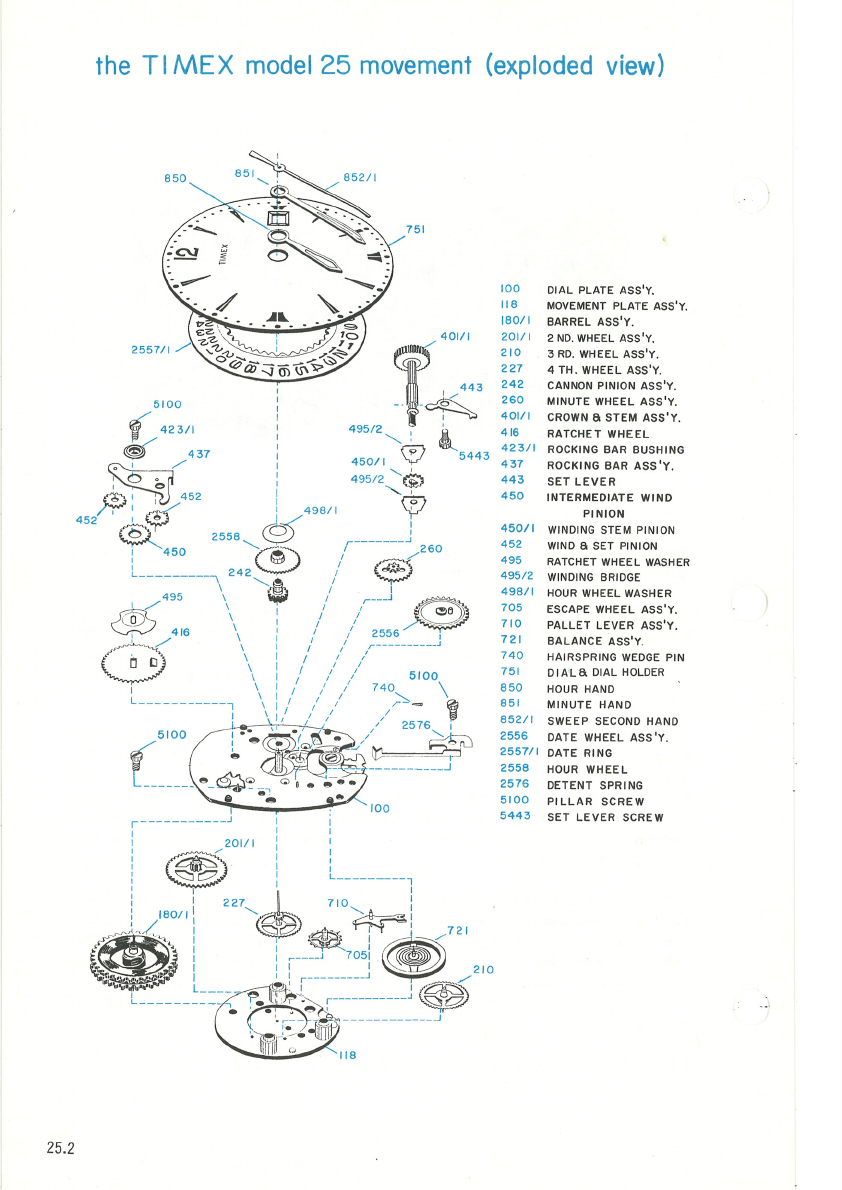

Timex 25 User manual

Other Timex Watch manuals

Timex

Timex W205 User manual

Timex

Timex Expedition User manual

Timex

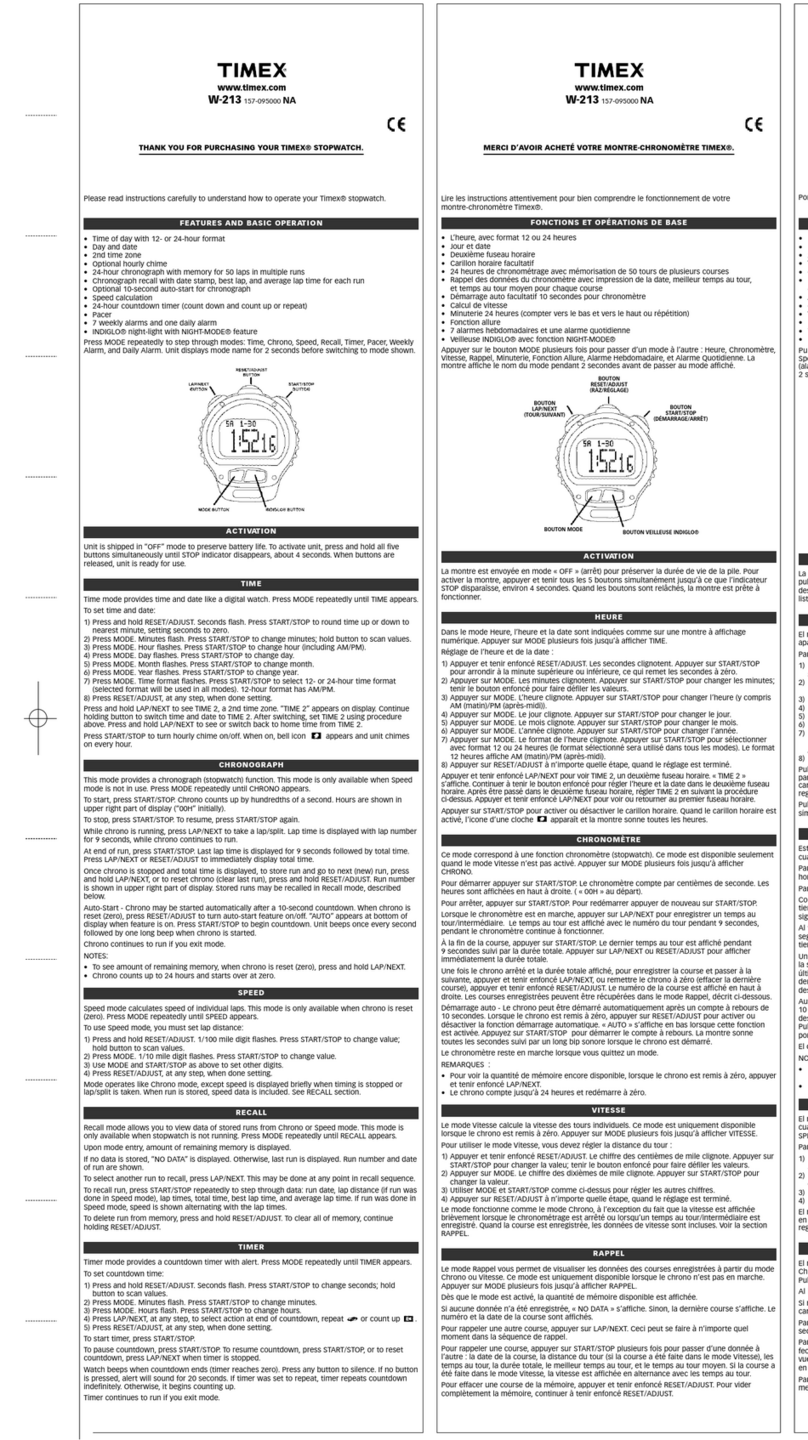

Timex 111-095009 User manual

Timex

Timex Ironman Data Link USB User manual

Timex

Timex INTELLIGENT QUARTZ User manual

Timex

Timex W-184 User manual

Timex

Timex Ironman SLEEK 250-LAP User manual

Timex

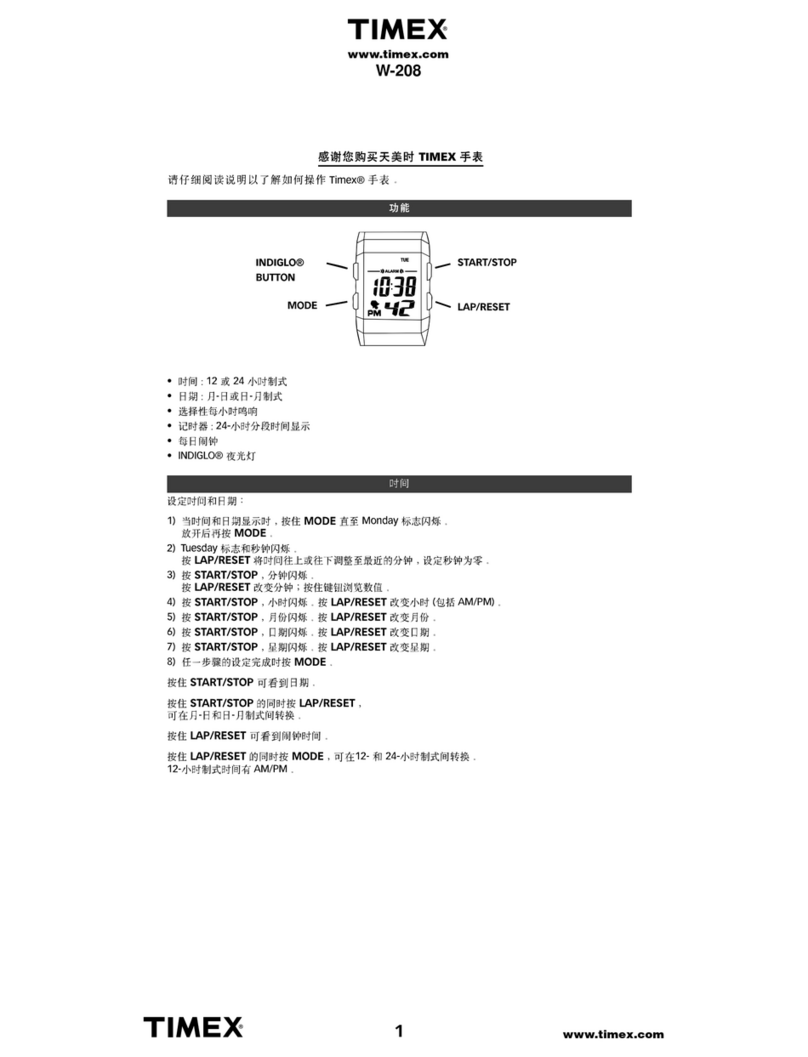

Timex W208 User manual

Timex

Timex Marathon User manual

Timex

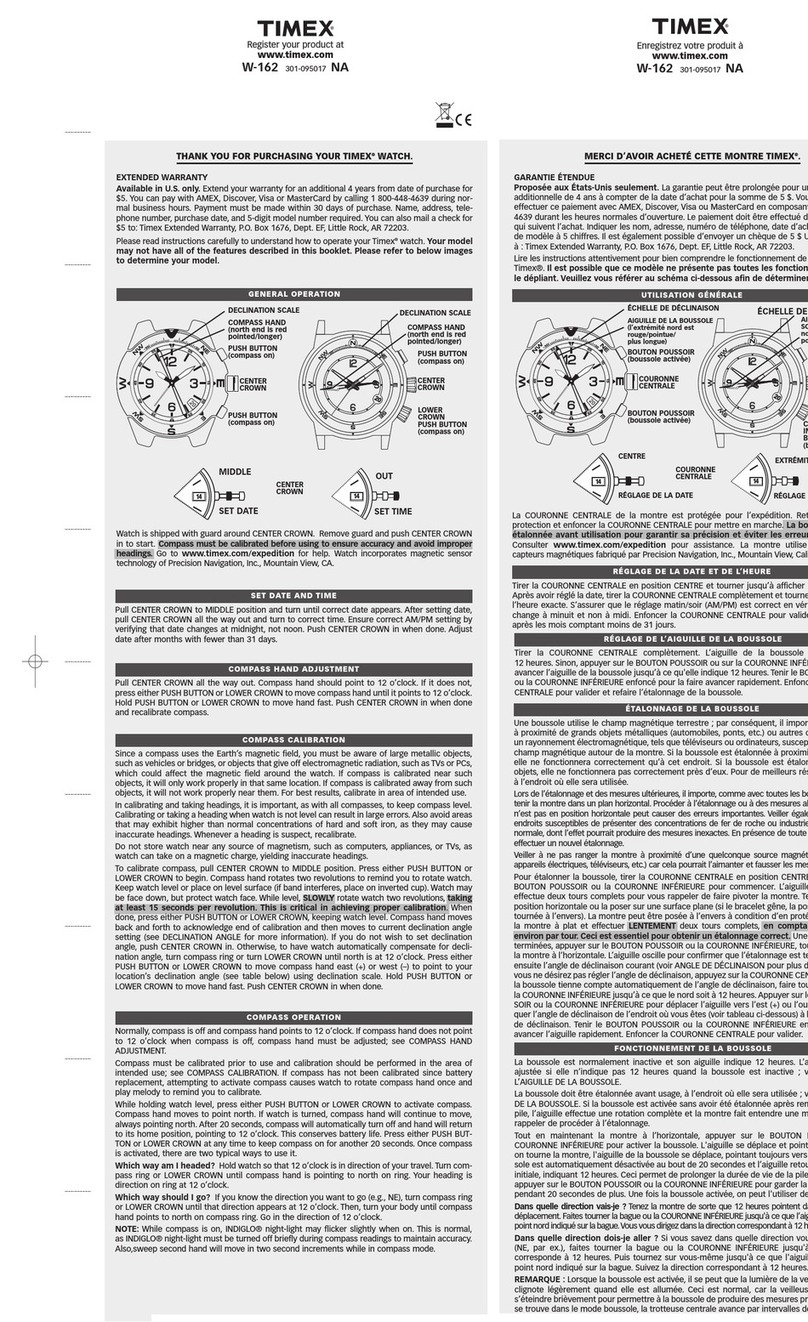

Timex W-162 User manual

Timex

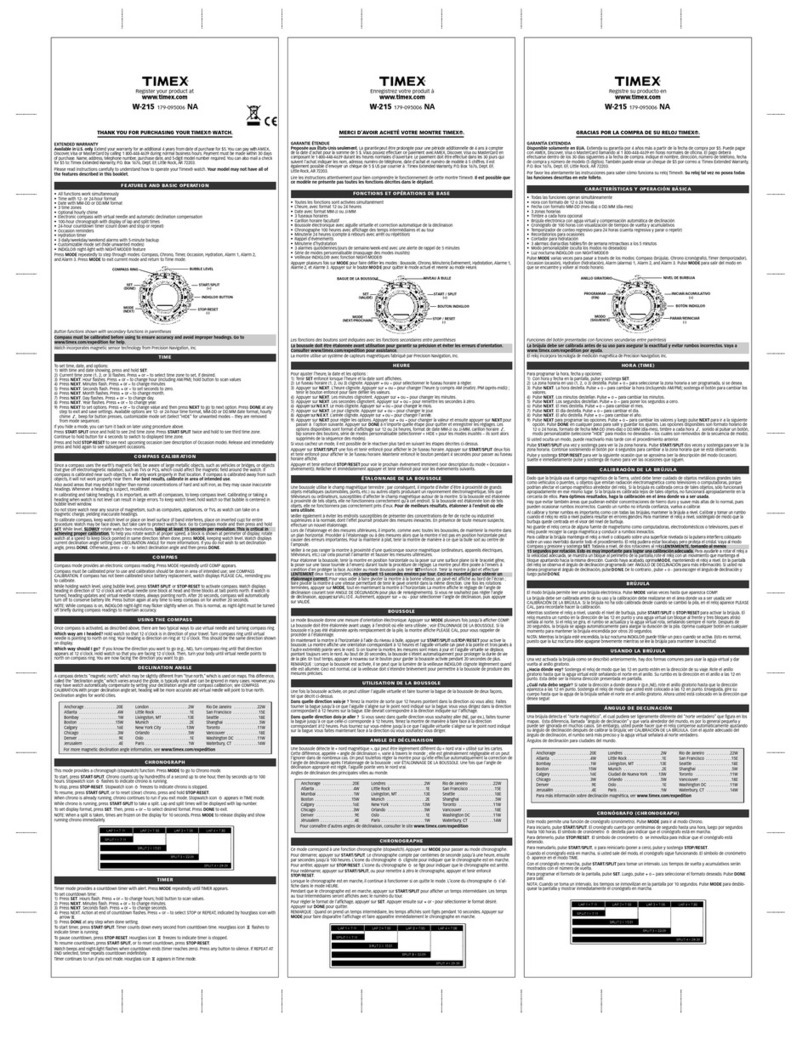

Timex W-215 User manual

Timex

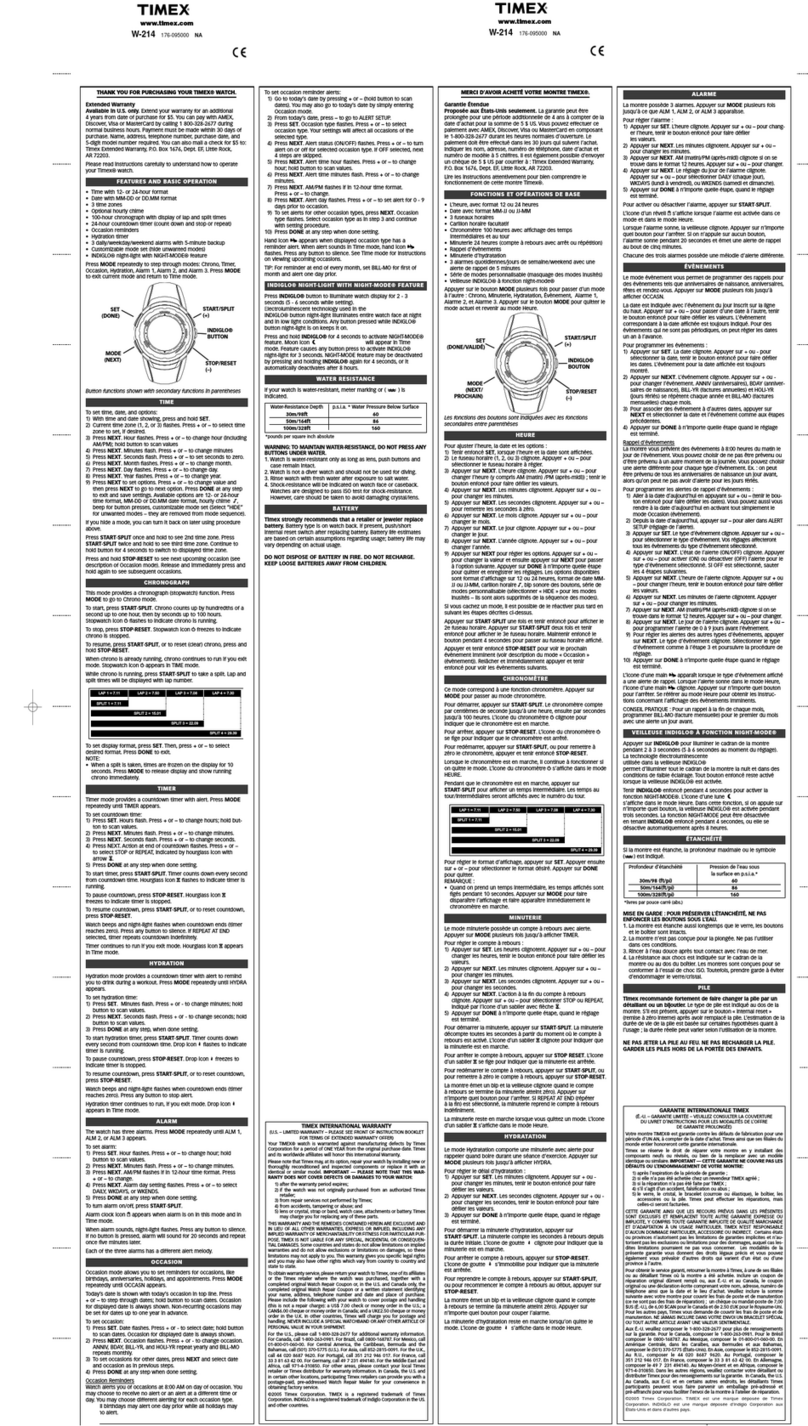

Timex 176-095000 NA User manual

Timex

Timex Ironman Run x20 GPS M062 User manual

Timex

Timex W-106 User manual

Timex

Timex 22 User manual

Timex

Timex IronMan Run x50+ User manual

Timex

Timex Performance Watch User manual

Timex

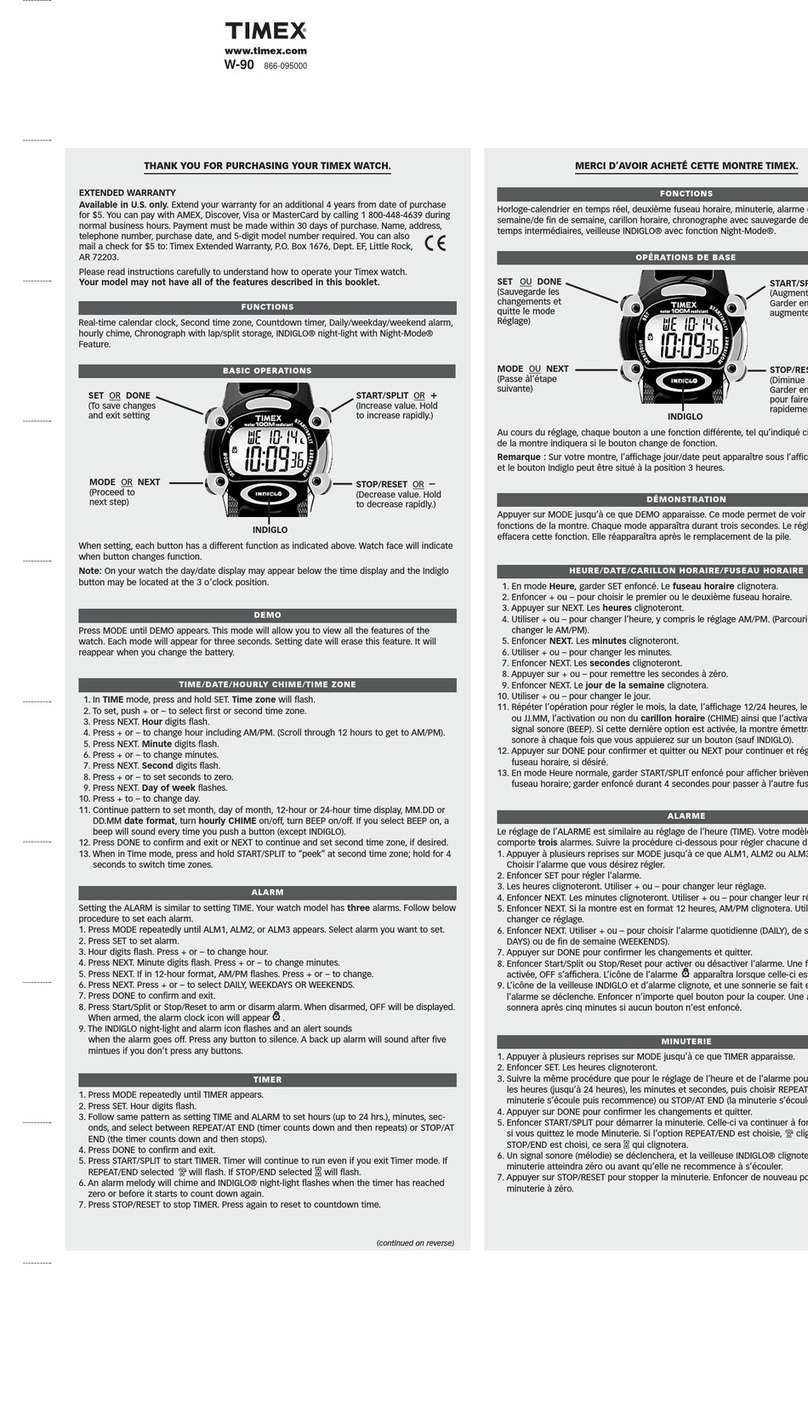

Timex W-90 User manual

Timex

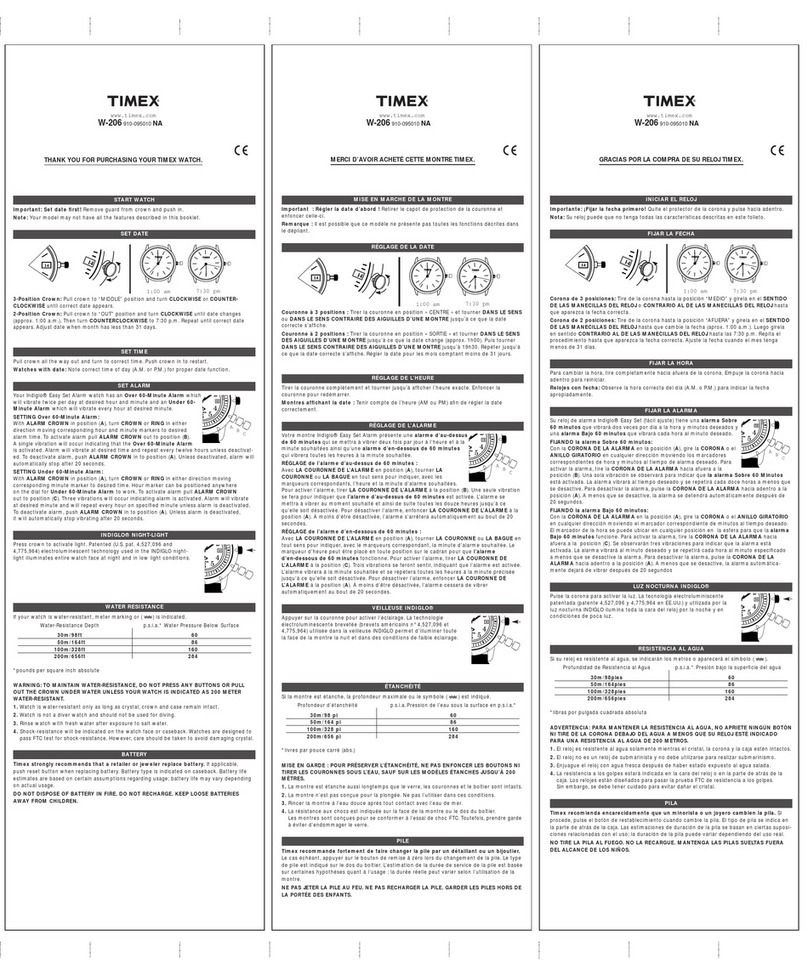

Timex W206 User manual

Timex

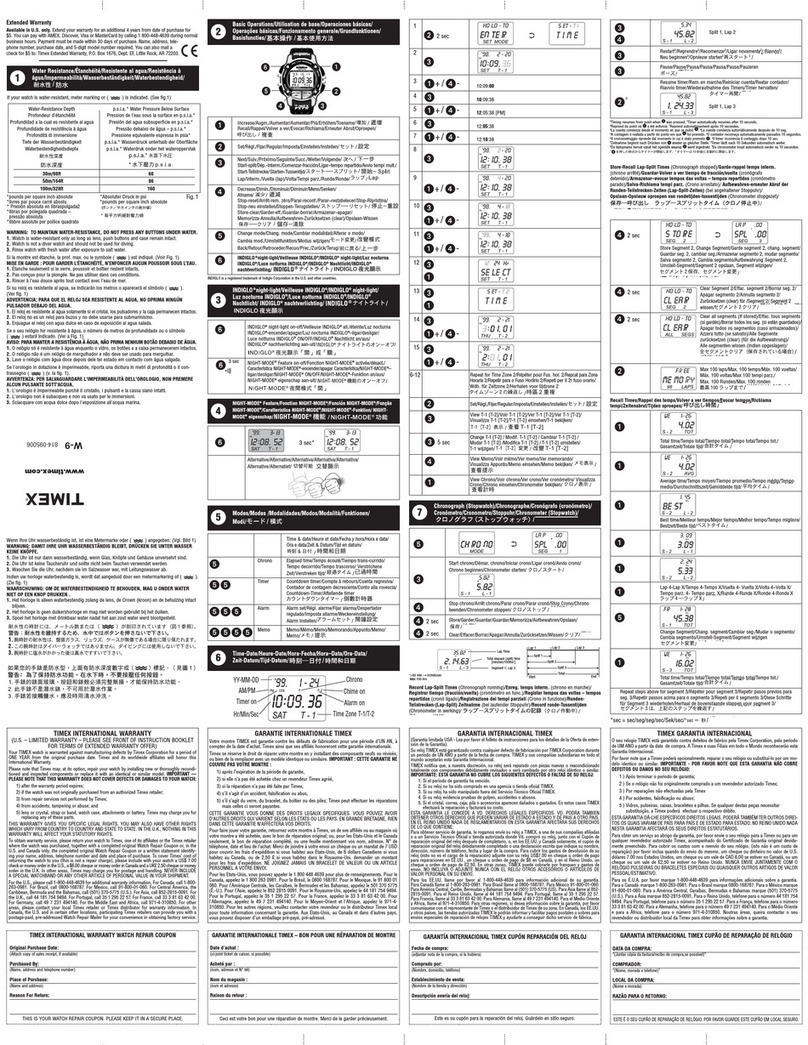

Timex 814-095006 User manual