP 15. Slide the connecting rod assembly onto the shaft until the eccentric face

positivly stops against the bearing. Align the eccentric setscrew with the flat of the shaft.

Rotate the eccentric and shaft 90 degrees so the set screw is visable through the access

hole in the housing, and tighten set screw to 125in•lbs.

STEP 16. Align the flat on the fan with

the flat on the motor shaft and slide the

fan back onto the motor shaft, making

sure you position the fan clip in the

same orientation as it was before you

removed it. Incorrect orientation of the

fan will not provide adequate cooling of

the compressor.

Figure 7

Hold the sleeve down against the

housing with one hand, and slowly

rotate the fan with the other hand to

ensure all components are lined up

properly. As the piston travels up and

down it will also rock from side to side.

This is a feature of the WOB-L Piston.

Repeat steps 9-16 on the other side of

compressor.

STEP 11. Insert the 5/32” allen wrench into

the access hole in the compressor hous-

ing. Loosen the set screw 1/4 turn. Rotate

connecting rod to top dead center (180°)

and slide the connecting rod/eccentric

assembly off the shaft and through the

opening in the housing.

3

Eccentric

Set Screw

Access

Hole

Eccentric

Set Screw

Figure 5

STEP 12. Secure the rod assembly in a fixture.

Remove the sleeve (1 - discard) from the con-

necting rod. Remove the screw (2 - discard )

from the cup retainer (3-retain for reassembly).

Remove the piston cup (4 - discard) and wipe

debris from the top of the connecting rod and

retainer with a clean damp cloth.

STEP 13. Carefully place new sleeve (1) over

connecting rod top. Place new cup (4) in center

of connecting rod top. Do not damage the cup.

Place retainer (3) on top of cup (counterbore

up), making sure that the cup inside diameter

is seated properly over retaining boss. Note

that the retainer has a locating boss that must

insert into rod top pilot. Drive new retainer screw

to 100 in•lbs. Carefully push sleeve up forming

the cup. Stop pushing the cylinder sleeve up

when the piston cup is positioned midway inside

the sleeve.

1

4

3

2

Figure 6

CHECK OPERATION

STEP 5. Remove the intake valve flapper

(1), keeper (2), restraint (3) if assembled,

and screw from the bottom of the valve plate

and discard. Clean the bottom of the plate

with a clean, soft cloth. Install the new intake

valve flapper, restraint, if one was removed,

and keeper. The valve keeper should be

placed on top of the flapper so that the word

“UP” is visible (See Fig. #2).

NOTE: Pay close attention to valve

assembly. Some parts in kit may not be for

your model.

NOTE: Torque new flapper screw to 18

inch-pounds.

STEP 6. Install the new O-ring, seating it

firmly into the groove with your finger or

blunt object. (See Fig. #2).

Figure 2

Figure 3

STEP 7. Remove the exhaust valve flapper

(1), restraint (2) and valve keeper (3)from

the top of the valve plate and discard them.

Clean the top of the plate with a clean, soft

cloth. Install the new exhaust valve flapper,

restraint and keeper. The valve keeper

should be placed on top of the flapper so

that the word “UP” is visible (See Fig. #3).

NOTE: Torque flapper screw to 18 inch-

pounds.

STEP 8. Install the new head gasket,

seating it firmly into the groove with your

finger or blunt object. (See Fig. #3). Set

aside. Repeat steps 5 thru 8 to service other

end of compressor.

STEP 9. Remove the fan guard by depressing

the 4 tabs on the side of the housing.

STEP 10. Remove the fan by using two flat

blade screwdrivers to pry off, making sure

screwdriver contact is made with hub back,

and not the fan blades. Note fan orientation

for reassembly.

2

Figure 4

O-Ring Groove

O-Ring Groove

Release Tab

View of fan

with spring

clip facing in.

CAUTION: Make sure gasket

is not twisted when seated in

groove.

REASSEMBLY

STEP 1. With the sleeves firmly seated on the housing, replace the valve plates

in same manner as they were. (See Fig. #8). Make sure the top edge of the

sleeve locates in the O-ring groove in the bottom of the valve plate.

Figure 8

5

1 2

3

1

3

2

DISASSEMBLY

NOTE: To avoid confusion, service one end of the compressor at a time.

STEP 1. Clean loose dirt from the outside of the compressor.

STEP 2. Loosen the 8 head screws (1) and remove the compressor head (2). Note orientation

of head and valve plates for reassembly (very important). Discard head screws.

Caution: Place capacitor off to side leaving it connected to

lead wires.

STEP 3. Carefully remove the valve plates (4) from the bottom of the head, or cylinder

sleeves

STEP 4. Remove the head gasket O-rings (3) and discard them. Turn the valve plates over.

Remove the valve plate O-rings (5) and discard them. Note orientation for reassembly.

1

Figure 1

Caution

To avoid property damage

or personal injury, always

try rotating the fan by HAND

prior to connecting the

unit to the power source.

Check for suction at the air

inlet port by placing your

finger over the port as you

turn the fan. You should

feel a slight suction with

each rotation of the fan. If

you don’t feel suction, or if

you feel or hear a thump as

you turn the fan, DO NOT

CONNECT THE UNIT TO A

POWER SOURCE; review

the assembly procedure for

possible error.

Numbers indicate tightening sequence

Power Leads

Head Assembly

5 3 7 1

4 6 2 8

STEP 2. Place head on the valve plates, making sure the same letter orientation is

as it was before disassembly. Torque the head screws to 55 inch lbs. in a criss-cross

pattern.

STEP 3. Push the fan guards into the housing until the release tabs “pop” into the

mounting holes in the compressor housing.

6

Note the tabs on

the valve plate

which indicate

exhaust side.

MODEL SK2660

COMPRESSOR SERVICE KIT

For use on 2660 and 2680 Model Compressors

CAUTION: Improper assembly or use of damaged parts may lead

to premature failure. To avoid frequent repairs follow the recom-

mended assembly procedures.

Part No.642648A 0605

NOTE: Before you begin, read these instructions thoroughly and

assemble the necessary tools. You will need:

1/4” Hex Socket attachment for torque wrench

Torx T-27 attachment for torque wrench (for retainer screws)

Torx T-25 attachment for torque wrench (for head screws)

5/32” Allen® wrench for torque wrench (eccentric screw)

Flat Screwdriver (2)

Clean Cloths

WARNING: Unplug the compressor before beginning disassembly.

This kit includes the following parts:

NOTE: All parts in kit may not apply to your specific model.

625175 Head Screw (8)

625776 Screw-Piston Cup (2)

618114 Cylinder Sleeve (2)

625094 Flapper Screw (4)

624677 Piston Cup (2)

623143 Head Gasket (2)

623137 O-Ring (2)

621485 Valve Flapper (4)

617562 Valve Keeper (4)

A Thomas Industries Company

1419 Illinois Avenue

Sheboygan, Wisconsin 53082 USA

(920) 457-4831 www.rtpumps.com

621647 Valve Backer (4)

626392 Piston Cup Retainer(2)617177 Valve Restraint (2)

Table of contents