TLV COSPECT M-COS-3 User manual

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 June 2015

Motorized Pressure Reducing Valve for Steam

COSPECT

M-COS-3 / M-COS-16 / M-COS-21

Copyright © 2015 by TLV CO., LTD.

All rights reserved

ISO 9001/ ISO 14001

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

1

Contents

Introduction ........................................................................ 1

Safety Considerations........................................................ 2

Specifications..................................................................... 4

Acceptable Operating Range............................................. 6

Correct Usage of the M-COS Motorized Pressure

Reducing Valve.................................................................. 7

Configuration...................................................................... 9

Installation........................................................................ 11

Controller Operation......................................................... 18

Maintenance..................................................................... 21

Disassembly..................................................................... 22

Reassembly ..................................................................... 31

Troubleshooting ............................................................... 32

Product Warranty ............................................................. 35

Introduction

Thank you for purchasing the M-COS motorized pressure reducing

valve for steam.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

The motorized pressure reducing valve for steam, model M-COS is a

high performance motor actuated remote type pressure reducing valve

adding a remote control function to the COS pressure reducing valve. It

can be easily adjusted by remote to supply dry saturated steam to the

process at the set pressure as needed without fluctuation, thus improving

steam use and contributing to the improvement of energy effeciency,

productivity and product quality..

If detailed instructions for special order specifications or options not

contained in this manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the

front cover. It is needed not only for installation, but also for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

2

Safety Considerations

•Read this section carefully before use and be sure to follow the instructions.

•Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

•The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

•The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment /

product damage

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

DO NOT use the product in excess of the maximum operating

pressure differential.

Such use could make discharge through the steam trap impossible

(blocked).

Use hoisting equipment for heavy objects (weighing

approximately 20 kg or more).

Failure to do so may result in back strain or other injury if the

object should fall.

Safety considerations are continued on the next page.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

3

CAUTION

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading

to fluid discharge, which may cause burns or other injury.

Make sure the power supply switch is OFF before carrying

out work on the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger

that equipment may malfunction or electric shock may occur,

leading to injury or other accidents.

Make sure that wiring work requiring a special license is

carried out by qualified personnel.

If carried out by unqualified personnel, overheating or short circuits

leading to injury, fires, damage or other accidents may occur.

When using this product, NEVER stand close to, or leave

tools anywhere near moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving

parts could lead to injury, damage or other accidents.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

4

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

DO NOT use the product in excess of the maximum operating pressure

differential; such use could make discharge impossible (blocked).

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

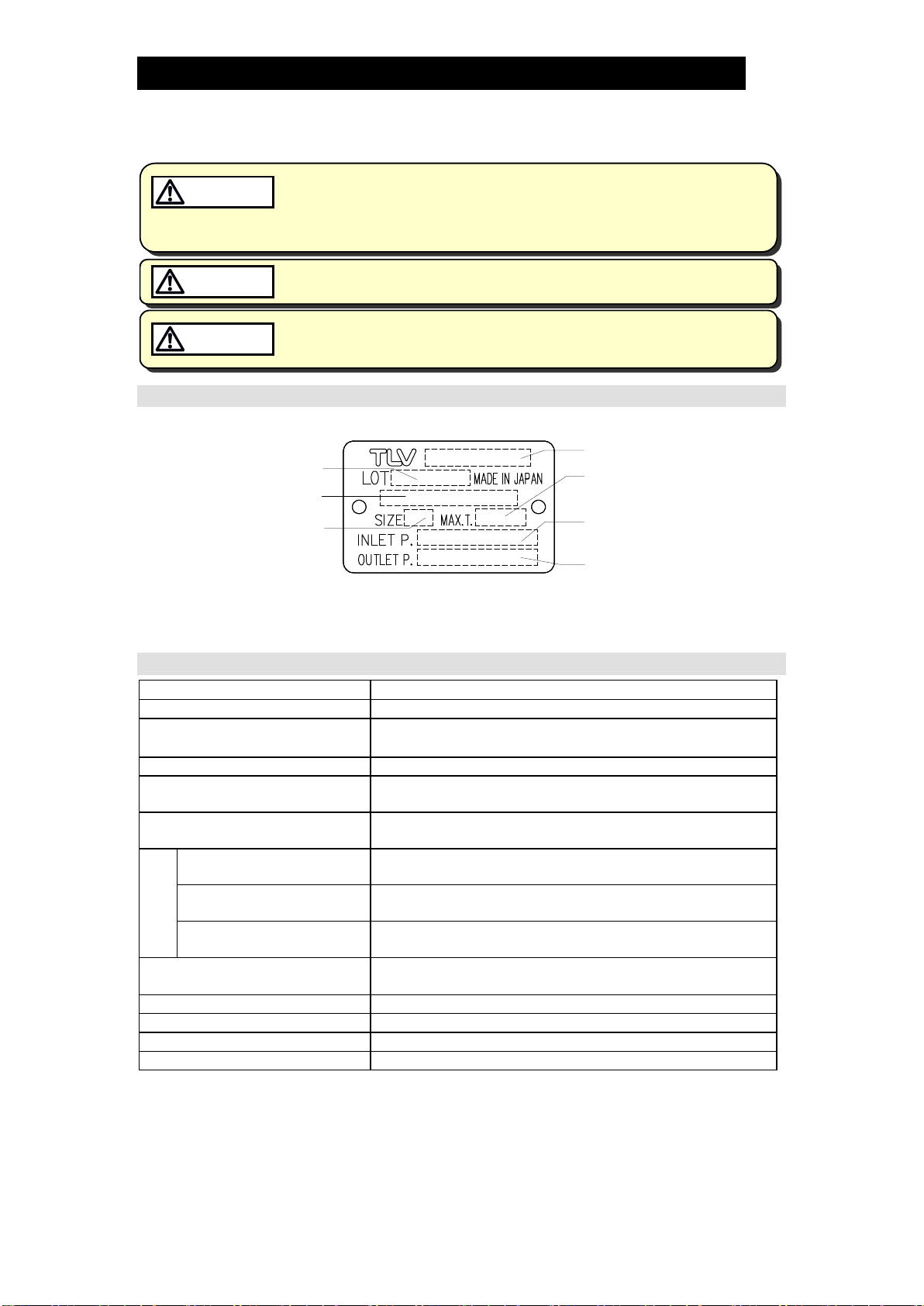

Valve

Refer to the product nameplate for detailed specifications.

Model

Nominal Diameter

Maximum Operating

Temperature

Valve No.*

Secondary Pressure

Adjustable Range

Primary Pressure

Range

Production Lot No.

* Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

Actuator

Model

M-COS-3 / M-COS-16 /M-COS-21

Drive System

ON/OFF control of reversible motor

Line Voltage

100/110 VAC

±

10% or 200/220 VAC

±

10% (50/60 H

Z

)

(Supplied from controller) (Single phase)

Power Consumption

Included in Controller

Withstand Voltage

Between power terminal and ground terminal:

1800 VAC (60 HZ) for 1 second

Insulation Resistance

Between power terminal and ground terminal:

Min. 100 MΩ(500 VDC)

Operating

Conditions

Ambient Temperature 0 – 60 °C

Water Resistance

JIS Rain-proof type

(Motor must not come into contact with dew)

Vibration Resistance Max. 0.5 G

Cable Heat Resistance

70 °C

(Cable must not come into contact directly with steam piping)

Thermal Protection

Motor with built-in 120 ºC thermal protector

Open/Close Time

Approx. 40 seconds

Continual Actuator Operation

Approx. 5 minutes maximum

Manual Operation

Possible

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

5

Controller

Model

MC-2

Pressure Display Function

Yes

(select between displays of measured pressure and

upper pressure)

Pressure Upper Limit Setting

Function

Setting is possible

Power Source Voltage

100/110 VAC

±

10% or 200/220 VAC

±

10% (50/60 HZ)

Power

Consumption

While motor is

stopped

7 VA

While motor is

in operation

(TYP.) 65 VA (MAX.) 75 VA

Withstand Voltage

Between power terminal and ground terminal:

1800 VAC (60 HZ) for 1 second

Insulation Resistance

Between ground terminal and each terminal:

Min. 100 MΩ(500 VDC)

Operating

Conditions

Ambient Temperature 0 –50 °C

Ambient Humidity 5 –90% RH (without dew, indoor use)

Vibration Resistance Max. 0.5 G

Dimensions (Unit: mm)

93 (W) ×184 (H) ×73 (D)

Weight

1.1 kg

Installation

Wall mounting (M5 screw x 4)

Material/Coating

Steel plate/black melamine

Pressure

Indication

Indication Range

0 –1999 kPaG

Indication Accuracy

±

0.5%F.S.

Pressure Sensor

Standard type

Allowable Pressure

Setting Range

0 – 1999 kPaG

Pressure Sensor

Standard type

Model

M-COS-3 M-COS-16

/

M-COS-21

Pressure Measurement Range

0– 0.5 MPaG (500 kPaG) type

0 – 2.0 MPaG type

0–0.5MPaG (500kPaG) type

*1

Signal Output

4 – 20 mADC (load resistance 250 Ω/15 VDC)

Measurement Accuracy

±

0.3%F.S.

Temperature Drift

±

0.02%F.S/°C

Maximum Allowable Pressure

2 times the maximum value of the measurement range

Ambient Temperature

−40 – +85 °C (Sensor must not come into contact with dew)

Water Resistance

JIS Rain-proof type

Material for Wetted Parts

AISI 316 / DIN W. No. 1.4401

Connection Thread

G(PF) 3/8

Weight

Approx. 400 g

Accessories

Siphon Tube

(connector screw for piping installation end: R(PT)

3

/8)

*1When the secondary pressure is 0.03 MPaG or less, choose a 0 –0.5 MPaG (500 kPaG)

type sensor

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

6

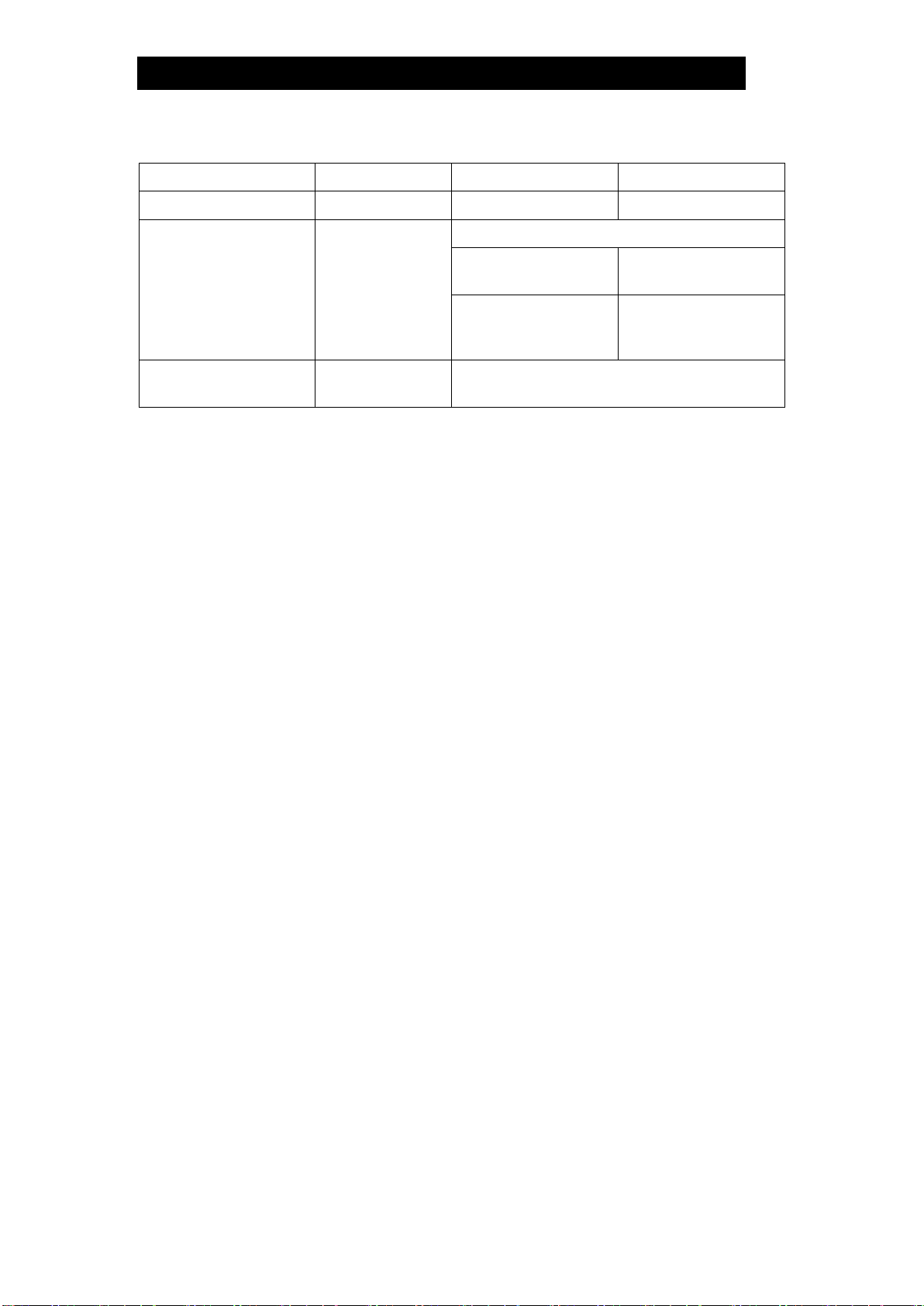

Acceptable Operating Range

Model

M-COS-3

M-COS-16

M-COS-21

Primary Pressure Range

0.1 – 0.3 MPaG

0.2 – 1.6 MPaG

1.35 – 2.1 MPaG

Secondary Pressure

Adjustable Pressure

Range

(All conditions must be

met)

0.01 – 0.05 MPaG

Within 10 –84% of the primary pressure

Minimum adjustable

pressure of 0.03 MPaG

Minimum adjustable

pressure of 0.55 MPaG

Pressure differential

between 0.07 – 0.85

MPa

Maximum pressure

differential of 0.85 MPa

Minimum Adjustable

Flow Rate

5% of rated flow

rate

5% of rated flow rate; 10% of rated flow rate for

sizes 65 mm – 100 mm

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

7

Correct Usage of the

M-COS

Motorized Pressure

Reducing Valve

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

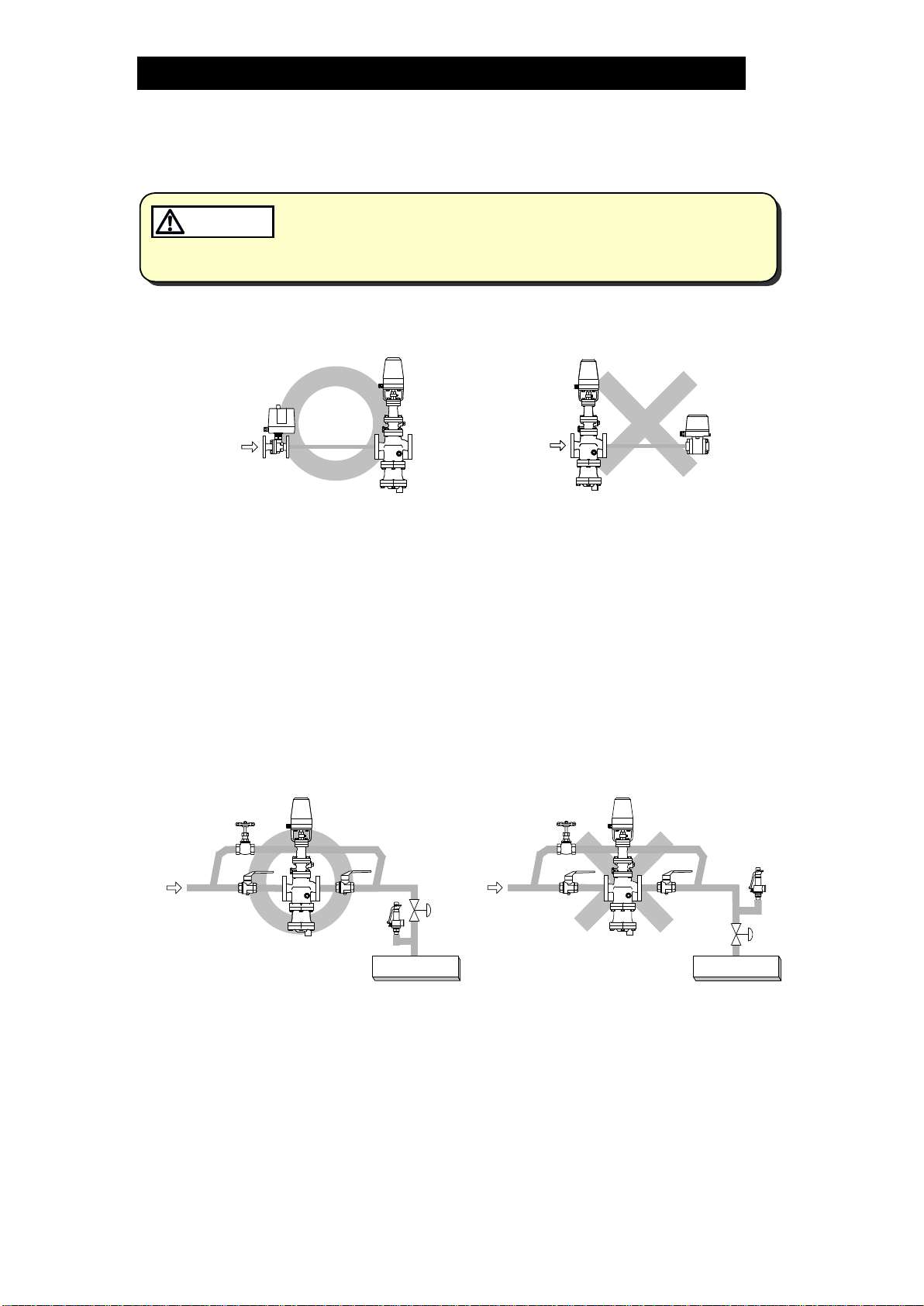

1.

The M-COS should be operated only within its specifications.

2.

Installing an ON/OFF Valve (Solenoid Valve or Motorized Valve)

M-COS

Motorized

Valve

Inlet side

Outlet side

Solenoid

Valve

Outlet side

Solenoid

Valve

M-COS

If an on-off valve, such as a motorized valve, is required to stop supply of steam to

the steam-using equipment, install it at the inlet side of the M-COS. If a solenoid

valve is installed at the outlet of the M-COS, its opening and closing will cause heavy

chattering and may lead to damage of the piston and main valve. (When the on-off

valve opens, the secondary pressure of the M-COS changes from zero to the set

pressure. Passing through an area of the reducing ratio of less than 10:1, where

adjustment is impossible, chattering occurs momentarily. To save energy, it is

recommended to install the on-off valve as near to the boiler as possible.

NOTE: To prevent water hammer, it is recommended that a slow-acting motorized

on-off valve be used. In particular, if a fast-acting on-off solenoid valve is

used for frequent temperature control, the potential water hammer effect

can damage the steam-using equipment and the M-COS.

3.

Installing a Control Valve

M-COS

Safety

Valve

Control

Valve

Steam-using

Equipment

Safety

Valve

Control

Valve

M-COS

Steam-using

Equipment

A control valve installed between the M-COS and the steam-using equipment

(downstream of the M-COS) for controlling equipment temperature may raise the

pressure between the M-COS and the control valve when the control valve is

closed, depending on the spatial relationship. A safety valve should be installed

downstream of the control valve.

NOTE: When installing a safety valve to protect the steam-using equipment, be

sure to install it on the steam-using equipment or directly before the inlet

of the steam-using equipment. If the safety valve is installed on the

outlet side of the M-COS between the M-COS and a control valve, an

eventual pressure rise could activate the safety valve.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

8

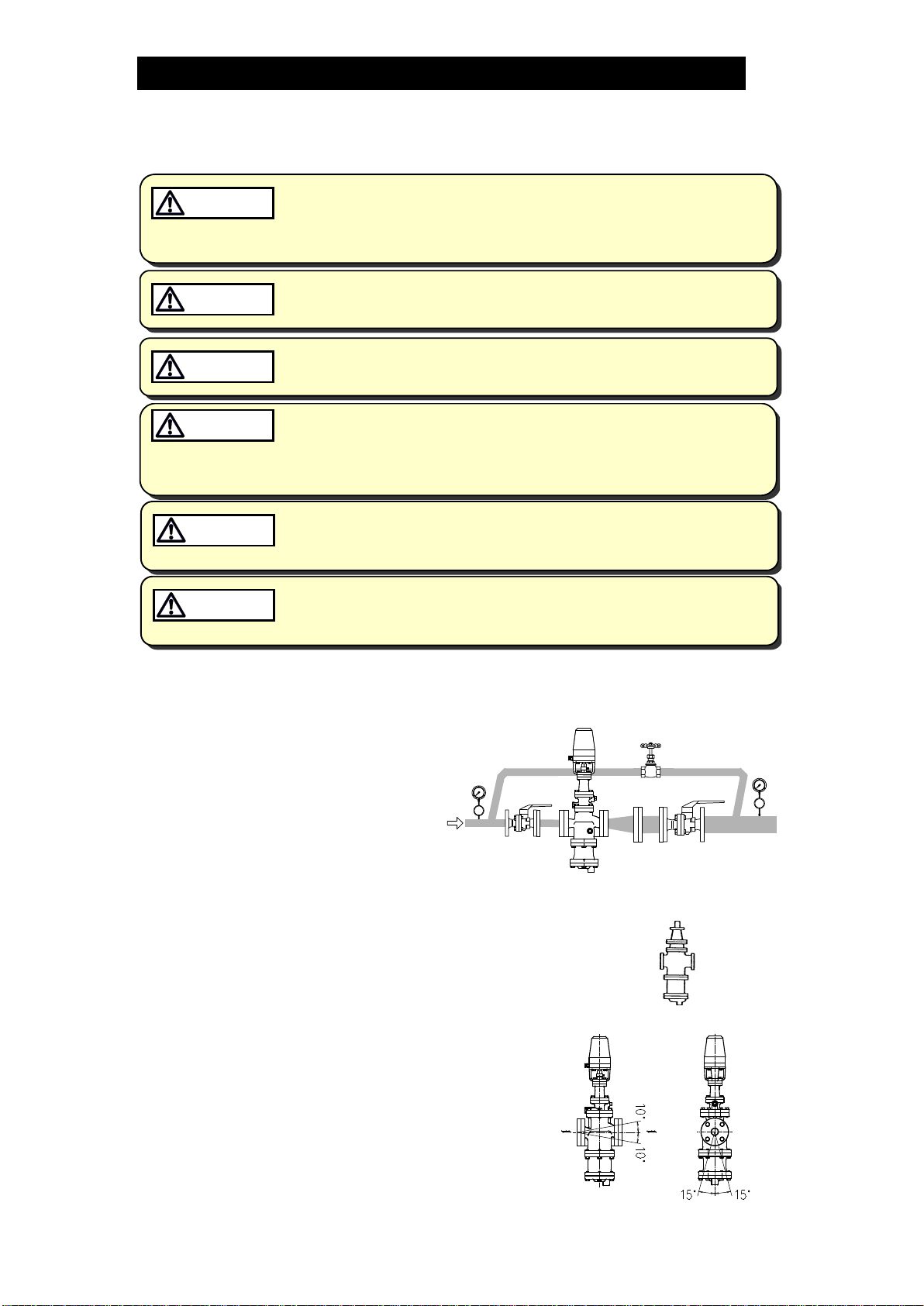

4.

Precautions for the Installation of Additional Fittings Before or After the M-COS

In order to ensure stable steam flow, the piping upstream and downstream of

the M-COS must be straight runs. If a M-COS is installed either directly before or

after an elbow or control valve, unevenness in steam flow may result in

chattering and unstable pressure.

To ensure stable steam flow, it is recommended that the M-COS be installed on

straight runs of piping, as illustrated below. (d = pipe diameter)

(1) Inlet (primary side) of the M-COS

Maintain a straight piping

run of 10 d or more when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size is 25

mm, have 250 mm or more)

M-COS

10 d or more

Less

than

10d

M-COS

Maintain a straight piping

run of 30 d or more when

an automated valve (on-off

valve) is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

30 d or more

M-COS

Automatic

Valve

Automatic

Valve

Less than

30 d

M-COS

(2) Outlet (secondary side) of the M-COS

Maintain a straight piping

run of 15 d or more when a

manual valve, a strainer or

an elbow, etc. is installed.

(Example: if nominal size is 25

mm, have 375 mm or more)

M-COS

15 d or more

Less

than

15 d

M-COS

Maintain a straight piping

run of 30 d or more when a

safety valve is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

M-COS

30 d or more

Safety Valve

Less than

30 d

Safety Valve

M-COS

Maintain a straight piping

run of 30 d or more when

another pressure reducing

valve is installed. (Two-

stage pressure reduction)

(Example: if nominal size is 25

mm, have 750 mm or more)

30 d or more

M-COS M-COS

Less than

30 d

M-COS M-COS

Maintain a straight piping

run of 30 d or more when a

control valve or an

automated valve (on-off

valve) is installed.

(Example: if nominal size is 25

mm, have 750 mm or more)

Control Valve

or

Automatic Valve

M-COS

30 d or more

Less than

30 d

M-COS Control Valve

or

Automatic Valve

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

9

Configuration

15 – 50 mm

Plug (option)

No.

Name

1

Main Body

2

Trap Body

3

Trap Cover

4

Separator

5

Float

6

Float Cover

7

Trap Valve Seat

8

Separator Screen

9

Main Valve Seat

10

Main Valve

11

Main Valve Holder

12

Piston

13

Cylinder

14

Pilot Screen

15

Pilot Screen Holder

16

Pilot Body

17

Pilot Valve

18

Pilot Valve Seat

19

Diaphragm

20

Diaphragm Support

21

Spring Housing

22

Coil Spring

23

Adjustment Screw

24

Adjustment Screw Guide

25

Plug – Sensing Line Port

26

Mounting Plate

27

Insulation Plate

28

Splined Shaft

29

Sleeve

30

Motor Cover

31

Motor Unit (Actuator)

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

10

65 – 100 mm

Plug (Option)

No.

Name

1

Main Body

2

Trap Body

3

Trap Cover

4

Separator

5

Float

6

Float Cover

7

Trap Valve Seat

8

Separator Screen

9

Main Valve Seat

10

Main Valve

11

Main Valve Holder

12

Piston

13

Cylinder

14

Pilot Screen

15

Pilot Screen Holder

16

Pilot Body

17

Pilot Cover

18

Pilot Valve

19

Pilot Valve Seat

20

Diaphragm

21

Diaphragm Support

22

Spring Housing

23

Coil Spring

24

Adjustment Screw

25

Adjustment Screw Guide

26

Plug – Sensing Line Port

27

Mounting Plate

28

Insulation Plate

29

Splined Shaft

30

Sleeve

31

Motor Cover

32

Motor Unit (Actuator)

33

Silencer

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

11

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg or more). Failure to do so may result in back strain or other injury if

the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Make sure the power supply switch is OFF before carrying out work on

the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

equipment may malfunction or electric shock may occur, leading to

injury or other accidents.

CAUTION

Make sure that wiring work requiring a special license is carried out by

qualified personnel.

If carried out by unqualified personnel, overheating or short circuits

leading to injury, fires, damage or other accidents may occur.

CAUTION

When using this product, NEVER stand close to, or leave tools anywhere

near moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving parts

could lead to injury, damage or other accidents.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1.

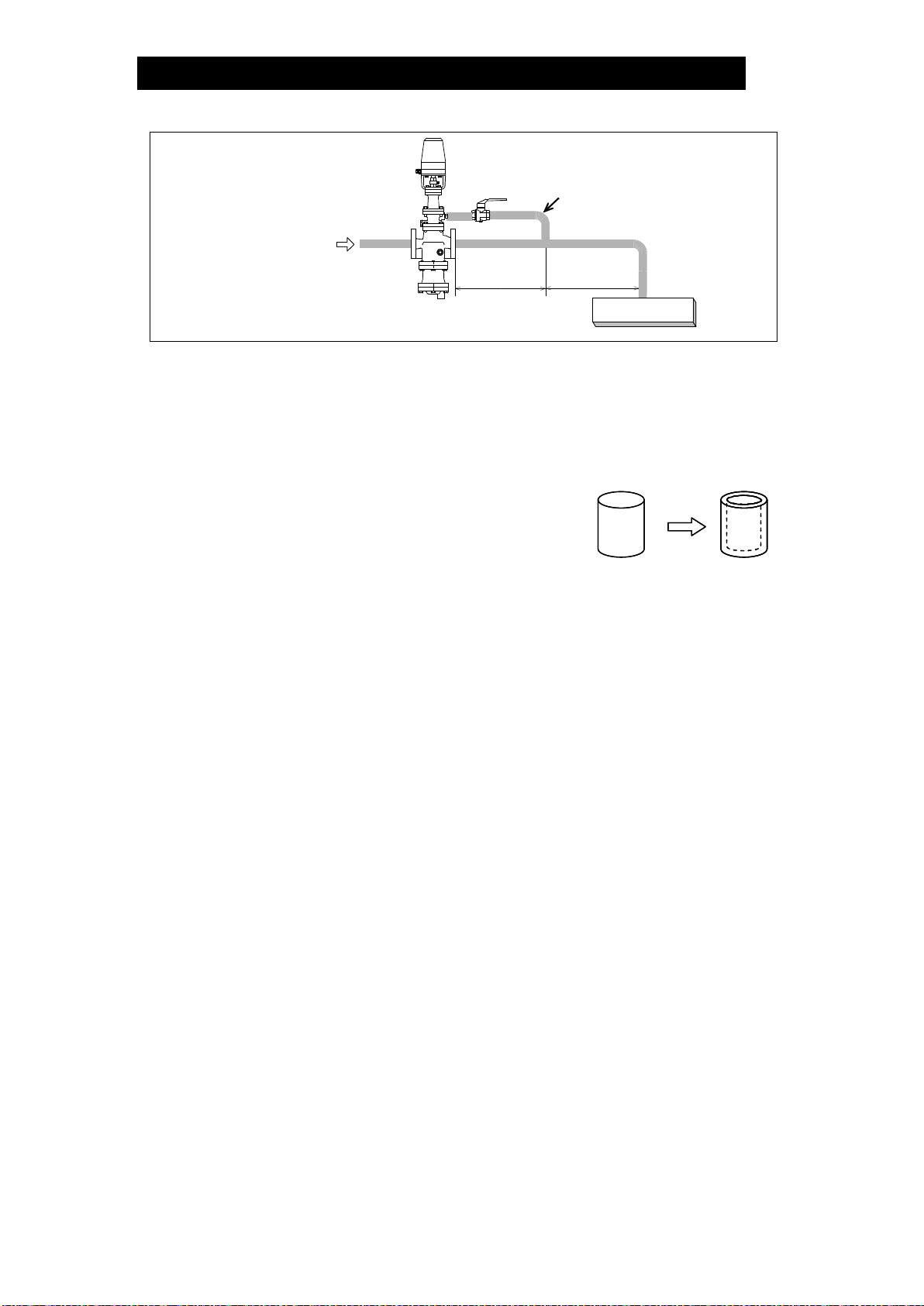

Blowdown

Before installing the

M-COS

, be

sure to blow down all piping

thoroughly. If this is not possible,

perform a blowdown using the

bypass valve.

Blowdown

is especially important

for newly installed piping or after

the system has been shut down

for a long period of time.

Open

Closed Closed

Blowdown using bypass valve

M-COS

2.

Removing Seal and Cap

Before installation, be sure to remove all protective

seals and caps.

(Found in 3 locations, on the product inlet and outlets.)

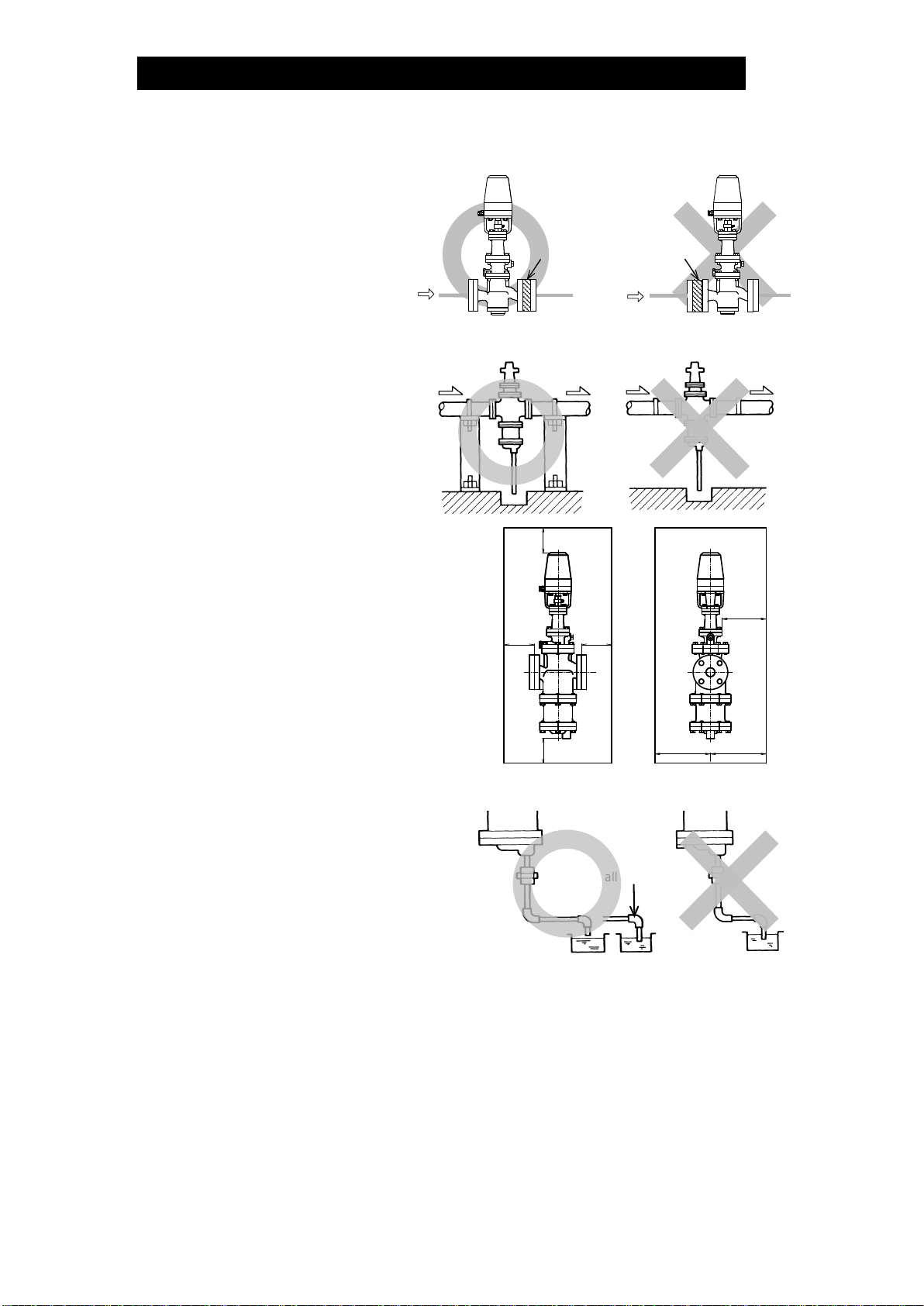

3.

Installation Angle

Install the

M-COS

vertically, so that the

arrow mark on the body points horizontally

in the direction of steam flow.

Allowable inclination is 10 degrees in the

fore-aft direction and 15 degrees in the

plane perpendicular to the steam flow line.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

12

4.

Spacer Installation

If spacing adjustment is

necessary to accommodate

installation, install a spacer on

the outlet flange. The spacer

should consist of a spacer,

gaskets, bolts and nuts. Fit

gaskets to both sides of the

spacer between the M-COS

outlet and the pipe flange.

Fasten with bolts and nuts.

Correct spacer

location

Correct spacer

location

5.

Piping Support

Install the M-COS, paying

attention to avoid excessive

load, bending and vibration.

Support the inlet and outlet

pipes securely.

6.

Maintenance Space

150

100 100

100 400 400

Approx.

300

Leave sufficient space for

maintenance, inspection and repair.

(Unit: mm)

7.

Trap Outlet Piping

For ease of maintenance, installation

of a union connection is

recommended for the trap outlet pipe.

Connect the outlet pipe to a

condensate return line, or extend it to

a trench. In the case of the latter,

make sure the end of the pipe is

above the waterline.

(Dirt and water may otherwise be

sucked up by the vacuum formed

during trap closure and system

shutdown.)

Small hole

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

13

8.

Blowdown Valve (requires optional plug)

Remove the 10 mm

(3/8 in) plug (optional)

and install the

blowdown valve

In an environment of heavy dirt or scale, or when the

steam-using equipment is used only periodically,

such as for room heating equipment be sure to use

a blowdown valve.

1. Remove the plug from the main body.

2. Install the blowdown valve.

3. Open the blowdown valve (while M-COS is pressurized) and blow any

residual dirt and scale off the separator screen.

4. Periodically activate the blowdown valve to keep the system free of dirt and

scale.

9.

Piping Size/Diffuser

If it is expected that the

secondary steam flow velocity

will be more than 30 m/s, install

a diffuser in order to keep the

flow velocity below 30 m/s. If the

distance between the M-COS

and the steam-using equipment

is great, a possible drop in

pressure should be taken into

consideration when selecting the

piping size.

Straight-run Piping Lengths:

Upstream = 10 d or more; Downstream = 15 d or more

Diffuser

M-COS

(d = pipe diameter)

M-COS

10.

Two-stage Pressure Reduction

Two-stage pressure reduction should be performed whenever the pressure cannot

be reduced to the desired level with a single M-COS due to operating range

limitations, such as when the reduction ratio is greater than 10:1.

M-COS

Pressure

Gauge

Bypass

Valve

Inlet

Valve Outlet

Valve Outlet

Valve

Safety Valve

(Relief Valve)

Inlet Outlet

Bypass

Valve

Inlet

Valve

M-COS

Pressure

Gauge

Inlet

Pressure

Gauge Pressure

Gauge

Inlet

Valve Outlet

Valve

Safety Valve

(Relief Valve)

Outlet

Bypass

Valve

M-COS

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

14

11.

Accessories

Always install a shut-off valve, pressure gauge and bypass lines at both inlet

and outlet.

Ball valves, which will not retain condensate, are recommended for inlet and

outlet shut-off valves. The bypass pipe should be at least 1/2of the size of the

inlet (primary side) pipe.

M-COS has a built-in strainer, however in case an external strainer is installed,

it should be installed ahead of M-COS and the strainer should be installed

horizontally with the basket at the 3 or 9 o’clock position in order to prevent

condensate accumulation.

Ball Valve

Ball Valve

Glove Valve

M-COS

Pressure

Gauge

Pressure

Gauge

M-COS

12.

Installation of the Controller Unit

Mount the controller unit securely on a wall, etc. with self-tapping screws

inserted in the holes.

The controller is not waterproof. Be sure to install it indoors in a suitable

protected area.

The ambient temperature range specified for the normal operation of the unit is

between 0 and 50 °C. Avoid operation beyond this specified range.

Install the controller unit in a suitable place with low humidity and vibration.

13.

Installation of the Pressure Sensor

Install the pressure sensor on or near the steam using equipment on the piping.

Arrange the piping as perpendicularly as practical with the siphon tube

supplied. (Direct mounting of the sensor to the equipment or to the piping may

result in damage to the pressure sensor due to conduction of heat.)

NOTE: The pressure sensor is made to withstand a maximum pressure of

2 times the maximum value of the measurement range.

If there is a possibility that excessive pressure beyond this limit will be

applied to the sensor due to water hammer or otherwise, consult our sales

staff before continuing the installation.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

15

14. External secondary pressure-sensing line (when required)

North American Models are factory prepared for external sensing.

An external sensing line MUST be installed.

DO NOT SUPPLY STEAM until all piping and a 10 mm secondary pressure

sensing line with a slightly falling pitch have been properly installed. Install a

shutoff valve in the pressure sensing line for maintenance purposes.

Keep the shutoff valve open at all times during operation. If the shutoff

valve is closed, M-COS will fully open and PRIMARY PRESSURE WILL BE

SUPPLIED TO THE EQUIPMENT (see “Piping Example” on next page).

CAUTION

Non-North American Models:

Factory-standard M-COS employs an internal secondary pressure-sensing

channel built into the body, saving the need to install an external pressure-

sensing line to detect the secondary pressure.

Installation of an external secondary pressure-sensing line involves closing the

internal pressure-sensing channel and installing a line from the sensing line port

to the point where pressure should be controlled. This can increase stability of

pressure control where steam loss in secondary piping and flow rate fluctuation is

high. In addition, the rated flow rate will be greater than an internal pressure-

sensing channel under the operational pressure reduction ratio of 2:1 or more.

Installation procedure

1) Loosen and remove the bolts that attach the pilot body to the main body (15 –

50 mm) or the pilot cover (65 – 100 mm) and remove the pilot body.

2) Install the blind pin (optional) by first removing the connecting tube from the

main body or pilot cover and then substituting the blind pin.

3) Re-install the pilot body and fasten the bolts evenly to the proper torque.

4) Remove the plug and connect the secondary pressure sensing line.

5) Install the secondary pressure sensing line with a slightly falling pitch. The

end of the secondary pressure sensing line should be connected to the place

on the main piping where the pressure is to be sensed (see the piping

example on next page). A shut-off valve and union should be installed in the

secondary pressure sensing line.

Main Body

Pilot Body

Secondary Pressure

Sensing Line Port

(Rc(PT)3/8, BSP3/8or NPT3/8)

Bolt

Secondary Pressure

Sensing Port

Connecting Tube

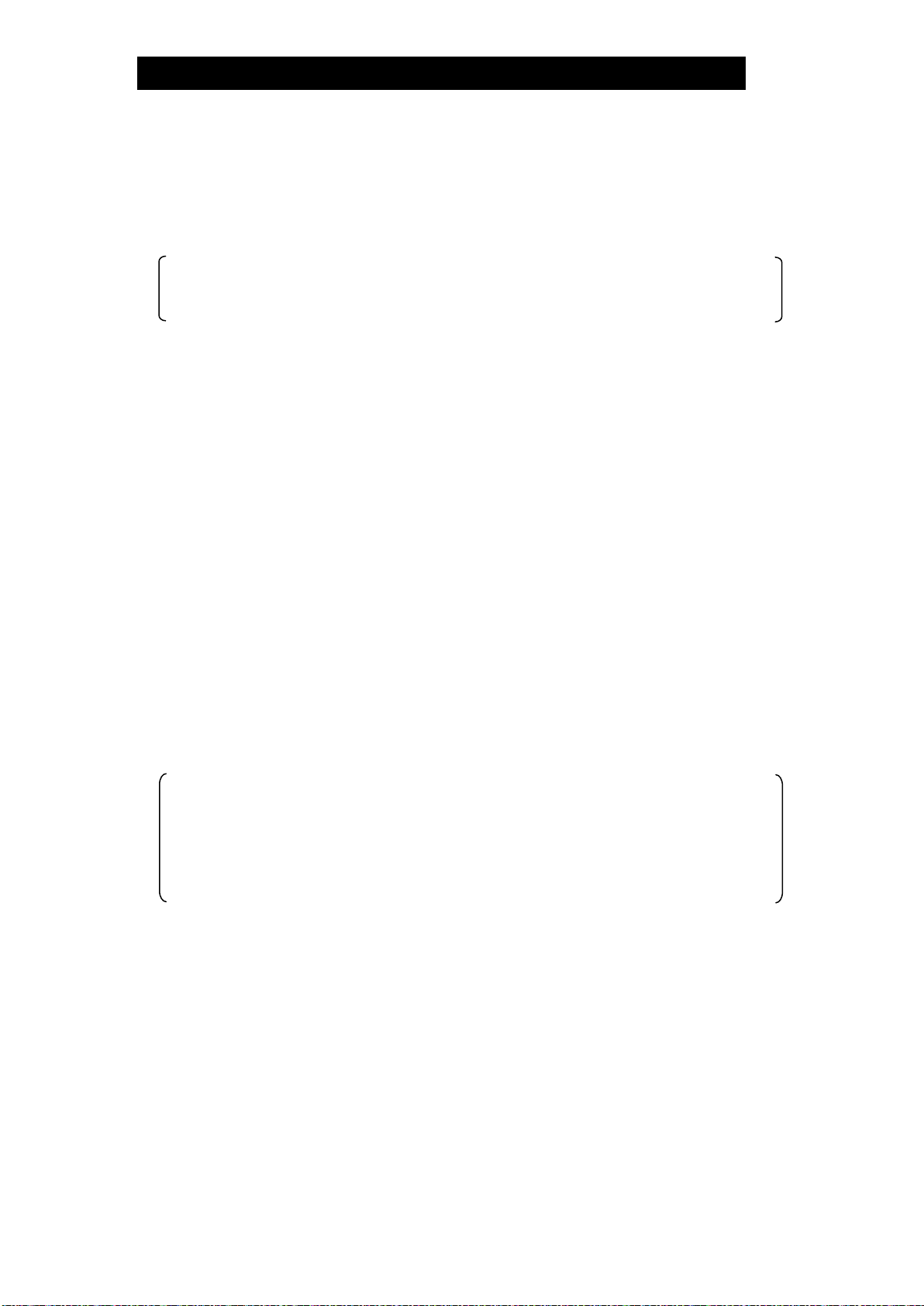

Replace the factory-

installed connecting tube

with the blind pin shipped

with the M-COS.Connecting

Tube Blind Pin

Pilot Body

15 –50 mm 65 –100 mm

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

16

Piping example::

10 mm Pressure Sensing Line

(with a slightly falling pitch towards

the sensing point)

M-COS

1 m or 15 d,

whichever is

larger

Valve

15 d or more

Steam-using

Equipment

d = pipe diameter

15. Internal sensing for North American models

All models except North American models are factory prepared for internal sensing.

When internal pressure sensing is required for North American models, please

contact the nearest TLV representative to request both a connecting tube, which

must be installed in place of the blind pin, and a threaded secondary pressure

sensing plug.* Follow the connecting tube installation procedure shown below:

1) Loosen and remove the four (4) bolts that attach the

pilot body to the main body (15 – 50 mm) or the pilot

cover (65 – 100 mm), and remove the pilot body.

2) Install the connecting tube by first removing the

blind pin from the secondary side of the main body

or pilot cover and then substituting the connecting tube.

3) Re-install the pilot body and fasten the four (4) bolts evenly.

Consult page 31 in this manual for torque requirements of these bolts.

4) If a secondary pressure sensing pipe has previously been installed, remove it and

be certain to install the threaded secondary pressure sensing line plug in its place.

*Internal sensing should not be used when 15 mm and 20 mm M-COS-16 will be

used below 0.3 MPaG and 0.1 MPaG respectively, and below 50% of primary

pressure.

Blind Pin Connecting Tube

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

17

Wiring

MC-2

Ground

Power

Supply Motor

Pressure

Sensor

AC100V

or

AC200V

Red Black White

1 2 3 4 5 6 7 8

Class 3

Grounding

Class 3

Grounding

Red White Shield*

(+) (–)

1. Before arranging wiring, check the correct supply voltage values specified for the

controller unit and for the actuator (motor) once again.

2. Connections of the wires to the terminal board must be made securely with

insulated pressure-connection terminals.

3. To ensure safety, be sure to ground the controller unit and the actuator.

Grounding requirements: Class 3 grounding or better

(Use mild steel wires of 2 mm2 (AWG 14) or larger size and of 100 Ωor less

resistance, extending up to 20 m.)

4. Wiring should be routed in the shortest distance practical, located at least 0.5 m

away from other pieces of equipment that can be noise-generating sources.

Wiring should never contact any exposed steam piping.

Cables used for wiring shall be as follows:

Power Cable

:

min. 0.5 mm2(AWG 20) x 2-core

Motor Cable

:

min. 0.5 mm2(AWG 20) x 3-core

Pressure Sensor

:

min. 0.5 mm2(AWG 20) x 2-core shielded wire

NOTE: Wiring for the shielded wire should be made only on the controller side

and not on the pressure sensor side.

(Shielded wire should never contact the pressure sensor case.)

5. To allow access for maintenance, provide 100 mm of clearance around the

actuator when arranging wiring.

6. Upon completion of wiring to the terminal board, fit the supplied insulation board

and fix it in securely in place.

* Wiring for the pressure

switch should be made

only when necessary.

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

18

Controller Operation

<MC-2>

(7) Maximum Allowable Pressure Setting Knob

(4) Maximum Allowable Pressure LED

(2) Pressure Setting Lever Switch

(3) Pressure Lock Switch

(1) Power Switch

(1) Power Supply LED

(5) Pressure Indicator

(6) Selector Switch

Part Names and Features

NOTE: Pressure values in parentheses ( ) are for the 500 kPa (0.5 MPaG) model.

(1) Power Switch/Power Supply LED

This is the main switch for the entire controller unit. By turning ON the power

switch, the power supply LED is lit to indicate that power is supplied to the unit.

(2) Pressure Setting Lever Switch

This switch is used for adjusting steam pressure. By pushing the lever switch

toward the UP side, the pressure-adjustment screw in the M-COS unit is pushed

in (rotates clockwise from top-down view), causing the secondary pressure to rise.

Conversely, by pushing it toward the DOWN side, the pressure-adjustment screw

is pulled back (rotates counterclockwise from top-down view) causing the

pressure to fall. (By releasing your hand, the switch returns to the OFF condition.)

NOTE: Do not operate the lever switch continuously for more than 5 minutes.

If the motor is run beyond that limit, the thermal protector for the motor is

activated to bring the motor to a standstill. (Motor condition is restored to

normal when the motor has cooled.)

(3) Pressure Lock Switch

When the pressure lock switch is turned to “LOCK ON”, the pressure setting lever

switch becomes inoperative.

When the “set pressure” valve is to be fixed at a certain level, turn this switch ON.

Then, even if the set pressure lever switch is operated by mistake, the set value

will not change. (Turn the pressure lock switch OFF if it is desired to change the

set value.)

(4) Maximum Allowable Pressure LED

The LED lights up when the maximum allowable pressure switch is activated.

Once the pressure switch LED is ON, the UP side of the pressure setting lever

switch becomes inoperative, thereby disabling setting of pressures higher than

that which has been set on the pressure switch.

(If it is desired to set the upper limit pressure for the protection of the steam-

using equipment, connect a suitable pressure switch externally.)

172-65188M-08 (M-COS 3,16,21 Pressure Reducing Valve) 24 Jun 2015

19

(5) Pressure Indicator

LED in the pressure indicator window light up when the power switch (1) is turned

ON indicating either the measured pressure or the maximum allowable pressure,

depending on the setting on the selector switch (6).

Values available for indication are between 000 to 1999 kPa (500 kPa).

Pressure indicator shows about -500 (-125) on the measured pressure side

when the pressure sensor is not connected. When the measured pressure

exceeds 1999 kPa, the display shows 1∗∗∗.

(6) Selector Switch

This switch is used for selecting the desired pressure indication item (5).

Indication of measured pressure values is selected by pushing the switch upward,

and the maximum allowable pressure is selected when it is pushed downward.

Normally the selector switch is set at the measured pressure indication side.

(7) Maximum Allowable Pressure Setting Knob

This knob is used to set the maximum allowable pressure to protect the steam-

using equipment against damage. By setting the selector switch (6) at the

maximum allowable pressure, the set maximum allowable pressure is indicated.

The maximum allowable pressure setting is increased by turning the knob

clockwise, and it is decreased by turning it counterclockwise.

Setting for the maximum allowable pressure is possible as desired within a range

from 0 to 1999 (500 kPa).

If, after setting the maximum allowable pressure, the measured pressure should

rise to that limit, the internal pressure switch is triggered making the pressure

setting lever switch (2) inactive, thus preventing pressure from rising further.

At that moment, the maximum allowable pressure LED (4) lights up indicating

that the pressure switch has been activated.

The pressure setting lever switch (2) has become inactive at the UP side only;

the DOWN side can be operated.

If it is desired to cancel this action, shift the lever switch to the DOWN side and

lower the level of measured pressure by at least 30 (10) kPa from the maximum

allowable pressure, thereby turning the maximum allowable pressure LED (4)

OFF. The action of the pressure switch is released, restoring the UP side to the

normal operative condition. The UP side of the lever switch remains inoperative

so long as the maximum allowable pressure LED (4) remains ON.

NOTE: When no setting is made for the maximum allowable pressure, the upper

limit value should be set at least 100 (50) kPa higher than the maximum

value allowed for pressure setting.

The upper limit pressure is set at around 1800 (400) kPa at the time of

shipment.

This manual suits for next models

2

Table of contents

Other TLV Control Unit manuals

Popular Control Unit manuals by other brands

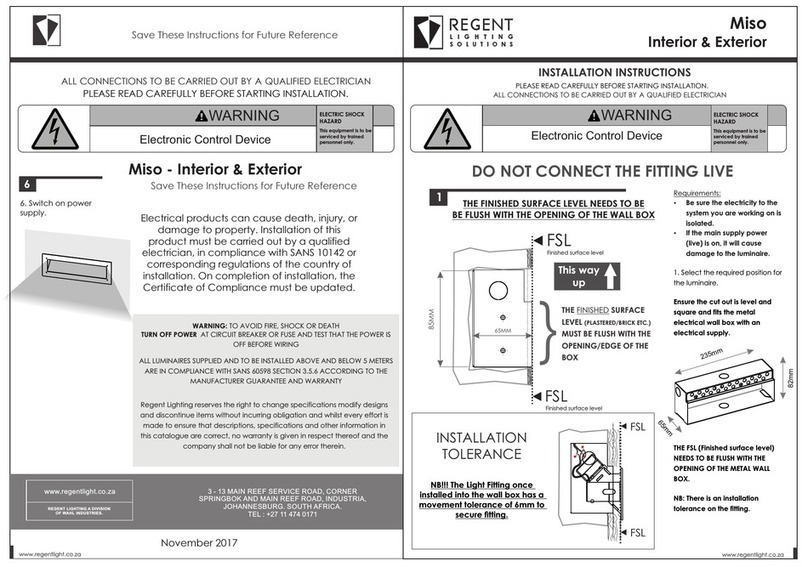

Regent Lighting Solutions

Regent Lighting Solutions Miso installation instructions

Giacomini

Giacomini DB Series Instruction

ewo

ewo 5370.100 operating instructions

ZSK

ZSK T8 Quick reference guide

Fireye

Fireye FlameWorx MBUV-100D manual

Squibb-Taylor

Squibb-Taylor AL404 Installation, operation, maintenance, disassembly and assembly Instructions