Electronic Variable Optical Attenuators Chapter 4: Operating Instructions & Details

Page 8 TTN116996-D02

USB chargers (e.g., for phones or tablets) will provide a maximum of 500 mA,

while others (e.g., those on a PC) will be as low as 100 mA. All charging rates

are sufficient to power the device while simultaneously charging the battery,

but charging will take longer at lower currents.

Two LEDs on the side utility panel indicate the charging status of the unit. A

yellow LED indicates that charging is in progress, while a green LED indicates

that charging is complete. If both LEDs are lit, there is a battery fault. Please

contact Thorlabs’ tech support (techsupport@thorlabs.com) if this occurs.

When the power is switched on, the attenuation will be set at the value

determined by the position of the manual power adjustment knob. If this value

is not known, we recommend rotating it completely counterclockwise before

switching the power on. This will ensure maximum attenuation.

When the power is switched off, a voltage remains on the internal VOA, such

that there will still be mid-range attenuation even when the power is off. This

is a precautionary feature that uses virtually no current, as the EVOA is an

ultra-low current device. This feature does not drain the battery meaningfully

faster than the battery itself would lose charge otherwise.

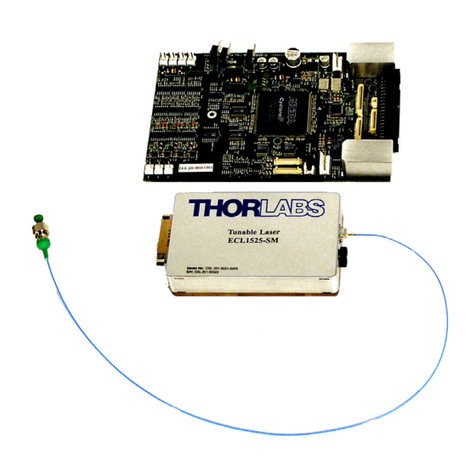

4.3. Fiber Connections

The fiber patch cable input and output bulkheads (see Figure 2) are both FC

style. They may be ordered with PC- or APC-style internal connectors:

Item # EVOA800F has FC/PC connectors.

Item # EVOA800A has FC/APC connectors.

The fiber patch cable and connectors should be cleaned whenever a

connection is made. Note that the insertion loss when coupling these types of

smaller core, single mode fibers can be well over 1 dB.

4.4. Wavelength Selection & Calibration

The digital output power display gives the calibrated output power at the

wavelength indicated by the selector knob. The first and second knob

positions are for 785 nm and 852 nm, while the third position (labeled “USER”)

can be calibrated by the user for any wavelength in the 780 - 980 nm operating

range. The user calibration trimpot is located on the side utility panel.

To calibrate the USER position on the knob, the following tools are required:

A single mode laser source at the desired wavelength,

An accurate power meter for that wavelength,

Input and output fiber patch cables, and

A small flathead screwdriver to adjust the trimpot.