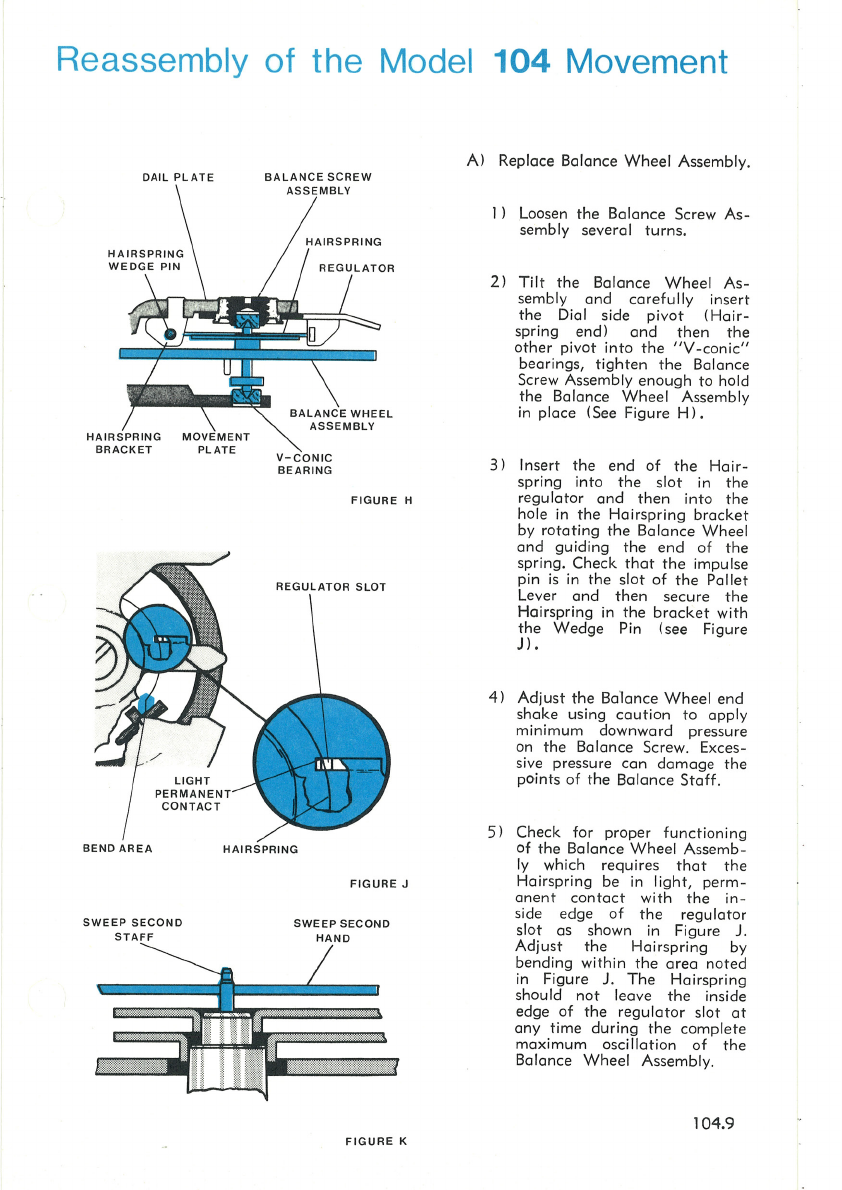

Timex 104 User manual

Other Timex Watch manuals

Timex

Timex W-139 User manual

Timex

Timex Performance Watch User manual

Timex

Timex IRONMAN R300 User manual

Timex

Timex W266 User manual

Timex

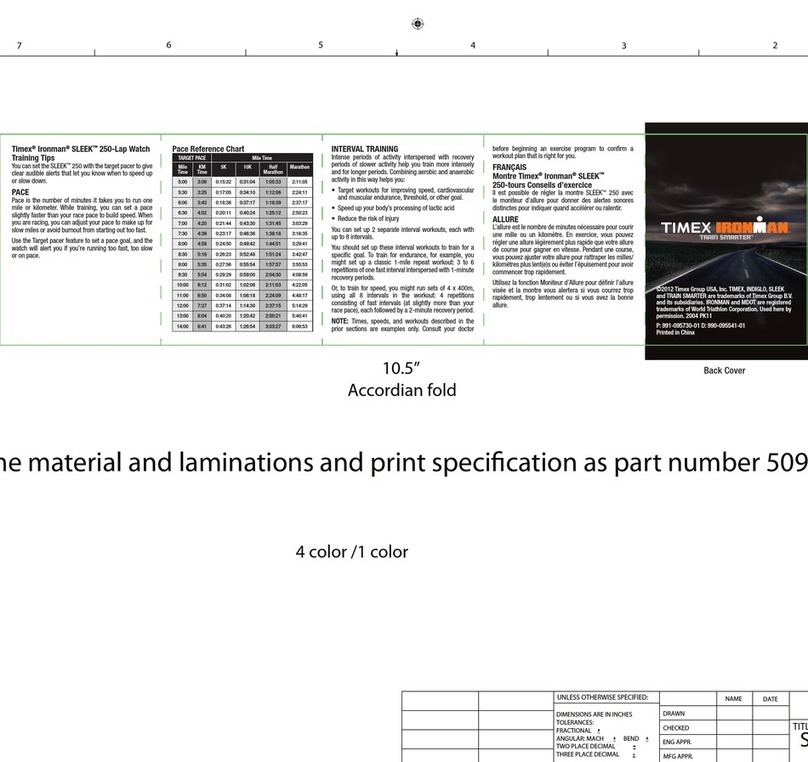

Timex Ironman SLEEK 250-LAP User manual

Timex

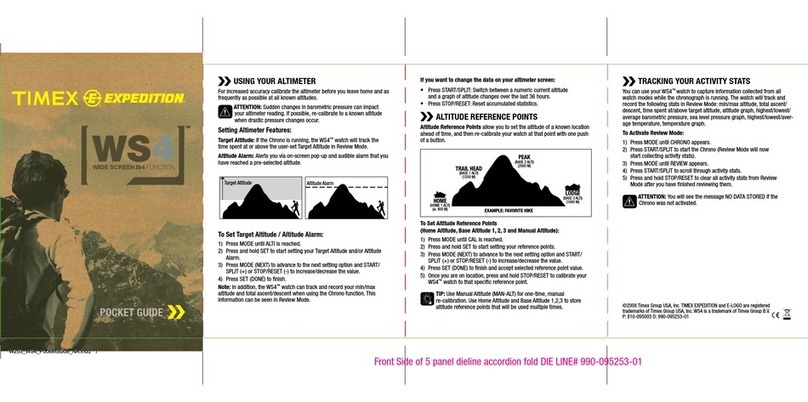

Timex Expedition WS4 User manual

Timex

Timex 222-0950012 User manual

Timex

Timex 106 User manual

Timex

Timex IronMan Run x50+ User manual

Timex

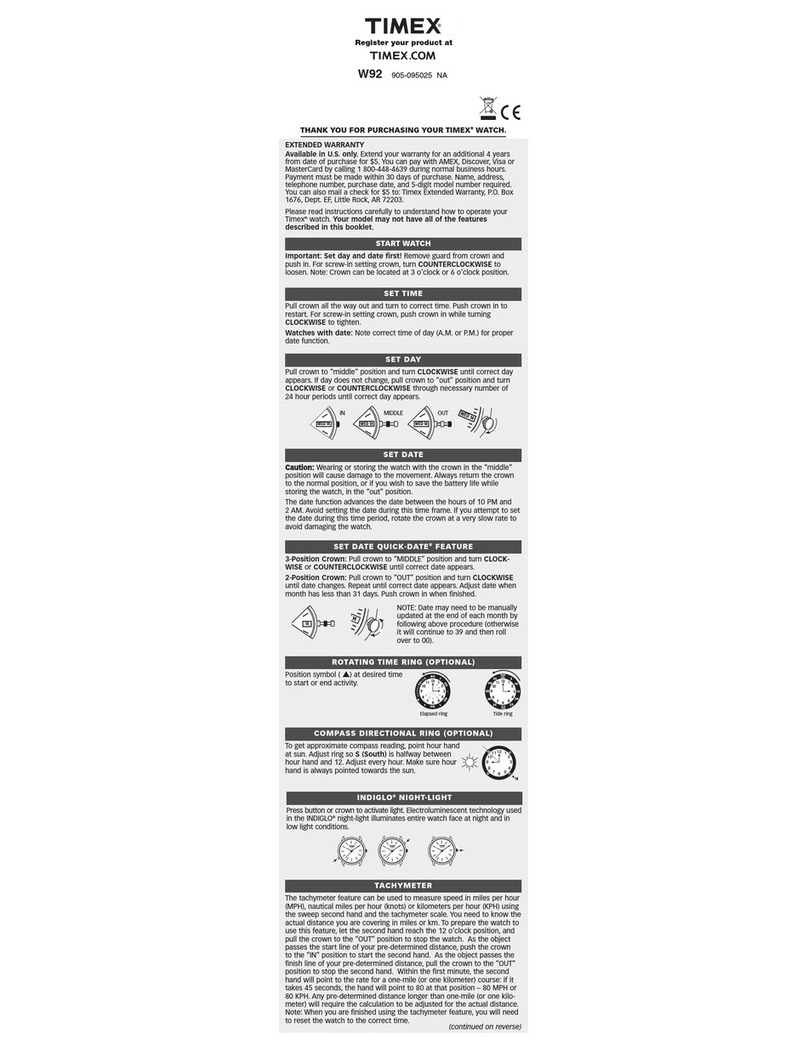

Timex W92 User manual

Timex

Timex IronMan Run x50+ User manual

Timex

Timex W-38 User manual

Timex

Timex Intelligent Quartz W273 User manual

Timex

Timex Expedition WS4 User manual

Timex

Timex INTELLIGENT QUARTZ User manual

Timex

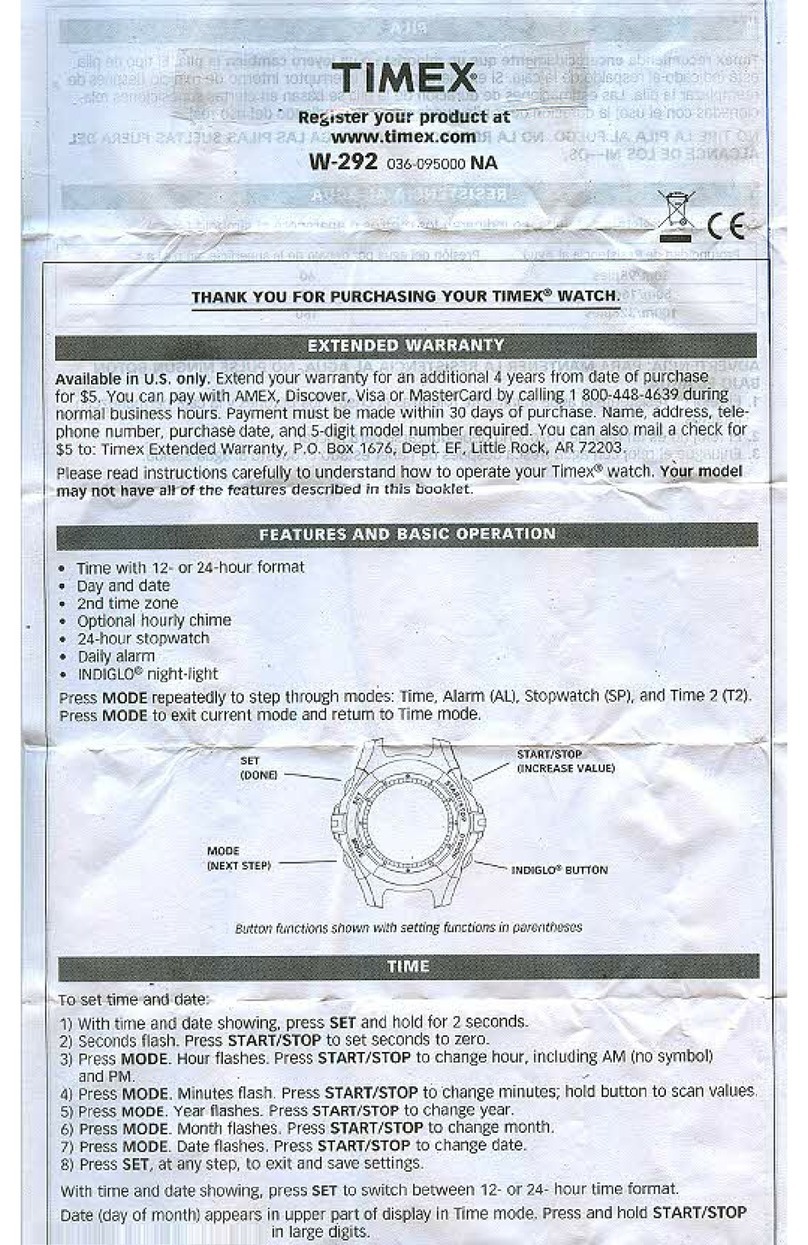

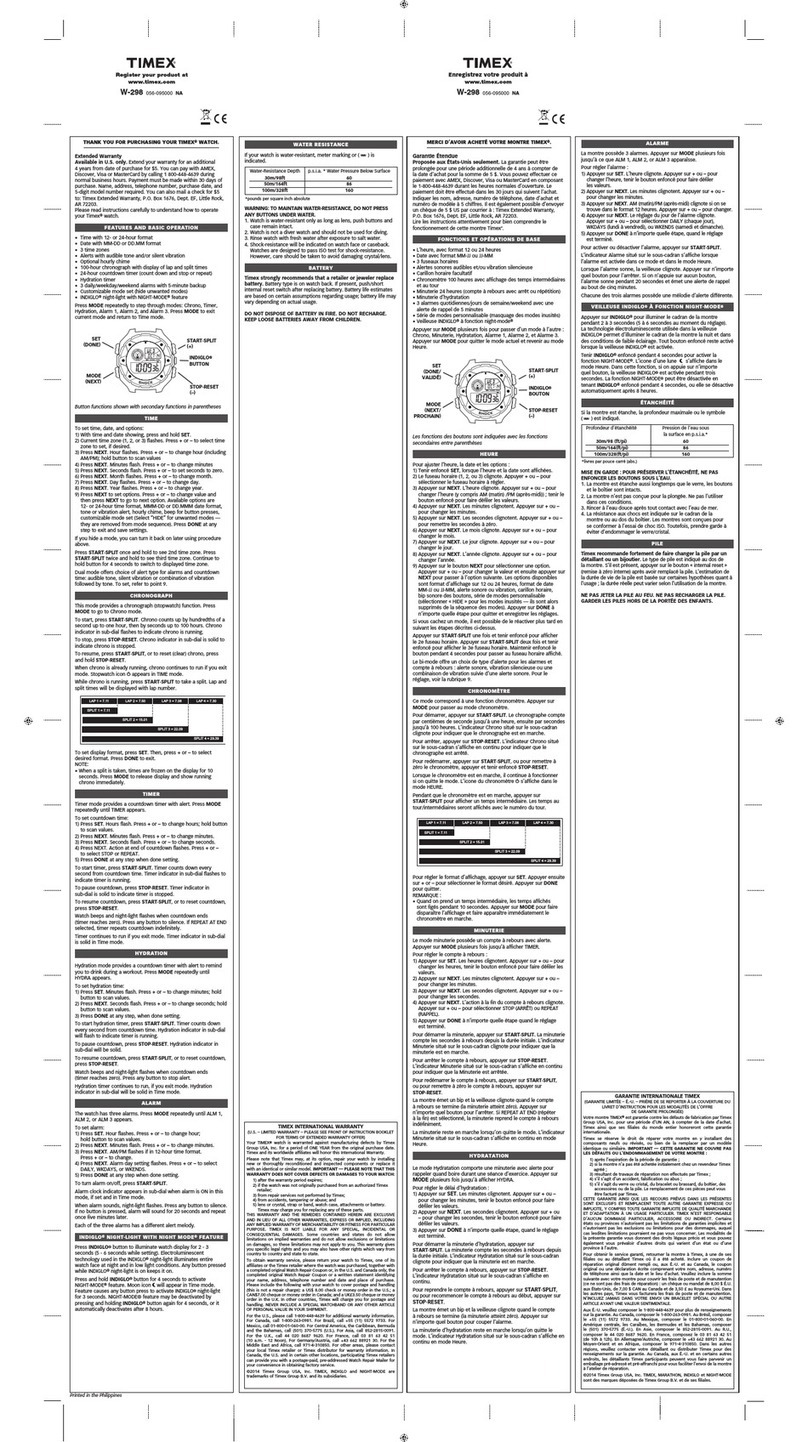

Timex W-292 User manual

Timex

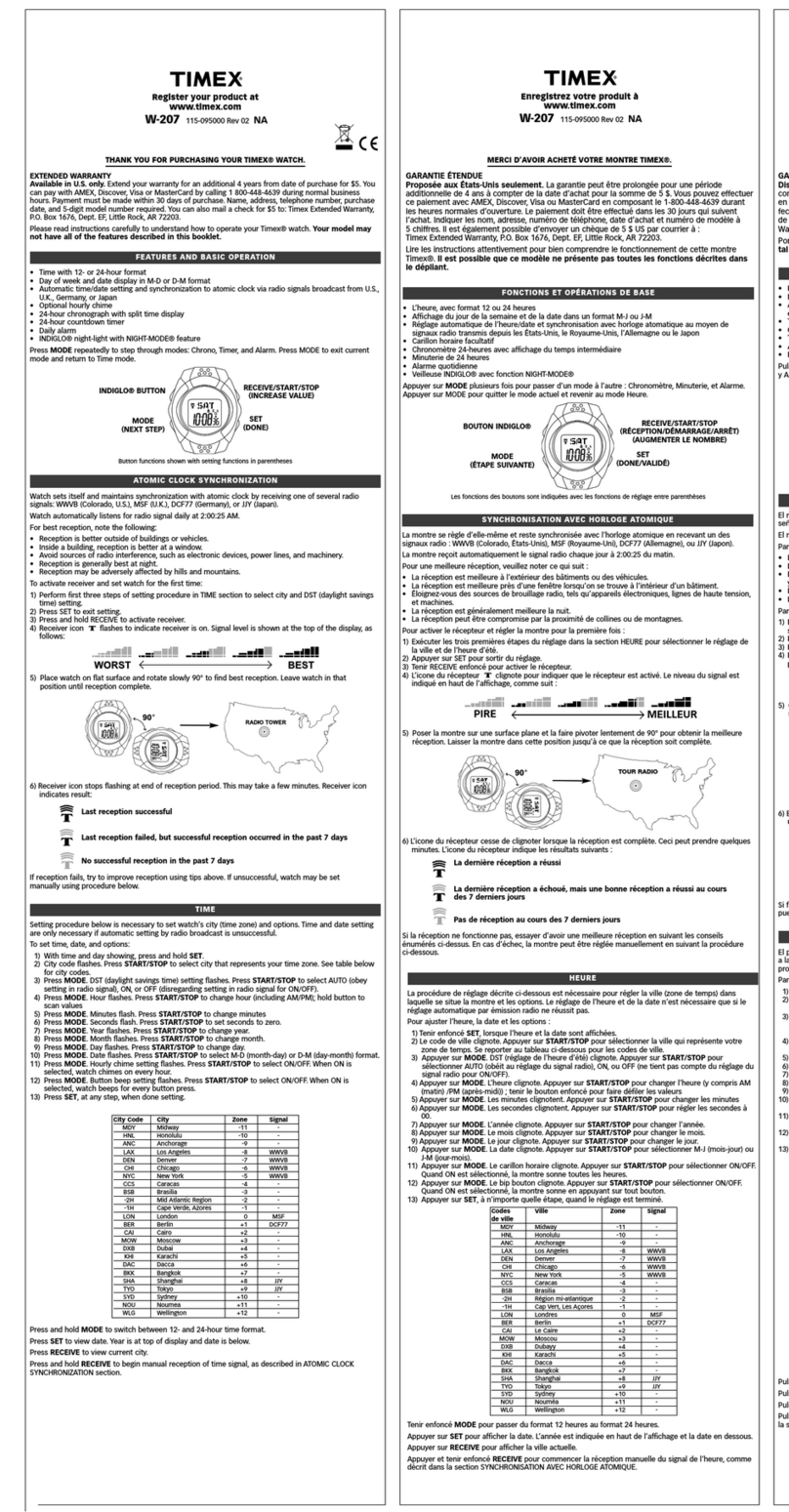

Timex W-207 User manual

Timex

Timex W-298 User manual

Timex

Timex Ironman SLEEK 250-LAP User manual

Timex

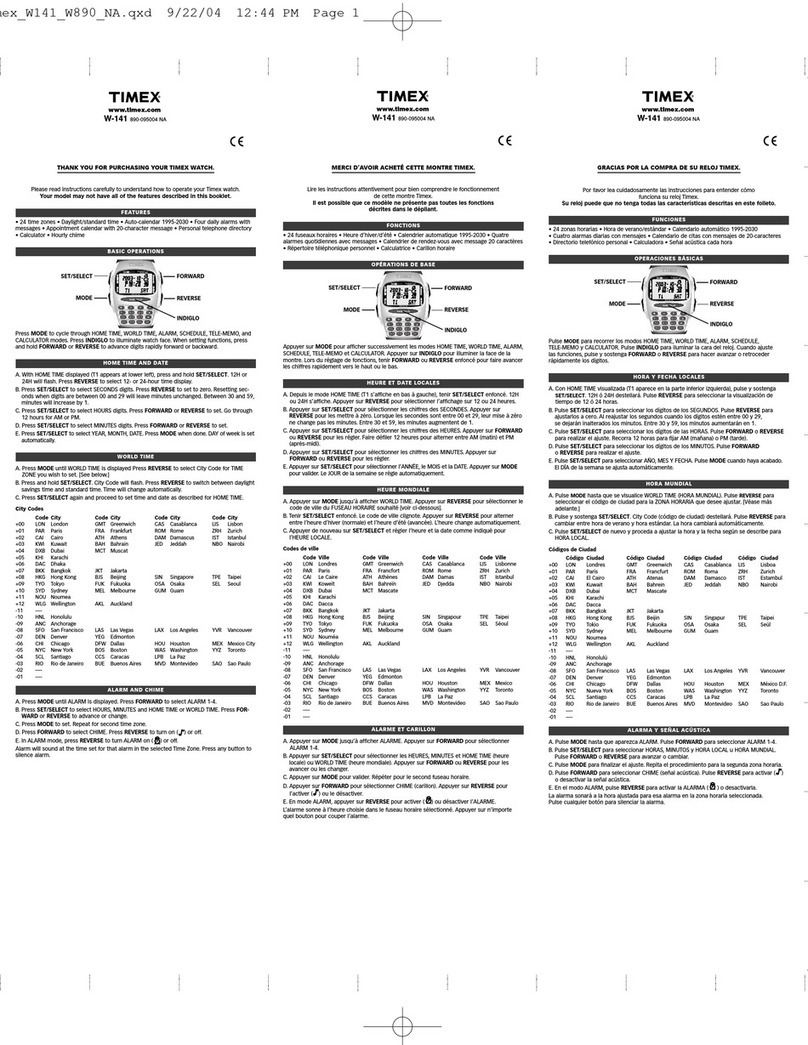

Timex W-141 User manual