Thuli Tables 350 Elevation User manual

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 2

Identication of Parts / Motor . . . . . . . . 3 - 4

Table Assembly . . . . . . . . . . . . . . . . . . . . . . 5

Headpiece Attachment & Operation . . . 6 - 10

Table Operation . . . . . . . . . . . . . . . . . . 11 - 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . 13

Care & Maintenance . . . . . . . . . . . . . . 14 -15

Motor Troubleshooting . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview of Products . . . . . . . . . . . . . Back

350 Owner’s Manual

Shown with Metal Base

Crescent Arm Rest

(optional)

THULI TABLES

www.thulitables.com

youtube.com/thulitables

800-458-4854

facebook.com/thulitables

Videos & Manuals

2

Introduction

Rick Thuli, D.C.

President

Sincerely,

We are pleased to provide you with an aesthically beautiful chiropractic

adjusting table that is versatile and precisely engineered. It has been

thoroughly inspected and tested right down to the smallest detail before

leaving our shop. We are condent that it will provide you with many

years of reliable service.

Please take the time to read this manual. It will familiarize you with the

table and instruct you on its proper operation and maintenance.

If you have any questions or comments, please contact us.

Thank you for your purchase of a 350 Elevation table.

Crescent Arm Rest

(optional)

Ankle Rest Extension

Pelvic Section

Fixed Section

Thoracic Section

Ankle Rest

Extension

Locking Knob Pelvic Cocking

Lever & Tension

Control Knob

Thoracic Cocking

Lever & Tension

Control Knob

Identification of Table Parts / Motor Information 3

MOTOR INFORMATION

Electric

Plug

Foot Pedal

Plug

Plug

Clip

Plug

Tab

Screwdriver

If the cord is not attached to

the motor, plug it in, making

sure the clip snaps onto the

tab. A at screwdriver may

be helpful to gently guide the

clip.

To extend the life of the motor, instruct the patient to get on and off at the center of the table.

Avoid elevating or lowering the table while the patient is not centered on the table.

The electric and foot pedal plugs are located at the base of the motor shaft.

Piston

4

Identification of Headpiece Parts

Tension Control Knob

(other side)

Paper Hold-Down Wire

Pivot Block

Slide Block

Paper Hanger

Remote Control Lever

Paper Tear-Off Bar

Straight Drop / Forward

Cocking Lever

Headpiece Mounting Remote Control Cable

Piston Pin

T-Bar

Piston Head

Lowering Lever

Prone Arm Rest Buckle

Flexion / Extension

Prone Arm Rest

Locking Link

Piston

Motion Knob

Bracket

Shown on 300 Stationary

ANKLE REST ATTACHMENT

HEADPIECE ATTACHMENT

ENGAGE T-BAR

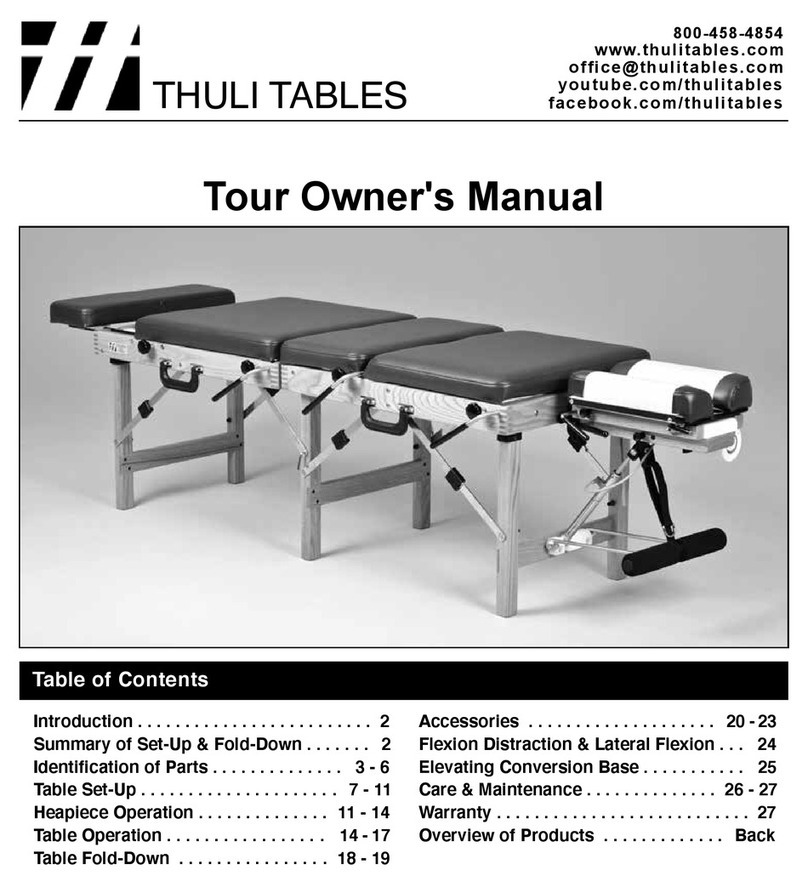

1. Place headpiece onto its cushions.

2. Lift the headpiece slide block to a 45 degree angle by grasping

the headpiece lowering lever.

3. Grasp the long rod of the T-Bar and insert it through the hole in

the locking link of the slide block.

4. Lower the slide block to a closed position by applying

counterclock-wise (downward) pressure to the headpiece

lowering lever.

1. Attach the piston/prone arm rest and crescent arm rest

mounting bracket (optional) to the headpiece plate,

matching up the colored dots.

2. Swing the piston/prone arm rest down out of the way

to provide room for attaching the headpiece.

5

Table Assembly

Your table will arrive in two boxes and is easy to assemble. The headpiece and ankle rest extension are packaged

separately from the table. We have included two different wrenches to assist you in the assembly process.

Paper Hold-Down Wire

PISTON / PRONE ARM REST ATTACHMENT

1. Remove the hitch pins and “O” rings from the ankle rest rods.

2. Loosen both ankle rest locking knobs.

3. Slowly insert the ankle rest rods through the frame and plastic

blocks. Note: If the rod does not slide in, the brass spacer that

is inside the plastic block (under the table) needs to be moved

out of the way. Simply insert an allen wrench into the small

hole on the side of the block and push the brass spacer past the

large hole, clearing the way for the rod (photo).

4. Push the ankle rest all the way in and replace the “O” rings

and hitch pins.

HEADPIECE ATTACHMENT (cont)

1. To attach the headpiece to the table, slide it between the

headpiece mounting bracket.

2. Visually line up the hole in the slide block with the top holes

of the mounting bracket and insert the mounting pin with a

twisting motion.

PISTON ATTACHMENT

1. Swing the exion/extension piston down toward the

off-centered slot in the headpiece slide block.

2. Remove the piston pin from the slide block and raise the

front end of the headpiece to allow the piston to engage in the

off-centered slot. If the piston head does not align with the

slot, operate the remote control lever to rotate the head as

needed.

Install the remote control lever into the bottom of the slide block

by inserting the cable into the narrow slot and tilting the cable

end of the lever into the recess until it snaps into place.

Operating the remote control will allow the headpiece to lay

ush with the table cushions.

Attach the Crescent Arm Rest by sliding the slotted end of the

brackets over the mounting rods. Push the front of the Crescent

Arm Rest down so that the plastic bars slide over the foam pads

on the Prone Arm Rest grips.

CRESCENT ARM REST (optional feature)REMOTE CONTROL LEVER ATTACHMENT

6

Table Assembly

3. Attach the piston to the slide block by visually lining up the

holes and inserting the piston pin.

7

Table Operation

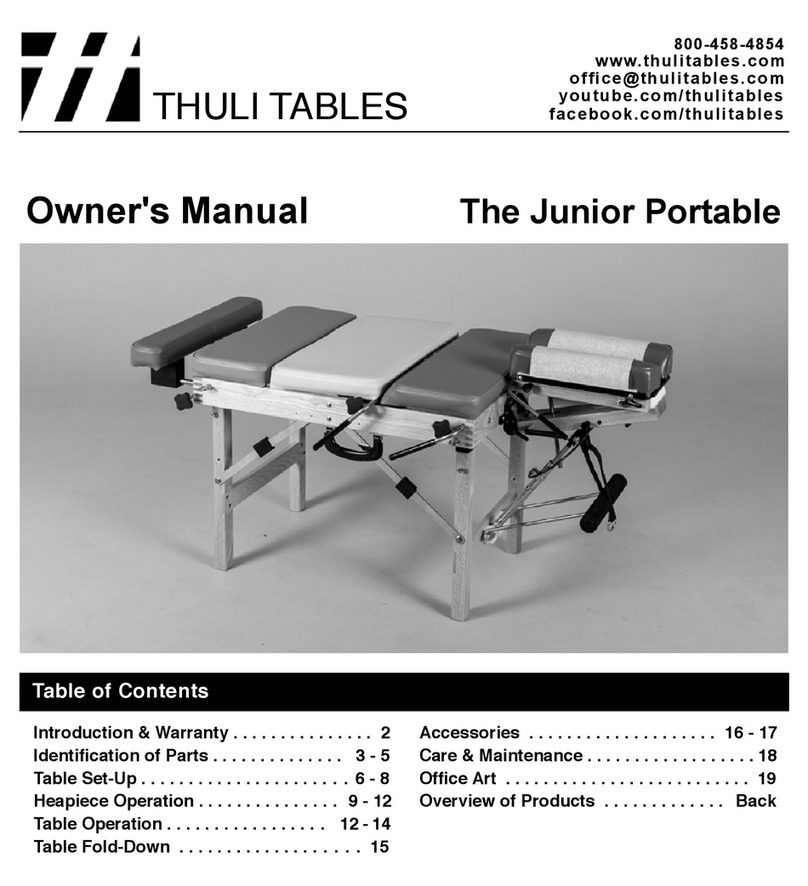

1. Install a 8.5” roll of headpiece paper.

2. Raise the paper hold-down wire and

tear-off bar. Advance the paper and

tuck it between the cushions.

3. Lower the hold-down wire between

the cushions, lower the tear-off bar

and tear off any excess paper.

HEADPIECE PAPER

4. To advance the headpiece paper, raise

the tear-off bar, hold your nger on

the hold-down wire and pull the paper

across the cushions. Pulling the paper

in an upward direction will reduce

friction, making it easier to pull.

5. To tear off used headpiece paper, use an

upward motion while holding down the

tear-off bar.

8

Headpiece Operation

STRAIGHT DROP FORWARD MOTION DROP

Flex and extend the headpiece by

grasping the front end of the headpiece

and operating the exion/extension

control lever.

LATERAL FLEXION (optional)

To ex the headpiece laterally, turn the

lateral exion lever in a counterclockwise

direction, manually position the headpiece,

then lock it into position by tightening

the lateral exion lever. This can be done

while the headpiece is in the exed,

extended or elevated position.

LATERAL FLEXION LEVER

The position of the lateral exion lever

can be changed. With the lateral exion

lever tightened, pull the lever directly

outward, rotate to the desired position

and release.

Knob pulled out

PRIOR to cocking

Knob pushed in PRIOR to cocking

FLEXION / EXTENSION

PRIOR to cocking the headpiece, set for straight drop by

pulling out the headpiece straight drop/forward motion knob

until you feel it is “set” into position. This will be just short

of coming into contact with the cocking bar. If you pull the

knob out too far, simply push it back in and continue.

PRIOR to cocking the headpiece, set for forward motion drop by

pushing in the headpiece straight drop/forward motion knob.

Cock the headpiece with an upward motion on the headpiece cocking lever.

Please note: Be sure to change the headpiece drop function

before cocking the headpiece to prevent an ineffective drop and

damage to the drop mechanism.

Set the desired tension by turning the tension control knob clockwise (increasing tension) or counter-clockwise (decreasing tension).

9

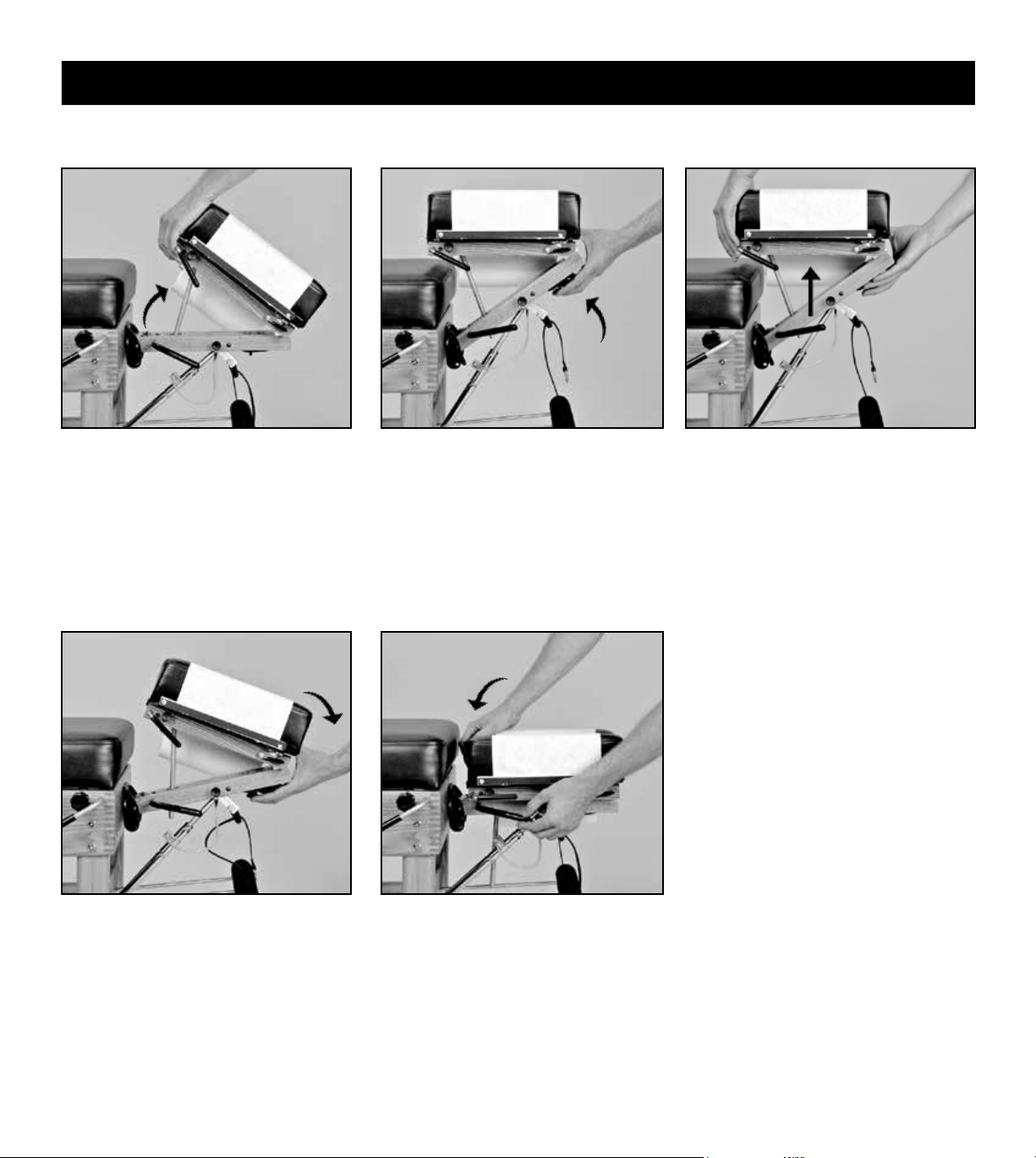

VERTICAL ELEVATION

Headpiece Operation

2. Raise the front end of the headpiece

by operating the exion/extension

control lever.

3. With practice, steps 1 and 2 can be

combined to vertically raise the

headpiece in one smooth motion.

VERTICAL LOWERING

1. Lower the front end of the headpiece

by operating the exion/extension

control lever.

2. In one smooth motion, lower the back

end of the headpiece by lifting the

headpiece lowering lever with one

hand while gently lowering the back

end of the headpiece with the other.

1. Raise the back end of the headpiece

by lifting the grey grip of the cocking

lever (without operating the lever).

Caution: Do not grasp the cushions to

raise the back end, which could stretch

and damage the small springs.

10

Headpiece Operation

PRONE POSITION

EYE COMFORT IN PRONE POSITION

For patients who are sensitive to pressure on their eyes, slightly raise the back end of the

headpiece. This will take pressure off of the eyes by supporting the weight of the head

at the mandible and zygomatic arches. Using this maneuver, in combination with slight

exing of the headpiece, will provide additional comfort for many patients.

Side posture positioning of the patient’s

head for lumbo-pelvic adjusting or

toggle recoil adjusting.

SIDE POSTURE POSITION SUPINE POSITION

Position the headpiece vertically to give

maximum support of the cervical spine and

patient’s head when in a supine position.

Position the patient sufciently forward

with arms outstretched and wrists resting

comfortably on the Prone Arm Rest, which

is adjustable in height. To raise, pull on

the loop at the end of the strap. To lower,

squeeze the cam lock (to loosen the strap)

and pull down on the Prone Arm Rest

grips. Advise the patient not to apply

weight on the Prone Arm Rest while

getting up from the table.

HEADPIECE CUSHIONS: ADJUSTABLE WIDTH

Neutral position. Narrower position for smaller faces

(eg children).

Wider position takes pressure off of

the patient's eyes.

The headpiece cushions are easily adjustable in width at the front end for individualized patient comfort. Firmly pull up on the front

end of each headpiece cushion and move in (one or two notches) or out (one or two notches) to desired position. Secure cushions

by engaging locating pins into notches provided.

11

Table Operation

SETTING THE TENSION

1. Advise your patient prior to setting the tension.

2. With the patient on the table, cock the drop section with an upward

motion of the cocking lever. There must be sufcient tension on

the drop to hold the patient's head or body weight.

3. Decrease the tension control knob by turning it counter-clockwise

until the section drops.

4. Increase the tension by turning the tension control knob

clockwise 3 - 4 half turns. As a general rule, the drop is now set

for the patient's weight, which may vary according to the

practitioner’s preference.

All drops have adjustable tension control and cock with an upward

movement of the cocking lever. Following is a general guideline

for setting the tension.

PELVIC DROP

Position the patient’s anterior superior iliac spine (ASIS) at

the juncture of the pelvic and thoracic sections.

Position the patient sufciently forward with their arms

outstretched and wrists resting on the prone arm rest.

This will insure that the skin on the back of the patient’s

arms will not be pinched between the thoracic section

and the table frame when using the drop.

THORACIC DROP

Pelvic Drop Thoracic Drop

12

ANKLE REST EXTENSION

The ankle rest can be extended up to 11”

to accommodate taller patients. Shorter

patients can drop their feet into the recess

created by the extended ankle rest.

Locking knobs are provided on both sides

of the table.

ANKLE REST ELEVATION AND LOWERING (optional feature)

To ELEVATE, simply lift up on the

ankle rest.

To LOWER, lift the center of the wood

bar with one hand while gently lowering

the ankle rest with the other hand.

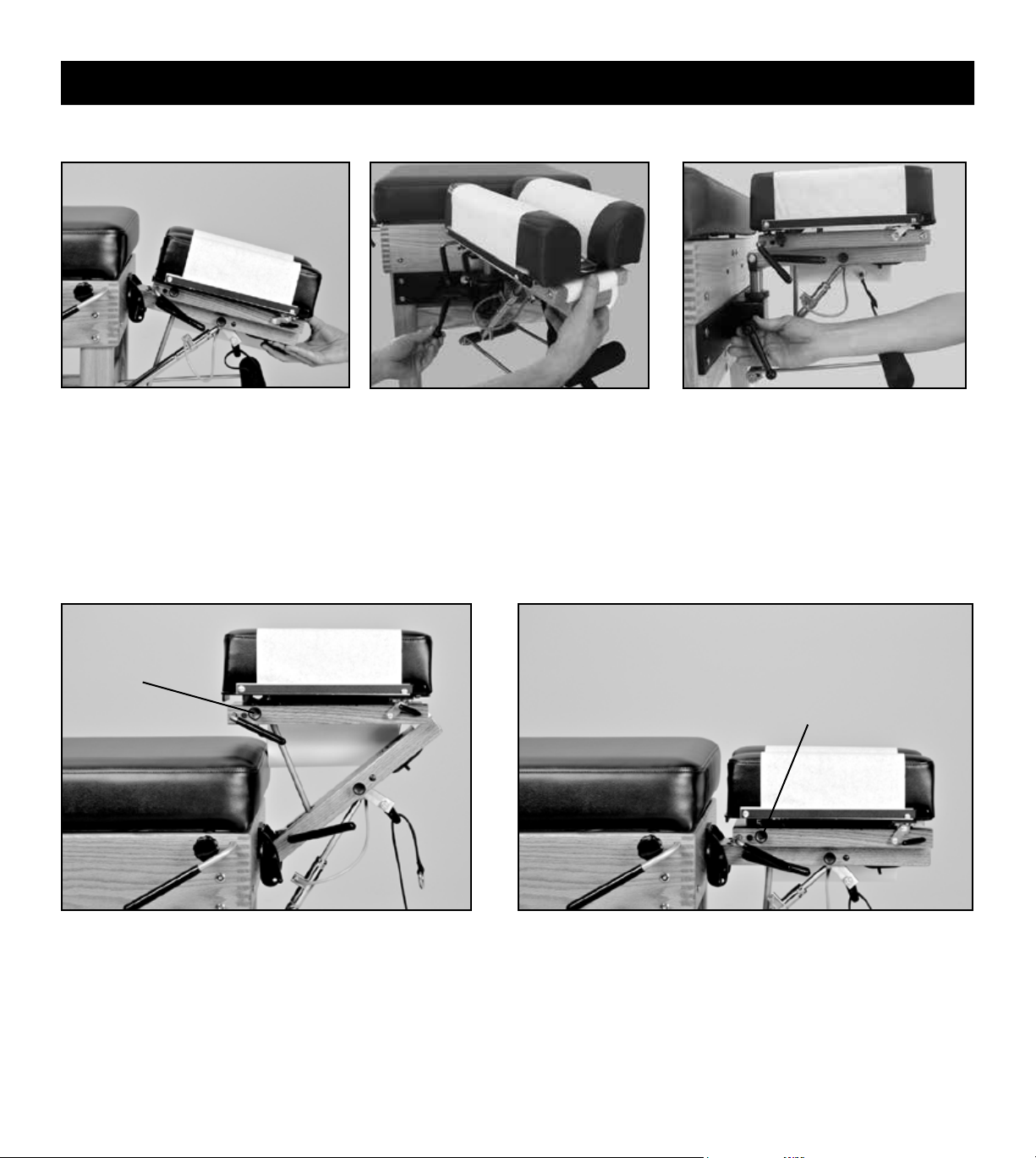

THORACIC INCLINE

Uses of the thoracic incline include anterior thoracic adjusting,

cervical palpation and diversied cervical adjusting. This

feature allows the practitioner to remain in a comfortable,

upright position.

CERVICAL PALPATION & ADJUSTING ANTERIOR THORACIC ADJUSTING

Table Operation

The thoracic section can be raised to a 20 degree angle. Lift the

thoracic section, swing the slant bar down and allow the rubber

tips to rest on top of the front legs (the right arm of the slant bar

will straddle the thoracic tension control knob).

12

13

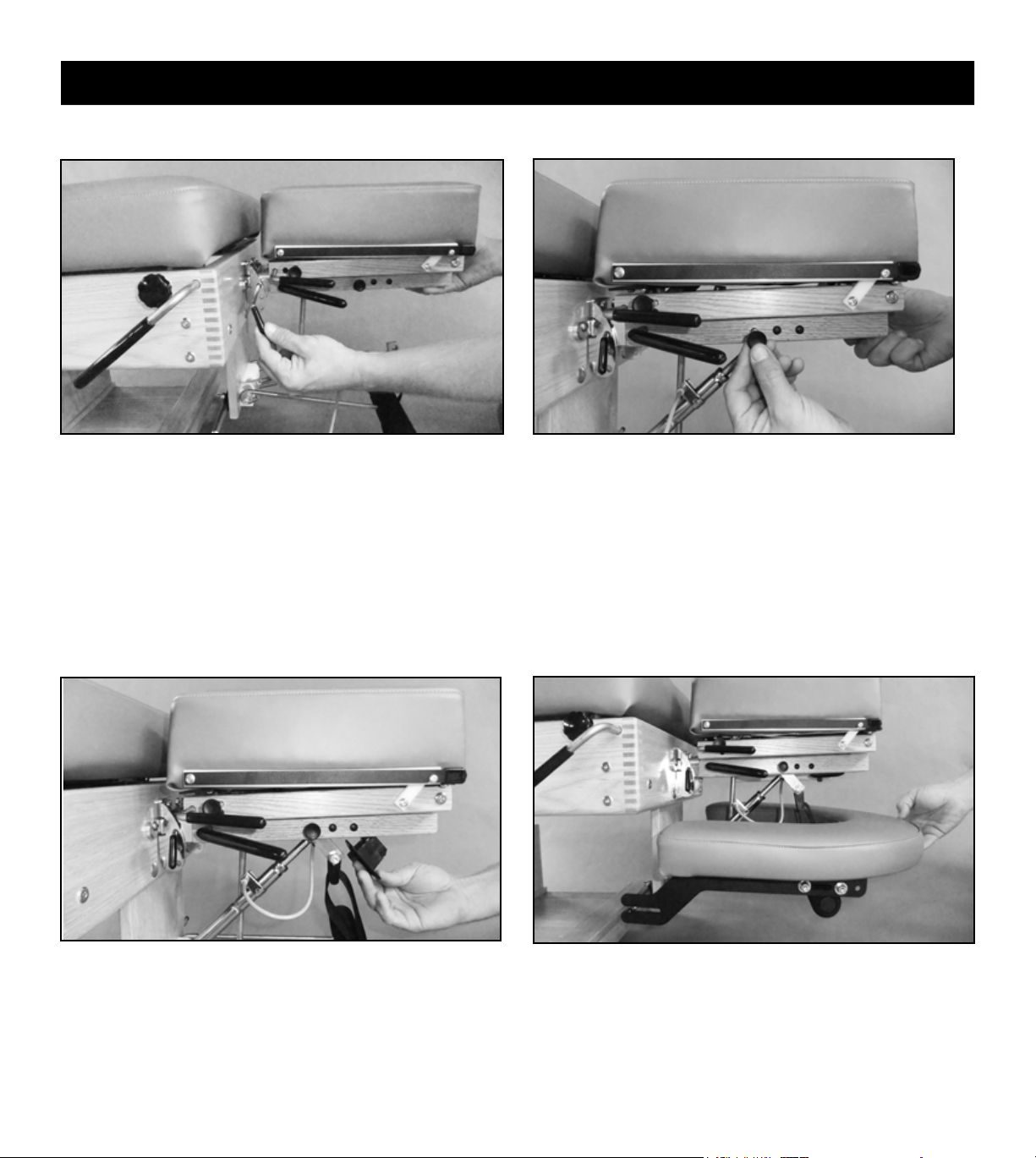

CRESCENT ARM REST

The Crescent Arm Rest provides additional forearm support in the

prone position. Simply slide both slotted ends of the bracket onto

the bolts located on the inside of the front legs and push down onto

the standard Prone Arm Rest. The Crescent Arm Rest will snap

into place and its positions are easily adjustable. Can be retrotted

to your table at anytime (minimal installation required).

Rotate the Comfort Pillow 180

degrees to provide cervical

support in the supine position.

COMFORT PILLOW

Base

Pillow

Accessories

The Comfort Pillow offers

massage quality comfort in the

prone position.

The Velcro on the

underside of the pillow

secures it to the base,

allowing for width

adjustability.

The base of the Comfort Pillow inserts into place between the

headpiece cushions. The opening is adjustable.

Comfort

Pillow

Crescent Arm Rest

Bolsters are 20" wide with a nonslip base. Choice of two

heights: 2.75" or 4.25". Use in prone position under ankles or in

supine position under knees to relax hamstrings.

BOLSTERS

2.75" x 20" Bolster (shown on Tour portable table)

PRONE ARM REST SHIELDS

Nonporous and durable plastic

shields slip over the prone arm rest

grips. Easy to sanitize.

14

Care & Maintenance

CERVICAL DROP THORACIC DROP

1. Cock the thoracic drop and raise the section to its inclined position.

Apply 3-IN-ONE oil onto the thoracic plunger.

2. Cock the pelvic drop. Raise the thoracic section as far as possible,

exposing the pelvic plunger just beyond the wood crosspiece. Using the

syringe, apply 3-IN-ONE oil onto the pelvic plunger and allow several

minutes for penetration.

Routine lubrication:

If the drops have not been lubricated on a regular basis:

1. Apply WD-40 onto the plungers (as above) and allow a few minutes

for penetration. Drop each section several times to clean from dust & debris.

2. It is important to follow the cleaning with 3-IN-ONE oil for lubrication.

DROP MECHANISMS: CLEANING & LUBRICATION

Periodic lubrication of the drop mechanisms will insure smooth, crisp drops. Use 3-IN-ONE oil every month or 500 adjustments.

If the drops have not been lubricated on a regular basis, rst apply WD-40 to clean the plungers from dust & debris. See below.

1. Raise the headpiece and cock the drop.

2. Apply 3-IN-ONE oil into the hole of the

plastic block. Allow a few minutes for

the oil to penetrate before using.

If the drop has not been lubricated on a

regular basis:

Routine lubrication:

1. Apply WD-40 into the hole and then drop

the headpiece several times to clean the

plunger from dust & debris.

2. It is important to follow the cleaning with

3-IN-ONE oil for lubrication.

PELVIC DROP

SYRINGE USE (FOR PELVIC DROP)

To access the pelvic plunger, use a small syringe (provided). Squeeze several drops of

3-IN-ONE oil onto a nonporous surface and suction into the syringe. Save the syringe

for future use.

TENSION CONTROL ADJUSTMENT

The resistance on the tension control rod can be increased or decreased.

Do this by adjusting the set screw on the bottom of the thoracic, pelvic

and caudal drop blocks using a 1/8” allen wrench:

Set Screw

Increase resistance: Turn the set screw clockwise. This is helpful

if the tension control rod is “backing out" while using the drop.

Decrease resistance: Turn the set screw counter-clockwise.

Care & Maintenance 15

VINYL CLEANING

1. Mild Daily Cleaning: Use dish soap and warm water (1:10) with a soft cloth. Follow with a thorough, clear water rinse.

If more cleaning is necessary, use a soft bristle brush with the same solution. Avoid harsh detergents and powdered abrasives.

Areas coming in contact with hair, body oils or perspiration should be washed frequently. Remove stains immediately to prevent

the possibility of becoming permanent.

2. Disinfecting Options:

Bleach: Dilute 4 tsp bleach in 1 quart of water in a spray bottle. Spray on vinyl, leave for 1-2 minutes and rinse well with water.

Hydrogen Peroxide (3%): Available in spray bottle. Use undiluted and leave on for 5 minutes and rinse well with water.

Alcohol (70% min): Use undiluted. Leave on for 1-2 minutes and rinse well with water.

REPLACEMENT VINYL: In the event of wear or damage, pre-sewn replacement vinyl is available from Thuli Tables.

3. Water Rinse: It is important to follow all cleaning with a thorough, clear water rinse to minimize premature deterioration of the

vinyl from extended exposure to chemicals.

14

Motor Troubleshooting 16

1. The outlet may not be working or the breaker is tripped. Test the outlet using another device.

2. The electrical connection in the back of the motor may be disengaged.

3. The air lines from the foot switch to the motor may be not be fully connected or may be kinked or broken.

If kinked, try to straighten. If broken, contact us for a replacement.

4. The foot switch may be worn out. Uplug the air lines from the foot switch and blow into both of them, one at a time.

If the motor operates by doing this, the foot switch is worn out. Contact us for a replacement.

1. Squealing or screeching noise: The electronic brake has likely failed and must be sent in for repair.

2. Clicking noise: This is normal and may get louder with age, but functionally the motor is ne.

MOTOR IS NOT WORKING

MOTOR IS MAKING NOISE

TABLE MOVEMENT

5. The wires inside the plug may be loose or disconnected.

To check, rst uplug the motor from the electricity and then follow the steps below.

L1

N

Remove the plug

from the motor by

lifting up on the

tab (using a at

screwdriver).

Remove the cover by

removing the 2 screws

(using a Philips screw

driver).

Loosen the 3 screws (using a at screwdriver)

and re-connect the wires as follows:

110 volt motor:

White wire goes into L1 (left)

Green wire goes into middle

Black wire goes into N (right)

220 volt motor:

Brown wire goes into L1 (left)

Green/Yellow goes into middle

Blue goes into N (right)

When the table is in an elevated position, some movement of the table is normal. If the movement becomes

excessive and interferes with function, it is likely that the motor needs replacing.

The motor is covered by a one year warranty. Please note that the motor, like all electrical products, will eventually wear out.

The life of the motor is determined by various factors including number of uses, weight and positioning of patients, humidity and

environmental conditions. To extend the life of the motor, instruct the patient to get on & off at the center of the table.

Also, avoid raising or lowering the table if the patient is not centered on the table. If the motor is not functioning properly, please go

through this checklist to determine the cause and resolution (which may include replacing the motor).

Warranty 17

If your table needs repair, whether under warranty or not, please contact us. We will determine what is needed and send you either

a replacement or the necessary part for repair. Our tables have been designed so that replacing a part is relatively easy to do yourself.

Please note that we do not cover labor costs if you hire someone to install the replacement part on your behalf.

Our tables are designed and built to high standards. We are proud to offer a limited lifetime warranty against manufacturing

defects, with the exception of the headpiece piston and the motor (on elevation tables), which are covered by a one year warranty.

This warranty is valid to the original owner if the table has not been altered in any way. It does not cover issues caused by normal

wear & tear or damage due to accidents, improper use or negligence.

Elevation Tables

Tour Portable 300 Stationary

Sport Portable

500 Stationary

Portable Drops

Lumbo-Pelvic Drop

Extremity Drop

and

Speeder Board

Headpiece

Junior Portable

www.thulitables.com

608.935.9300

800.458.4854

youtube.com/thulitables

facebook.com/thulitables

This manual suits for next models

9

Table of contents

Other Thuli Tables Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual