9

RL20-2 / Manual

Titgemeyer / 10342EN1121 / 1

English

10. Proper Use

To ensure that all the corresponding

safety measures are observed and that

the riveting tool will work properly, the

following is required:

— The system has to be used in compli-

ance with the tool’s technical data and

specications concerning the use, as-

sembly, connection, environment and

work conditions. These conditions are

stipulated in the documents related to

the order, user information (tags etc.)

and in the documentation delivered

with the system, which includes the

operating instructions, as well as the

maintenance and inspection instruc-

tions in this manual.

— The users have to act in compliance

with local and system-specic condi-

tions and pay corresponding attention

to the operating hazards and speci-

cations.

— All measures required for the main-

tenance of the tool, e.g. transport and

storage, as well as the requirements

for maintenance and regular inspec-

tion must be observed.

— Use only a safety quick coupler for

permanent connection to the com-

pressed air sources

— The mandrel collector must always

be emptied as soon as it exceeds half

load capacity

— Always set the riveting tool at the right

angle (90°) to the assembly surface

Compressed air supply

— For correct operation of the device,

it is necessary to observe the range

of inlet air pressure between the

minimum and maximum permissible

value of 6 – 7 bar. If necessary an

appropriate pressure reduction valve

has to be used. In case of non-com-

pliance, personal injury or damage to

the device may occur.

— The pressure regulator must be equip-

ped with a lter unit for separating dirt

and condensation from the air supply.

In case the pressure regulator with a

lter unit will not be used, it must be

ensured that the compressed air cannot

contain dirt and condensation.

— The length between the air supply

pressure regulator and the tool must

not exceed 3m.

— Supply line must be resistant to oil,

liquids and operating conditions

— Air hoses must have a 6 mm minimum

inner diameter.

— Maximum force depend on compliance

of the inlet pressure

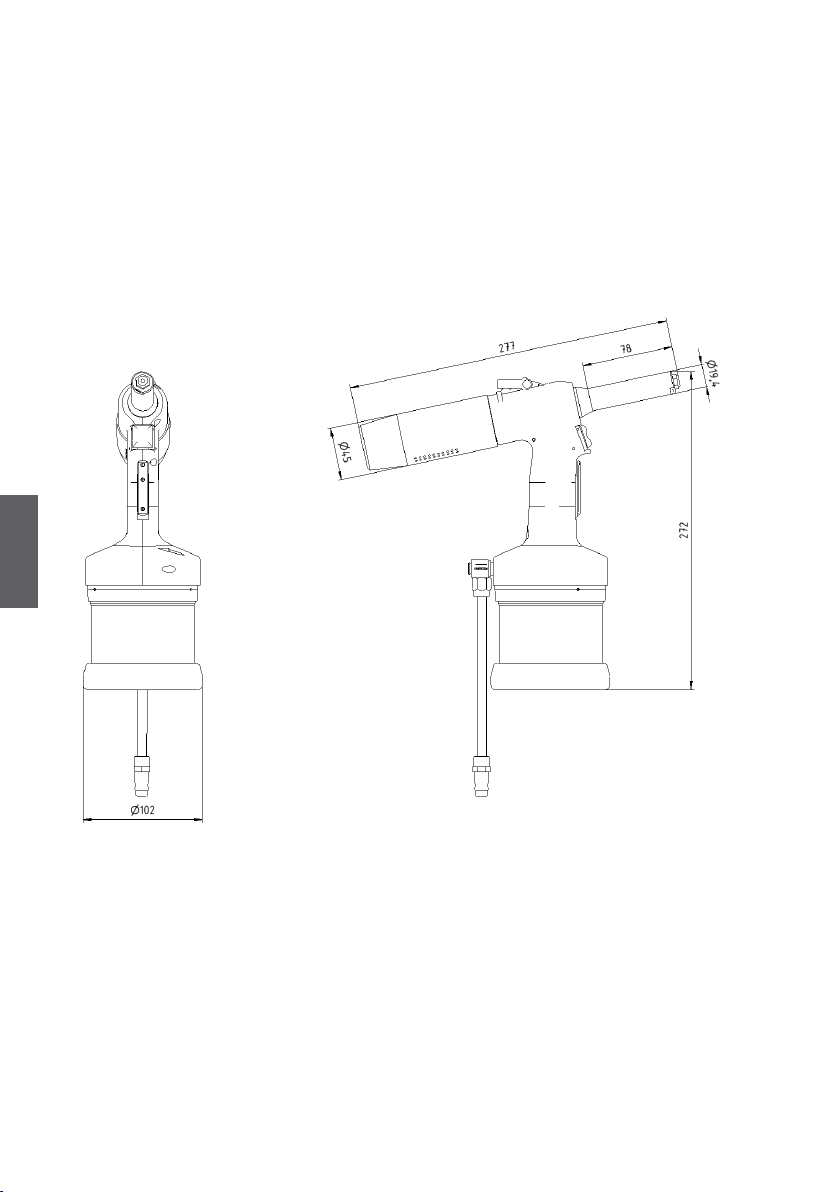

Perpendicular positio-

ning of the tool to the

surface

K= clamping thickness