Tigo TSI-7.6K-US User manual

Inverter

EI Inverter

!

1. General Information - Specications

2. Installation

ATTENTION - READ FIRST

!CAUTION - Use appropriate hardware for

the mounting surface !CAUTION - Check that all Disconnect switches are OFF

before wiring. For personal safety, do not operate with

electricity and always wear appropriate PPE.

1.1 Package Contents

1.3 EI Inverter Overview

1. Front panel

2. LED indicators

3. Wiring box cover

4. DC disconnect switch

5. PV input

6. Battery input

7. WiFi antenna port

8. Cellular antenna port

9. TAP /M et er /R SD input

10. Battery com input

11. Backup output

12. AC grid output

13. External Grounding point

14. Moun ti ng b rac ke t

15 . He at s in k

1 2 3 567 9 10 11 12 13 14 15

8

4

2.1 Installation requirements

1.2 AC Wiring Diagram

2.3 Mounting

3.1 Wire schedule/preparation

2.2 Prepare conduit openings

3.2 Connections

3.3 Inverter output connection - GRID

3.4 Backup output connection - Battery systems only

L2 L1 L1 N L2

Backup Grid

L2 L1 L1 N L2

Backup Grid

Inverter Model Over current rating

TSI-7.6K-US 40A (bi-directional)

TSI-11.4K-US 60A (bi-directional)

1 . Determine which inputs/ports will need to be opened 2. Remove wire box cover (3)

using 3/16” (5mm) screwdriver

3. With a hole saw, CAREFULLY

open the conduit drill guide for the

necessary openings.

Quick Start Guide - TSI-7.6/11.4K-US

Pg 1 of 4

Item Quantity

EI Inverter 1

Quick Start Guide 1

Mounting Bracket 1

Tigo Access Point (TAP) 1

Rapid Shutdown label 1

E-stop button 1

DC wire ferrules 7.6kW: 16

11.4kW: 20

AC wire ferrules 5

RS485 3-pin connector (meter) 1

Grounding ring terminal 1

Hex-head Self tapping screws (inverter

mounting) 5

Philips-head screw (E-stop mounting) 4

White wall anchors (inverter) 5

Green wall anchors (e-stop) 4

WiFi antenna 1

Cellular antenna (only in cell-enabled models) 1

¾” conduit hole plug, with nut 1

1” conduit hole plug 2

1” conduit hole plug nut 2

Item W (inch/mm) H (inch/mm) D (inch/mm)

TSI-7.6K-US 15.75/400 22.4/570 7/170

TSI-11.4K-US 15.75/400 25.2/638 7.4/187

Use Type Size

Equipment Grounding Conductors Yellow-green jacketed or solid bare copper 10 - 8 AWG

AC output conductors

(BACKUP/GRID) Multi-color jacket, copper 8 - 6 AWG

PV Input conductors Red/Black Photovoltaic Wire (ex: PV1-F) 10 - 8 AWG

Battery input conductors Red/Black Photovoltaic Wire (ex: PV1-F) 12 - 8 AWG

≤15°

≥12”≥12”

≥12”

≥12”

≥12”

References in

Guides

Label on

Inverter

# on

diagram Drill / if installing

PV input DC (left side) 5 Yes

Battery input DC (right side) 6 Yes / battery

Comm COM (left side) 9 Yes / TAP or meter

Comm COM (right side) 10 Yes / battery

Backup output AC (left side) 11 Yes / ATS

AC grid output AC (right side) 12 Yes

3. Electrical Connections

NG

Inv Grid Inv

L1 L1 L2 L2

Backup

Panel

L1 N L2

ATS

Input

Inv Grid Inv

L1 L1 L2 L2

Backup

Panel

L1 N L2

ATS

Input

EI Inverter

ATS

L2 L1

ACGrid

L1 N L2

EGC

EI Inverter

ATS

L2 L1

ACGrid

L1 N L2

EGC

CT L1 CT L2

+

ACGrid

L1 N L2

EnergyMeter

-+ -

CT L1 CT L2

+

ACGrid

L1 N L2

EnergyMeter

-+ -

N

G

Grid

Meter

Grid

Meter

Backup Panel

Main Panel

1. This document is for quick guidance only. For details, please refer to the Energy Intelligence (EI) Inverter Installation & Operations Manual.

2. Damage caused by failure to follow the contents of the EI Inverter Installation & Operations Manual is not covered by the warranty.

3. Before installing the system, check that the package contents are intact and complete against the packing list. If any damage is found or any component is

missing, contact your dealer.

1. Do NOT install the EI inverter in the direct sun, rain or

snow

2. If installing more than one inverter, refer to the EI Inverter

Installation & Operations Manual for clearances

1. To prepare the DC conductors (PV+, PV- and BAT), strip 5/8”/16mm of the DC connector’s

jacket and crimp on the DC wire ferrule.

2. To prepare the AC conductors (GRID and BACKUP), strip 0.7”/18mm of the AC conductor’s

jacket and crimp on the AC wire ferrule.

3.2.1 Pressure Terminals

1. Insert 1/8” at blade screwdriver in the terminal

at a right angle to the terminal face. Press the

clamp open by tilting down.

2. Insert conductor into the terminal’s round

opening.

3. Remove screwdriver to release the clamp and

secure the conductor.

4. Gently tug conductor to ensure it is secure.

3.2.2 Screw Terminals

1. Insert equipment grounding

conductor (EGC) into the grounding

busbar.

2. Use an #2 philips screwdriver to

tighten the set screw and securing

the EGC.

3. Gently tug the conductor to ensure

it is secure.

1. Install the AC conduit to the AC grid output opening (12). Use appropriate

conduit ttings and bond where necessary. Run AC grid conductors.

2. Terminate the AC grid conductors to the appropriate terminal.

3. Connect the AC EGC to the grounding busbar.

4. Terminate the opposite end of the inverter output conductors at the main

service panel with the appropriately sized OCPD.

1. Install the AC conduit to the AC grid output opening (11).

Use appropriate conduit ttings and bond where necessary.

Run AC backup conductors.

2. Terminate the AC backup conductors to the appropriate

terminal.

3. Connect the AC EGC to the grounding busbar.

4. The opposite end of the Backup conductors terminate at the

ATS. To complete the ATS connections at this time, refer to

the ATS manual. Ver. Dec. 20, 2021

PN: 002-00078-00

EI Inverter

Quick Start Guide - TSI-7.6/11.4K-US

Pg 2 of 4

4. Communications connections

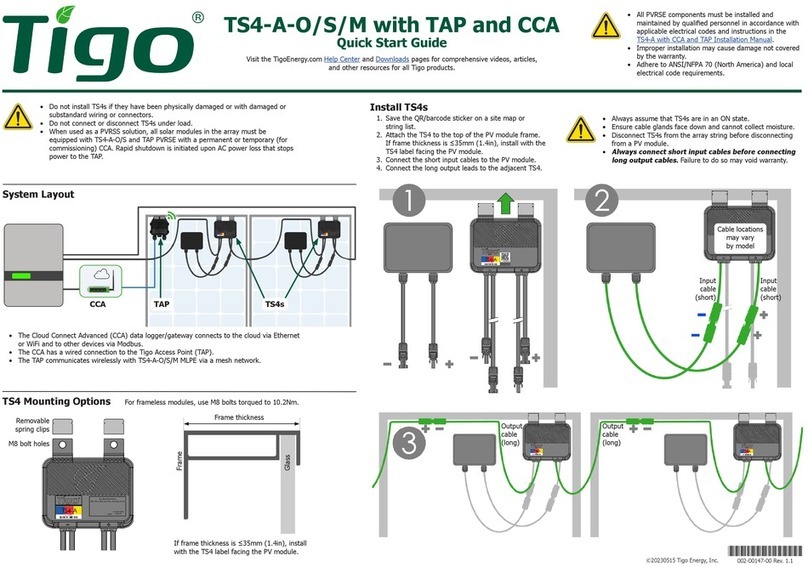

Scan here for the TS4 downloads

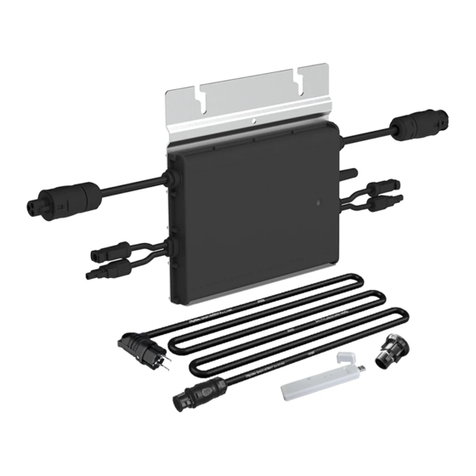

3.5 TS4 Installation

CAUTION - To prevent damage to the TS4,

always connect PV modules to the TS4 input

before connecting output conductors in the

string. Refer to the TS4 Installation Manuals

for the TS4 installation requirements.

!

CAUTION - Do not reverse positive and

negative of the battery input terminal.

!

CAUTION -Do not cut or extend CT wires. The CTs wires are 80”, plan accordingly.

!

3.6 PV connections

1 2 341234 + -

PV+ PV- BAT

RJ45

Pin

Wire color

Signal denition Function

T568B T568A

1 White/Orange White/Green Enable+ Wake-up

2 Orange Green Enable-

3 White/Green White/Orange CANL CAN Communication

4 Blue Blue CANH

5 White/Blue White/Blue GND GND

6 Green Orange Received NC

7 White/Brown White/Brown RS485B RS485 communication

8 Brown Brown RS485A

3.7 Battery connections - Battery systems only

1 2 341234 + -

PV+ PV- BAT

4.1 Tigo Access Point (TAP) installation

4.2 Battery communications - Battery systems only

4.3 Meter connections

1. Using a cable cutter/stripper, remove the 1/2in of the external

insulation/jacket from the CAT5/6 cable, exposing the 4 twisted

pairs of wire.

2. Untwist approximately 1/2in of the end of the wires and insert the

eight wires into the an RJ45 connector. Choose either T568A or

T568B standard for wiring – stay consistent.

3. Crimp the connector with the appropriate crimping tool.

4. Install the battery communications conduit to the COM battery

input opening (10), use appropriate conduit ttings and bond

where necessary. Run battery CAT5/6 cable.

5. Connect the communications cable from the battery to the RJ45

port in the inverter wire box.

1. Install the meter communications conduit from the main service panel (location of the meter) to the inverter’s TAP/meter COM input (9) and run the RS485

(3 wires needed). Additional wires may need to share this raceway (E-stop, TAP). Plan the conduit layout with this in mind.

2. Remove the cable’s external insulation using a crimping tool or cable cutter.

3. Insert the RS485 communication cable into the 4-pin connector. Note – the farthest right terminal on the male adaptor is not used.

4. Plug connector into the meter communications terminal.

5. Clamp CT’s around the corresponding grid input conductors (L1, L2) ensuring that the arrow is pointing away from the grid.

6. Connect the meter’s L1, L2, N to the main service panel, using 15A circuit breaker on L1, L2.

1. Install the Battery conduit to the DC Battery input

opening (6), use appropriate conduit ttings and

bond where necessary. Run the battery conductors.

2. Terminate the battery conductors to the appropriate

terminal.

3. Connect the battery EGC to the grounding busbar.

1. Install the TAP within the array boundary.

2. Run the RS485 or CAT5/6 cable from the TAP to the inverter.

3. Terminate the TAP communications wire in the inverter at the 4-

pin connector. From bottom to top: -, +, B, A. 1. Carefully screw WiFi antenna in the WiFi antenna port, ANT1 (7).

2. If the inverter includes the cellular function, carefully screw the

Cellular antenna in the Cellular antenna port, ANT2 (8).

1. Install the PV conduit to the DC PV input opening (5), use

appropriate conduit ttings and bond where necessary. Run the

PV string conductors.

2. Terminate the PV strings to the appropriate terminal.

3. Connect the PV EGC to the grounding busbar.

1. Install the TS4 module-level power electronics (MLPE) on

the back of the PV modules.

2. Connect the PV module to the TS4 input conductors.

3. Connect the TS4 output conductors together to form a

string.

4. If using the TS4-A-F/TS4-A-2F, no additional steps are

necessary.

5. Remove each barcode sticker from the TS4-A-O and place

in the grid on the last page of this document in the position

and orientation of the module as it is in the array. If using

the TS4-A-F/TS4-A-2F, this step is not necessary.

NOTE: The TSI-7.6K-US has 3 MPPTs, the TSI-11.4K-US has 4

MPPTs.

NOTE: The TAP is a required to enable module-level monitoring,

and rapid shutdown functionality in the TS4-A-O.

NOTE: All EI Inverters come with the WiFi antenna. The cellular

antenna is included for inverters which include this communication.

NOTE: This connection is required for the operation of the EI Battery.

12345678 12345678

T568B T568A

RJ-45 Male Plug

NG

EI Inverter

ATS

L2 L1

ACGrid

L1 N L2

EGC

CT L1 CT L2

+

ACGrid

L1 N L2

EnergyMeter

-+ -

Grid

Meter

Grid

Meter

Main panel

A G B

RS-485

A+ B- G

4.4 Antenna connections

Ver. Dec. 20, 2021

PN: 002-00078-00

EI Inverter

Quick Start Guide - TSI-7.6/11.4K-US

Pg 3 of 4

5. Pre-commissioning checklist

6. Commissioning

CAUTION - For personal safety always wear appropriate PPE.

This Rapid Shutdown (RSD) initiation switch is intended to act as the National

Electric Code (NEC) required activation device for rapid shutdown systems. The

RSD switch is a normally closed (NC) contact. When the button is pushed, the

state of the initiation switch is open and the system’s PV array enters rapid

shutdown in which all conductors from the modules to the Tigo EI inverter are

reduced to less than 30VDC within 30 seconds. This solution complies with the

2017 and 2020 NEC.

8.1 General Information

7. LED Status

TSI-7.6/11.4K-US inverters come with four LED indicators. On the front cover, from left to right, the indicators show POWER, Battery status, COM, and FAULT.

Check Item Acceptance Criteria

Inverter installation The inverter is installed correctly, securely and reliably.

Conduit/Cable layout Conduit/Cables and conductors are routed properly, and as requested by the customer.

Cable connections The AC output conductors, DC input conductors, and communications cables are labeled and connected correctly and securely.

Cable ties Cable ties are secured evenly with no sharp protrusions.

Grounding Ground conductors are connected correctly, securely and reliably.

Conduit connections All conduit attachments are sealed and bonded, when necessary.

Unused conduit openings Any unused conduit openings are tted with waterproof caps (provided) or left unopened.

Disconnect switches The inverter’s DC disconnect switch and all external disconnect switches connecting to the EI Inverter are in the OFF position.

Wirebox cleanliness The wirebox is left clean and tidy.

Installation environment An appropriate installation space had been chosen and the environment is left clean and accessible.

Symbol Function Color Status Action Description

POWER Green

ON Steady Feed in grid

Blink 3s on / 1s off DC ON / AC OFF

Blink 1s on / 3s off DC OFF / AC ON

Blink 0.5s on / 0.5s off Checking

Blink 2s on / 2s off Standby mode

COM

Green

ON Steady 4G/WiFi, local WiFi ok

Blink 0.5s on / 0.5s off Local WiFi connecting

Blink 1s on / 1s off 4G/WiFi failure, local WiFi ok

Blink 1s on / 3s off Local WiFi failure, 4G/WiFi ok

Blank Off Steady Communications failure

BAT Green

ON Steady Battery is in normal operation

Blink 1s on / 3s off Battery is in low power

Blink 0.5s on / 0.5s off Battery is in fault mode

FAULT Red

ON Steady with audible buzzer alarm Arc fault

Blink 1s on / 1s off Warning

ON Steady Fault

8. PVRSS initiation switch

CAUTION - Use appropriate hardware for the mounting surface.

!

8.3 Mounting the RSD initiation switch

CAUTION - Make sure the inverter is OFF. Pull up on the RSD button to ensure it is in the “normally close” position.

!

!

8.4 Wiring the RSD initiation switch

Items needed for the installation:

• Signal conductors (24V rated)

• Conduit and appropriate

weatherproof connectors

• Drill with 5mm bit

• Philips head screwdriver

• Installed EI Inverter

Included in the packaging for

this installation:

Item Quantity

Green plastic wall

anchor 4

Philips-head self-

tapping screws 4

8.2 Required for installation

Ver. Dec. 20, 2021

PN: 002-00078-00

9. Your Customer Service Contact

Tigo Energy, Inc.

655 Campbell Technology Pkwy

Campbell, CA 95008

T: +1 408 402 0802

https://support.tigoenergy.com/

1. Using a Philips head screwdriver, unscrew the 4 plastic screws of the assembled RSD

initiation switch to open the enclosure.

2. Use the base of the enclosure to mark 4 holes on the wall and drill the holes out. Insert

the wall anchors into the holes.

3. Align the holes of the RSD initiation switch base with the holes in the wall. Using a

Philips screwdriver, screw the self tapping screws through the enclosure base into the

wall anchors.

1. Install RSD switch conduit to the TAP/Meter/RDS COM input (9), use appropriate conduit ttings and bond where necessary. Run

the signal conductors.

2. Connect the conductors to the RSD switch as shown.

3. Reinstall the RSD initiation switch cover and tighten the plastic screws to secure.

4. Remove the 3-pin connector from terminal CN14 and remove the jumper across the pins.

5. Insert the conductors in the 3-pin conductor’s positions 1 and 3, as shown.

6. Replace the connector in the terminal CN13 and replace the inverter wirebox cover.

The steps to turn on the inverter are as follows:

1. Before powering on, please make sure all voltages and current are within the specication of the inverter, otherwise damage may occur.

2. Turn on the DC disconnect switch between the battery and the inverter.

3. Turn on the DC disconnect switch at the bottom of the Tigo EI Inverter.

4. Turn on the BAT switch located on the left side of the Tigo EI Battery.

5. Turn on the service disconnect between the grid and the Tigo EI Inverter.

6. Ensure the e-stop button (if used) is not in the de-pressed position.

7. Open the Tigo EI app to complete commissioning by making all required inverter and battery settings.

NOTE: The shutdown steps are the opposite to the order above.

EI Inverter

Quick Start Guide - TSI-7.6/11.4K-US

Pg 4 of 4

Examples:

Place TS4-A-O barcode stickers in the grid below per the system azimuth and layout for scanning into the EI App. Ver. Dec. 20, 2021

PN: 002-00078-00

Battery

EI Battery Storage

(1) Handle

(2) Battery enclosure

(3) Base

(4) Disconnect Switch

(5) DC Knockout

(6) Power Button

(7) Communications knockout

(8) Inverter connection wirebox

(9 ) Fr on t co ve r

(10) LED indicator

(11) Base front cover

(12) Battery expansion wirebox

(1 3) G EC /b on ding te rm in al

(1 4) M ou nt in g tabs

(1 5) H ea t si nk

Door locking clips

(behind front panel)

1 2 3 456 7 8 9 10 11 12 13 14 15

1. General Information - specication

Note – The battery module’s power terminals face the right side of the enclosure. Install top battery before bottom battery packs.

Three battery modules per enclosure: 1 on top, 2 on bottom.

2.5 Install the battery modules

2.4 Removing the cover

Quick Start Guide - TSB-10/20-US

Pg 1 of 3

ATTENTION: READ FIRST

!

WARNING – the door has a grounding wire and display cable attached to the interior. Use caution and detach wires before

attempting to remove the door.

!

CAUTION - Ensure 12” clearance around all sides. Use appropriate hardware for the mounting surface.

For personal safety always wear appropriate PPE.

!

1.1 Package Contents

1.2 EI battery enclosure overview

Item Quantity

Battery Enclosure 1

Quick Start Guide 1

Safety-lock screws 6

Sleeve anchors 2

Wire ferrules 4

2.1 System overview

Inverter – battery wiring connection.

All inverter connections are made on the left

side of the battery enclosure.

Battery expansion wiring connections.

All battery – battery connections are made on the right side of each battery.

2. Installation

BAT+

BAT-

COM

Left side

2.3 Mounting

1

1

3

3

2

2

1. This document is for quick guidance only. For details, please refer to the Energy Intelligence

(EI) Battery Storage Installation & Operations Manual.

2. Damage caused by failure to follow the contents of the EI Battery Storage Installation &

Operations Manual is not covered by the warranty.

3. Before installing the system check that the package contents are intact and complete against

the packing list. If any damage is found or any component is missing, contact your dealer.

1. Remove the bottom plate (11) and remove 3 screws from each side, 6 total. Unlatch the 2 front door locks from the bottom.

2. Tilt up and CAREFULLY swing door to the left, using caution to not pull ground or display wires.

3. Unscrew ground conductor and unplug display cable then set door aside.

1. The battery module serial numbers will be needed for the

commissioning. These are labeled on the module and the

box they shipped in.

2. Place the battery in the enclosure then slide the brackets

inward on each side of the battery and tighten the wingnut

to secure.

3. Repeat for batteries 2 and 3.

1. Rotate mounting tabs (14) 90° to face outward.

2. Mark holes for drilling. Drill 2” deep holes with an 8mm bit.

3. Insert anchor bolt sleeve. Position the battery enclosure mounting tabs anchor sleeve. Secure with washers and bolts.

2”

8 MM

≥12”

≥12”

≥12”

≥12”

BAT+

BAT-

COM

Primary

Primary - Left side Primary - Right side Secondary - Right side

Secondary

Top

Front

EI Battery Storage

Quick Start Guide - TSB-10/20-US

Pg 2 of 3

If an external bonding point or grounding electrode conductor is

required, these may be connected to right side of the enclosure

at the GEC/Bonding terminal. This is not required for the

operation of the equipment.

3.4 GEC/Bonding terminal

3.3 Battery expansion

Note – This section applies to systems with multiple battery enclosures. The battery expansion cables/conductors should not exceed 6ft-7in.

If installing only one enclosure, skip this step.

Note – In the next section, Wiring the EI

Battery – Battery expansion, a communication

cable is routed between the two enclosures. At

the second enclosure this cable will terminate

at the Link-in terminal of battery module 4

(upper module/enclosure 2).

Wiring the battery modules (Battery enclosure 2)

If installing a second EI Battery enclosure complete

the power,Link-In and Link-Out connections as

described in the previous section.

EI Battery enclosure 1

Remove the terminating cap from the CAN/COM

terminal in the Battery expansion wire box (12) and

insert it in the Link-in terminal of battery module 1

(upper module/enclosure 1).

EI Battery enclosure 2

The terminating cap is inserted in the CAN/COM

terminal in the Battery expansion wire box (12). Do not

remove this cap.

Note – IF INSTALLING ONLY ONE BATTERY ENCLOSURE, A terminating cap is required

in the CAN COM port in the battery expansion wirebox (12).

3.2 Wiring the lower batteries

!CAUTION – Do not reverse positive and negative of the battery input terminal.

Lower battery connections

1. Locate the cables labeled for the lower battery modules.

2. Connect provided lower inner battery link-out cable

(loose cable) to the lower inner battery terminal labeled

link-out.

3. Connect the opposite end of the lower inner battery

link-out cable from step 2 to the link-in terminal on the

lower outer battery.

4. Connect the lower inner battery link-in cable to the

lower inner battery link-in terminal.

5. Connect the lower inner battery + plug to the lower

inner battery red terminal labeled +.

6. Connect the lower inner battery - plug to the lower

inner battery black terminal labeled -.

7. Connect the lower outer battery + plug to the lower

outer battery red terminal labeled +.

8. Connect the lower outer battery - plug to the lower

outer battery black terminal labeled -.

9. Connect the outer lower battery link-out cable to the

link-out terminal on the lower outer battery.

Note – The battery conductors and communications cables are labeled and located

inside the enclosure. CAREFULLY cut cable ties and connect as shown. When properly

installed a click will be heard.

3. Connecting the Batteries

3.1 Wiring the upper battery

!CAUTION – Do not reverse positive and negative of the battery input terminal.

Upper battery connections

1. Locate the cables labeled for the upper battery module.

2. Connect the PCS cable to the battery terminal labeled PCS.

3. Connect the upper battery link-out cable to the battery port

labeled link-out.

4. Connect the + plug to the red battery terminal labeled +.

5. Connect the - plug to the black battery terminal labeled -.

upper

battery

lower

battery

3.3 Battery expansion - cont.

Note – This section applies to systems with multiple battery enclosures. The battery expansion cables/conductors should not exceed 6ft-7in.

If installing only one enclosure, skip this step.

1. Using a Philips screwdriver, loosen 2 captive screws on the expansion wirebox (12) on the right side of each enclosure.

2. Install 2 conduits from the right side of enclosure 1 to the right side of enclosure 2 for the DC conductors and communication cable. Use appropriate

conduit ttings to provide a water-tight seal.

3. Prepare 2 DC conductors 6AWG and route through the conduit and one CAT5/6 with RJ45 connectors on each end.

4. Connect BAT-Expansion + from enclosure 1 to BAT-Expansion + of enclosure 2.

5. Connection BAT-Expansion - from enclosure 1 to BAT-Expansion - of enclosure 2.

6. Connect CAN COM from enclosure 1 to CAN COM of enclosure 2.

Primary Secondary

CAN

COM

CAN

COM

CLICK

CLICK

CLICK

CLICK

CLICK

CLICK

Inner battery

Outer battery

BAT 1

Upper

Enclosure 1 Enclosure 2

BAT 2

Lower Inner

BAT 3

Lower Outer

Bottom

Top Upper BAT Link-out

Lower inner BAT Link-in

Lower outer BAT Link-out

Upper BAT Link-out

Lower inner BAT Link-in

Lower outer BAT Link-out

Terminating

Cap

Terminating

Cap

BAT 4

Upper

BAT 5

Lower Inner

BAT 6

Lower Outer

Bottom

Top

Lower inner BAT Link-out

Lower outer BAT Link-in

(12) (12)

EI Battery Storage

Quick Start Guide - TSB-10/20-US

Pg 3 of 3

Ver. Oct. 25, 2021

PN: 002-00083-00

5. Pre-power checklist

6. Powering on the battery storage system

7. LED indicators

LED lights are displayed as follows in TSB-10/20-US different states:

A: Middle indicator (indicate status)

B: Ring indicator (indicate battery power)

B4

B1

A

B3 B2

Number Status LED light display

1Standby state Center leaf; ashing green (0.5 seconds on and 2 seconds off)

indicates the standby state. Ring indicator-refer to Discharge state.

2Charge state

Center leaf; green light is on. Ring indicator indicates

1. Power≤25%, LED B1 ashes, LED B2/3/4 are off;

2. Power≤50%, LED B1 is on, LED B2 ashes, LED B3/4 are off;

3. Power≤75%, LED B1/2 are on, LED B3 ashes, LED B4 is off;

4. Power>75%, LED B1/2/3 are on, LED B4 ashes.

3Discharge state

Center leaf green light is on. Ring indicator indicates

1. Power≤25%, LED B1 is on, LED B2/3/4 are off;

2. Power≤50%, LED B1/2 are on, LED B3/4 are off;

3. Power≤75%, LED B1/2/3 are on, LED B4 are off;

4. Power>75%, LED B1/2/3/4 are on.

4Alarm state Center leaf; green light ashes (0.5 seconds on and 0.5

seconds off, 0.5 seconds on and 2 seconds off). Ring indicator-refer to Discharge state.

5Fault state Center leaf; red light ashes (1 second on and 1 second

off). Ring indicator-refer to Discharge state.

6Upgrade state Center leaf; yellow light ashes(1 second on and 1 second off) indicates the upgrade state. Ring

indicator-refer to number 1.

7Manual forced power

on

Center leaf; green light ashing (0.1 seconds on and 0.1

seconds off) . Ring indicator-refer to Discharge state.

8Manual forced

shutdown

Center leaf; red light ashing (0.1 seconds on and 0.1 seconds off). Ring indicator-refer to Discharge

state.

Note – All other components of the EI Battery Storage system, including the energy meter must be installed for the system to operate.

!CAUTION – For personal safety always wear appropriate PPE.

8. Forced start/shutdown

Check Item Acceptance Criteria

Communications cable The communications cable is labeled and properly connected to both the inverter and battery communications terminals.

Battery power conductors The battery power conductors are labeled and properly connected to the inverter and battery terminals.

GEC/bonding If required, the GEC/bonding conductor is properly connected.

Expansion wiring If multiple batteries installed, BAT-Expansion+/BAT-Expansion- conductors and communications cable are properly connected.

Conduit connections All conduit attachments are sealed and bonded, when necessary.

Unused conduit openings Any unused conduit openings are tted with waterproof caps (provided) or left unopened.

Disconnect switches The BAT-switch and all other switches connecting to the EI Battery are OFF.

Installation environment An appropriate installation space had been chosen and the environment is left clean and accessible.

9. Your Customer Service Contact

Tigo Energy, Inc.

655 Campbell Technology Pkwy

Campbell, CA 95008

T: +1 408 402 0802

https://support.tigoenergy.com/

1. Turn ON the BAT-switch in the Inverter connections wirebox (8).

2. If multiple batteries installed, turn on the BAT-Expansion breaker in the Battery expansion wirebox (12). Otherwise, skip this step.

3. Turn on the inverter, while waiting 10 seconds for the inverter to send the wake-up signal observe the LED indicator of the battery enclosure. Conrm the

battery system enters the discharge state (center leaf is lit).

4. The battery storage system has been successfully started.

To force start or shutdown the EI Battery:

1. Using a Philips screwdriver, remove the screws from the cover of

the forced start power button (6).

2. Press and hold the button for 10 seconds until:

1. OFF: The center leaf changes from green to red and begins

ashing quickly (0.1s on/off)

2. ON: The center leaf begins ashing green (0.1s on/off).

3. After the forced start/shutdown is successful, reinstall the cover.

8. Forced start/shutdown

4. Connecting the inverter

Note – This section corresponds to section 3.7 and 4.2 in the EI Inverter Quick Start Guide.

Reference that document by scanning the QR code.

!CAUTION – Risk of electric shock! Ensure the inverter and battery cabinet are completely powered off when these

steps take place. Make sure to connect the battery inverter first and then connect the communications cable to the

inverter.

1 2

3

4

1. Loosen the two captive screws of the battery enclosure’s inverter connection wirebox (8).

2. Remove the two waterproof knockouts (5), (7) at the bottom of the left side of the enclosure. Connect two conduits from the battery

enclosure to the inverter. Use appropriate water-tight ttings.

3. Prepare two conductors, 10-8AWG with wire ferrules and route through the conduit.

4. Verify the BAT-switch is in the OFF position, and connect the conductors as follows:

1. Insert the battery conductors into the terminals of BAT+ and BAT- (EI Inverter Quick Start Guide 3.7).

2. Insert the RJ45-CAT5/6 communications cable into the INV terminal (EI Inverter Quick Start Guide 4.2).

5. Once complete, replace the wirebox covers and the enclosure cover by reversing the steps of section 2.4

50A ATS

EI Automatic Transfer Switch (ATS)

2. Installation

1. General Information

3. Electrical connections

Conductor Schedule

Conductor Quantity Type Size

Grid 2

Min. 90°C rated, insulated, copper, solid or

stranded (not ne stranded)

L1, L2: 10-6AWG

Inv Backup 2 L1, L2: 10-6AWG

Load 3 L1, L2, N: 10-6AWG

Load EGC 1

Min. 90°C rated, insulated or bare, copper, solid

or stranded (not ne stranded) EGC: 6AWGGrid EGC 1

Inv backup EGC 1

Quick Start Guide - TSS-50-US

Pg 1 of 2

1. This document is for quick guidance only. For details, please refer to the Energy Intelligence (EI) ATS Installation & Operations Manual.

2. Damage caused by failure to follow the contents of the EI ATS Installation & Operations Manual is not covered by the warranty.

3. Before installing the system, check that the package contents are intact and complete against the packing list. If any damage is found or any component

is missing, contact your dealer.

1.4 EI ATS Overview

1. Mounting bracket

2. 1 1/4" knockout

3. Front door

4. Door locks

5. 1 1/4" knockout

6. 1” backup load knockout

7. 1” inverter knockout

8. 1” grid knockout

3 4 5 6 7 81 2

!ATTENTION – READ FIRST

!CAUTION – Use tools with insulated handles. Always wear

appropriate PPE.

!CAUTION - Use appropriate hardware

for the mounting surface

1.1 Package Contents

2.1 Mounting

1.2 Required Tools

3.1 Wire schedule/preparation

1.3 AC wiring diagram

Item Quantity

TSS-50-US ATS 1 Box

Quick Start Guide 1 Box

Sleeve anchors 3 Bag

Mounting screws 2 Bag

O-type terminal 3 Bag

Wire ferrules 8 Bag

Keys 2 Bag

Mounting bracket 1 Box

Item

Wire cutter/crimp tool

Screwdriver

Rubber mallet/hammer

Drill

Level

1. Reserve at least 12” on all sides of the ATS.

2. Use a level and the mounting bracket (1) to

mark the mounting holes. Drill out mounting

holes to 1.6” (40mm) depth.

3. Place the sleeve anchor in each hole, tap with

the mallet/hammer. Place mounting bracket

aligned with the anchors exposed through the

screw holes and use the 3 mounting screws to

attach to the wall.

4. Conrm bracket is level and screws are tight

then lift ATS on to the mounting bracket.

5. To open the door, insert key into top lock, turn

90° counterclockwise, then repeat on bottom

lock.

!CAUTION - Check that all Disconnect switches are OFF before wiring. For personal safety, do not operate with electricity and

always wear appropriate PPE.

1. To prepare the AC conductors (L1, L2, N), use the wire cutters to strip 15mm of insulation from one side of the conductor and crimp the wire ferrule to the

end of the conductor.

2. To prepare the ground conductors, strip 7mm of insulation (if using insulated conductors) from one side of the conductor and crimp the O-type terminal to

the end.

1 2

3

45

≥12”

≥12”

≥12”

≥12”

NG

Inv Grid Inv

L1 L1 L2 L2

Backup

Panel

L1 N L2

ATS

Input

Inv Grid Inv

L1 L1 L2 L2

Backup

Panel

L1 N L2

ATS

Input

EI Inverter

ATS

L2 L1

ACGrid

L1 N L2

EGC

EI Inverter

ATS

L2 L1

ACGrid

L1 N L2

EGC

CT L1 CT L2

+

ACGrid

L1 N L2

EnergyMeter

-+ -

CT L1 CT L2

+

ACGrid

L1 N L2

EnergyMeter

-+ -

N

G

Grid

Meter

Grid

Meter

BackupPanel

Main Panel

Ver. Oct. 25, 2021

PN: 002-00086-00

Tigo Energy, Inc.

655 Campbell Technology Pkwy

Campbell, CA 95008

T: +1 408 402 0802

https://support.tigoenergy.com/

7. Your Customer Service Contact

5. Commissioning

After completing the Pre-power checklist, close the cover.

If the battery, inverter, backup load panel installations are already complete, the system may now be turned on for operation. Follow the EI Inverter’s

Commissioning instructions (Section 6) to commission the system.

Keep the instruction manual and keys nearby.

EI Automatic Transfer Switch (ATS)

Quick Start Guide - TSS-50-US

Pg2 of 2

4. Pre-power checklist

Check Item Acceptance Criteria

ATS installation The ATS is installed correctly, securely and reliably.

Conduit/Cable layout Conduit/cables and conductors are routed properly, and as requested by the customer.

Cable connections The AC output conductors, DC input conductors, and communications cables are labeled and connected correctly and securely.

Cable ties Cable ties are secured evenly with no sharp protrusions.

Grounding Ground conductors are connected correctly, securely and reliably.

Conduit connections All conduit attachments are sealed and bonded, when necessary.

Unused conduit openings Any unused conduit openings are tted with waterproof caps or left unopened.

Disconnect switches All external disconnect switches connecting to the ATS are in the OFF position.

Wirebox cleanliness The wirebox is left clean and tidy.

Installation environment An appropriate installation space had been chosen and the environment is left clean and accessible.

Issue Check

In grid-on operation the ATS does not

switch over when there is loss of grid.

1. Turn OFF the EI Inverter and the grid.

2. Open the ATS door and check the grid and INV conductors are properly connected to the correct terminals.

3. If issues persist, please contact Tigo Customer Service team.

Backup load panel has no power.

1. Turn OFF the EI Inverter and the grid.

2. Open the ATS door and check the control line, the INV and BACKUP conductors are properly connected to the correct

terminals.

3. If issues persist, please contact Tigo Customer Service team.

!CAUTION – For personal safety always wear appropriate PPE.

6. Troubleshooting

!

CAUTION - Two control lines are terminated to positions

3 and 5 of the contactor. These are necessary for the

operation of the ATS. DO NOT REMOVE.

3.2 Inverter connections

1. Use the screwdriver to loosen screws in positions R2 and R8 at the

contactor’s INV inputs.

2. Insert L1 and L2 of the INV backup conductors into the INV input

terminals of R2 and R8.

3. Tighten to 2.5Nm.

4. Use the screwdriver to secure the inverter-backup EGC to the

grounding bus bar.

Note – Refer to section 3.4 Backup output connections in the EI

Inverter quick start guide for the connection of these conductors

in the inverter.

3.3 Grid connections

1. Use the screwdriver to loosen screws in positions 4and 6at the

contactor’s GRID inputs.

2. Insert L1 and L2 of the GRID conductors into the GRID input

terminals of 4and 6.

3. Tighten to 2.5Nm.

4. Use screwdriver to secure the GRID EGC to the grounding bus bar.

Note – The opposite end of the GRID conductors is fed from the

main service panel by a 50A circuit breaker.

3.4 Backup connections

1. Use the screwdriver to loosen the three screws on the BACKUP

terminals.

2. Insert L1, L2, and N of the BACKUP load conductors into the L1,L2,

and N BACKUP terminals.

3. Tighten to 3.5Nm.

4. Use screwdriver to secure the BACKUP EGC to the grounding bus

bar.

Note – The opposite end of the BACKUP load conductors feed

the subpanel dedicated to backup loads.

IN V

INV

IN V

IN V

200A ATS v1

EI Automatic Transfer Switch (ATS)

2. Installation

1. General Information

3. Electrical connections

Conductor Schedule

Conductor Qty Type Size

Grid 4

Min. 90°C rated, insulated

(or bare-EGC conductors),

copper, solid or stranded

(not ne stranded)

L1, L2, N: 4-4/0 AWG,

EGC: 6-1/0 AWG

Load 4 L1, L2, N: 1/0-4/0 AWG,

EGC: 6-1/0 AWG

Inverter 4 L1, L2, N: 8-6 AWG,

EGC: 8 AWG

Communications 1 RS485 shielded, twisted

pair (2-wire) 24 AWG

Quick Start Guide - TSS-200-US

Pg 1 of 3

1. This document is for quick guidance only. For details, please refer to the Energy Intelligence (EI) ATS Installation & Operations Manual.

2. Damage caused by failure to follow the contents of the EI ATS Installation & Operations Manual is not covered by the warranty.

3. Before installing the system, check that the package contents are intact and complete against the packing list. If any damage is found or any component

is missing, contact your dealer.

1.4 EI ATS Enclosure Overview

1. Status display

2. 1¼" Inverter knockouts

3. 2½" Load knockout

4. 2½" Grid knockout

5. 1¼" Communication knockout

6. 1¼" unassigned knockout

7. 1¼" Generator knockouts

8. Heat sink

!

!

ATTENTION – READ FIRST

!CAUTION – Use tools with insulated handles. Always wear appropriate PPE.

Although the Tigo ATS comes with

mounting hardware, use the appropriate

hardware for the mounting surface.

1.1 Package Contents

2.1 Mounting & opening the ATS

1.2 Required Tools

3.1 Electrical connections overview & conductor schedule

1.3 System wiring diagram

Item Quantity

TSS-200-US ATS 1

Mounting bracket 1

Quick Start Guide 1

Sleeve anchors 2

M6 Mounting screws 2

M5 Security screws 2

3-pin Connector 1

6-pin Connector 1

Item Use

Wire cutter/crimp tool Wiring the ATS

Philips Screwdriver Wiring terminals

Rubber mallet/hammer Mounting

Drill Mounting

Level Mounting

2.5mm-8mm Allen keys Cover/Security Bracket/Wire Terminals

1. Reserve at least 12” on all sides of the ATS. Install

vertically or tilted back no more than 15 degrees.

2. Use a level and the mounting bracket to mark the

mounting holes.

3. Drill out mounting holes to 1.7” (45mm) depth.

4. Place the sleeve anchor in each hole, tap with the mallet/

hammer. Place mounting bracket aligned with the anchors

exposed through the screw holes and use the mounting

screws to attach to the wall.

5. Conrm bracket is level and screws are tight then lift ATS

on to the mounting bracket.

6. Insert security screws into each side of the bracket,

fastening the bracket to the ATS with a 4mm Allen key.

7. Remove the caps covering the Allen head screws on the

front cover. Using an 5mm Allen key, loosen the Allen

screws and remove the cover.

!CAUTION - Check that all Disconnect switches are OFF before wiring. For personal safety, do not operate with electricity and

always wear appropriate PPE.

1 3

-

4

5 6

ATS

Communications

Key

Power

Main Panel

EI Battery EI Battery

Whole Home

Load

EI Inverter

TS4 MLPE

TAP

(TS4-A-O

systems only)

C

O

M

G

E

N

E

R

A

T

O

R

I

N

V

3

I

N

V

3

I

N

V

1

LOAD GRID

1

2

5 6 7

3 4

8

2 2

Inverter

communications

terminals

Grid terminal

L1 L1L2 L2

Load terminals

Neutral terminals

Ground terminals

Inverter

terminals

Neutral

terminals

Note – (3) additional 2½” knockouts

available on back (2) and side (1)

1. Run appropriately sized conduit from the inverter to an Inv knockout (2).

Use appropriate conduit ttings to ensure a water-tight seal. Route the

appropriate conductors from the inverter to the ATS.

2. Strip 10mm of insulation from the end of the Neutral and EGC of the

Inverter conductors. Insert into the Neutral and Ground busbars

respectively. Torque to 16.6ft-lbs (22.5 Nm).

3. Strip 10mm of insulation from the end of L1 and L2 of the Inverter

conductors. Insert into the Inverter’s breaker terminals. Torque to 1.5ft-lbs

(2 Nm).

!Do not wire until COMMUNICATIONS have been

completed.

3.5 Inverter power connections

EI Automatic Transfer Switch (ATS)

Quick Start Guide - TSS-200-US

Pg 2 of 3

3.2 Grid connections

3.3 Load connections

1. Run appropriately sized conduit to the Load knockout (3). Use

appropriate conduit ttings to ensure a water-tight seal and run the

Grid conductors.

2. Strip 10mm of insulation from the end of the Neutral and Ground

conductors and terminate at the neutral and ground bus bars with

16.6ft-lbs (22.5Nm).

3. Strip 10mm of insulation from the end of the L1 and L2 Load

conductors and terminate at the Load Terminals with 16.6ft-lbs

(22.5Nm).

Note – This connection feeds all power sources to the main load

panel to the home.

!

Check that the Grid disconnects/breakers, if

present, are in the OFF position before wiring the

ATS.

!The COMMUNICATIONS cable must be connected before

the INVERTER power connections.

3.4 Inverter communications connections

1. Run appropriately sized conduit from the inverter to the Com knockout (5).

Use appropriate conduit ttings to ensure a water-tight seal. Route the

RS485 cable from the inverter to the ATS.

2. The top 6-pin connector in the ATS is used for inverter communications.

Only the center two pins are used. Connect the wires to positions 3and 4

at the ATS.

3. At the inverter, the RS485 cable connects to the 3-pin connector above the

DC inputs. Only pins 1and 3are used. Ensure pin 1at the inverter is

connected to pin 3at the ATS and pin 3at the inverter is connected to pin

4at the ATS.

1. Run appropriately sized conduit to the Grid knockout (4). Use

appropriate conduit ttings to ensure a water-tight seal and run the

Grid conductors.

2. Strip 10mm of insulation from the end of the Neutral and Ground

conductors and terminate at the neutral and ground bus bars with

16.6ft-lbs (22.5Nm).

3. Strip 10mm of insulation from the end of the L1 and L2 Grid

conductors and terminate at the Grid Terminals with 16.6ft-lbs

(22.5Nm).

Note – This connection feeds power to the ATS from the utility

grid. Direct connection to utility feeders or a line side may

require coordination with the local utility company.

11

1

2

3

4

5

6

2 3

CN8

Tigo Energy, Inc.

655 Campbell Technology Pkwy

Campbell, CA 95008

T: +1 408 402 0802

https://support.tigoenergy.com/

8. Your Customer Service Contact

Ver. 1 Apr. 15 2022

PN: 002-00094-00

6. Commissioning

!CAUTION – For personal safety always wear appropriate PPE.

If the battery, inverter, and grid installations/connections are complete, the system may now be turned on for operation.

1. Turn on the battery DC switch.

2. Turn on the PV DC Disconnect switch at the bottom of the inverter. Release the RSD button. If inverter does not turn on, press and hold the push button

from left of the battery to force start the inverter. Note – Inverter error light will be ashing red due to no grid is detected.

3. Turn on the inverter circuit breaker inside ATS.

4. Turn on the AC Disconnect from the grid.

5. Download our App and start commissioning process.

6. Note - The “battery” light on the ATS becomes solid green if the inverter sees the grid. If no error light on the inverter and ATS, proceed to step 7.

7. Close the ATS door and torque the Allen screws to 1.8ft-lbs (2.5Nm).

EI Automatic Transfer Switch (ATS)

Quick Start Guide - TSS-200-US

Pg 3 of 3

5. Pre-power checklist

Check Item Acceptance Criteria

ATS installation The ATS is installed correctly, securely and reliably.

Conduit/Cable layout Conduit/cables and conductors are routed properly, and as requested by the customer.

Cable connections The AC output conductors, DC input conductors, and communications cables are labeled and connected correctly and securely.

Grounding Ground conductors are connected correctly, securely and reliably.

Conduit connections All conduit attachments are sealed and bonded, when necessary.

Disconnect switches All external disconnect switches connecting to the ATS are in the OFF position.

Workmanship Cable ties are secured evenly, have no sharp edges, the wirebox and installation area are left clean and accessible.

4. LED Status

Symbol Function Color Status Action Description

Grid Green

ON N/A Grid power is ON

OFF N/A No Grid power

Communications Green

ON N/A Normal operation

OFF 0.5s on / 0.5s off Abnormal communications with the

inverter

System Status Green

ON N/A Normal operation (on-grid)

Flashing 1s on/off N/A Normal operation (off-grid)

Fault Red

ON 0.5s on / 0.5s off A Fault has occurred

OFF N/A Normal operation

Flashing 1s on/off 1s on / 3s off The connected loads are overloading

the available output power

Issue Check

In grid-on operation the ATS does not

switch over when there is loss of grid.

1. Turn OFF the EI Inverter and the grid.

2. Open the ATS door and check the grid and INV conductors are properly connected to the correct terminals.

3. If issues persist, please contact Tigo Customer Care team.

Load panel has no power.

1. Check the Status Display (1) for error codes and follow recommended steps if codes are active.

2. Check that the grid voltage is within 180-270V and frequency is 45-65Hz.

3. Check for communications error codes and miswiring.

4. If issues persist, please contact Tigo Customer Care team.

7. Troubleshooting

200A ATS v2

EI Automatic Transfer Switch (ATS)

2. Installation

1. General Information

3. Electrical connections

Conductor Schedule

Conductor Qty Type Size

Grid 4

Min. 90°C rated, insulated

(or bare-EGC conductors),

copper, solid or stranded

(not ne stranded)

L1, L2, N: 4-4/0 AWG,

EGC: 6-1/0 AWG

Load 4 L1, L2, N: 1/0-4/0 AWG,

EGC: 6-1/0 AWG

Inverter 4 L1, L2, N: 8-6 AWG,

EGC: 8 AWG

Communications 1 RS485 shielded, twisted

pair (2-wire) 24 AWG

Quick Start Guide - TSS-200-US

Pg 1 of 3

1. This document is for quick guidance only. For details, please refer to the Energy Intelligence (EI) ATS Installation & Operations Manual.

2. Damage caused by failure to follow the contents of the EI ATS Installation & Operations Manual is not covered by the warranty.

3. Before installing the system, check that the package contents are intact and complete against the packing list. If any damage is found or any component

is missing, contact your dealer.

1.4 EI ATS Enclosure Overview

1. Status display

2. 1¼" Inverter knockouts

3. 2½" Load knockout

4. 2½" Grid knockout

5. 1¼" Communication knockout

6. 1¼" unassigned knockout

7. 1¼" Generator knockouts

8. Heat sink

9. 200A Main Circuit breaker Access door

!

!

ATTENTION – READ FIRST

!CAUTION – Use tools with insulated handles. Always wear appropriate PPE.

Although the Tigo ATS comes with

mounting hardware, use the appropriate

hardware for the mounting surface.

1.1 Package Contents

2.1 Mounting & opening the ATS

1.2 Required Tools

3.1 Electrical connections overview & conductor schedule

1.3 System wiring diagram

Item Quantity

TSS-200-US ATS 1

Mounting bracket 1

Quick Start Guide 1

Sleeve anchors 2

M5 Security screws 2

M4 Phillips screw with washers 2

3pin wiring connector 2

6pin wiring connector 1

200A circuit breaker interlocking kit 1

Item Use

Wire cutter/crimp tool Wiring the ATS

Philips Screwdriver Wiring terminals

Rubber mallet/hammer Mounting

Drill Mounting

Level Mounting

2.5mm-8mm Allen keys Cover/Security Bracket/Wire Terminals

1. Reserve at least 12” on all sides of the ATS. Install

vertically or tilted back no more than 15 degrees.

2. Use a level and the mounting bracket to mark the

mounting holes.

3. Drill out mounting holes to 1.7” (45mm) depth.

4. Place the sleeve anchor in each hole, tap with the mallet/

hammer. Place mounting bracket aligned with the anchors

exposed through the screw holes and use the mounting

screws to attach to the wall.

5. Conrm bracket is level and screws are tight then lift ATS

on to the mounting bracket.

6. Insert security screws into each side of the bracket,

fastening the bracket to the ATS with a 4mm Allen key.

7. Remove the caps covering the Allen head screws on the

front cover. Using an 5mm Allen key, loosen the Allen

screws and remove the cover.

!CAUTION - Check that all Disconnect switches are OFF before wiring. For personal safety, do not operate with electricity and

always wear appropriate PPE.

1 3

-

4

5 6

C

O

M

G

E

N

E

R

A

T

O

R

I

N

V

3

I

N

V

3

I

N

V

1

LOAD GRID

1

2

5 6 7

3 4

8

2 2

9

Inverter

communications

terminals

200A Main Circuit Breaker

L1 L1L2 L2

Load terminals

Neutral terminals

Ground terminals

Inverter

terminals

Neutral

terminals

Note – (3) additional 2½” knockouts

available on back (2) and side (1)

PV Grid

NL2 L1 Grid

Meter

Grid

Meter

NG

Main Panel

Load

L2 L1

Grid

L2 L1N

G

Grid

G

Inverter

L1 L2 NG

PV1+ PV1-

…

PV4+ PV4- G N

200A

Breaker

Breaker

Battery

BAT+ BAT-

…

ATSEI Inverter

Refer to inverter manualfor

parallel dualbatteries

PV array

Generator

L1 L2 NG

Generator control is

developing. Expected be

ready in the next generation.

1. Run appropriately sized conduit from the inverter to an Inv knockout (2).

Use appropriate conduit ttings to ensure a water-tight seal. Route the

appropriate conductors from the inverter to the ATS.

2. Strip 10mm of insulation from the end of the Neutral and EGC of the

Inverter conductors. Insert into the Neutral and Ground busbars

respectively. Torque to 16.6ft-lbs (22.5 Nm).

3. Strip 10mm of insulation from the end of L1 and L2 of the Inverter

conductors. Insert into the Inverter’s breaker terminals. Torque to 1.5ft-lbs

(2 Nm).

!Do not wire until COMMUNICATIONS have been

completed.

3.5 Inverter power connections

EI Automatic Transfer Switch (ATS)

Quick Start Guide - TSS-200-US

Pg 2 of 3

3.2 Grid connections

3.3 Load connections

1. Run appropriately sized conduit to the Load knockout (3). Use

appropriate conduit ttings to ensure a water-tight seal and run the

Grid conductors.

2. Strip 10mm of insulation from the end of the Neutral and Ground

conductors and terminate at the neutral and ground bus bars with

16.6ft-lbs (22.5Nm).

3. Strip 10mm of insulation from the end of the L1 and L2 Load

conductors and terminate at the Load Terminals with 16.6ft-lbs

(22.5Nm).

Note – This connection feeds all power sources to the main load

panel to the home.

!

Check that the Grid disconnects/breakers, if

present, are in the OFF position before wiring the

ATS.

!The COMMUNICATIONS cable must be connected before

the INVERTER power connections.

3.4 Inverter communications connections

1. Run appropriately sized conduit from the inverter to the Com knockout (5).

Use appropriate conduit ttings to ensure a water-tight seal. Route the

RS485 cable from the inverter to the ATS.

2. The top 6-pin connector in the ATS is used for inverter communications.

Only the center two pins are used. Connect the wires to positions 3and 4

at the ATS.

3. At the inverter, the RS485 cable connects to the 3-pin connector above the

DC inputs. Only pins 1and 3are used. Ensure pin 1at the inverter is

connected to pin 3at the ATS and pin 3at the inverter is connected to pin

4at the ATS.

1. Run appropriately sized conduit to the Grid knockout (4). Use

appropriate conduit ttings to ensure a water-tight seal and run the

Grid conductors.

2. Strip 10mm of insulation from the end of the Neutral and Ground

conductors and terminate at the neutral and ground bus bars with

16.6ft-lbs (22.5Nm).

3. Strip 10mm of insulation from the end of the L1 and L2 Grid

conductors and terminate at the 200A Main Circuit with 16.6ft-lbs

(22.5Nm).

Note – This connection feeds power to the ATS from the utility

grid. Direct connection to utility feeders or a line side may

require coordination with the local utility company. Note – CTs are factory installed to monitor grid power.

A

1

2

3

4

5

6

G B

CN8

Tigo Energy, Inc.

655 Campbell Technology Pkwy

Campbell, CA 95008

T: +1 408 402 0802

https://support.tigoenergy.com/

8. Your Customer Service Contact

Sept. 9 2022

PN: 002-00094-00 REV 2.0

6. Commissioning

!CAUTION – For personal safety always wear appropriate PPE.

If the battery, inverter, and grid installations/connections are complete, the system may now be turned on for operation.

1. Turn on the battery DC switch.

2. Turn on the PV DC Disconnect switch at the bottom of the inverter. Release the RSD button. If inverter does not turn on, press and hold the push button

from left of the battery to force start the inverter. Note – Inverter error light will be ashing red due to no grid is detected.

3. Turn on the inverter circuit breaker inside ATS.

4. Turn the 200A main circuit breaker ON, and any other disconnect switch on the grid side.

5. Download our App and start commissioning process.

6. Note - The “battery” light on the ATS becomes solid green if the inverter sees the grid. If no error light on the inverter and ATS, proceed to step 7.

7. Close the ATS door and torque the Allen screws to 1.8ft-lbs (2.5Nm).

EI Automatic Transfer Switch (ATS)

Quick Start Guide - TSS-200-US

Pg 3 of 3

5. Pre-power checklist

Check Item Acceptance Criteria

ATS installation The ATS is installed correctly, securely and reliably.

Conduit/Cable layout Conduit/cables and conductors are routed properly, and as requested by the customer.

Cable connections The AC output conductors, DC input conductors, and communications cables are labeled and connected correctly and securely.

Grounding Ground conductors are connected correctly, securely and reliably.

Conduit connections All conduit attachments are sealed and bonded, when necessary.

Disconnect switches All external disconnect switches connecting to the ATS are in the OFF position.

Workmanship Cable ties are secured evenly, have no sharp edges, the wirebox and installation area are left clean and accessible.

4. LED Status

Symbol Function Color Status Action Description

Grid Green

ON N/A Grid power is ON

OFF N/A No Grid power

Communications Green

ON N/A Normal operation

OFF 0.5s on / 0.5s off Abnormal communications with the

inverter

System Status Green

ON N/A Normal operation (on-grid)

Flashing 1s on/off N/A Normal operation (off-grid)

Fault Red

ON 0.5s on / 0.5s off A Fault has occurred

OFF N/A Normal operation

Flashing 1s on/off 1s on / 3s off The connected loads are overloading

the available output power

Issue Check

In grid-on operation the ATS does not

switch over when there is loss of grid.

1. Turn OFF the EI Inverter and the grid.

2. Open the ATS door and check the grid and INV conductors are properly connected to the correct terminals.

3. If issues persist, please contact Tigo Customer Care team.

Load panel has no power.

1. Check the Status Display (1) for error codes and follow recommended steps if codes are active.

2. Check that the grid voltage is within 180-270V and frequency is 45-65Hz.

3. Check for communications error codes and miswiring.

4. If issues persist, please contact Tigo Customer Care team.

7. Troubleshooting

This manual suits for next models

1

Table of contents

Other Tigo Inverter manuals

Tigo

Tigo EI User manual

Tigo

Tigo ENERGY MODULE MAXIMIZER ES Series User guide

Tigo

Tigo TSS-3PS User manual

Tigo

Tigo EI Inverter User manual

Tigo

Tigo TSS-1PS User manual

Tigo

Tigo EI ATS 200A User manual

Tigo

Tigo TS4-F User manual

Tigo

Tigo TSI-6K3DTSI-10K3D User manual

Tigo

Tigo TS4-A-2F User manual

Tigo

Tigo EI User manual

Popular Inverter manuals by other brands

Hoymiles

Hoymiles HM-800 Quick installation guide

Fischer Panda

Fischer Panda 8000 user manual

Centech

Centech 60704 Owner's manual & safety instructions

SUNGOLD POWER

SUNGOLD POWER LFPV Series user manual

Delta

Delta M70A 260 Installation and operation manual

FRONIUS

FRONIUS CL Service manual and spare parts list