Page 0 22115-D02

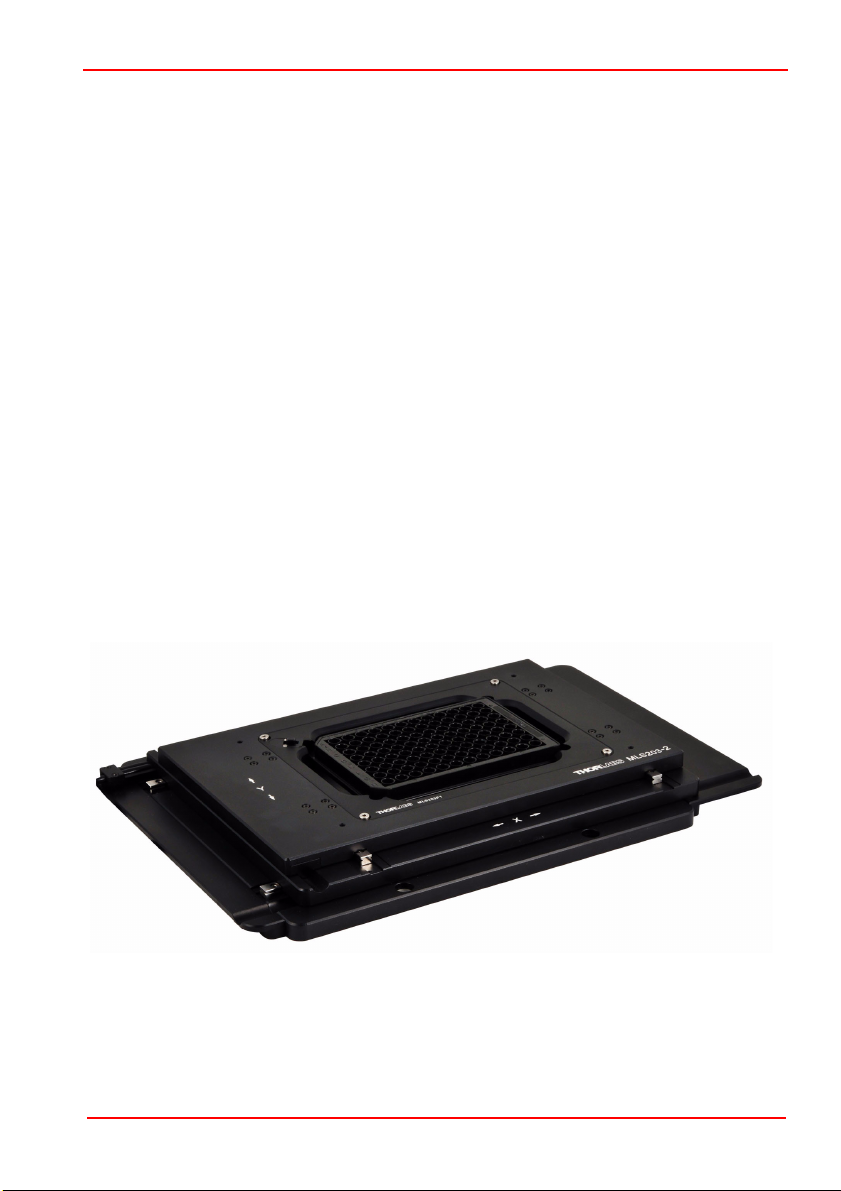

MLS203 Series XY Scanning Stage

Contents

Chaper 1 Overview ..................................................................................................... 1

1.1 Introduction ........................................................................................ 1

Chaper 2 Safety .......................................................................................................... 3

2.1 Safety Information ............................................................................. 3

2.2 General Warnings .............................................................................. 3

Chaper 3 Installation .................................................................................................. 4

3.1 Unpacking ........................................................................................... 4

3.2 Mounting ............................................................................................. 4

3.2.1 General ................................................................................................... 4

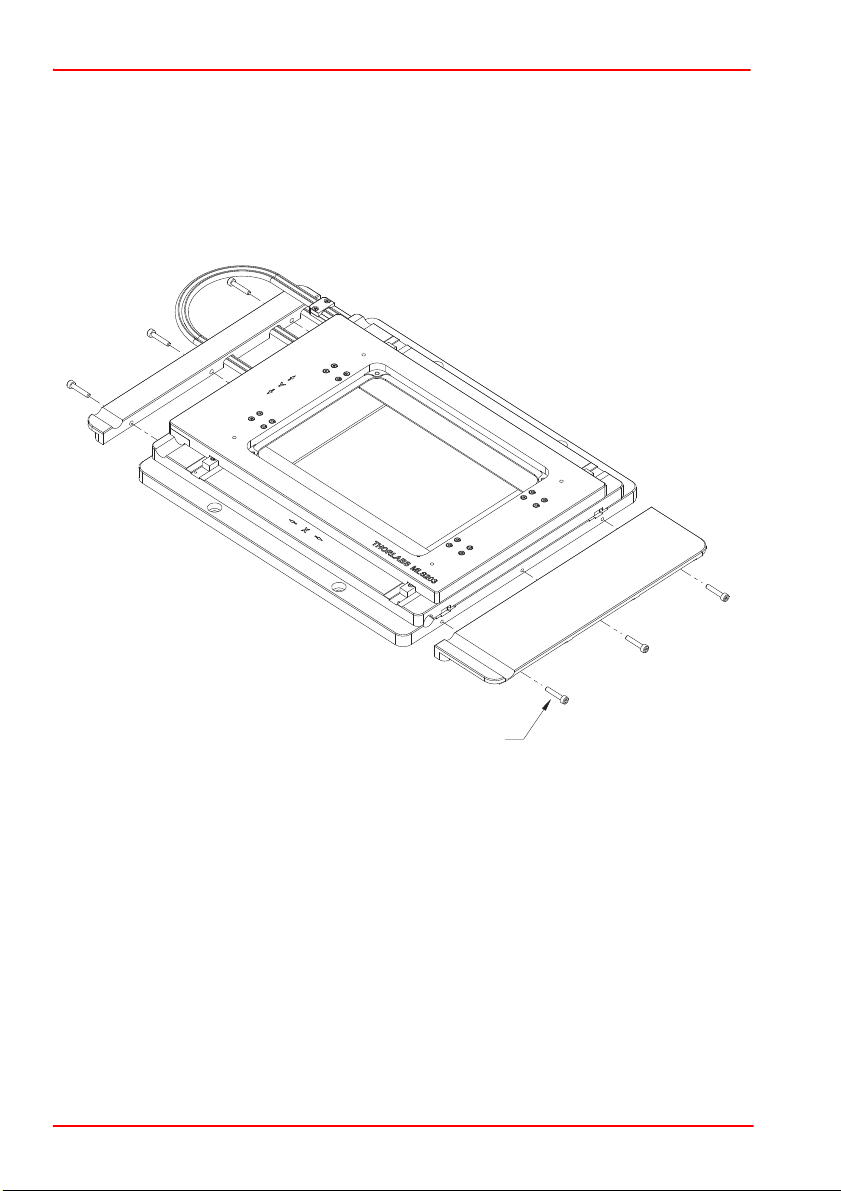

3.2.2 Fitting the Finger Guards ........................................................................ 5

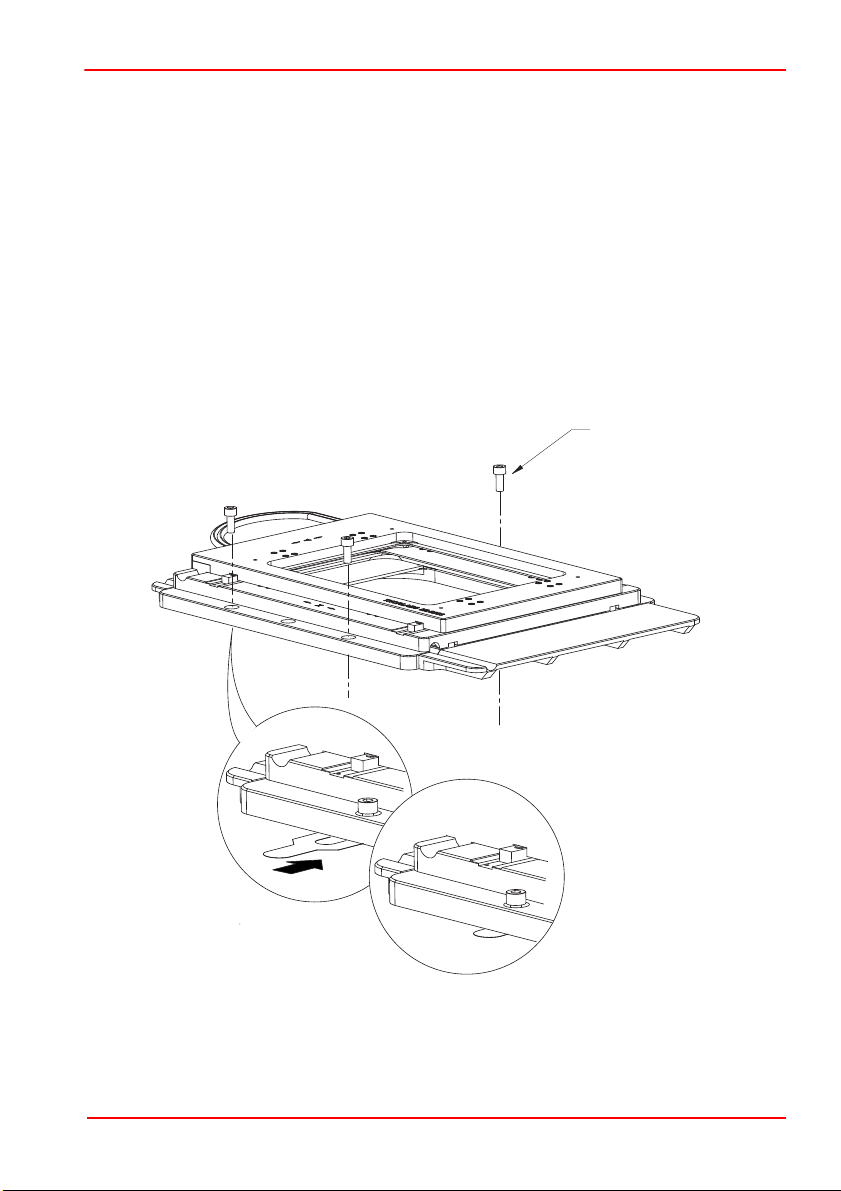

3.2.3 Mounting To Microscope ......................................................................... 5

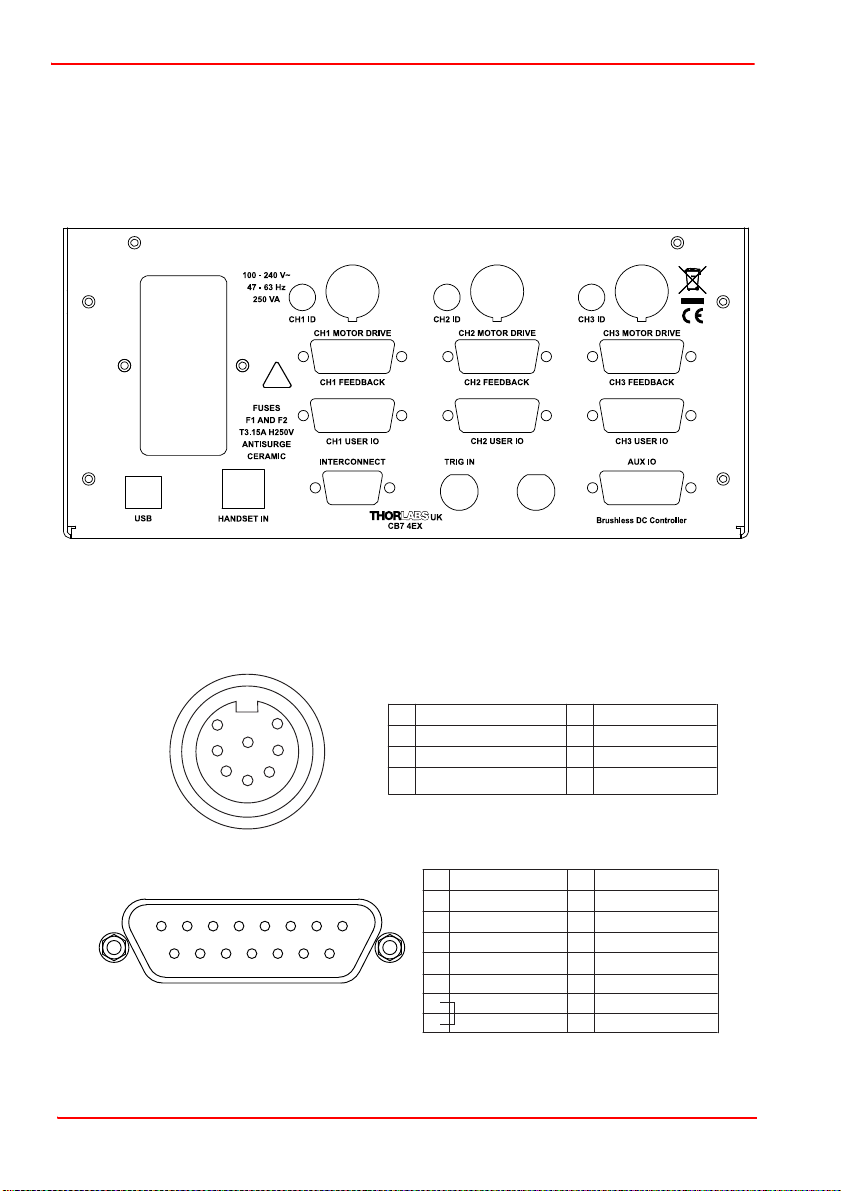

3.3 Electrical Connections ...................................................................... 6

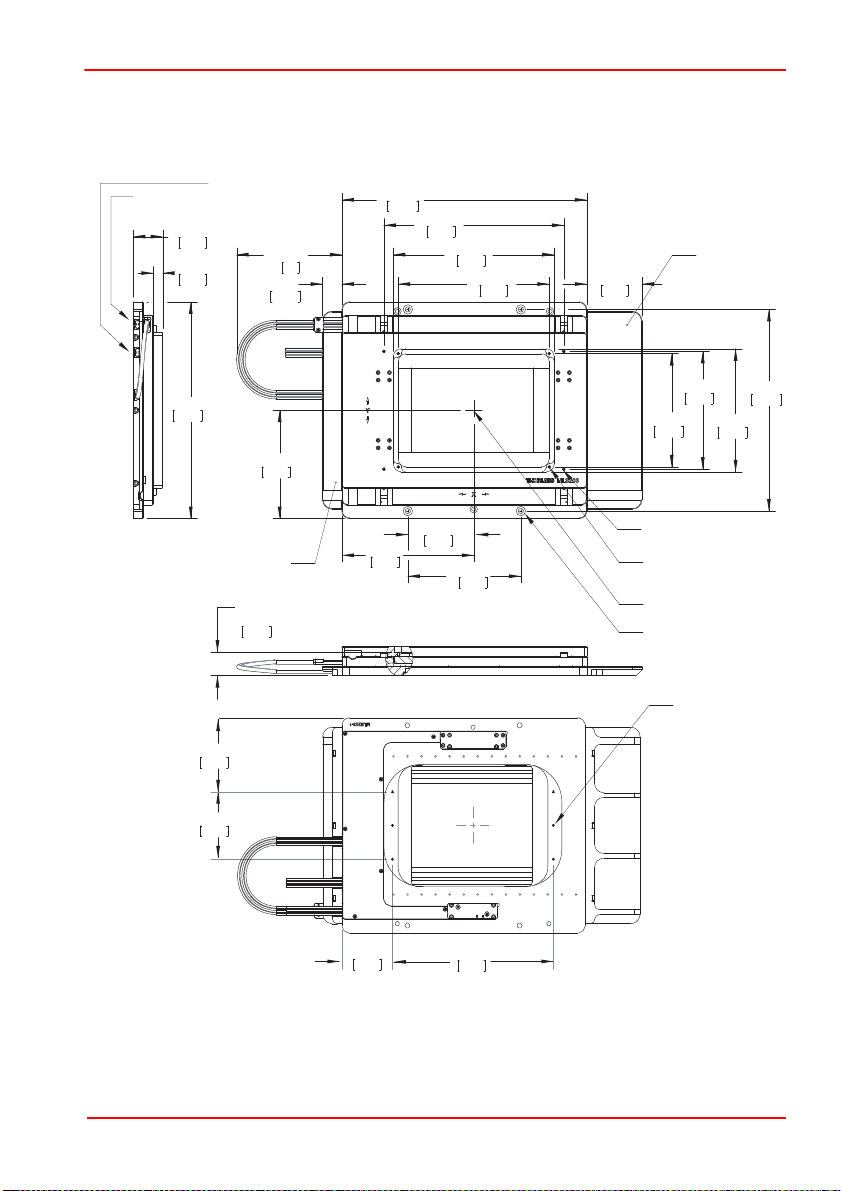

3.4 Dimensions ......................................................................................... 7

3.4.1 MLS203-1 Dimensions ............................................................................ 7

Chaper 4 Operation .................................................................................................... 8

4.1 General ............................................................................................... 8

4.2 Using the Kinesis software ............................................................... 9

4.3 Using the APT software ................................................................... 12

4.4 Position Error Messages. ................................................................ 14

4.5 Transportation .................................................................................. 15

4.6 Maintenance ..................................................................................... 15

4.7 Transportation .................................................................................. 15

Chaper 5 Specification ............................................................................................. 16

Chaper 6 Spares and Accessories .......................................................................... 17

6.1 Parts List ........................................................................................... 17

Chaper 7 Regulatory ................................................................................................ 18

7.1 Declarations Of Conformity ............................................................ 18

7.1.1 For Customers in Europe ...................................................................... 18

7.1.2 For Customers In The USA ................................................................... 18

7.2 CE Certificates ................................................................................. 19

Chaper 8 Thorlabs Worldwide Contacts ................................................................ 20