172-65169MA-08 (MC-COS Multi-control Valve) 28 May 2010

1

Contents

Introduction ........................................................................ 1

Safety Considerations ........................................................ 2

Specifications ..................................................................... 4

Correct Usage of the MC-COS Multi-control Valve ............ 6

Configuration...................................................................... 8

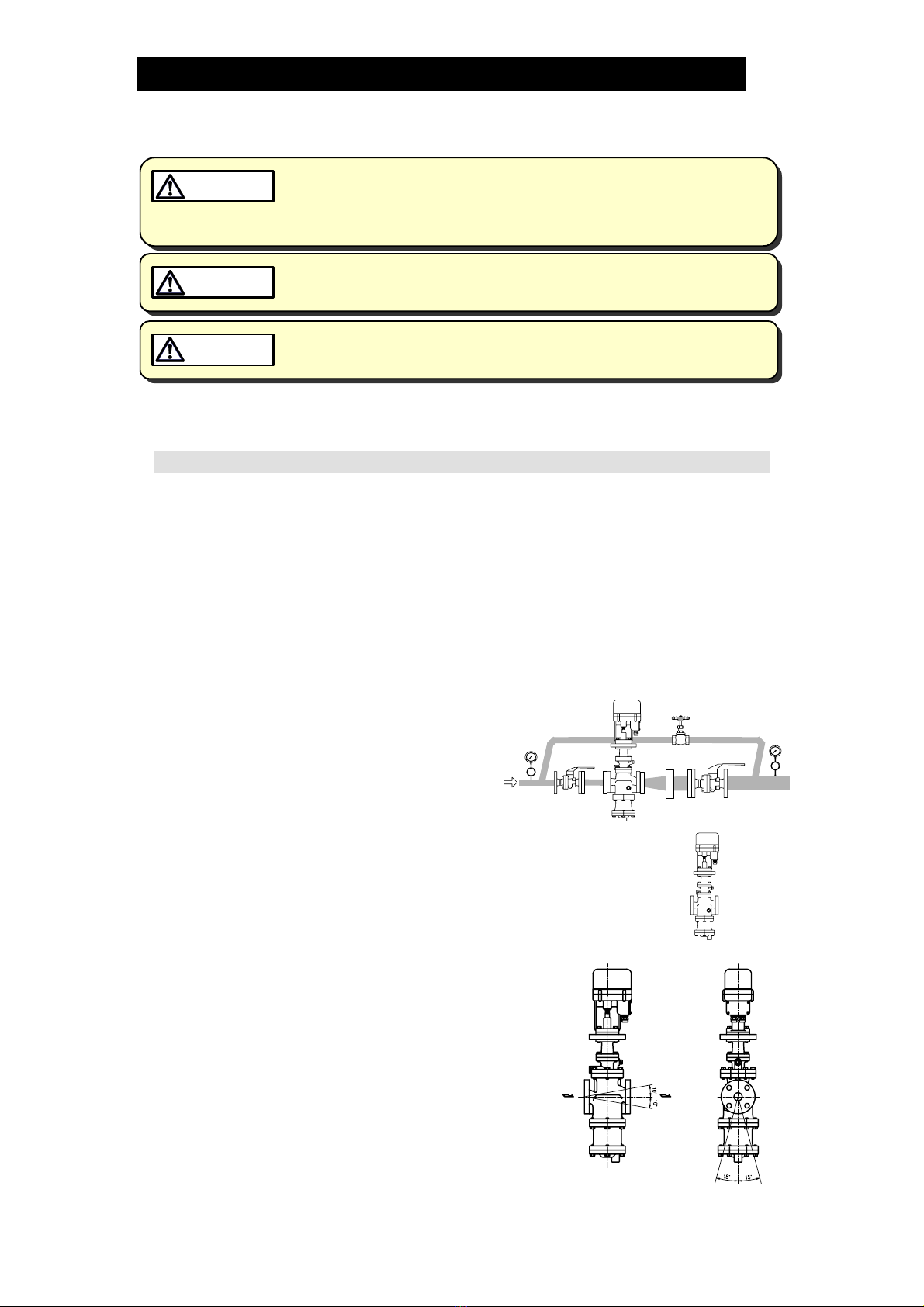

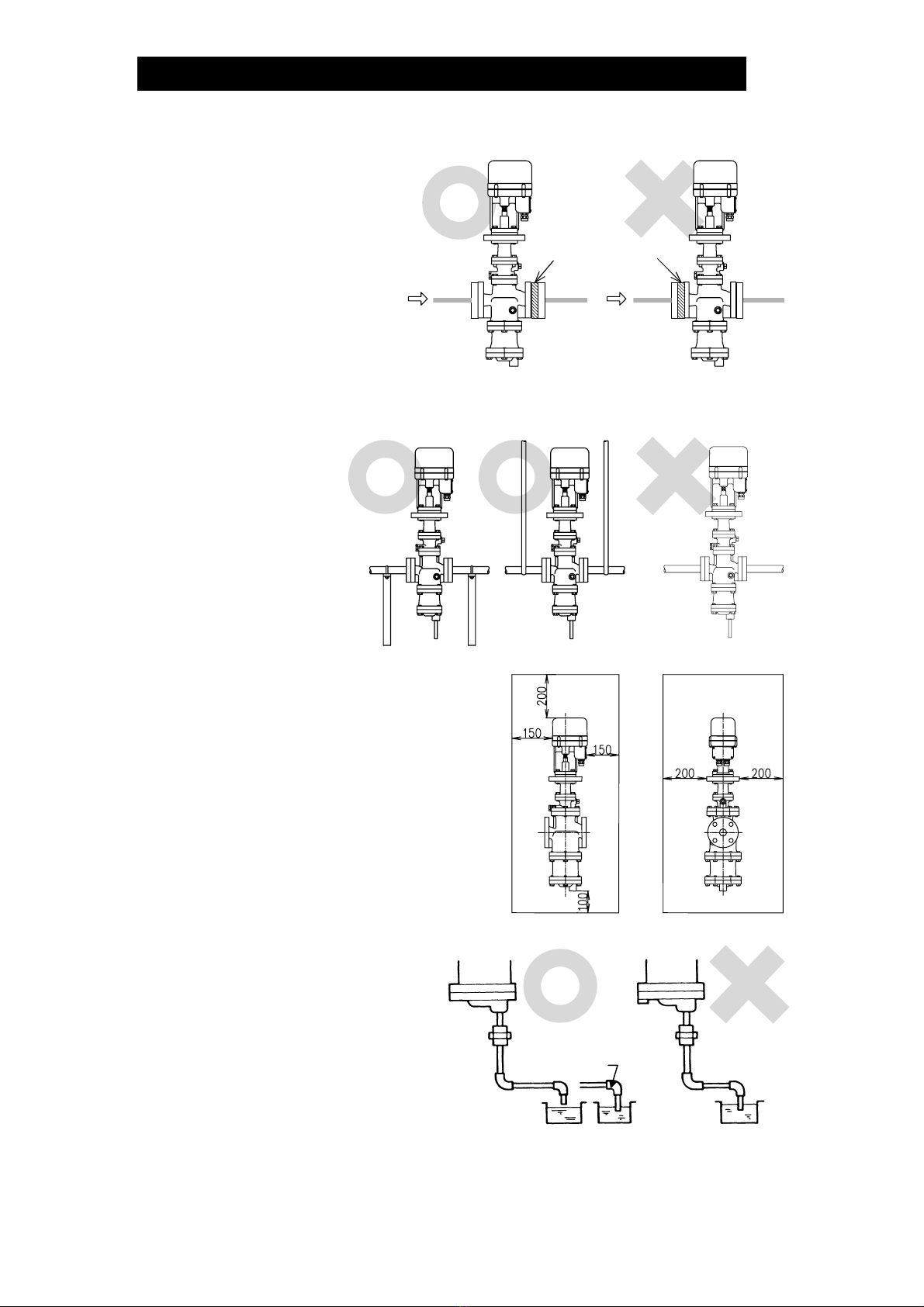

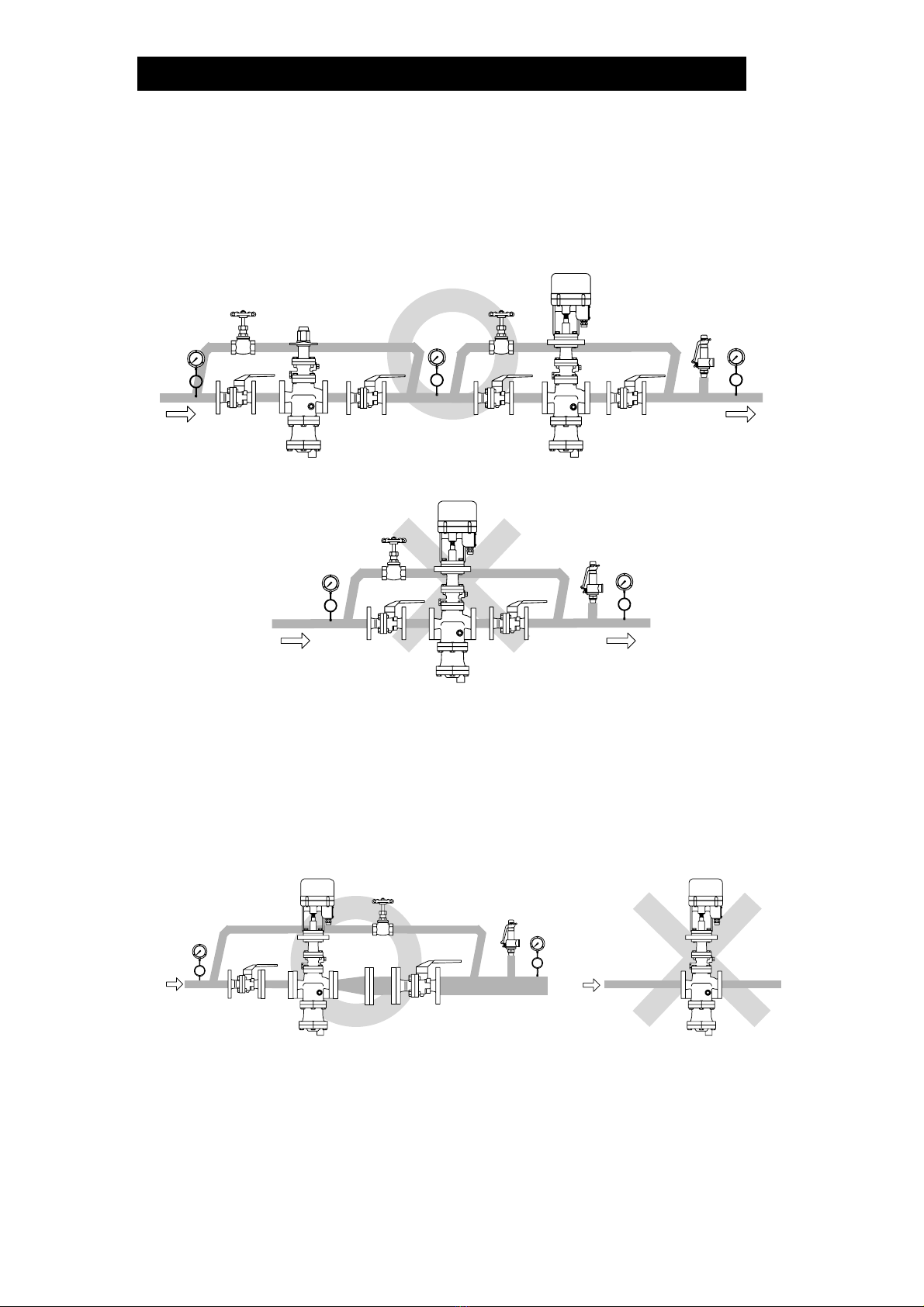

Installation ........................................................................ 10

Wiring Instructions............................................................ 17

Setting the Valve Coefficient ............................................ 19

Operation ......................................................................... 20

Inspection and Maintenance ............................................ 22

Disassembly..................................................................... 23

Reassembly ..................................................................... 29

Troubleshooting ............................................................... 30

Product Warranty ............................................................. 36

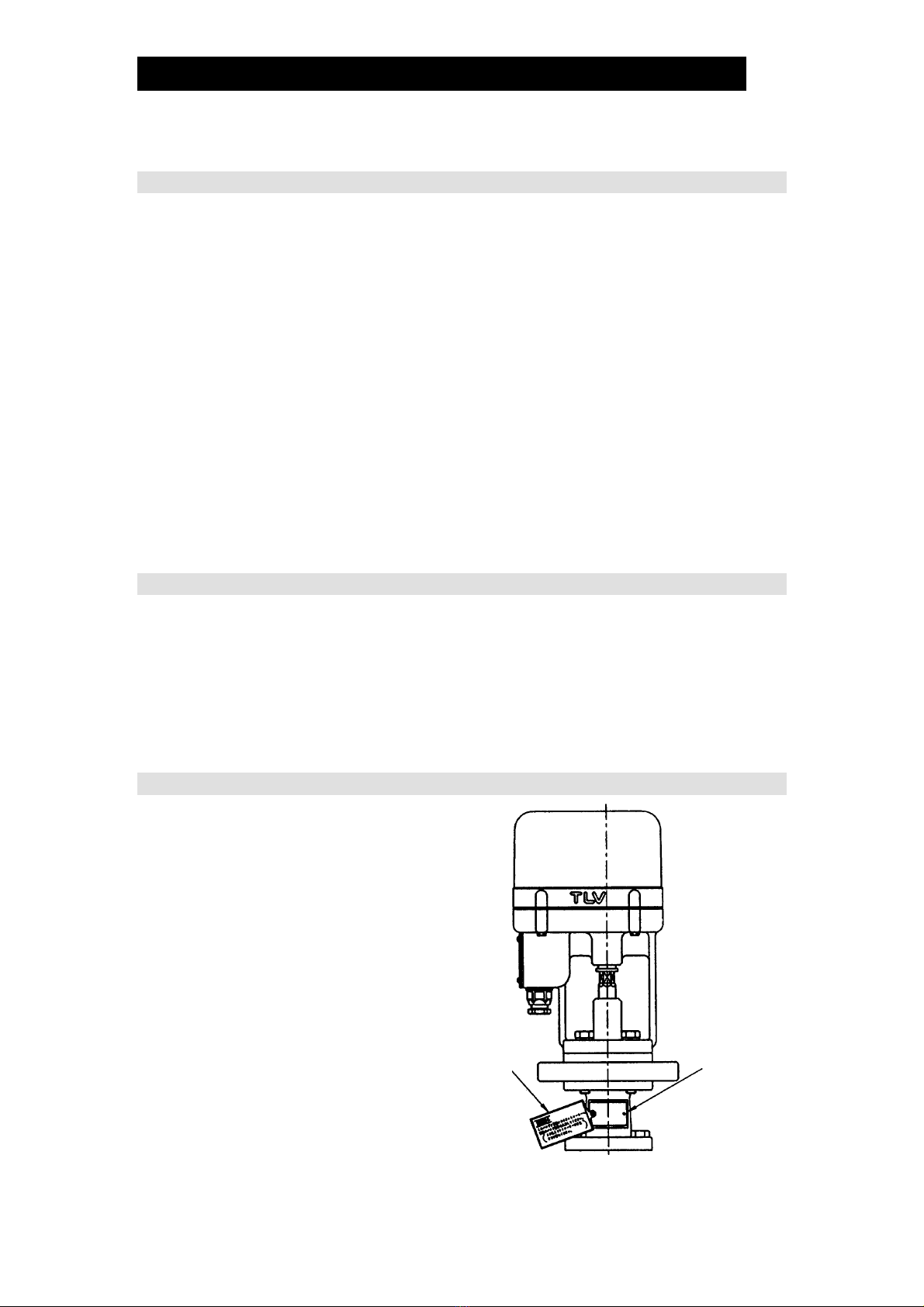

Introduction

Thank you for purchasing the MC-COS high-precision multi-control

valve for steam.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

Steam-using equipment can achieve its intended efficiency only if the steam

being used is very dry. Using steam in which matter such as condensate,

scale, types of grease or air is entrained can not only result in problems with

the steam-using equipment and in lowered productivity, but can also lead to

shortened service life for and malfunction of the multi-control valves.

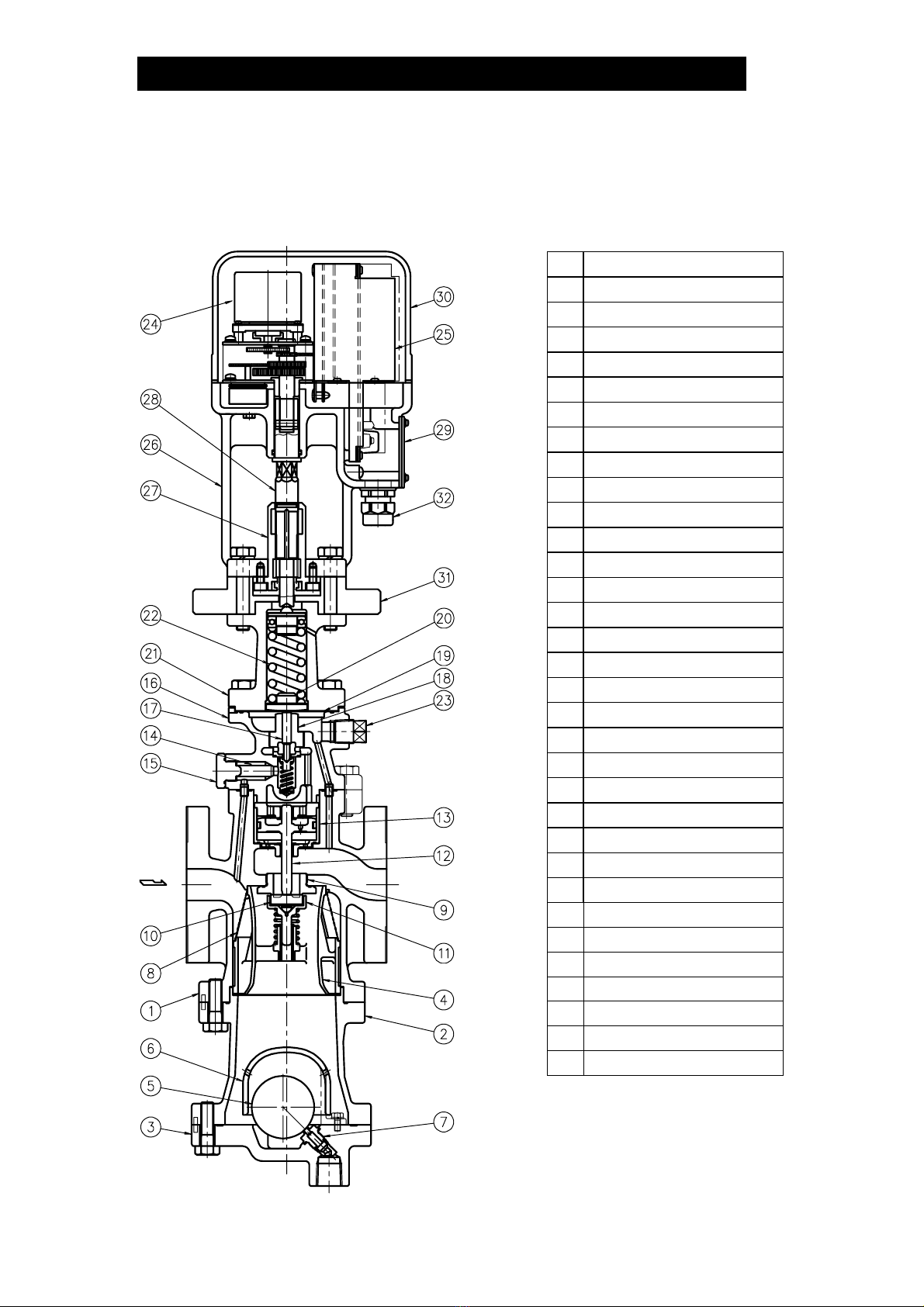

The high-precision multi-control valve, model MC-COS, provides

accurate pressure control (MC-COS-3, MC-COS-16) and temperature control

(MC-COS-16) when combined with the SC-F70 digital indicator

controller or the SP-F70 programmable indicator controller.

If detailed instructions for special order specifications or options not contained

in this manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the front

cover. It is needed not only for installation, but also for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.