PH: 330.273.6185 | Fax: 330.273.4468

Toll-Free Ph: 800.942.0829 | Toll-Free Fax: 800.942.0828

The Leader in Pedestrian Access Control

0220

1535 Industrial Parkway South

Brunswick, Ohio 44212

www.controlledaccess.com

Applications:

The Tiffany™ T80 Series is a three-vane turnstile

with a weather resistant nish and is ideal

for interior or exterior placement – whenever

style and durability are needed. It is crafted

from 6061 and 6063 aluminum extrusions

and features transparent scratch-resistant

polycarbonate yoke assemblies.

Product Features:

Materials & Finishes:

• Various 6061 & 6063 extruded aluminum

• 3/16" scratch-resistant polycarbonate

• Finish: Standard anodizing nish is clear. Also

available in dark bronze. Other colors can be

quoted upon request.

Assembly & Hardware:

• Major components pre-assembled with

concealed rods and spring pins

• Barrier and yokes secured with 3/4" rod

epoxied into concrete

• Rotor pivots on a sealed load runner bearing,

secured with high strength plastic coupling

anchored into concrete

• Minimum of 4” needed for removal of cover

Dimensions:

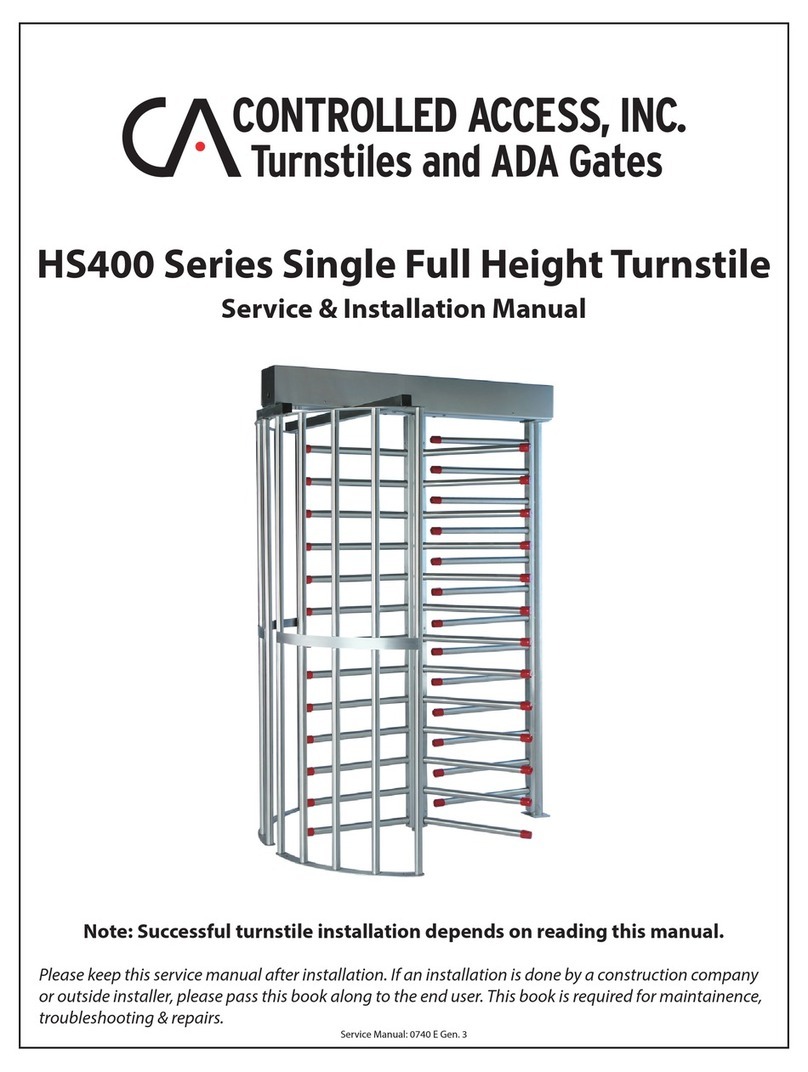

T80-S (Single)

•Ovaline Arms: 1/2" x 2" x 24"

•Exterior Height: 91" (2311.4mm)

•Interior Height: 84" (2133.6mm)

•Width: 66.250" (1682.7mm)

•Pedestrian Clearance: 27.750" (704.8mm)

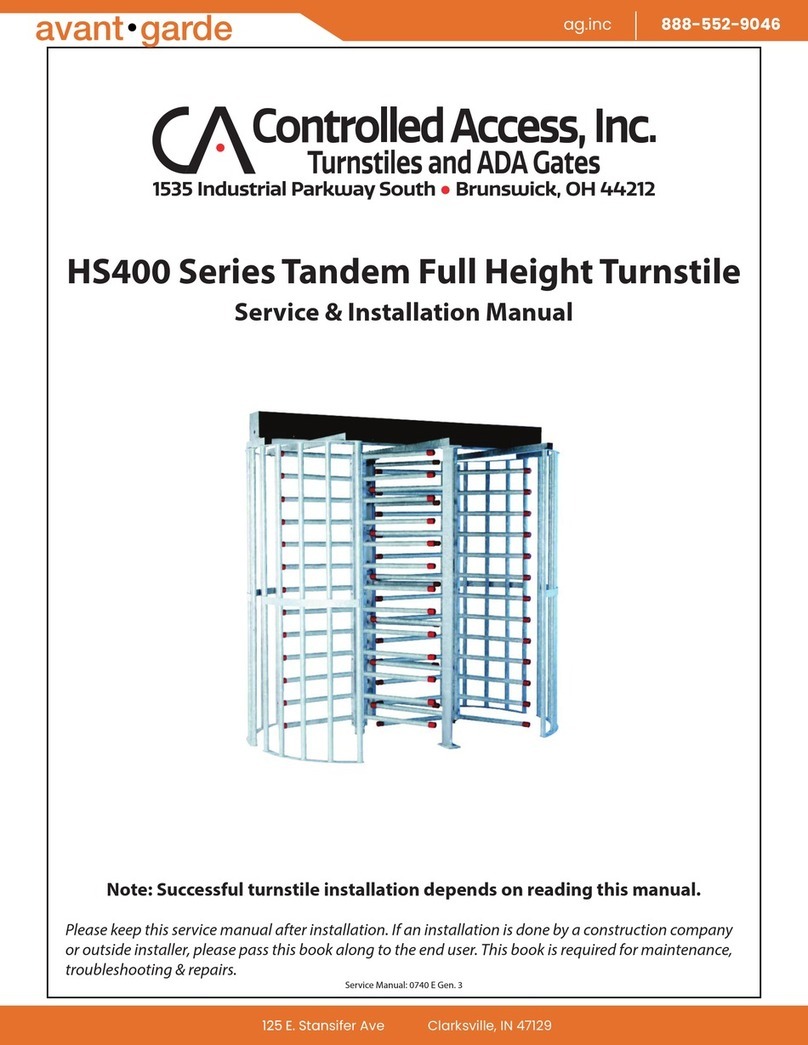

T80-T (Tandem)

•Ovaline Arms: 1/2" x 2" x 24"

•Exterior Height: 91" (2311.4mm)

•Interior Height: 84" (2133.6mm)

•Width: 96.250" (2444.7mm)

•Pedestrian Clearance: 27.750" (704.8mm)

Operation Features

6500 Series Control Head:

• Auto-indexing (self-centering) with adjustable

hydraulic shock suppression

• Hardened tool steel locking bars, cam and

roller assemblies

• Permanently lubricated bearings

• Your choice of manual or electronic control on

both directions

• Nearly universal integration to any number of

access control systems

• Your choice on each electronic direction of

locking or unlocking on power failure

Options:

• Card reader mounting plates

• Daylight visible indicator lights

• Bi-directional key overrides

• 8 digit key resettable LCD counter with seven

year lithium battery

• Metal detection portal

• Cold weather package, including thermostat

controlled heater and insulated mainframe

• Additional options available upon request

* Dimensions are approximate

Warranty:

Units are warranted against

defects in materials and

workmanship for a period of

one year from date of delivery.

See warranty information for

specic details.

Electrical Specications:

Input Voltage: 100-240 VAC

Input Current: 1.3 - .55 A

Frequency: 50/60 Hz

Storage Temperature: -40 to 158°F

Operating Temperature: -4 to 131°F

Operating Voltage: 24VDC

Operating Current: 1.2 A (typical)

The 6500 Series Control Head

is certified to conform to the

following standards:

UL 294, UL 325, UL Subject 2593,

CAN/ULC S319 & CSA C22.2#247

4008027

The Tiffany™ T80 Series T80-S | T80-T

Full-Height Turnstile |Interior & Exterior Application

T80-T

Controlled Access, Inc. is certified

by Advantage International Registrar

to be an ISO 9001:2015 company

* Dimensions are subject to change without notice

T80-S